Inconel 738

About Inconel 738 Superalloy

Inconel 738, known by equivalent names such as Alloy 738, is a high-performance nickel-based superalloy. With ASTM B637 and DIN/EN 2.4652 standards, this alloy offers excellent thermal and mechanical properties, ensuring its usage in extreme environments.

The alloy is also recognized under the Chinese standard GB/T 14992: GH738. Its balanced composition of nickel, chromium, cobalt, aluminum, and titanium makes it an ideal material for high-stress components used in aerospace, energy, and gas turbines.

Inconel 738 Basic Introduction

Inconel 738 is designed to meet the demands of extreme operating conditions. Known for its strength retention at elevated temperatures, it offers excellent oxidation and thermal fatigue resistance.

This alloy is commonly used in gas turbines, jet engines, and power plants due to its long-term durability at 982°C, maintaining strength even under prolonged stress. Its resistance to deformation, coupled with superior fatigue properties, makes it reliable in high-performance settings.

Alternative Superalloys of Inconel 738

Alternative materials for Inconel 738 include Inconel 718, René 80, and Haynes 282. These alloys share similar high-temperature performance, corrosion resistance, and mechanical properties.

Inconel 718, for example, provides excellent weldability but is optimized for lower-temperature applications. René 80 offers better creep strength, making it suitable for advanced turbine blades. Haynes 282, on the other hand, is favored for its enhanced machinability while maintaining high oxidation resistance.

Inconel 738 Design Intention

Inconel 738 is engineered to withstand high temperatures and extreme stresses over prolonged periods. The alloy’s composition ensures oxidation, corrosion, and creep deformation resistance at elevated temperatures.

Its design intention focuses on turbine blades, vanes, and combustion liners, where mechanical reliability is critical. With high fatigue resistance and stable metallurgical structure, Inconel 738 supports safe operations in thermal cycling environments and contributes to the longevity of aerospace and power systems.

Inconel 738 Chemical Composition

The chemical composition of Inconel 738 provides the necessary strength, fatigue resistance, and oxidation resistance at elevated temperatures. Nickel ensures overall stability, while chromium offers corrosion protection. Including aluminum and titanium strengthens the alloy, promoting resistance to creep deformation.

Element | Composition (%) |

|---|---|

Nickel (Ni) | 60.0-65.0 |

Chromium (Cr) | 15.5-16.5 |

Cobalt (Co) | 19.0 |

Aluminum (Al) | 3.4-3.8 |

Titanium (Ti) | 3.4-3.8 |

Tungsten (W) | 1.5 |

Iron (Fe) | Balance |

Inconel 738 Physical Properties

Inconel 738’s physical properties reflect its ability to withstand high temperatures while maintaining mechanical strength and structural stability.

Property | Value |

|---|---|

Density (g/cm³) | 8.12 |

Melting Point (℃) | 1300 |

Thermal Conductivity (W/(m.k)) | 10.7 |

Modulus of Elasticity (GPa) | 210 |

Metallographic Structure of Inconel 738 Superalloy

Inconel 738 exhibits a well-defined gamma (γ) matrix reinforced by gamma prime (γ') precipitates. This microstructure ensures exceptional mechanical stability and resistance to creep deformation under high-temperature operations. The γ phase consists of nickel, aluminum, and titanium, enhancing the alloy's fatigue and oxidation resistance.

The alloy's microstructure also minimizes grain boundary sliding, essential for maintaining mechanical integrity under prolonged stress and thermal cycling. Its balanced composition contributes to the uniform distribution of phases, supporting high performance in gas turbine applications.

Inconel 738 Mechanical Properties

Inconel 738 offers excellent mechanical strength, fatigue resistance, and thermal stability, making it ideal for aerospace and industrial components operating at high temperatures.

Property | Value |

|---|---|

Tensile Strength (MPa) | 1030-1100 |

Yield Strength (MPa) | 830-900 |

Creep Strength | High at 982°C/10,000 hours |

Hardness (HRC) | Rockwell C35-40 |

Elongation (%) | 10 |

Fatigue Strength (MPa) | High fatigue resistance |

Thermal Fatigue Resistance | Excellent thermal resistance |

Key Features of Inconel 738 Superalloy

High-Temperature Strength Inconel 738 maintains excellent mechanical strength at temperatures up to 982°C, making it ideal for aerospace and gas turbine applications. Its ability to withstand extreme conditions ensures the reliability of critical components.

Exceptional Fatigue Resistance This alloy exhibits high fatigue strength, making it suitable for cyclic applications such as turbine blades and combustion liners. It performs well under repeated stress and temperature fluctuations.

Oxidation and Corrosion Resistance Inconel 738 offers superior oxidation resistance, protecting components from chemical degradation in high-temperature environments. This property is crucial for applications exposed to combustion gases and corrosive atmospheres.

Long-Term Creep Strength Designed for long-term stability, Inconel 738 offers excellent creep resistance, maintaining structural integrity at elevated temperatures over extended periods. This makes it a preferred material for continuous operation in turbines.

Versatility in Harsh Environments Inconel 738's balanced composition ensures adaptability across various industries. It performs exceptionally well in aerospace, power generation, and marine environments, providing reliable service in challenging conditions.

