Aluminum 3D Printing Service

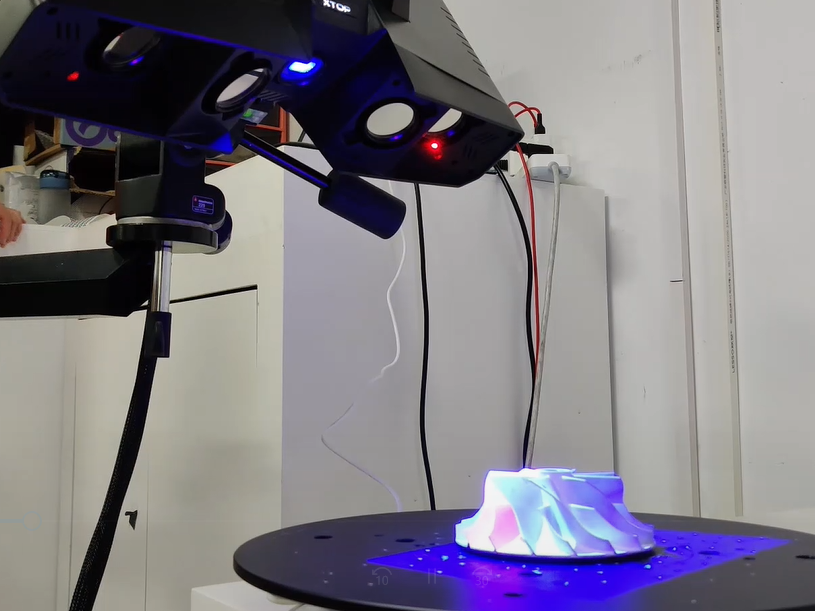

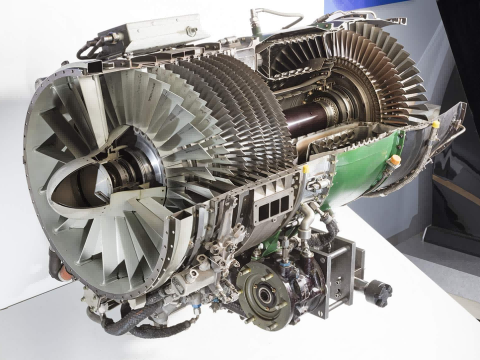

Neway provides cutting-edge aluminum 3D printing services using advanced technologies like SLM, LENS Laser Melting Deposition (LMD), WAAM, and LC. Our expertise ensures lightweight, high-strength components with excellent thermal conductivity and corrosion resistance, suitable for aerospace, automotive, and industrial applications.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

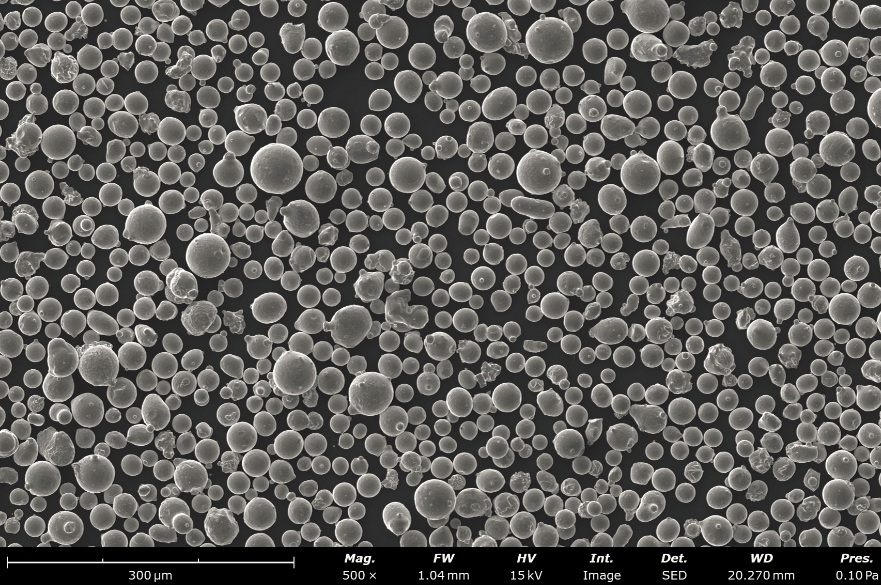

Aluminum 3D Printing Materials

Our Aluminum 3D Printing Technology

Neway offers cutting-edge aluminum 3D printing services utilizing advanced technologies such as SLM, LENS Laser Melting Deposition (LMD), WAAM, and LC. Our expertise delivers lightweight, high-strength components with superior thermal conductivity and corrosion resistance.

