Localized Repair with LENS Deposition for Aluminum Components

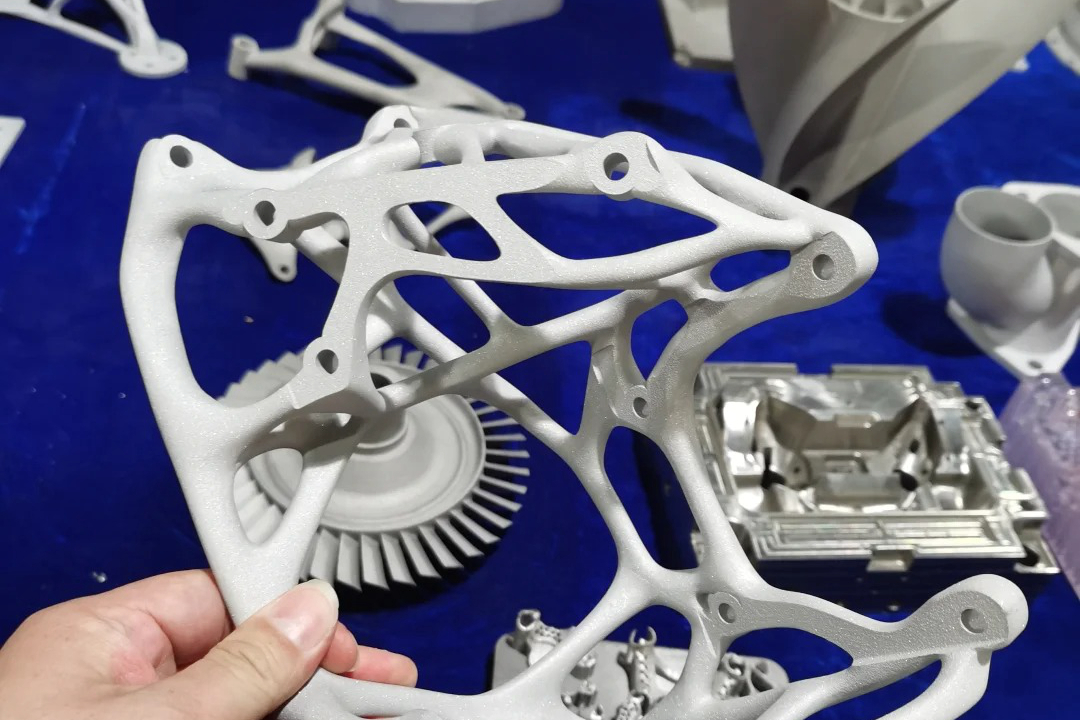

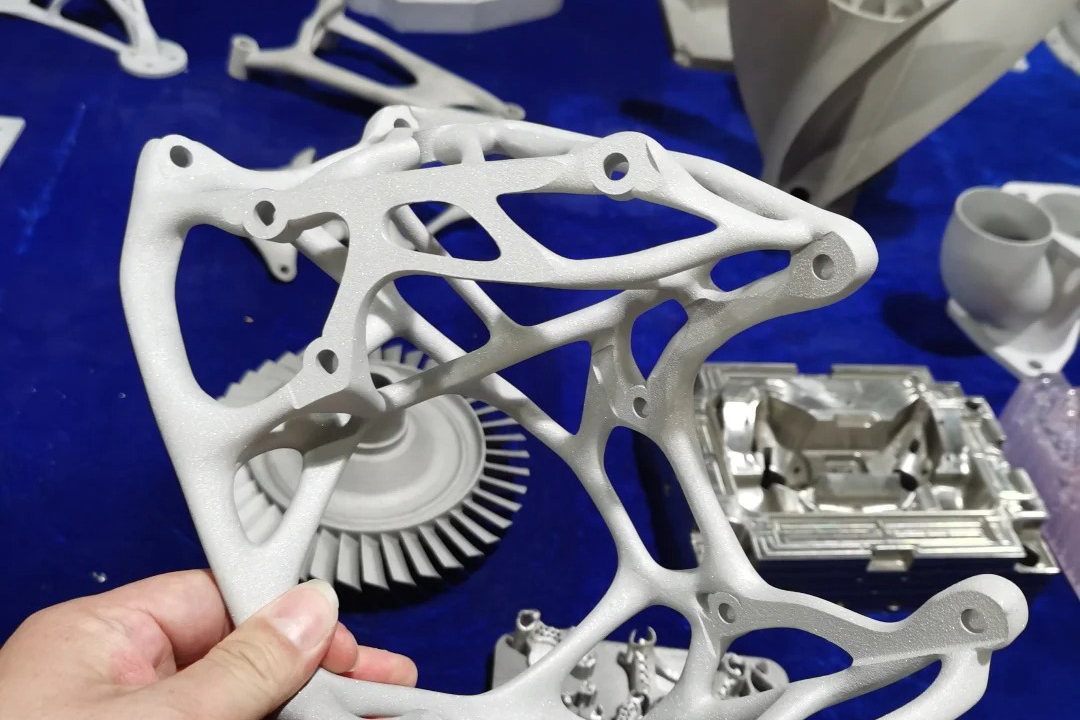

Localized repair of aluminum components using Laser Engineered Net Shaping (LENS) deposition technology offers a revolutionary approach to extend the lifespan of critical parts. LENS is an advanced additive manufacturing process that uses a focused laser beam to melt metal powders and deposit them layer by layer onto a substrate to build or repair metal components. This technique is precious for