Rene 108

About Rene 108 Superalloy

Name and Equivalent Names

Rene 108 is a nickel-chromium-based superalloy known for its exceptional performance in high-temperature environments. It adheres to AMS 5836 standards, and although it lacks specific ASTM or ISO equivalents, it is highly regarded for aerospace and power generation applications requiring excellent thermal and mechanical stability.

Rene 108 Basic Introduction

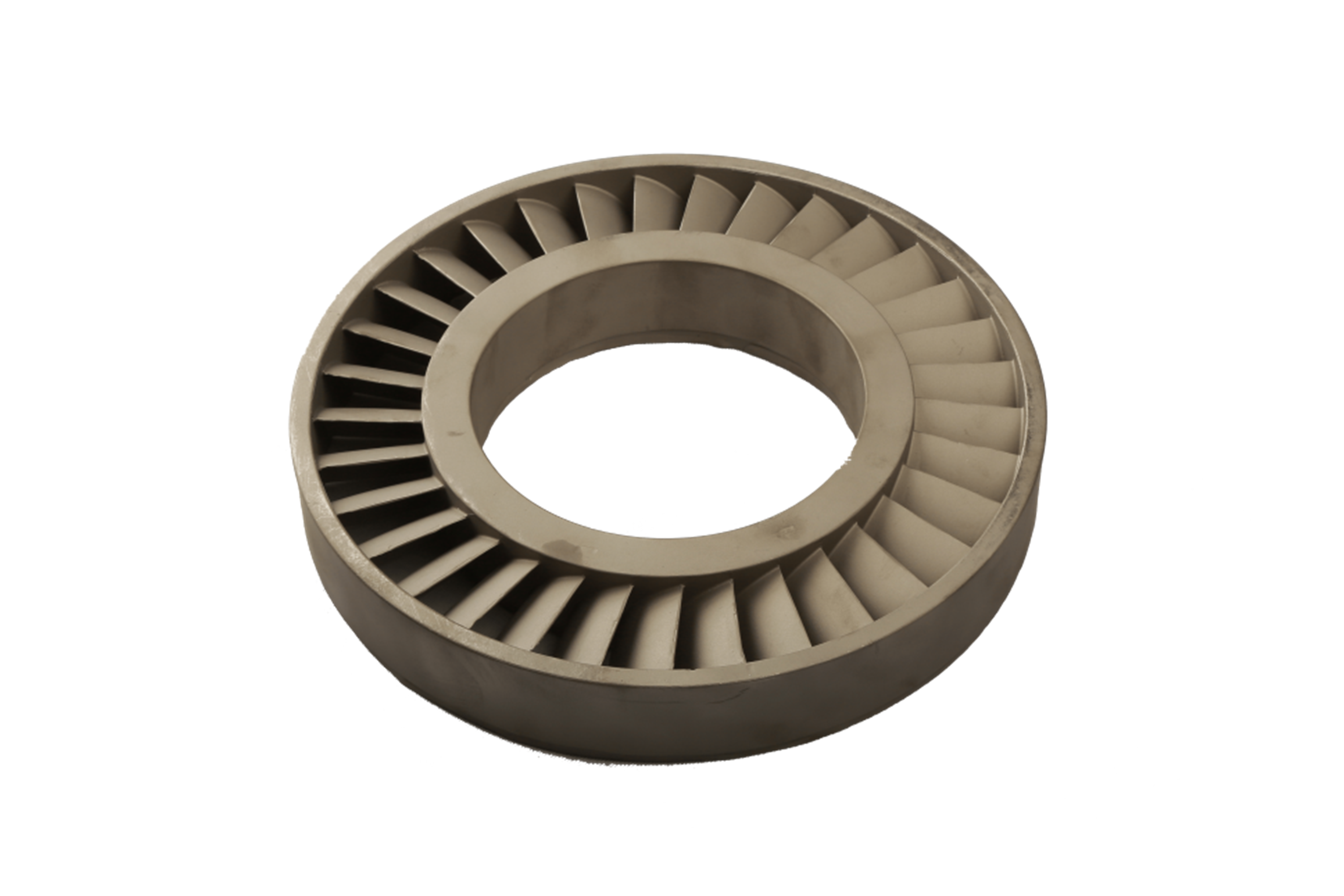

Rene 108 is a nickel-based superalloy designed for extreme operating conditions, providing superior mechanical strength, thermal fatigue resistance, and creep stability. The alloy's robust metallurgical properties are ideal for high-stress environments such as turbine blades and aerospace engines.