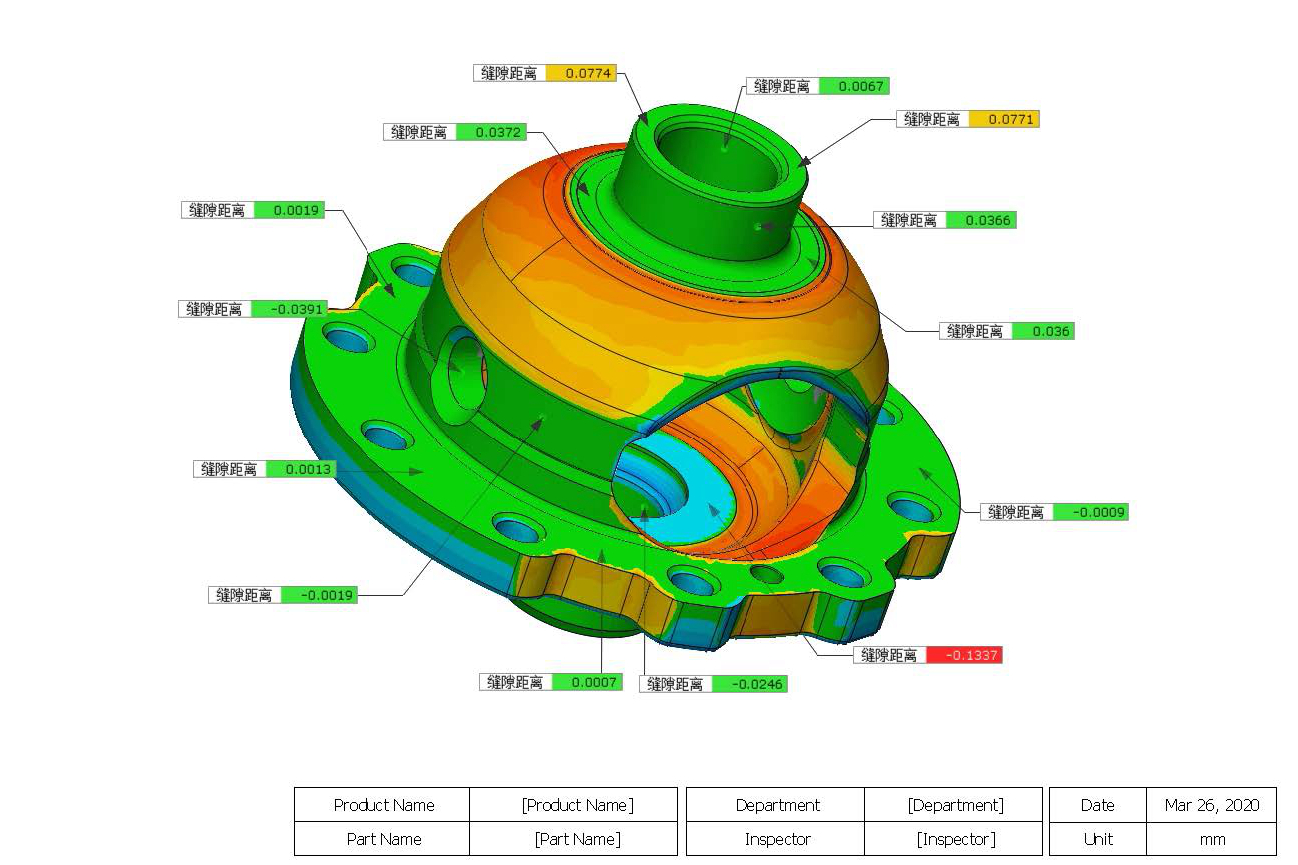

3D Printed Aluminum Parts Post Processing Services

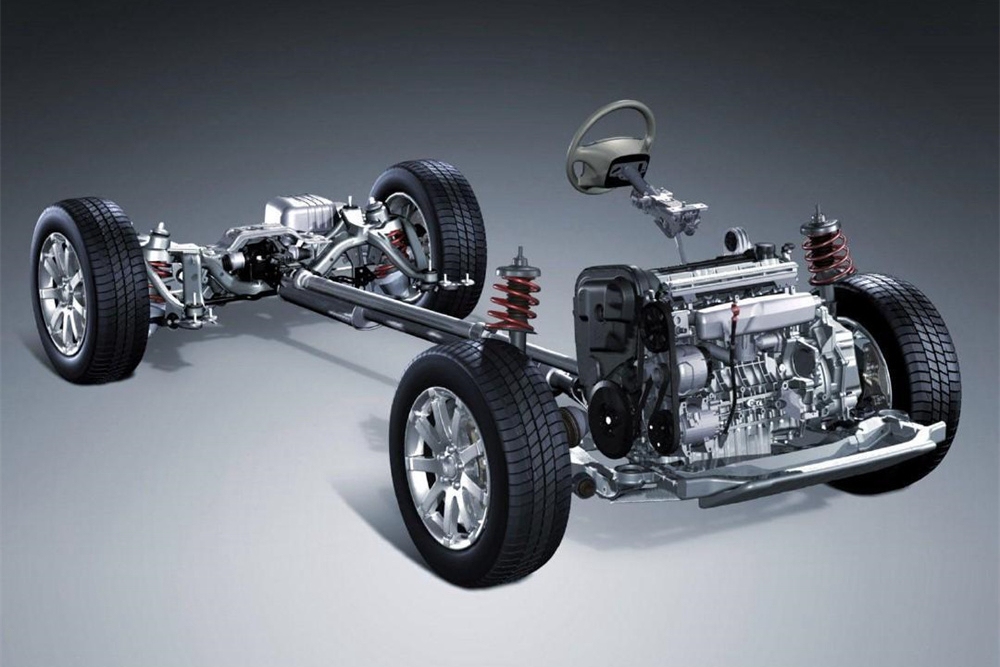

3D-printed aluminum components offer lightweight, durable, and corrosion-resistant solutions across industries. In aerospace and automotive, they improve fuel efficiency and performance. Power generation and energy sectors benefit from enhanced thermal management. Oil, gas, and marine industries use them for corrosion-resistant parts. In chemical, pharmaceutical, and military applications, they ensure precision and reliability, while mining and nuclear sectors leverage them for lightweight, high-strength components.

Superalloy 3D Printed Components in Different Industries

Industries benefit from 3D-printed superalloy components through enhanced performance, rapid prototyping, and lightweight, customized designs. These parts offer superior heat resistance, corrosion resistance, and mechanical strength, increasing efficiency and reliability in harsh environments. 3D printing reduces lead times, minimizes waste, and enables complex geometries, optimizing operations in aerospace, energy, automotive, marine, mining, and pharmaceutical sectors.

