Rene 88

About Rene 88 Superalloy

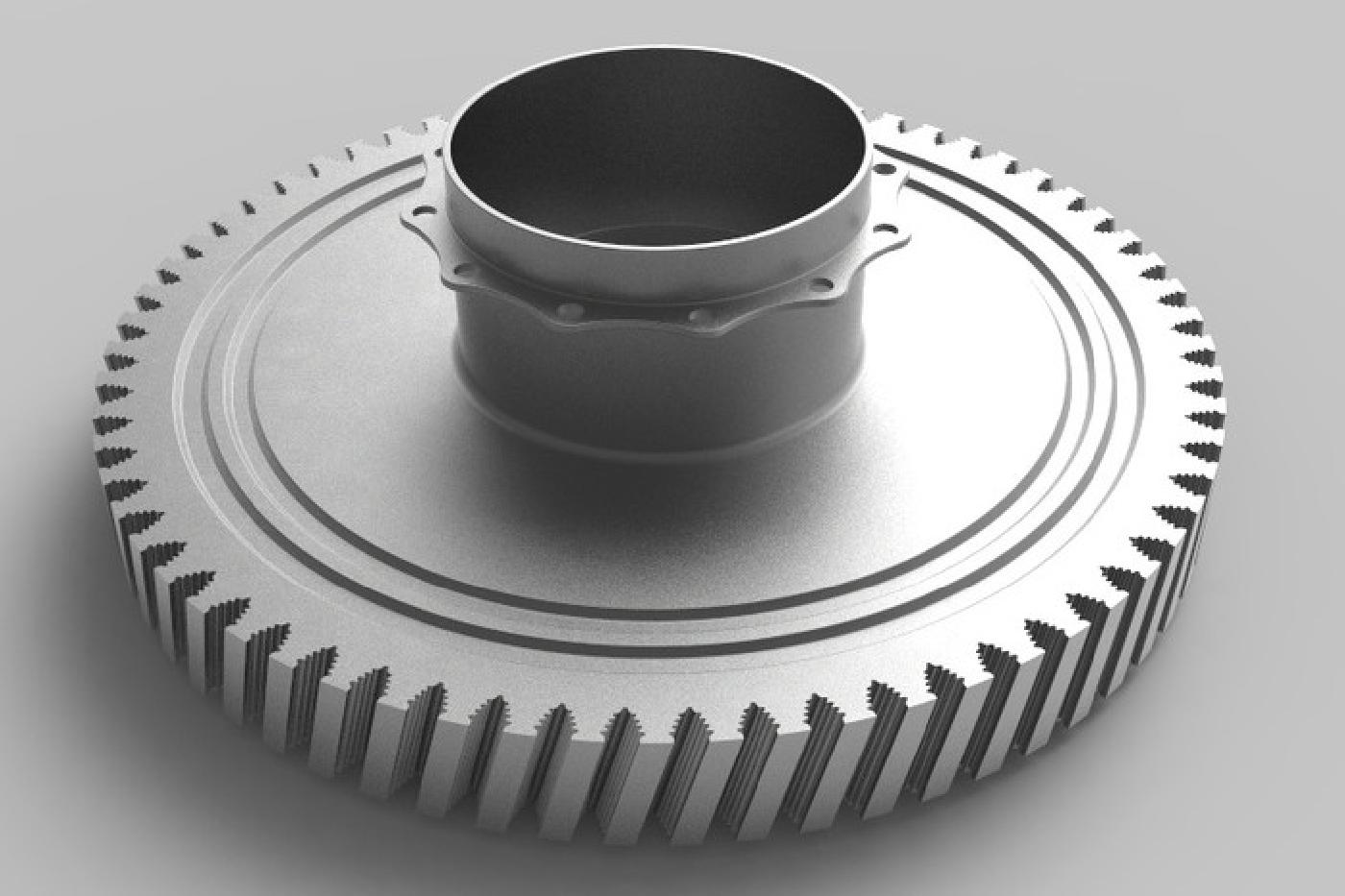

Rene 88 is a nickel-based superalloy known for its high mechanical strength and outstanding performance under extreme conditions. It has excellent fatigue resistance and corrosion properties, making it suitable for components exposed to high thermal stress, such as turbine blades and discs.

The material is typically used in gas turbines and jet engines, where sustained performance at elevated temperatures is critical. With excellent oxidation resistance, Rene 88 remains a reliable choice for aerospace, energy, and oil and gas industries.

Rene 88 Basic Introduction

Rene 88 is a nickel-chromium-based superalloy that provides excellent performance in high-temperature environments. It is often used in jet engines and industrial turbines due to its exceptional thermal fatigue resistance and creep strength.

