Nimonic 86

About Nimonic 86 Superalloy

Name and Equivalent Name

Nimonic 86, also referred to as Nickel-Chromium Alloy 86, is designated by UNS N07086 and meets AMS 5910 standards. The alloy is known for its high-temperature performance and corrosion resistance, making it a reliable choice for demanding applications.

Nimonic 86 Basic Introduction

Nimonic 86 is a high-performance superalloy primarily composed of nickel and chromium, designed to withstand extreme temperatures and stress without deformation. It is beneficial in applications that require long-term stability and durability, such as gas turbines, jet engines, and industrial furnaces.

This alloy provides excellent creep and fatigue resistance, ensuring reliable operation at temperatures between 700-800°C. Its ability to resist thermal stress and maintain mechanical integrity makes it ideal for aerospace and energy systems where high performance under thermal cycles is critical.

Alternative Superalloys of Nimonic 86

Inconel 718 and Nimonic 75 are alternatives when moderate thermal stability is required. For higher creep resistance, Rene 41 is an excellent substitute. In chemical environments, Hastelloy C276 provides superior corrosion resistance.

When oxidation resistance is crucial, Nimonic 80A can be a suitable choice, while Waspaloy is another option where fatigue resistance is required under continuous thermal cycles. Material selection depends on the specific operating conditions and service environment.

Nimonic 86 Design Intention

Nimonic 86 is engineered to offer long-term creep resistance and high-temperature strength for critical applications. Adding chromium ensures excellent oxidation resistance, while the high nickel content provides mechanical stability at elevated temperatures.

The alloy is optimized for components subjected to severe thermal cycling and stress, such as turbine blades, exhaust systems, and heat exchangers. Its aluminum and titanium content supports precipitation hardening, enhancing mechanical properties for extended operational life.

Nimonic 86 Chemical Composition

Nimonic 86's chemical composition ensures a balance of strength, oxidation resistance, and thermal stability. Nickel provides toughness, while the other elements enhance high-temperature performance.

Element | Composition (%) |

|---|---|

Nickel (Ni) | Balance |

Chromium (Cr) | 15.0 – 19.0 |

Titanium (Ti) | 4.0 – 5.0 |

Cobalt (Co) | 15.0 – 21.0 |

Molybdenum (Mo) | 2.5 – 3.5 |

Aluminum (Al) | 4.5 – 6.0 |

Tungsten (W) | 0.5 max |

Nimonic 86 Physical Properties

Nimonic 86 exhibits excellent thermal stability and high-temperature strength, making it suitable for demanding environments.

Property | Value |

|---|---|

Density | 8.3 g/cm³ |

Melting Point | 1340°C |

Thermal Conductivity | 10.5 W/(m·K) |

Modulus of Elasticity | 206 GPa |

Metallographic Structure of Nimonic 86 Superalloy

Nimonic 86 features a face-centered cubic (FCC) crystal structure typical of nickel-based alloys, offering excellent mechanical strength and toughness. Its microstructure consists of finely dispersed precipitates, which form due to the presence of aluminum and titanium, enhancing creep resistance through precipitation hardening.

Under extreme thermal conditions, the alloy maintains microstructural stability, preventing grain boundary sliding and phase transformations. This stability ensures that components made from Nimonic 86 deliver consistent mechanical performance even after prolonged exposure to high temperatures.

Nimonic 86 Mechanical Properties

Nimonic 86 provides outstanding mechanical strength and thermal fatigue resistance, ensuring excellent performance in high-stress, high-temperature applications.

Property | Value |

|---|---|

Tensile Strength | 850-900 MPa |

Yield Strength | 500-600 MPa |

Hardness | Rockwell C35-40 |

Elongation | ~30% |

Elastic Modulus | ~205 GPa |

Creep Strength | High at 700-800°C |

Creep Rupture Life | ~10,000 hours at 800°C |

Fatigue Strength | ~350 MPa |

Key Features of Nimonic 86 Superalloy

High-Temperature Strength Nimonic 86 offers exceptional mechanical strength up to 800°C, ensuring components like turbine blades and exhaust systems remain structurally sound under continuous heat stress.

Creep and Fatigue Resistance The alloy provides long-term creep resistance, reducing deformation under stress and making it suitable for critical components subjected to prolonged high temperatures.

Oxidation and Corrosion Resistance: Chromium and cobalt content protect Nimonic 86 from oxidation and corrosion, enhancing durability in harsh environments such as jet engines and gas turbines.

Thermal Stability The alloy exhibits excellent thermal stability, making it resistant to phase transformation and grain boundary sliding during cyclic thermal operations. This ensures reliability over the long term.

Precipitation Hardening With aluminum and titanium, Nimonic 86 undergoes precipitation hardening, increasing its strength and making it suitable for aerospace and energy applications requiring high mechanical performance.

