Rene N6

About Rene N6 Superalloy

Name and Equivalent Names

Rene N6 is a high-performance nickel-chromium alloy recognized under AMS 5971 standards. Though there are no direct ASTM or ISO equivalents, it meets the stringent requirements of NACE MR0175 for corrosion resistance, making it highly suitable for aerospace and gas turbine applications.

Rene N6 Basic Introduction

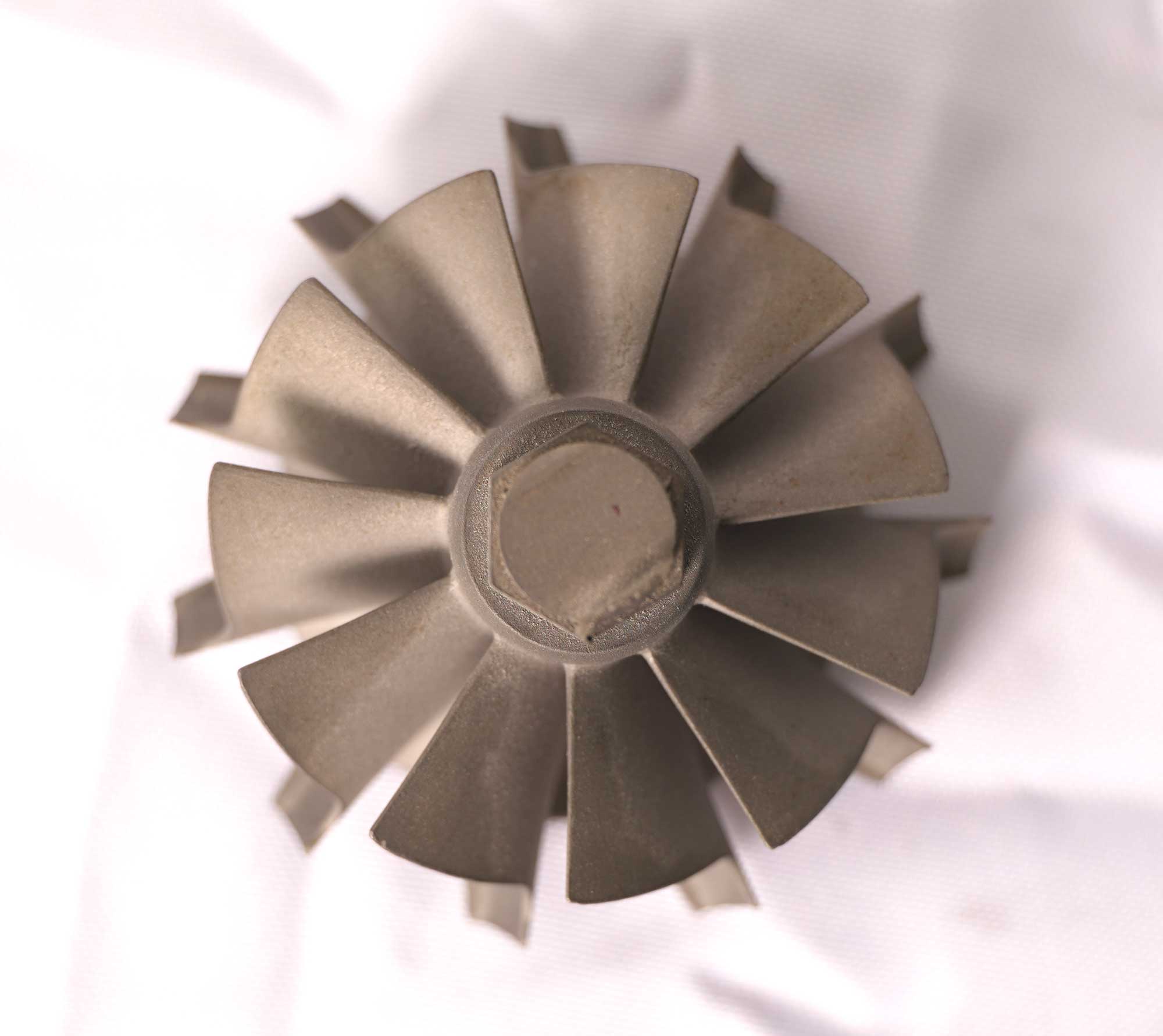

Rene N6 is a single-crystal superalloy engineered for high-temperature environments, providing excellent thermal fatigue resistance and structural integrity. Its unique composition, including rhenium and hafnium, ensures durability in extreme conditions, such as turbine engines.

This alloy excels in aerospace applications, particularly gas turbines, where components are subjected to continuous thermal cycling. Rene N6’s fatigue resistance and mechanical stability minimize downtime, making it a reliable material for long-term use at temperatures above 1000°C.

Alternative Superalloys of Rene N6

Comparable alternatives to Rene N6 include CMSX-4, Rene N5, and Inconel 738. CMSX-4 offers similar high-temperature fatigue resistance with minor differences in composition. Rene N5 provides comparable thermal stability but focuses more on fatigue resistance. Inconel 738 offers oxidation resistance but lacks the single-crystal properties essential for turbine blades.

Rene N6 Design Intention

Rene N6 is designed explicitly for critical aerospace applications, where fatigue resistance and high-temperature strength are paramount. The single-crystal structure eliminates grain boundaries, reducing the risk of creep deformation under sustained stress.

Including rhenium and hafnium enhances the alloy’s ability to withstand extreme thermal cycles, making it suitable for turbine blades and other engine components. Its design ensures long-term performance, minimizing maintenance requirements and extending the service life of critical systems.

Rene N6 Chemical Composition