learn more

Aerospace and Aviation

learn more

Power Generation

learn more

Oil and Gas

learn more

Energy

learn more

Marine

learn more

Mining

learn more

Automotive

learn more

Chemical Processing

learn more

Pharmaceutical and Food

learn more

Military and Defense

learn more

Nuclear

learn more

More Cases

learn more

New Technology

learn more

Products Gallery

learn more

Various Industries

learn more

Surface Finishings

learn more

Post-Process

learn more

Manufacturing Technology

learn more

R&D and Simulation

learn more

Manufacturing Equipments

learn more

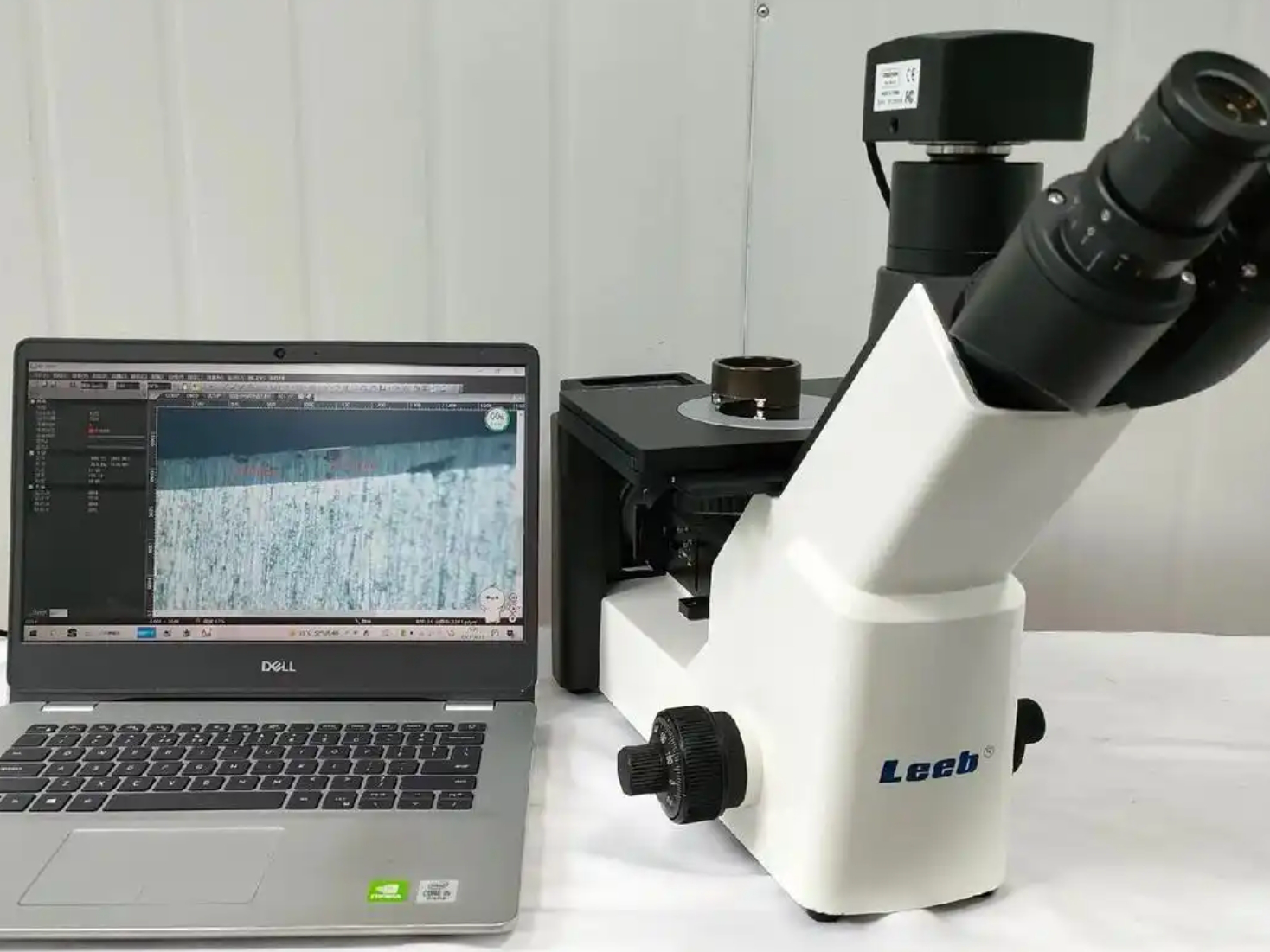

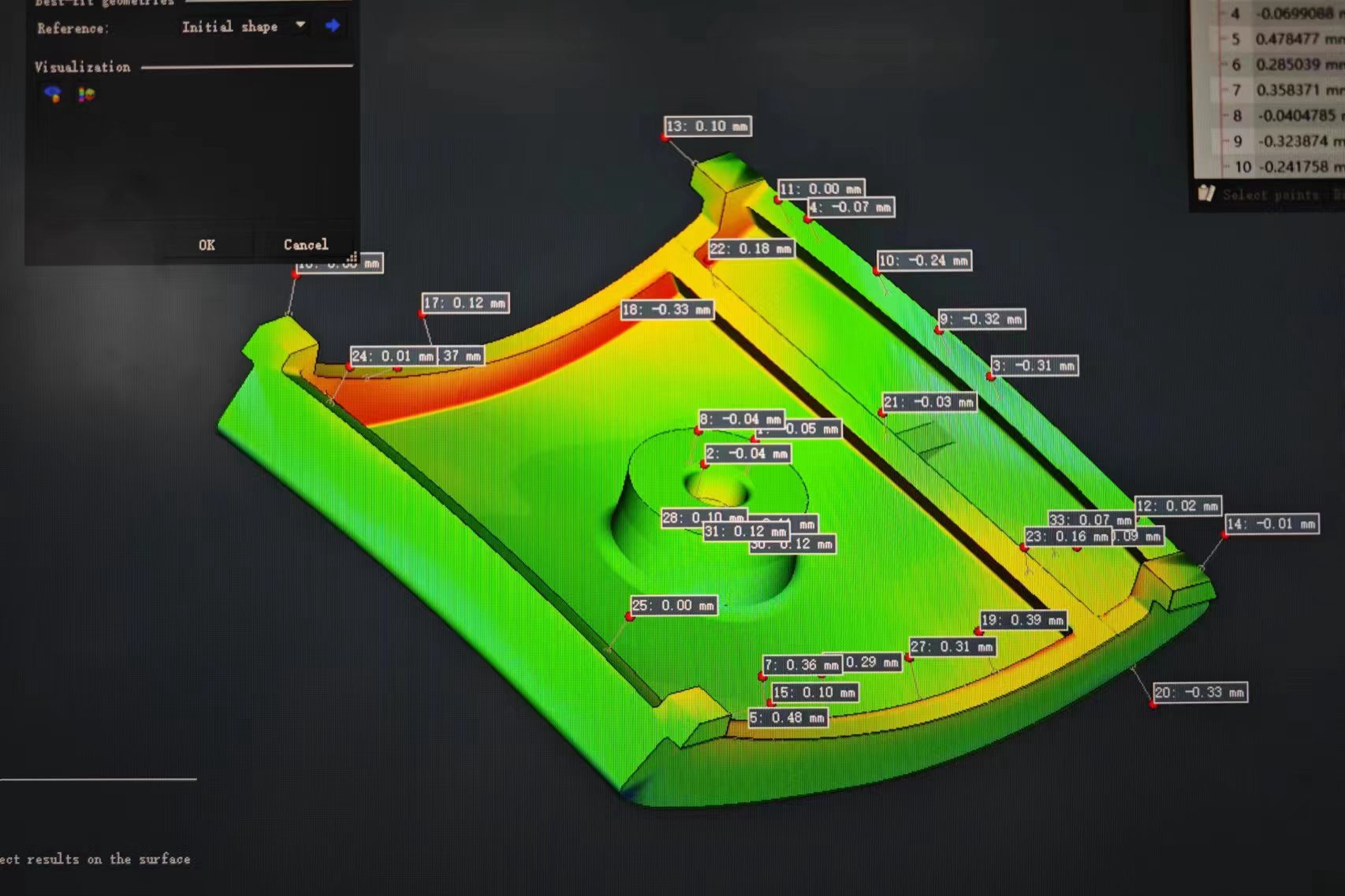

Testing Equipments

learn more

BLOGS

learn more

FAQs

learn more

Contact

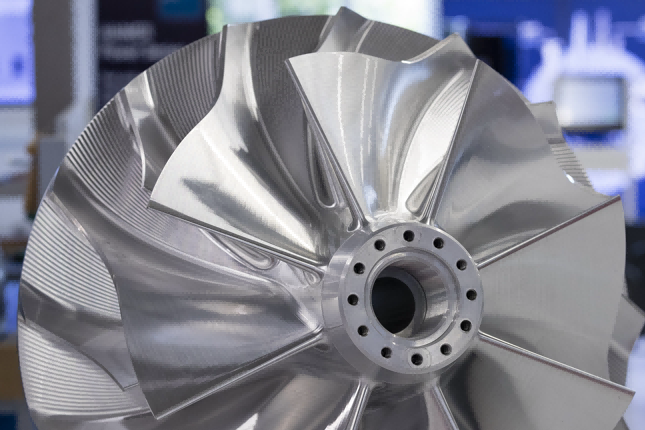

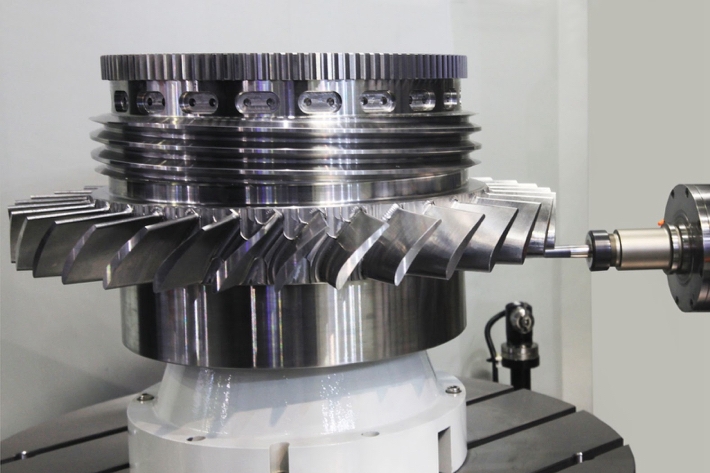