Nimonic 86 Superalloy’s Machinability

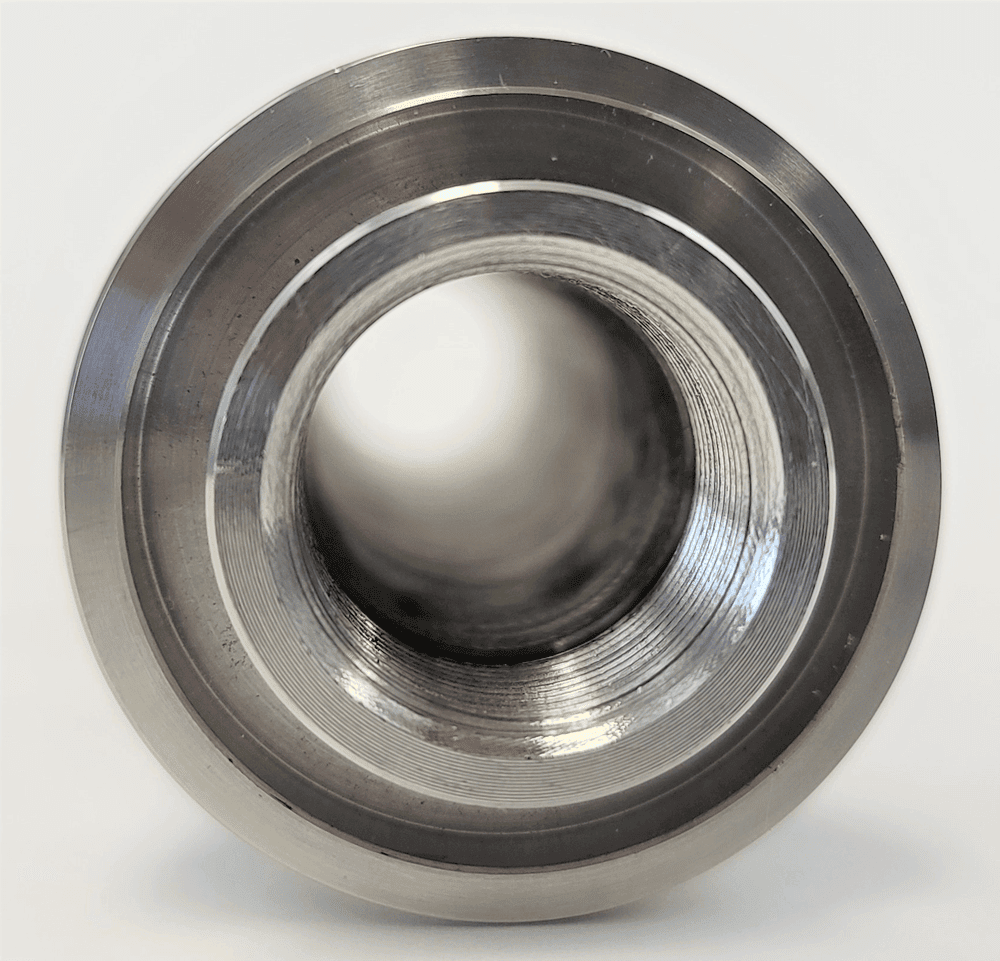

Nimonic 86 is compatible with Vacuum Investment Casting, allowing the precise creation of complex turbine and aerospace components due to its high-temperature stability.

The alloy is unsuitable for Single Crystal Casting, as it lacks the specific properties required for single-crystal structures used in advanced jet engines.

It can be effectively used in Equiaxed Crystal Casting, which ensures isotropic mechanical properties, making it reliable for high-temperature aerospace applications.

Nimonic 86 performs well in Superalloy Directional Casting, where aligned grains improve creep resistance, enhancing durability in turbine components.

Unlike powdered consolidation, the alloy is not ideal for powder metallurgy turbine disc production due to its casting-oriented properties.

Nimonic 86 works well with Superalloy Precision Forging, delivering high mechanical strength for critical components like turbine blades and exhaust systems.

Due to its high melting point, Nimonic 86 is unsuitable for Superalloy 3D Printing, as it complicates additive manufacturing processes.

It offers good dimensional stability for CNC Machining, making it ideal for precision components that demand excellent mechanical strength.

Nimonic 86 is suitable for Superalloy Welding, but advanced techniques are needed to prevent cracking due to its high cobalt and chromium content.

The alloy performs exceptionally well under Hot Isostatic Pressing (HIP), which enhances fatigue strength and reduces porosity for better mechanical properties.

Nimonic 86 Superalloy Applications

In Aerospace and Aviation, Nimonic 86 is used in turbine blades, jet engines, and exhaust systems, where creep resistance and thermal stability are essential.

For Power Generation, Nimonic 86 is employed in gas turbines and heat exchangers to maintain performance under thermal stress and continuous operation.

In the Oil and Gas industry, the alloy ensures reliability in high-temperature pipelines, valves, and components exposed to extreme environments.

Nimonic 86 enhances energy systems used in industrial furnaces, turbines, and energy storage systems for long-lasting performance.

Marine applications benefit from Nimonic 86’s corrosion resistance, making it suitable for exhaust systems and propulsion components exposed to seawater.

The alloy is used in Mining for drilling tools, pump housings, and components subjected to high wear and thermal stress.

In Automotive, Nimonic 86 is applied in turbochargers and exhaust systems, where durability under high temperatures is critical.

The Chemical Processing industry utilizes Nimonic 86 for reactors and piping, benefiting from its resistance to corrosion and high-temperature degradation.

In Pharmaceutical and Food processing, Nimonic 86 ensures non-reactive, heat-resistant valves, pumps, and equipment.

In Military and Defense, the alloy is utilized in missile systems and jet engines, offering high thermal fatigue resistance and long-term reliability.

Nuclear applications rely on Nimonic 86’s stability under radiation and heat, making it suitable for reactors and critical components.

When to Choose Nimonic 86 Superalloy

Nimonic 86 is ideal for custom superalloy parts requiring high thermal stability, creep resistance, and oxidation resistance. It performs exceptionally well in aerospace, energy, and chemical industries where components must operate under extreme thermal stress.

This alloy is particularly suitable for turbine blades, exhaust systems, and valves that encounter high temperatures and mechanical loads. Nimonic 86 is also a reliable material for industries requiring durability and resistance to corrosion, such as marine, oil and gas, and nuclear sectors.

If your application involves long-term high-temperature exposure, such as jet engines or industrial furnaces, Nimonic 86 ensures consistent performance with minimal maintenance. Explore our custom superalloy parts service for tailored solutions to your needs.