Rene 80

About Rene 80 Superalloy

Name and Equivalent Names

Rene 80, designated by UNS N07080, is a nickel-based superalloy. It conforms to ASTM B637, DIN/EN 2.4952 (NiCr20TiAl), and GB/T 14992 (GH4033). It is also covered under AMS 4592 and ASME SB-637, making it a recognized material for high-temperature applications.

Rene 80 Basic Introduction

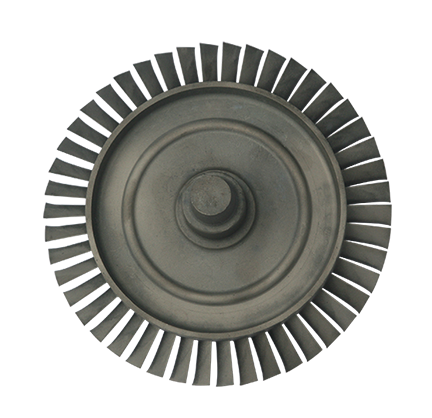

Rene 80 is a high-strength nickel-chromium alloy designed to withstand extreme temperatures and mechanical stress. This superalloy offers excellent fatigue resistance, thermal stability, and creep rupture life, making it suitable for gas turbines, aerospace components, and power generation systems.

With superior performance at temperatures exceeding 850°C, Rene 80 maintains mechanical integrity over extended periods. It is widely used for turbine blades, combustion chambers, and components that experience thermal cycling and high-pressure conditions.

Alternative Superalloys of Rene 80

Inconel 718, Inconel 738, and Hastelloy X are viable alternatives to Rene 80. Inconel 718 offers enhanced corrosion resistance, especially in marine environments, while Inconel 738 provides excellent oxidation resistance, making it suitable for turbine blades. Hastelloy X is known for its weldability and high-temperature stability and is often used in jet engines and aerospace applications. These alloys can substitute Rene 80 based on specific performance requirements.

Rene 80 Design Intention

Rene 80 was developed to address the demand for materials that combine high mechanical strength, excellent fatigue resistance, and thermal stability. It is intended for applications subjected to extreme temperatures, such as turbines and aerospace engines. The alloy’s chemical composition, including titanium and boron, enhances its creep resistance and long-term structural integrity, ensuring reliable performance under continuous mechanical stress and thermal cycling.

Rene 80 Chemical Composition

The chemical composition of Rene 80 contributes to its high-temperature strength and fatigue resistance. Nickel forms the base, with chromium improving oxidation resistance. Aluminum, titanium, and tungsten enhance the alloy’s strength and thermal stability through precipitation hardening.

Element | Content (wt%) |

|---|---|

Nickel (Ni) | Balance |

Chromium (Cr) | 14 |

Cobalt (Co) | 9 |

Molybdenum (Mo) | 4 |

Aluminum (Al) | 3 |

Titanium (Ti) | 5 |

Tungsten (W) | 4 |

Boron (B) | Max 0.015 |

Rene 80 Physical Properties

Rene 80 exhibits high density and thermal conductivity, essential for heat-resistant applications. Its modulus of elasticity ensures structural stability under mechanical stress, and the alloy maintains excellent performance in high-temperature environments.

Property | Value |

|---|---|

Density (g/cm³) | 8.79 |

Melting Point (°C) | 1340 |

Thermal Conductivity (W/m·K) | 11.5 |

Modulus of Elasticity (GPa) | 211 |

Metallographic Structure of Rene 80 Superalloy

Rene 80 features an γ-phase nickel matrix with γ' (gamma prime) precipitates, providing high-temperature strength and stability. The γ phase limits dislocation movement, which enhances creep resistance and maintains mechanical integrity during prolonged exposure to stress.

The alloy’s structure also benefits from boron, strengthening grain boundaries and improving fatigue resistance. This metallographic arrangement ensures that Rene 80 can withstand extreme thermal cycling, making it an ideal material for aerospace engines and power turbines.

Rene 80 Mechanical Properties

Rene 80 offers outstanding mechanical strength and fatigue resistance at high temperatures. It maintains stable performance over long durations, with exceptional creep rupture life at elevated temperatures.

Property | Value |

|---|---|

Tensile Strength (MPa) | 1200–1300 |

Yield Strength (MPa) | ~1000 |

Creep Strength | High at >850°C |

Hardness (HRC) | 35–40 |

Elongation (%) | 10–12 |

Elastic Modulus (GPa) | ~215 |

Key Features of Rene 80 Superalloy

1. Superior High-Temperature Strength

Rene 80 offers tensile strength up to 1300 MPa and maintains mechanical integrity at temperatures above 850°C, making it suitable for aerospace engines and gas turbines.