This superalloy performs well in environments that demand superior mechanical stability, oxidation resistance, and long service life. With advanced fatigue resistance, Rene 88 enables the production of turbine discs and components that must endure severe cyclic loading conditions.

Alternative Superalloys of Rene 88

Materials like Inconel 718, Hastelloy X, and Waspaloy offer similar properties to Rene 88. Inconel 718 provides high strength at elevated temperatures, making it ideal for aerospace applications. Waspaloy exhibits comparable oxidation resistance and creep strength and is suitable for high-performance turbine components.

Hastelloy X, with excellent oxidation and corrosion resistance, is often used in harsh environments such as chemical processing and aviation. However, Rene 88 stands out for its unique balance of fatigue resistance, creep strength, and thermal performance, making it ideal for turbine discs.

Rene 88 Design Intention

Rene 88 was designed to deliver superior thermal stability, fatigue resistance, and high creep strength. Its microstructure ensures minimal grain boundary degradation, enhancing long-term durability in demanding environments.

The alloy was developed explicitly for turbine discs and other critical rotating components in jet engines, where thermal stress and mechanical fatigue occur simultaneously. Its ability to maintain structural integrity under continuous stress cycles makes it suitable for aerospace and power generation applications.

Rene 88 Chemical Composition

The chemical composition of Rene 88 includes nickel as the primary element, with additions of chromium, cobalt, and molybdenum to enhance strength, oxidation resistance, and mechanical properties. The presence of aluminum and titanium improves its fatigue resistance, while small amounts of hafnium and tantalum offer creep strength at elevated temperatures.

Element | Composition (%) |

|---|---|

Nickel (Ni) | Balance |

Chromium (Cr) | 14 – 16 |

Cobalt (Co) | 13 – 15 |

Molybdenum (Mo) | 3 – 4 |

Aluminum (Al) | 2 – 3 |

Titanium (Ti) | 1 – 2 |

Tungsten (W) | 3 – 4 |

Hafnium (Hf) | 0.5 – 1 |

Tantalum (Ta) | 2 – 3 |

Rene 88 Physical Properties

Rene 88 is characterized by high density, excellent thermal conductivity, and outstanding thermal stability, making it ideal for turbine applications. Its high modulus of elasticity ensures mechanical strength under cyclic stress conditions.

Property | Value |

|---|---|

Density | 8.7 g/cm³ |

Melting Point | 1350°C |

Thermal Conductivity | 10.5 W/(m·K) |

Modulus of Elasticity | 215 GPa |

Metallographic Structure of Rene 88 Superalloy

Rene 88 exhibits a unique metallographic structure composed primarily of a gamma matrix with gamma-prime precipitates distributed throughout. The gamma matrix provides structural stability, while the gamma-prime phase enhances mechanical strength and creep resistance.

This microstructure ensures that Rene 88 maintains its properties even under high-temperature fatigue conditions. With minimal grain boundary weakening, the alloy offers superior durability and resistance to mechanical stress, ideal for aerospace applications.

Rene 88 Mechanical Properties

Rene 88 exhibits excellent tensile, yield strength, and superior fatigue resistance. These properties allow it to withstand continuous stress cycles and high temperatures in turbine engines and power systems.

Mechanical Property | Value |

|---|---|

Tensile Strength | 1280 MPa |

Yield Strength | 1050 MPa |

Creep Strength | Excellent at 982°C |

Hardness | 40 HRC |

Elongation | 8 – 10% |

Elastic Modulus | 220 GPa |

Key Features of Rene 88 Superalloy

1. Outstanding Thermal Stability

Rene 88 offers excellent performance at elevated temperatures, making it suitable for applications where components must endure continuous thermal stress. Its ability to maintain mechanical strength beyond 1000°C ensures reliable operation in demanding conditions.

2. High Fatigue Resistance

The alloy’s gamma-prime microstructure enables it to withstand cyclic loading, making it ideal for jet engines and turbines where mechanical fatigue can lead to failure. Rene 88 ensures longer service life with minimal maintenance.

3. Excellent Oxidation Resistance

Rene 88 is highly resistant to oxidation, preventing surface degradation even under high-temperature exposure. It is excellent for turbine discs and engine components operating in harsh environments.

4. Superior Creep Strength

The alloy's ability to resist deformation under prolonged stress ensures it performs exceptionally well in high-temperature, high-stress applications. This makes it suitable for gas turbines and power generation systems.

5. Long Service Life

Rene 88 offers long-lasting performance with minimal grain boundary weakening, ensuring durability and reduced maintenance. Its advanced properties contribute to lower operating costs and reliability in critical aerospace applications.