industries that rely on high-performance materials, as it allows for the targeted repair of aluminum components without requiring extensive disassembly or replacement.

Manufacturing Process of Localized Repair Using LENS Deposition

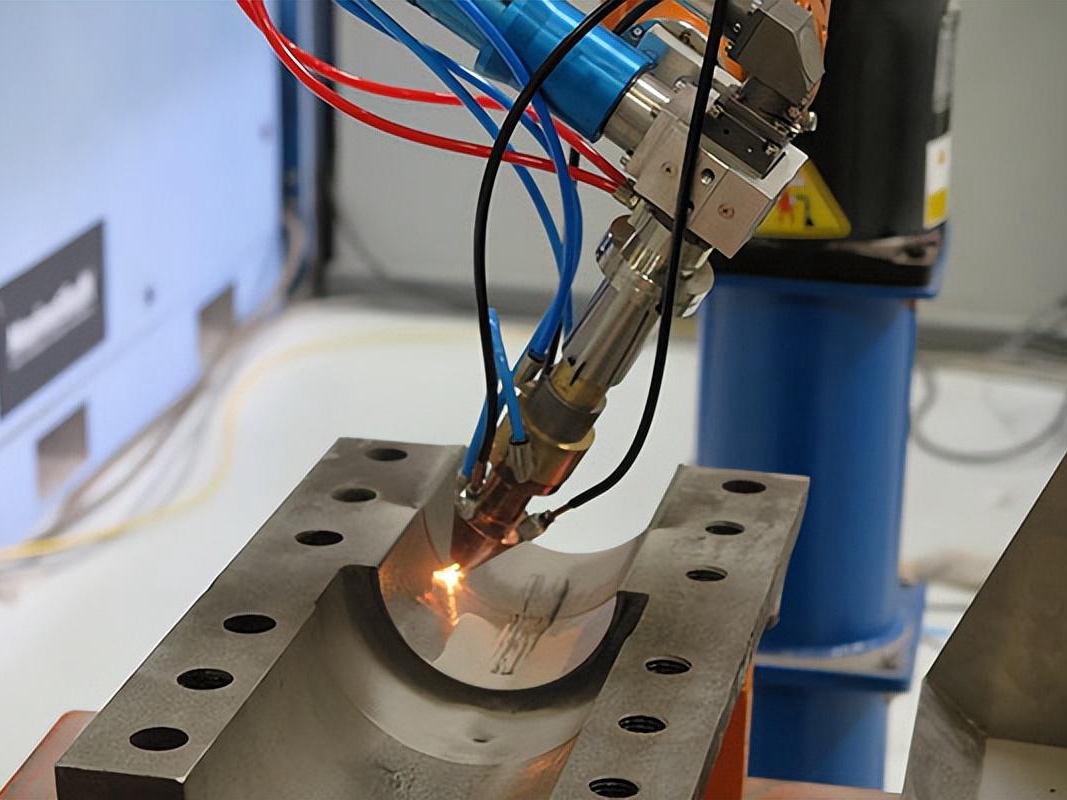

The LENS deposition process involves applying a high-powered laser to fuse metal powder onto a substrate, creating a new material layer. In the case of localized repair, this process allows for restoring damaged or worn parts without replacing the entire component.