2. Excellent Fatigue Resistance

The alloy’s strong fatigue resistance ensures it performs reliably under cyclic thermal and mechanical loads, reducing the risk of mechanical failure.

3. Exceptional Thermal Stability

With a creep rupture life exceeding 10,000 hours at 982°C, Rene 80 delivers reliable performance over extended periods in high-temperature applications.

4. High Oxidation Resistance

The chromium content ensures oxidation resistance, preventing degradation in harsh environments, including gas turbines and power plants.

5. Strong Grain Boundary Strength

Adding boron strengthens the grain boundaries, enhancing the alloy’s structural stability and resistance to cracking under stress.

Rene 80 Superalloy’s Machinability

Rene 80 is suitable for Vacuum Investment Casting due to its excellent thermal stability and ability to produce high-precision components for gas turbines and aerospace applications.

However, it is not typically used in Single Crystal Casting because it is optimized for polycrystalline structures rather than single-crystal growth, which limits its suitability for this process.

Rene 80 performs exceptionally well in Equiaxed Crystal casting, offering a uniform grain structure with excellent creep and thermal fatigue resistance for high-temperature components.

The alloy can also be used in Superalloy Directional Casting, but its polycrystalline nature may limit the advantages gained from directional solidification.

Rene 80 is not ideal for Powder Metallurgy Turbine Discs due to challenges in powder processing and a focus on casting-based applications.

The alloy is highly compatible with Superalloy Precision Forging, producing solid, durable components with excellent mechanical properties for high-temperature environments.

Superalloy 3D Printing is not widely used for Rene 80 due to difficulties maintaining its mechanical properties during additive manufacturing.

Due to its strength and thermal stability, Rene 80 is suitable for CNC Machining, allowing for the precise fabrication of turbine blades and aerospace components.

Superalloy Welding with Rene 80 requires careful handling and heat treatment to prevent cracking and maintain mechanical integrity during welding.

Hot Isostatic Pressing (HIP) is highly effective for Rene 80, eliminating porosity and enhancing its mechanical properties, ensuring uniform strength across components.

Rene 80 Superalloy Applications

In Aerospace and Aviation, Rene 80 is used for turbine blades and combustion chambers, providing high strength and reliability under extreme thermal stress.

In power generation, the alloy is applied to gas turbines and heat exchangers, ensuring operational stability and resistance to thermal fatigue.

In the Oil and Gas sector, Rene 80 is used in high-temperature valves and downhole equipment, providing excellent mechanical strength and corrosion resistance.

For Energy systems, the alloy’s thermal stability makes it ideal for turbine and heat exchange components, supporting long-term performance under continuous operation.

In Marine applications, Rene 80 offers excellent corrosion resistance, making it suitable for exhaust systems and propulsion components exposed to seawater environments.

In Mining, Rene 80 is used in wear-resistant parts, such as pump components and drill bits, ensuring durability under high-pressure and abrasive conditions.

The automotive industry benefits from Rene 80’s thermal fatigue resistance, which is applied to turbochargers and exhaust systems for high-performance vehicles.

In Chemical Processing, Rene 80’s oxidation resistance ensures reliability in reactors and heat exchangers exposed to extreme temperatures and chemicals.

For the Pharmaceutical and Food industries, Rene 80 is used in valves and processing equipment, ensuring stability and safety under challenging operating conditions.

In Military and Defense, Rene 80 is employed for missile and jet engine components, offering reliability under high thermal and mechanical loads.

The Nuclear industry leverages Rene 80 for reactor parts, where resistance to radiation and thermal fatigue is essential for safety and performance.

When to Choose Rene 80 Superalloy

Rene 80 is ideal for applications with high mechanical strength, excellent thermal stability, and fatigue resistance. This alloy is particularly suitable for custom superalloy parts used in aerospace engines and gas turbines, where extreme temperatures and continuous stress are the norm.

Energy, automotive, and chemical processing industries benefit from Rene 80’s ability to maintain mechanical integrity over extended periods. It is preferred for components subjected to high-temperature environments, such as combustion chambers, turbine blades, and exhaust systems. When long-term durability and resistance to oxidation are required, Rene 80 delivers unmatched performance.