This alloy maintains its strength at temperatures exceeding 950°C, ensuring high performance under cyclic loading. Its carefully balanced composition, including elements like rhenium, hafnium, and tantalum, enhances durability and prolongs critical components' service life under extreme heat and mechanical stress.

Alternative Superalloys of Rene 108

Rene 95, Inconel 718, and Hastelloy X are alternative alloys to Rene 108. Rene 95 offers similar creep resistance but may not match Rene 108’s thermal fatigue performance. Inconel 718 is preferred for corrosion resistance and weldability, while Hastelloy X provides enhanced oxidation resistance for aerospace applications. The selection depends on the application's specific thermal, mechanical, and environmental demands.

Rene 108 Design Intention

Rene 108 was developed to meet the increasing demand for materials that maintain strength and stability under prolonged high temperatures. This alloy is optimized for components exposed to cyclic loading, such as turbine blades and jet engine parts, where thermal fatigue resistance is critical.

Rene 108 leverages a unique combination of rhenium, hafnium, and tantalum for applications requiring excellent creep resistance to strengthen grain boundaries and resist deformation. This ensures consistent performance under extreme stress, reducing maintenance costs and extending the lifespan of critical components.

Rene 108 Chemical Composition

The chemical composition of Rene 108 ensures excellent high-temperature strength, creep resistance, and fatigue durability. Nickel forms the base, with chromium improving oxidation resistance. Rhenium, hafnium, and tantalum enhance grain boundary stability and creep resistance.

Element | Content (wt%) |

|---|---|

Nickel (Ni) | Balance |

Chromium (Cr) | 13.5 |

Cobalt (Co) | 9.75 |

Molybdenum (Mo) | 3.0 |

Aluminum (Al) | 5.0 |

Titanium (Ti) | 3.75 |

Tungsten (W) | 2.0 |

Rhenium (Re) | 2.8 |

Hafnium (Hf) | 0.2 |

Tantalum (Ta) | 3.25 |

Rene 108 Physical Properties

Rene 108 offers excellent density and thermal conductivity, making it ideal for high-temperature environments. Its high modulus of elasticity ensures that it maintains structural stability under stress.

Property | Value |

|---|---|

Density (g/cm³) | 8.74 |

Melting Point (°C) | 1375 |

Thermal Conductivity (W/m·K) | 10.9 |

Modulus of Elasticity (GPa) | 215 |

Metallographic Structure of Rene 108 Superalloy

Rene 108 has an γ-phase nickel matrix with γ' (gamma prime) precipitates, which provide excellent strength at high temperatures. The γ' phase impedes dislocation movement, enhancing mechanical stability and creep resistance under prolonged stress.

Adding rhenium, hafnium, and tantalum strengthens the grain boundaries, improving resistance to thermal fatigue and preventing deformation. This unique metallurgical structure ensures that Rene 108 performs consistently in environments with high cyclic loads and extreme heat, such as aerospace engines and gas turbines.

Rene 108 Mechanical Properties

Rene 108 demonstrates exceptional tensile strength, fatigue resistance, and creep performance at elevated temperatures. These properties make it a reliable choice for high-temperature turbine components.

Property | Value |

|---|---|

Tensile Strength (MPa) | 1200 – 1250 |

Yield Strength (MPa) | ~1000 |

Creep Strength | Strong at >950°C |

Hardness (HRC) | ~40 |

Elongation (%) | 10 – 12 |

Elastic Modulus (GPa) | ~215 |

Key Features of Rene 108 Superalloy

1. Excellent Creep Resistance

Rene 108 offers superior creep resistance, ensuring that components maintain mechanical integrity at temperatures exceeding 950°C. This makes it ideal for turbine blades and aerospace applications.