During the LENS process, a laser melts the metal powder, which is then deposited onto the damaged area of the aluminum component. The laser beam moves in a controlled manner to ensure that the material is deposited precisely where it is needed, allowing for repairs with minimal waste. The process is highly controlled, and parameters such as laser power, scanning speed, and powder feed rate are optimized for each repair job to ensure the highest deposition quality.

Before the LENS deposition can begin, the aluminum component must be adequately prepared. This typically involves cleaning the part's surface to remove contaminants and preheating the component to an optimal temperature. Surface preparation is crucial because it ensures the deposited material adheres appropriately to the base aluminum, creating a solid bond. Sometimes, the part may need to be machined to remove damaged material, creating a clean surface for the new deposition to adhere to.

Once the LENS process is complete, the repair zone can cool and solidify. The LENS process's precise nature ensures minimal thermal distortion occurs during the deposition, reducing the risk of warping or dimensional inaccuracies in the repaired area.

Suitable Materials for LENS Deposition

The effectiveness of LENS deposition for localized repair depends on selecting the right materials. Different alloys provide different properties, and choosing the right one for the job ensures the repaired part will have the strength, durability, and resistance required for its intended application.

Inconel Alloys

Inconel alloys are high-performance superalloys made primarily from nickel and chromium, with excellent resistance to heat, oxidation, and corrosion. These properties make Inconel particularly useful for repairs in high-temperature and high-stress environments, such as in aerospace and power generation. Inconel deposition ensures that the repaired area can withstand harsh conditions for aluminum components subjected to extreme temperatures or chemical exposure. Components like turbine blades, engine parts, and combustion chambers often benefit from Inconel repair due to its ability to maintain strength at elevated temperatures.

Monel Alloys

Monel alloys, primarily composed of nickel and copper, are known for their excellent corrosion resistance, particularly in seawater and other aggressive environments. Monel is ideal for localized repairs of aluminum components exposed to marine environments, such as shipbuilding and offshore oil rigs. It is also useful in the chemical processing industry, where components are regularly exposed to corrosive substances. The corrosion-resistant properties of Monel allow for effective repairs of aluminum parts that need to resist oxidation, pitting, and other forms of corrosion.

Hastelloy Alloys

Hastelloy alloys are a family of high-performance superalloys made primarily from nickel, molybdenum, and chromium, known for their outstanding resistance to corrosion and high-temperature stability. Hastelloy alloys are often used for localized repair in highly corrosive or extreme thermal environments, such as chemical processing plants or aerospace applications. When repairing aluminum components exposed to harsh chemicals or elevated temperatures, Hastelloy deposition can provide a durable and corrosion-resistant surface that extends the part's life.

Titanium Alloys

Titanium alloys are prized for their high strength, low weight, and excellent corrosion resistance. Titanium is commonly used in aerospace, medical, and marine applications, and it is particularly effective in localized repairs of aluminum components where strength and weight savings are essential. When used for repairs, titanium alloys enhance the mechanical properties of aluminum parts, providing strength without significantly increasing the weight. The ability to repair lightweight yet high-strength components like aircraft fuselages and marine vessels makes titanium alloys an essential choice for LENS deposition.

Post-Processing for LENS Deposition Repairs

While LENS deposition offers precision and efficiency, the parts often require post-processing to enhance their mechanical properties, surface quality, and dimensional accuracy. Post-processing techniques can improve the repaired component's strength, wear resistance, and overall performance.

Heat Treatment and Stress Relief

Heat treatment is one of the most common post-processing steps following LENS deposition. It involves heating the part to a specific temperature and then cooling it rapidly to relieve any internal stresses that may have been introduced during the deposition process. This step is critical for ensuring the integrity of the repair, as residual stresses can lead to cracking or warping of the part over time. In some cases, hot isostatic pressing (HIP) may also be used to eliminate any porosity in the deposited material and further improve its mechanical properties. HIP is especially effective in improving the material's strength and extending component lifespan.

Surface Finishing and Refining

Surface finishing techniques are applied to improve the appearance and function of the repaired part. Standard methods include polishing, grinding, and bead blasting, all used to remove roughness and achieve a smooth, even surface. In some cases, additional surface coatings or anodizing may be applied to improve corrosion resistance or provide a protective barrier for the repaired component. Surface finishing is especially important in industries where the part’s aesthetic quality, performance, and durability are critical. Polishing helps achieve a high-quality surface finish that enhances functional and aesthetic properties.