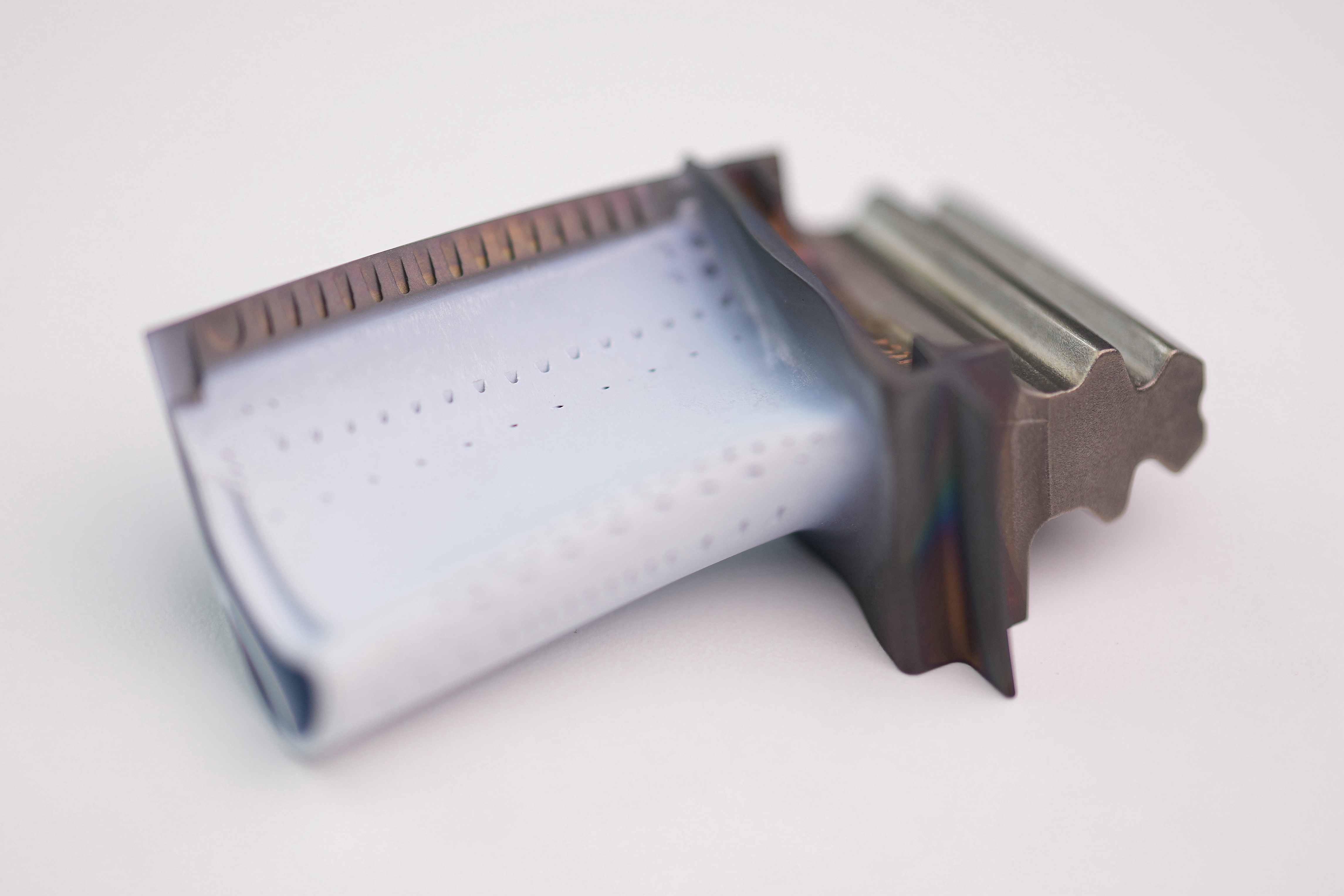

Custom Parts Gallery

At our custom parts gallery, we understand that every project is unique. That's why we work closely with our customers to ensure that their custom parts are designed to meet their exact specifications. With our attention to detail and commitment to quality, you can trust that your custom parts will exceed your expectations.

Let's Start A New Project Today