The chemical composition of Rene N6 ensures high mechanical stability and resistance to thermal fatigue, making it ideal for aerospace applications.

Element | Content (wt%) |

|---|---|

Nickel (Ni) | Balance |

Chromium (Cr) | 12.5 |

Cobalt (Co) | 12.5 |

Aluminum (Al) | 5.8 |

Titanium (Ti) | 5.5 |

Tungsten (W) | 5.0 |

Rhenium (Re) | 3.0 |

Hafnium (Hf) | 0.15 |

Rene N6 Physical Properties

Rene N6 exhibits excellent physical properties for high-temperature environments, ensuring stable performance in demanding applications.

Property | Value |

|---|---|

Density (g/cm³) | 8.72 |

Melting Point (°C) | 1350 |

Thermal Conductivity (W/m·K) | 10.7 |

Modulus of Elasticity (GPa) | 214 |

Metallographic Structure of Rene N6 Superalloy

Rene N6 is a single-crystal alloy with a unique γ/γ' phase structure. The absence of grain boundaries enhances its resistance to creep deformation, ensuring mechanical stability under extreme conditions.

The alloy’s rhenium-enriched composition improves thermal fatigue resistance, making it ideal for components subjected to cyclic loading. The metallurgical design ensures high durability and excellent thermal conductivity, reducing the risk of mechanical failure in turbine engines.

Rene N6 Mechanical Properties

Rene N6 offers superior mechanical performance in high-stress environments, ensuring reliable operation under extreme conditions.

Property | Value |

|---|---|

Tensile Strength (MPa) | ~1300 |

Yield Strength (MPa) | ~1150 |

Creep Strength | Excellent at 1100°C |

Hardness (HRC) | ~45 |

Elongation (%) | 8 – 10 |

Elastic Modulus (GPa) | ~225 |

Key Features of Rene N6 Superalloy

1. Outstanding Thermal Fatigue Resistance

Rene N6 excels in resisting thermal fatigue, ensuring consistent performance in environments with frequent temperature fluctuations.

2. Superior Mechanical Stability

The alloy’s single-crystal structure eliminates grain boundaries, improving resistance to creep and stress rupture at elevated temperatures.

