Plastic Parts 3D Printing Manufacturing: Everything You Have to Know

Plastic parts 3D printing has revolutionized manufacturing processes across industries. This additive manufacturing technique offers numerous advantages over traditional methods, from prototypes to end-use parts. As industries evolve, 3D printing provides increased flexibility, faster production, and cost-effective solutions. This blog explores the manufacturing process, suitable materials, post-processing techniques, testing, and applications of plastic parts 3D printing, helping you understand why it's becoming the go-to choice for many manufacturers.

Manufacturing Process of Plastic Parts 3D Printing

The manufacturing process of 3D printing for plastic parts involves creating three-dimensional objects by adding material layer by layer based on a digital model. The process begins with designing a Computer-Aided Design (CAD) model that precisely defines the part's geometry. This CAD file is then converted into a format readable by the 3D printer (usually an STL or OBJ file).

Several 3D printing methods are used for plastic parts, each with unique features. Some of the most common methods include:

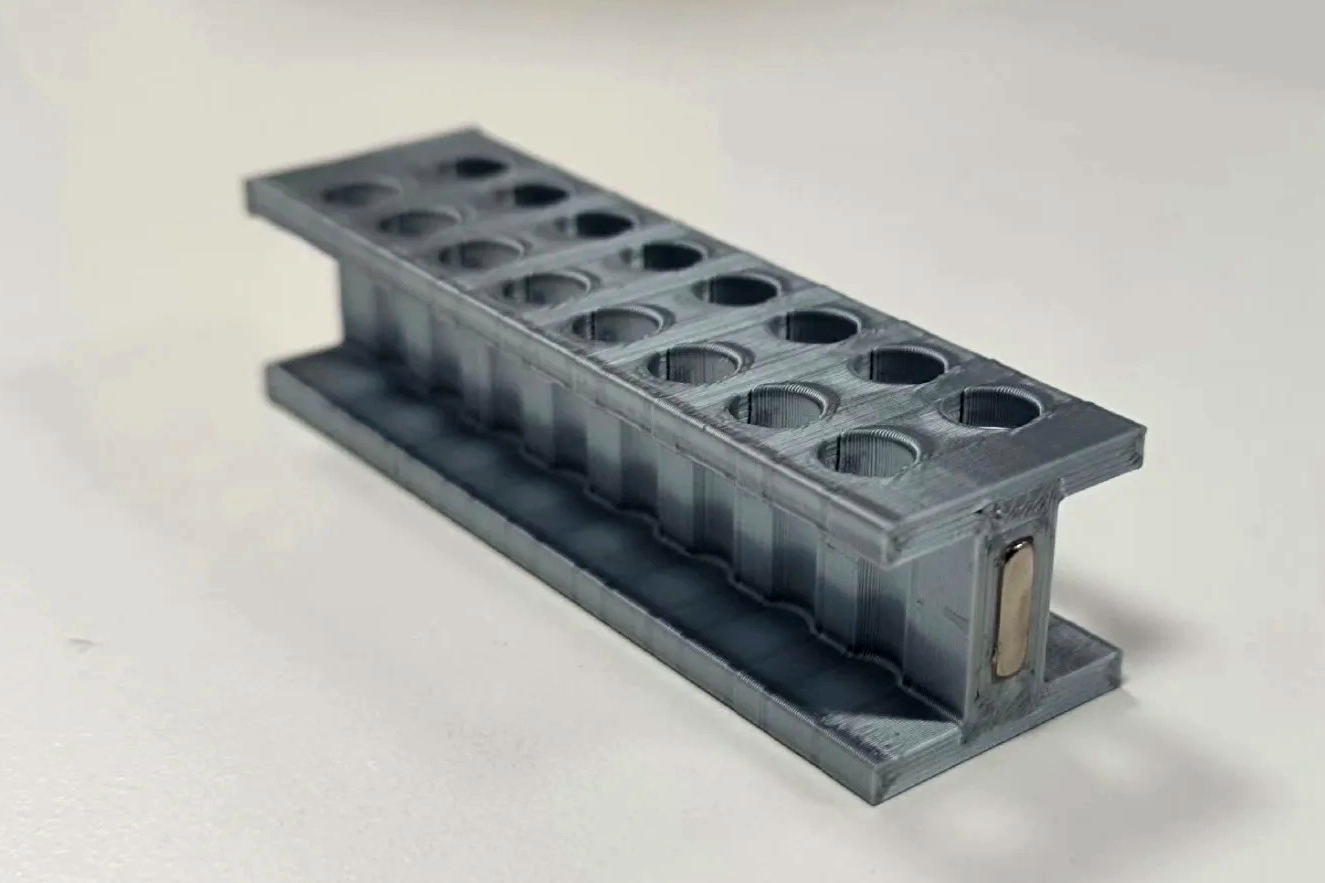

Fused Deposition Modeling (FDM): This is the most widely used 3D printing method for plastic parts. FDM works by melting a filament of thermoplastic material and extruding it through a heated nozzle, which deposits the material layer by layer. It is trendy for creating prototypes and functional parts due to its cost-effectiveness and ability to work with a wide range of thermoplastics.

