Nimonic PE16

About Nimonic PE16 Superalloy

Nimonic PE16, Nickel-Chromium Alloy PE16, is an advanced nickel-based superalloy designed for high-performance applications. It is identified by UNS N07016, with global standards such as ASTM B637, DIN/EN 2.4964, and ISO 15156. Its chemical composition includes chromium, molybdenum, titanium, and aluminum, making it highly resistant to heat and oxidation.

This superalloy is widely recognized for its excellent strength at elevated temperatures, particularly between 700°C and 800°C, making it suitable for aerospace, energy, and gas turbine industries.

Nimonic PE16 Basic Introduction

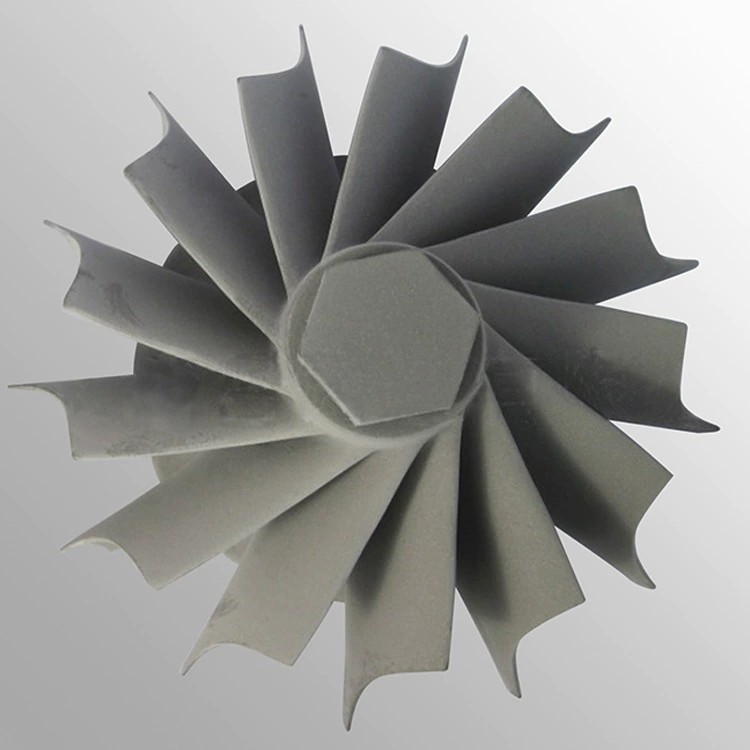

Nimonic PE16 is known for its outstanding thermal stability, mechanical properties, and resistance to oxidation and creep. Developed to perform under high stress and extreme environments, this alloy is utilized in components such as turbine blades, discs, and structural elements in aerospace engines.

Due to its long-term stability and resistance to fatigue, Nimonic PE16 is often preferred for cyclic thermal applications. Its metallurgical composition supports exceptional stress rupture life, ensuring longevity and durability in high-temperature service environments.

Alternative Superalloys of Nimonic PE16

Several alternative superalloys perform similarly to Nimonic PE16, including Inconel 718 for high-temperature strength and Nimonic 90, known for fatigue resistance in turbine applications. Hastelloy X is another suitable alternative, delivering excellent oxidation resistance, especially in gas turbines and aerospace applications.

These alternatives are selected based on specific operational needs, such as higher corrosion resistance or enhanced creep strength, making them suitable complements or replacements depending on service requirements.

Nimonic PE16 Design Intention

Nimonic PE16 is designed to maintain mechanical strength at elevated temperatures while providing excellent resistance to fatigue and oxidation. Its primary design focus is to extend the lifecycle of components exposed to cyclic thermal loads.

This alloy is commonly used in high-stress applications such as gas turbine components, exhaust valves, and aerospace engine parts. Its optimized chemical composition ensures long-term performance while reducing susceptibility to creep deformation.

Nimonic PE16 Chemical Composition

The key components of Nimonic PE16, including nickel, chromium, molybdenum, and titanium, work together to provide exceptional thermal fatigue resistance, high tensile strength, and oxidation protection. Aluminum enhances heat resistance, while iron balances the alloy, contributing to structural stability.

Element | Composition (%) |

|---|---|

Nickel (Ni) | Nominal 42.0 |

Chromium (Cr) | 14.0-18.0 |

Titanium (Ti) | 1.9-2.5 |

Cobalt (Co) | Nominal 30.0 |

Molybdenum (Mo) | Nominal 4.0 |

Aluminum (Al) | 0.9-1.3 |

Iron (Fe) | Balance |

Nimonic PE16 Physical Properties

Nimonic PE16’s physical properties make it ideal for high-temperature applications, offering excellent strength and thermal conductivity. The following table summarizes its properties:

Property | Value |

|---|---|

Density | 8.22 g/cm³ |

Melting Point | 1340°C |

Thermal Conductivity | 11.8 W/(m·K) |

Modulus of Elasticity | 207 GPa |

Metallographic Structure of Nimonic PE16 Superalloy

The microstructure of Nimonic PE16 features a matrix of nickel-based γ-phase strengthened by γ'-precipitates. These precipitates ensure mechanical strength and resistance to deformation at elevated temperatures. The alloy also forms carbides and intermetallic compounds, contributing to its wear resistance and long-term stability.

