Plastic 3D Printing Service

Looking for a fast, cost-effective way to prototype your plastic parts? Look no further than a plastic 3D printing service! Our plastic 3D printing service can produce high-quality parts quickly and efficiently.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Plastic 3D Printing Materials

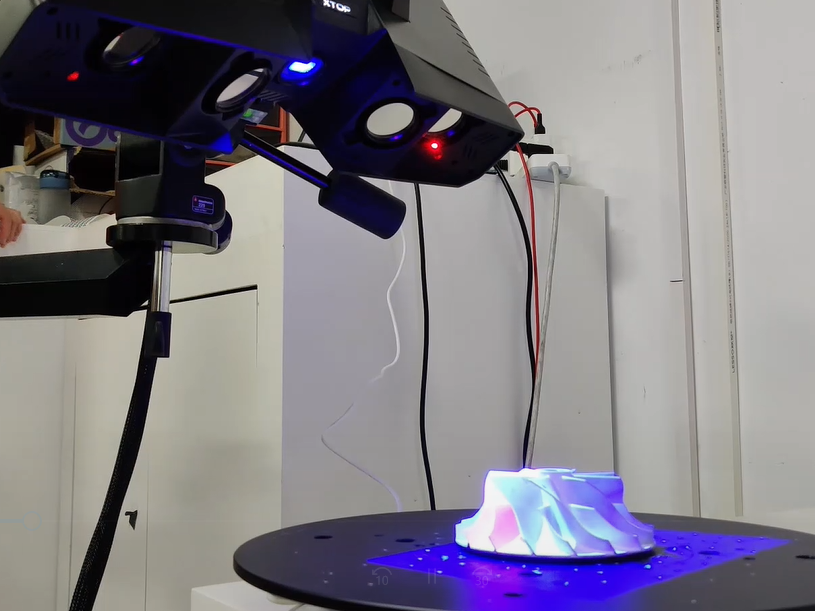

Plastic 3D Printing Technology

Neway offers cutting-edge aluminum 3D printing services utilizing advanced technologies such as SLM, LENS Laser Melting Deposition (LMD), WAAM, and LC. Our expertise delivers lightweight, high-strength components with superior thermal conductivity and corrosion resistance.

Plastic 3D Printed Parts in Different Industries

Plastic 3D-printed parts provide lightweight, cost-effective, and customizable solutions across industries. Aerospace, automotive, and energy sectors benefit from rapid prototyping and lightweight components. In healthcare, they enable custom medical devices and prosthetics. Consumer goods and electronics use them for enclosures and prototypes. In chemical processing, marine, and food industries, plastic parts offer corrosion resistance, while military applications utilize them for non-critical, lightweight systems.