Dimensional Accuracy and Tolerance

After the LENS deposition and post-processing steps, the repaired aluminum component must be checked for dimensional accuracy. This ensures that the part meets the required specifications and can be integrated appropriately into its assembly. CNC machining or other precision machining techniques are commonly used to refine the dimensions of the repaired area. The ability to maintain tight tolerances is crucial for industries like aerospace, where even small deviations can affect the performance and safety of the component. Achieving precision machining ensures that all parts conform to exacting standards for performance and safety.

Testing for Quality Assurance of LENS Deposition Repairs

Several testing methods are used to ensure the repaired aluminum component meets the necessary performance standards. These tests evaluate the repair's strength, integrity, and functionality, ensuring that it can withstand its designed conditions.

Mechanical Property Testing

Tensile, fatigue, and hardness testing are commonly used to assess the mechanical properties of the repaired component. Tensile testing measures the material's ability to withstand stretching forces, while fatigue testing evaluates how the part will hold up under cyclic loading. Hardness testing ensures that the repaired area has the desired resistance to indentation and wear. These tests help determine whether the LENS deposition repair has restored or improved the original material's performance.

Surface Integrity and Defect Detection

X-ray inspection, ultrasonic testing, and visual inspection are used to check the surface integrity of the repaired part. These methods help detect hidden defects, such as porosity or cracks, that could compromise the part’s performance. X-ray inspection, for example, allows for non-destructive analysis of internal features, while ultrasonic testing can detect subsurface flaws. These methods are critical for ensuring the repaired part meets safety and quality standards.

Dimensional Accuracy and Fit Testing

Coordinate Measuring Machines (CMM) and laser scanning are employed to measure the repaired part’s dimensions and verify that they are within the required tolerances. Dimensional accuracy is crucial in industries like aerospace, where even small deviations from specifications can result in catastrophic failure. This testing ensures the repaired component fits precisely with other parts and functions as expected.

Corrosion Resistance Testing

Since many aluminum components are used in environments exposed to harsh elements, corrosion resistance testing is crucial. Salt spray and immersion testing are commonly used to evaluate how well the repaired aluminum part resists corrosion over time. These tests simulate exposure to environmental conditions such as seawater, industrial chemicals, or extreme temperatures, ensuring that the part will maintain its integrity in the field.

Industries and Applications for Localized Repair Using LENS Deposition

Localized repair with LENS deposition benefits industries that require durable, high-performance components. The ability to quickly and efficiently repair critical aluminum components reduces downtime and minimizes the need for costly replacements.

Aerospace and Aviation

In aerospace and aviation, aluminum components such as turbine blades, engine parts, and structural elements often require repair after prolonged use. LENS deposition offers a cost-effective and efficient solution to restore these parts to their original specifications, ensuring continued performance in high-stress environments. For example, turbine blades can be restored to improve performance in extreme conditions.

Automotive

The automotive industry benefits from LENS deposition for repairing engine components, suspension parts, and other aluminum components that experience wear and tear over time. Automotive manufacturers can reduce costs and improve production timelines by repairing components rather than replacing them. Suspension parts can be effectively restored, extending the lifespan of critical vehicle systems.

Marine and Offshore

In marine and offshore industries, aluminum components are often exposed to corrosive seawater and harsh weather conditions. LENS deposition is particularly valuable for repairing aluminum ship hulls, offshore platforms, and subsea components, as it provides an efficient solution to restore corrosion-resistant properties. For example, marine hulls can be restored to improve their durability in challenging maritime environments.

Oil & Gas and Chemical Processing

In the oil and gas and chemical processing sectors, components like heat exchangers, valves, and pumps experience constant exposure to extreme temperatures and corrosive environments. LENS deposition can repair these parts, restoring their functionality and extending their service life. Heat exchangers can be repaired efficiently, avoiding the need for costly replacements and minimizing downtime.

Industrial Equipment

After prolonged use, industrial machinery, tools, and production equipment often require repairs. With LENS deposition, these components can be repaired on-site with minimal downtime, reducing the need for expensive replacements. Production equipment can be restored quickly, improving productivity and reducing maintenance costs.