Selective Laser Sintering (SLS): A laser beam is used to sinter (or fuse) tiny plastic material particles to form a solid structure. Unlike FDM, SLS doesn't require support structures, which allows for more complex geometries. It is highly effective for producing functional prototypes and low-volume production parts.

Stereolithography (SLA): SLA uses a UV laser to cure liquid resin layer-by-layer. It produces high-resolution parts with smooth surfaces, making it ideal for creating intricate, fine-detail plastic parts. SLA is commonly used in industries that require precision, such as dental, jewelry, and electronics.

Each of these technologies offers unique benefits depending on the application. The choice of method depends on factors like part complexity, material requirements, and the intended use of the parts.

The overall process of 3D printing involves several key stages. First, a CAD model is prepared, followed by slicing it into thin layers. The printer then builds up the part layer by layer. After printing, the part may require post-processing, such as cleaning, support removal, or finishing, to meet the desired specifications.

Suitable Materials for Plastic Parts 3D Printing

Plastic 3D printing is versatile in material selection, offering various options to meet specific part requirements. Common 3D printing materials for plastic parts include:

PLA (Polylactic Acid)

PLA is one of the most popular and environmentally friendly 3D printing materials. It is biodegradable and easy to print, making it a popular choice for hobbyists and prototyping. PLA offers a good surface finish and fine details, though it is less heat-resistant than other materials.

ABS (Acrylonitrile Butadiene Styrene)

ABS is a more robust and durable thermoplastic than PLA, offering improved heat resistance and impact strength. It is widely used in functional prototypes, automotive parts, and consumer goods. However, ABS emits fumes during printing, so proper ventilation is recommended.

Nylon

Nylon (PA) Known for its strength, durability, and flexibility, it is used in applications where parts must withstand wear and tear. It's commonly used for gears, hinges, and mechanical parts due to its resistance to abrasion and fatigue.

PETG (Polyethylene Terephthalate Glycol)

PET is a durable, impact-resistant material that offers excellent clarity and ease of printing. It’s commonly used for manufacturing consumer goods, medical products, and packaging components. PETG offers the best of both PLA and ABS, with superior impact resistance and ease of use.

TPU (Thermoplastic Polyurethane)

TPU is a flexible, rubber-like material ideal for producing parts that need to bend, stretch, or compress. It is widely used for creating wearable products, seals, and gaskets.

PEEK (Polyether Ether Ketone)

PEEK is a high-performance thermoplastic known for its excellent chemical resistance, high strength, and thermal stability. It’s used in aerospace, automotive, and medical device manufacturing applications where parts must withstand extreme conditions.

High-Performance Plastics (PEI, ULTEM)

Ultem (PEI) (Polyetherimide) and PEI are known for their high heat resistance and mechanical strength. These materials are used in aerospace, automotive, and industrial manufacturing industries, where high-temperature stability and strength are crucial.

Choosing the right material depends on the intended application and specific performance requirements. Factors like strength, flexibility, heat resistance, and durability must be considered when selecting the best material for plastic parts 3D printing.

Post-Processing of Laser-Cladded Aluminum Parts

While laser cladding offers several advantages in material deposition and surface enhancement, the process typically requires post-processing to optimize the final part's mechanical properties, dimensional accuracy, and surface quality. Post-processing techniques for laser-cladded aluminum parts include heat treatment, surface finishing, welding, and coating.

Heat Treatment

Heat treatment is often necessary to relieve internal stresses and enhance the mechanical properties of laser-cladded aluminum parts. The cooling process during cladding can introduce residual stresses that may cause warping or cracking. Heat treatment processes such as stress relief and annealing are applied to mitigate this. These processes help to improve the toughness, strength, and flexibility of the cladded parts, ensuring they meet the necessary specifications for performance and durability. Heat treatment also helps to ensure dimensional stability in high-performance components.

Surface Finishing

Although laser cladding produces a high-quality surface, it may require additional surface finishing processes, such as grinding, polishing, and machining. Surface finishing removes any excess cladding material, smoothens the surface, and improves the overall appearance of the part. Polishing, in particular, is crucial for applications where the cladded aluminum part will be exposed to wear or corrosion, as it helps create a smooth, uniform surface that reduces friction and improves longevity. CNC machining is also frequently used to achieve precise dimensions and surface quality.

Welding and Fusion

Further welding or fusion may be required to ensure the cladding material is fully bonded to the base aluminum substrate. This is particularly important when dealing with parts that undergo heavy load or mechanical stress. Fusion processes help to strengthen the interface between the cladding and the base material, ensuring the part maintains its structural integrity during use. Superalloy welding is crucial for ensuring the welded areas are defect-free and maintain high strength.