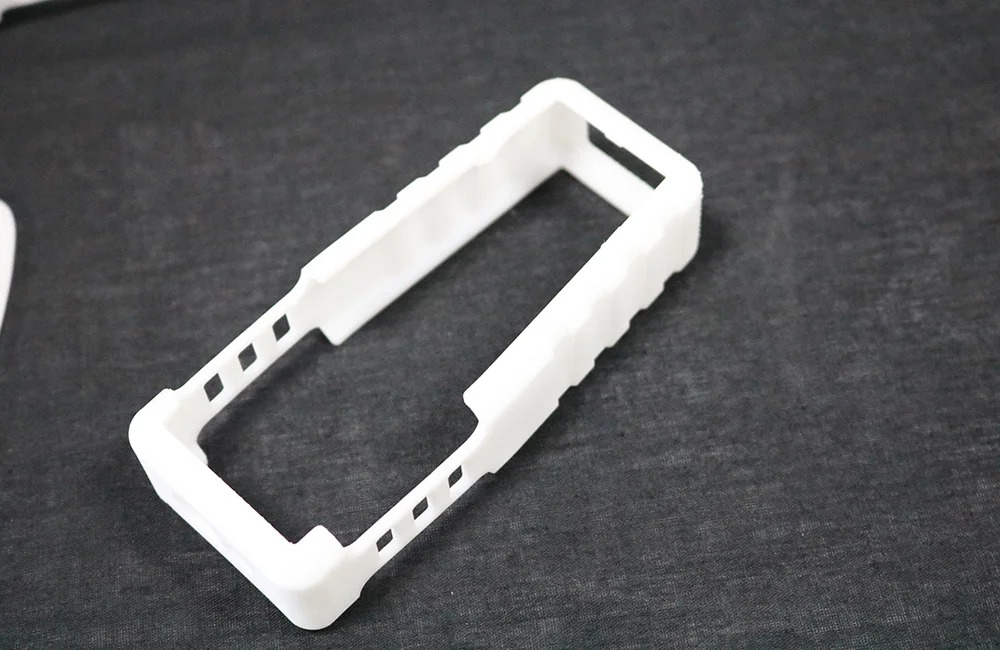

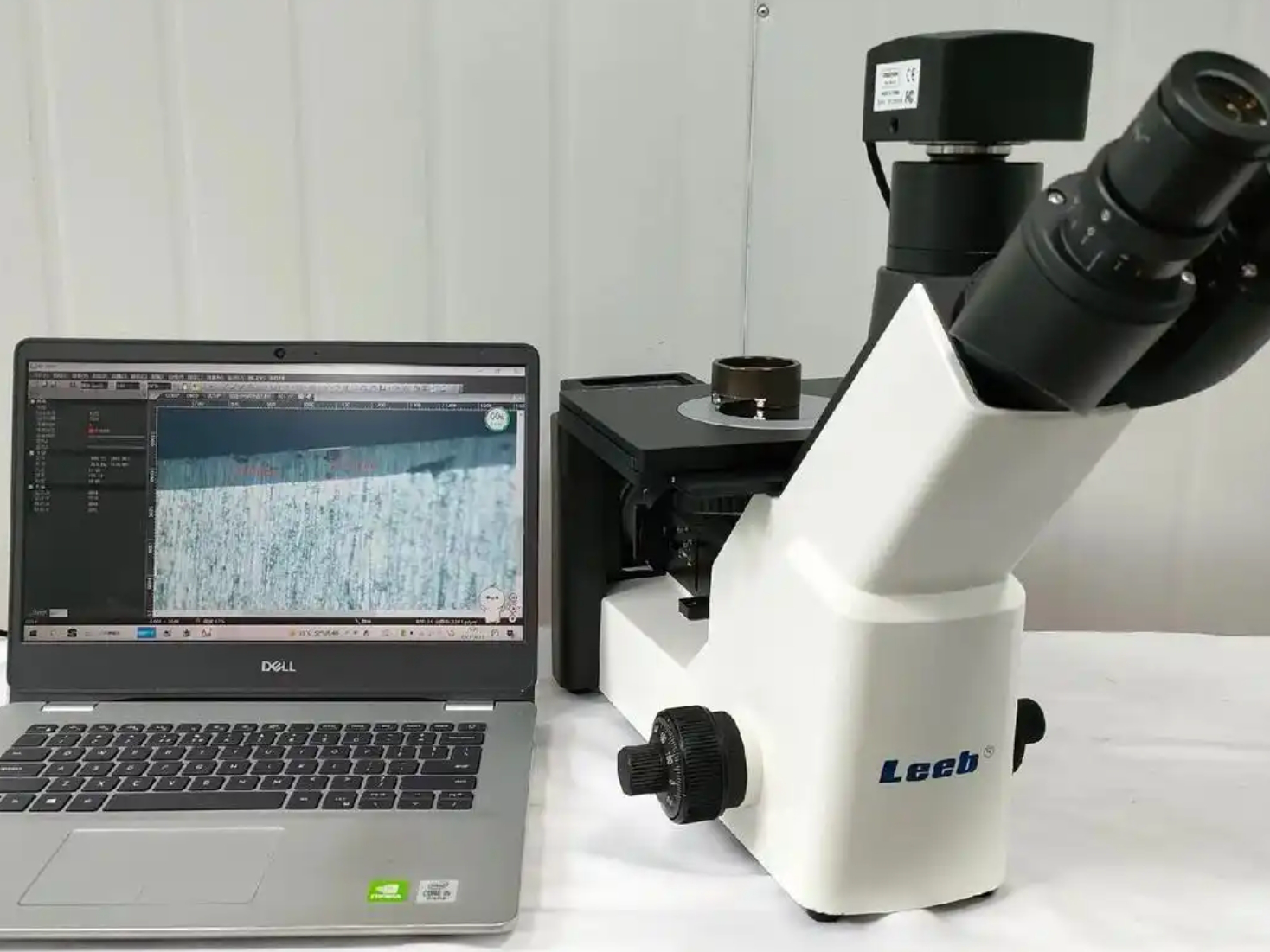

Custom Parts Gallery

At our custom parts gallery, we understand that every project is unique. That's why we work closely with our customers to ensure that their custom parts are designed to meet their exact specifications. With our attention to detail and commitment to quality, you can trust that your custom parts will exceed your expectations.

Let's Start A New Project Today