2. Strong Fatigue Resistance

The alloy performs exceptionally well under cyclic loading, resisting mechanical fatigue over extended periods. This capability reduces the likelihood of component failure in high-stress environments.

3. High-Temperature Stability

With a melting point of 1375°C, Rene 108 maintains its strength and performance in extreme heat, making it a preferred material for aerospace engines and power generation turbines.

4. Grain Boundary Strength

Rhenium, hafnium, and tantalum enhance grain boundary strength, improving the alloy’s resistance to stress-induced deformation and prolonging component life.

5. Long Service Life

Under severe thermal and mechanical stress, Rene 108 provides extended service life. Its durability reduces maintenance costs and ensures operational efficiency in critical systems.

Rene 108 Superalloy’s Machinability

Rene 108 is suitable for Vacuum Investment Casting because it can form complex, high-strength parts with excellent dimensional precision, particularly in aerospace applications.

Rene 108 is not typically used in Single Crystal Casting because it is optimized for polycrystalline structures, which offer better fatigue resistance in specific applications.

Equiaxed Crystal casting works well with Rene 108, as the uniform grain structure enhances thermal fatigue resistance and long-term performance.

While Superalloy Directional Casting is possible, the benefits of this process are less pronounced for Rene 108, as it is tailored for high-performance equiaxed applications.

Rene 108 is not ideal for Powder Metallurgy Turbine Disc applications due to the challenges of maintaining consistent mechanical properties in powder form.

The alloy performs well in Superalloy Precision Forging, delivering components with excellent mechanical properties suitable for high-stress environments.

Superalloy 3D Printing is not widely used for Rene 108 due to difficulties achieving uniform material properties through additive manufacturing.

Rene 108 is compatible with CNC Machining, allowing for the production of complex parts with high precision and excellent surface quality.

The alloy requires specialized Superalloy Welding techniques, but proper pre- and post-weld treatments ensure strong joints.

Hot Isostatic Pressing (HIP) enhances Rene 108’s properties by eliminating internal porosity, ensuring mechanical consistency, and improving fatigue resistance.

Rene 108 Superalloy Applications

In Aerospace and Aviation, Rene 108 is used for turbine blades, discs, and structural components, providing high thermal stability and fatigue resistance.

For Power Generation, the alloy ensures reliable performance in gas turbines by withstanding high temperatures and continuous thermal cycling.

Rene 108 supports the Oil and Gas sector with durable components for valves, downhole tools, and other critical equipment subjected to high pressures and temperatures.

In the Energy industry, Rene 108 enhances turbine efficiency and longevity, maintaining mechanical integrity under continuous operation.

Marine applications benefit from Rene 108’s corrosion resistance, making it suitable for propulsion systems and marine exhaust components.

In Mining, Rene 108 offers excellent wear resistance, ensuring durability for pump parts, shafts, and drill bits in harsh environments.

The Automotive industry uses Rene 108 for high-performance exhaust systems and turbochargers, ensuring durability under extreme thermal loads.

In Chemical Processing, the alloy provides oxidation resistance for reactors and heat exchangers, ensuring operational stability under harsh conditions.

For the Pharmaceutical and Food industries, Rene 108 provides corrosion-resistant valves and seals, ensuring safety and durability in processing environments.

The Military and Defense sector employs Rene 108 for missile and jet engine components, offering high performance under extreme thermal and mechanical stress.

In Nuclear applications, Rene 108 ensures safety and reliability for reactor components, providing excellent resistance to radiation and thermal fatigue.

When to Choose Rene 108 Superalloy

Rene 108 should be selected for applications that demand high strength, thermal fatigue resistance, and reliable performance under extreme conditions. It is beneficial for custom superalloy parts in aerospace engines, power generation turbines, and military systems, where components face continuous thermal cycling and mechanical stress.

This alloy’s ability to resist creep and maintain stability at temperatures above 950°C makes it a top choice for turbines and jet engines. It is also valuable in the oil and gas, automotive, and marine industries, where corrosion resistance and mechanical reliability are essential. Rene 108’s versatility ensures it meets the performance demands of critical systems, delivering long-term durability and operational efficiency.