Coatings

Laser-cladded aluminum parts may also be coated with additional protective layers to enhance their performance further. Standard coatings include thermal barrier coatings (TBCs) that protect against high-temperature environments and corrosion-resistant coatings to protect against harsh chemicals or environmental conditions. These coatings help prolong the part's lifespan and improve its wear, oxidation, and corrosion resistance. Thermal barrier coatings improve high-temperature performance and protect against degradation.

Stress Relief

Stress relief is a vital post-processing step for laser-cladding aluminum components to minimize the risk of distortion and ensure dimensional accuracy. This process involves carefully controlling the temperature of the part to allow internal stresses to dissipate without causing warping or dimensional changes. Stress relief ensures the final part retains its desired shape and functional properties. Stress relief techniques are essential to achieve dimensional stability after cladding and other high-temperature processes.

Testing and Quality Assurance for Plastic Parts

Testing is essential in producing plastic 3D-printed parts to meet performance and safety standards. Common testing methods include:

Tensile Testing

This test measures the material’s strength by pulling the part until it breaks. It helps determine how much stress the part can withstand before deforming or failing. Tensile testing provides valuable insights into the material's ability to resist stress and deformation, ensuring reliability in various applications.

Flexural Testing

Flexural testing measures a part’s ability to withstand bending forces. This is particularly important for plastic parts that need to retain their shape when exposed to external forces. The hardness testing also plays a role in evaluating material resistance to external deformation.

Impact Testing

Impact testing evaluates a part’s resistance to sudden shocks or impacts. It is commonly used for automotive, aerospace, and consumer goods applications. The test ensures that parts can withstand mechanical impacts without failure, vital for safety-critical applications.

Heat Resistance and Thermal Stability Tests

Heat resistance tests for parts exposed to high temperatures, such as those used in automotive or aerospace applications, determine the material's ability to maintain its properties in extreme conditions. Simultaneous thermal analysis can provide valuable information regarding the heat tolerance of materials used in 3D printing.

In addition to these mechanical tests, parts may undergo visual inspections and dimensional accuracy checks to ensure they meet the required specifications. High precision is often critical, especially in medical, aerospace, and automotive industries, where part failure can have serious consequences. Dimensional inspection ensures that the parts meet tight tolerances and are ready for use in complex applications.

Applications of Plastic Parts 3D Printing

Plastic 3D printing is used across various industries, offering various benefits such as customization, rapid prototyping, and cost savings. Some of the most common applications include:

Aerospace

In the aerospace industry, 3D printed plastic parts produce lightweight components, custom brackets, and prototype parts. Plastic 3D printing helps reduce weight, improve fuel efficiency, and accelerate the design process. Aerospace and aviation companies leverage 3D printing to quickly iterate on designs and produce complex parts for aircraft engines and structures.

Automotive

The automotive industry benefits from plastic 3D printing for producing custom parts, prototypes, and low-volume production runs. It allows for rapid prototyping, which helps manufacturers reduce development times and test new designs quickly. For automotive manufacturers, plastic 3D printing facilitates faster product development and greater flexibility in customizing vehicle components.

Medical

Plastic 3D printing creates custom prosthetics, orthotics, medical devices, and even surgical models for preoperative planning. The ability to create complex geometries and tailor designs to individual patients is a major advantage in healthcare. Medical industries benefit from 3D printing to produce patient-specific solutions with improved precision and reduced lead times.

Consumer Goods

Custom plastic parts, packaging components, and prototypes are produced using 3D printing in the consumer goods industry. 3D printing offers an efficient solution for producing bespoke items on-demand, reducing manufacturing costs and lead times. The consumer goods sector is adopting plastic 3D printing to enable more personalized and cost-effective production.

Electronics

In the electronics industry, 3D-printed plastic parts create custom housings, connectors, and brackets. The ability to prototype quickly helps accelerate product development cycles. Electronics companies use 3D printing to create functional prototypes and low-volume production parts often customized for specific electronic devices.

Industrial Manufacturing

In industrial manufacturing, 3D-printed parts are used for jigs, fixtures, tooling, and other components. These parts are often produced in low volumes and can be customized to meet specific operational requirements. Industrial manufacturing utilizes plastic 3D printing to create specialized tools and equipment with complex geometries that are not easily achievable with traditional methods.

Entertainment

3D printing is widely used in the entertainment industry for creating models, movie set designs, and props. It allows for quick prototyping of detailed objects, reducing costs and production time. The entertainment sector benefits from plastic 3D printing to bring imaginative designs to life with high accuracy and detail, enhancing the creative process.

FAQs

What are the different types of 3D printing methods used for plastic parts?

How do I choose the suitable material for my plastic 3D printed part?

What are the most common post-processing techniques for plastic parts?

How is the testing process for 3D-printed plastic parts conducted?

Can 3D printed plastic parts be used in high-performance applications like aerospace or automotive?