Rene 88 Superalloy’s Machinability

Vacuum Investment Casting Rene 88 is compatible with Vacuum Investment Casting due to its excellent creep resistance and oxidation properties. This casting process ensures minimal contamination, preserving the alloy’s mechanical integrity and making it ideal for precision components like turbine blades.

Single Crystal Casting Rene 88 is not commonly used in Single Crystal Casting since it’s typically processed as an equiaxed alloy. However, the alloy's fatigue resistance and stability at elevated temperatures can still be helpful for select applications.

Equiaxed Crystal Casting Equiaxed Crystal casting is well-suited for Rene 88, as it offers superior fatigue strength and oxidation resistance. This method enhances its grain structure, ensuring durability in high-stress turbine components.

Directional Casting Rene 88 performs well in Directional Casting applications where components experience high temperatures. Its thermal stability ensures consistent performance, even under cyclic stress conditions in gas turbines.

Powder Metallurgy Turbine Disc While Rene 88 can be used in Powder Metallurgy Turbine Disc applications, its optimal performance lies in traditional casting processes. The alloy’s fatigue resistance makes it valuable in discs requiring high mechanical strength.

Precision Forging Rene 88 is not typically processed through Superalloy Precision Forging. However, in specific cases, it offers the required mechanical properties, such as fatigue resistance and creep strength, for forged components.

Superalloy 3D Printing The use of Rene 88 in Superalloy 3D Printing is currently limited. However, with advancements in additive manufacturing, the alloy’s potential in high-precision, high-temperature parts is promising.

CNC Machining Rene 88 is well-suited for CNC Machining due to its excellent fatigue resistance and mechanical strength. It is commonly used to machine turbine discs and blades, ensuring high precision and durability.

Superalloy Welding Rene 88 can be welded with careful control, making it viable for Superalloy Welding. Pre-weld heating and post-weld treatments are essential to prevent cracking, ensuring structural integrity in high-stress environments.

Hot Isostatic Pressing (HIP) Rene 88 benefits from Hot Isostatic Pressing (HIP) to enhance its density and mechanical properties. This process minimizes porosity, improving fatigue resistance and creep strength, particularly in aerospace applications.

Rene 88 Superalloy Applications

Aerospace and Aviation Rene 88 is widely used in Aerospace and Aviation for manufacturing turbine blades and discs. Its high fatigue strength and thermal stability ensure reliable performance in jet engines under continuous stress and extreme temperatures.

Power Generation In Power Generation, Rene 88 is ideal for gas turbine components exposed to high temperatures. It's oxidation resistance and long service life improve efficiency and reduce maintenance costs.

Oil and Gas The alloy’s fatigue resistance makes it suitable for critical components in Oil and Gas operations. Rene 88 ensures durability under high pressure and extreme temperatures in drilling and refining equipment.

Energy Rene 88 finds applications in the Energy sector, particularly in steam turbines. Its mechanical strength and creep resistance allow efficient energy conversion under challenging conditions.

Marine Rene 88’s corrosion resistance makes it suitable for Marine applications, such as gas turbines used in naval vessels. Its long service life and resistance to thermal fatigue enhance operational reliability.

Mining The alloy’s durability makes it an asset in Mining equipment that operates under extreme wear and stress. Rene 88 ensures reliable performance in high-temperature mining processes.

Automotive Rene 88 is utilized in high-performance vehicles for turbocharger components in the Automotive industry. Its ability to withstand thermal stress ensures optimal performance in harsh driving conditions.

Chemical Processing Rene 88’s corrosion resistance makes it useful in Chemical Processing environments where exposure to corrosive agents occurs daily. It ensures a longer lifespan for critical equipment.

Pharmaceutical and Food In the Pharmaceutical and Food industries, Rene 88 is used for components that require high cleanliness and resistance to thermal cycling, ensuring product safety and equipment durability.

Military and Defense Rene 88’s ability to withstand high temperatures makes it indispensable for Military and Defense applications. It ensures durability and reliability in jet engines and missile systems under extreme operational conditions.

In Nuclear reactors, Rene 88 is used for components requiring high mechanical stability and thermal fatigue resistance. Its performance ensures safety and longevity under extreme radiation and heat.

When to Choose Rene 88 Superalloy

Rene 88 is the preferred material when high-temperature performance, fatigue resistance, and oxidation stability are essential. It is ideal for applications in aerospace and gas turbines, where components must endure extreme conditions with minimal wear and deformation. Its use ensures long service life, reduced maintenance, and enhanced efficiency in critical operations.

For manufacturers seeking precision-engineered parts, Rene 88 provides a reliable solution. Its compatibility with advanced processes like Custom superalloy parts production makes it a versatile choice across various industries.