3. Enhanced Service Life

With excellent high-temperature performance, Rene N6 ensures long service life in turbine engines, minimizing maintenance costs and operational downtime.

4. Optimized for Aerospace Applications

Rene N6’s thermal resistance and mechanical durability are ideal for gas turbine blades and components exposed to extreme operating conditions.

5. High-Temperature Strength

The alloy maintains mechanical strength at temperatures exceeding 1100°C, making it suitable for demanding aerospace and power generation applications.

Rene N5 Superalloy’s Machinability

Rene N5 is not optimal for Vacuum Investment Casting because it performs better under casting methods tailored for single-crystal alloys, such as single-crystal casting.

Rene N5 is ideal for Single Crystal Casting, as this process ensures a structure without grain boundaries, optimizing its creep resistance and thermal stability at high temperatures.

Rene N5 is unsuitable for Equiaxed Crystal Casting due to its design as a single-crystal material, which would lose its superior properties with this casting method.

It can be used in Superalloy Directional Casting, but the best performance is achieved through single-crystal techniques.

Rene N5 is not recommended for Powder Metallurgy Turbine Disc applications because preserving its single-crystal properties in powder metallurgy is challenging.

The alloy is unsuitable for Superalloy Precision Forging due to its brittle nature at forging temperatures, limiting its deformation capabilities.

Due to challenges maintaining single-crystal integrity, Rene N5 is generally not applicable for Superalloy 3D Printing.

CNC Machining is effective for Rene N5, allowing precision shaping and finishing of components like turbine blades.

Superalloy Welding of Rene N5 requires specialized processes to prevent cracking, as the alloy's high strength limits its weldability.

Rene N5 benefits significantly from Hot Isostatic Pressing (HIP), which enhances density and mechanical performance by eliminating internal voids.

Rene N5 Superalloy Applications

Aerospace and Aviation

In Aerospace and Aviation, Rene N5 is used for turbine blades and vanes, where its thermal stability ensures optimal engine performance.

Power Generation

For Power Generation, the alloy is employed in gas turbines, contributing to enhanced efficiency and longer service life under extreme temperatures.

Oil and Gas

In Oil and Gas, Rene N5 provides corrosion resistance and creep strength, making it ideal for harsh drilling environments.

Energy

Rene N5 is valuable for Energy applications, especially in turbines, due to its resistance to cyclic thermal stress.

Marine

The alloy’s corrosion resistance makes it reliable for Marine engines and propulsion systems exposed to seawater.

Mining

In Mining, Rene N5’s wear resistance ensures longevity in equipment like drills and pumps.

Automotive

The Automotive industry utilizes Rene N5 for turbochargers and high-performance engines, where thermal stability is essential.

Chemical Processing

For Chemical Processing, Rene N5 components maintain mechanical integrity in high-temperature reactors and heat exchangers.

Pharmaceutical and Food

In Pharmaceutical and Food production, Rene N5’s corrosion resistance ensures hygienic, durable processing equipment.

Military and Defense

The alloy is critical in Military and Defense applications, such as aircraft engines, ensuring operational readiness and long-term reliability.

Nuclear

For Nuclear reactors, Rene N5 offers excellent thermal performance and resistance to radiation-induced degradation.

When to Choose Rene N5 Superalloy

Rene N5 is ideal for environments with exceptional thermal and mechanical stability. It performs well in high-performance engines, turbines, and aerospace applications where operating temperatures exceed 1000°C. The alloy’s fatigue resistance makes it particularly useful in gas turbines and jet engines, ensuring long-term reliability and minimal maintenance.

The alloy’s application in aerospace, power generation, and military defense demonstrates its ability to withstand extreme thermal stress and mechanical fatigue. Rene N5 offers optimal performance and ensures long service life for custom-engineered solutions, such as custom superalloy parts.