Due to controlled alloying with elements such as chromium and aluminum, the alloy resists oxidation and surface degradation, maintaining structural integrity under stress. The homogeneous distribution of secondary phases further enhances creep resistance.

Nimonic PE16 Mechanical Properties

The mechanical properties of Nimonic PE16 enable it to withstand high loads and temperatures. Below are the vital mechanical values:

Property | Value |

|---|---|

Tensile Strength | ~1050-1200 MPa |

Yield Strength | ~850-900 MPa |

Creep Resistance | Excellent at 700-800°C |

Hardness | Rockwell C35-45 |

Elongation | ~10-12% |

Fatigue Strength | ~400-450 MPa |

Key Features of Nimonic PE16 Superalloy

High-Temperature Stability: Nimonic PE16 maintains strength at elevated temperatures, making it suitable for aerospace engines and gas turbines operating under extreme heat conditions.

Exceptional Fatigue Resistance: Designed for cyclic thermal applications, Nimonic PE16 provides superior fatigue strength, ensuring longer operational life for critical components.

Oxidation and Creep Resistance: The alloy offers high resistance to oxidation, minimizing material degradation, while its creep resistance ensures stability during prolonged service at high temperatures.

Excellent Mechanical Strength: Nimonic PE16’s tensile and yield strength support high-stress operations, making it a reliable material for heavy-duty applications such as aerospace components and power turbines.

Adaptability Across Industries: With versatile physical and mechanical properties, Nimonic PE16 finds applications in industries such as energy, automotive, and aerospace, enhancing performance in demanding environments.

Nimonic PE16 Superalloy’s Machinability

Nimonic PE16 suits Vacuum Investment Casting due to its excellent thermal properties and oxidation resistance. This method ensures precise component structures while maintaining material integrity.

However, it is not typically used for Single Crystal Casting since its composition and grain structure are optimized for other applications, such as fatigue resistance, which makes it less ideal for single-crystal applications.

Nimonic PE16 performs well in Equiaxed Crystal casting, ensuring consistent grain structures suitable for high-temperature environments and maintaining fatigue strength.

The alloy can be used in Superalloy Directional Casting, providing enhanced creep resistance, essential for turbine applications.

Nimonic PE16 is not preferred for powder metallurgy turbine discs due to processing efficiency limitations compared to alloys explicitly tailored for this method.

The alloy is also suitable for Superalloy Precision Forging, offering high fatigue resistance and stability for aerospace and energy components.

While Superalloy 3D Printing is advancing, Nimonic PE16 is not widely adopted for this method due to challenges in maintaining its mechanical properties through additive manufacturing.

CNC Machining processes are effective with Nimonic PE16, but precision tooling and cooling strategies are necessary to prevent work hardening and maintain dimensional accuracy.

It is weldable using Superalloy Welding techniques, though pre- and post-weld heat treatments are recommended to prevent cracking and maintain mechanical strength.

Finally, Nimonic PE16 is compatible with Hot Isostatic Pressing (HIP) to improve mechanical properties by eliminating internal porosities and enhancing fatigue strength.

Nimonic PE16 Superalloy Applications

In Aerospace and Aviation, Nimonic PE16 is used in turbine blades and exhaust systems, benefiting from its fatigue resistance and thermal stability.

For Power Generation, it is employed in gas turbines, ensuring long-term performance under cyclic loads and high-temperature environments.

In the oil and gas sector, the alloy is applied to high-pressure valves and equipment, providing resistance to heat and corrosion.

Within the Energy sector, Nimonic PE16 supports critical operations in turbines, ensuring durability in extreme conditions.

The alloy is utilized in Marine applications such as heat exchangers, offering corrosion resistance in harsh maritime environments.

In Mining, it is used for drill components and wear-resistant parts, benefiting from its mechanical strength.

In Automotive, Nimonic PE16 plays a role in exhaust valves for high-performance engines, providing thermal stability.

For Chemical Processing, it ensures reliable performance in reactors and pipelines exposed to corrosive substances.

The alloy is utilized in the pharmaceutical and food industries, offering heat and corrosion resistance to production equipment.

In Military and Defense, Nimonic PE16 is used in missile and jet engine components due to its fatigue resistance.

Finally, Nuclear applications benefit from their strength and stability under radiation exposure and extreme temperatures.

When to Choose Nimonic PE16 Superalloy

Nimonic PE16 is ideal for custom superalloy parts in environments requiring thermal fatigue resistance and long-term stability. It is specifically suited for aerospace and energy components operating under cyclic loads.

The alloy’s oxidation and creep resistance are valuable in gas turbines and exhaust valves, where temperatures are constant. Additionally, marine and chemical processing industries benefit from its corrosion-resistant properties, ensuring durability in aggressive environments.

Nimonic PE16 is also a top performer in military and nuclear applications, providing reliable mechanical strength over extended periods under extreme conditions. It delivers robust performance across various demanding sectors, whether for precision-forged parts or CNC-machined components.