Inconel 738 Superalloy’s Machinability

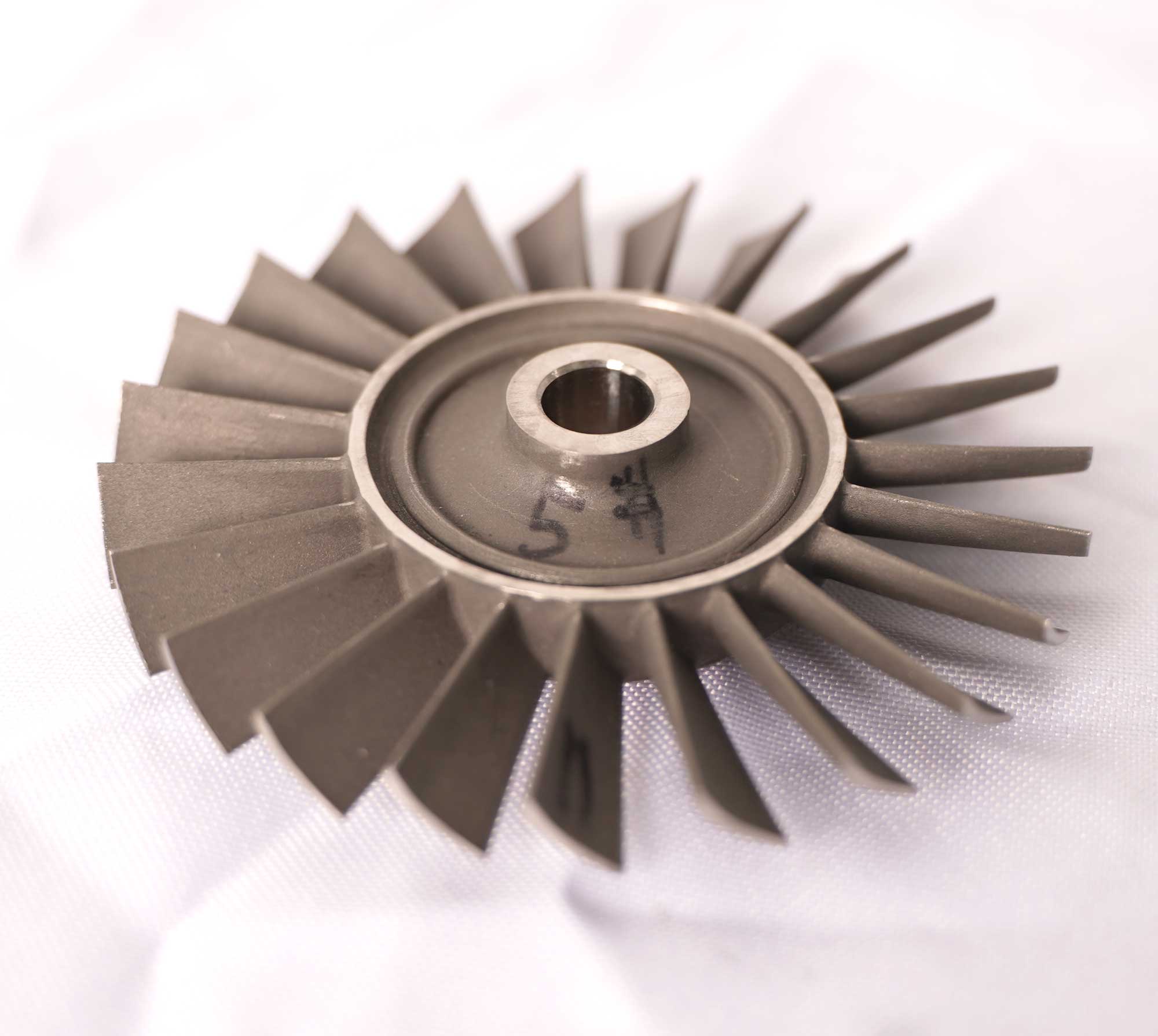

Inconel 738 is well-suited for Vacuum Investment Casting due to its stable microstructure and excellent high-temperature oxidation resistance. This makes it ideal for manufacturing complex turbine blades and aerospace components.

However, Inconel 738 is not recommended for Single Crystal Casting as it primarily focuses on equiaxed and directional casting applications, where grain structure uniformity is prioritized over single-crystal growth.

Inconel 738 performs well in Equiaxed Crystal casting, providing high mechanical strength and oxidation resistance. This alloy is often used in gas turbines and combustion liners, benefiting from its fatigue strength and durability.

Superalloy Directional Casting is another suitable process for Inconel 738, enhancing creep resistance and fatigue properties by aligning grain structures for optimal mechanical performance under stress.

Inconel 738 is not typically used for Powder Metallurgy Turbine Disc applications due to its alloying elements favoring casting over powder metallurgy processes.

While Inconel 738 offers mechanical strength, it is not recommended for Superalloy Precision Forging due to its casting-oriented design, which focuses more on thermal resistance.

The alloy is unsuitable for Superalloy 3D Printing since it requires intricate casting techniques rather than additive manufacturing processes.

Inconel 738 can be effectively used for CNC Machining. However, machining this alloy can be challenging due to its hardness, requiring advanced tooling and optimized machining strategies.

This alloy performs well with Superalloy Welding when preheating is applied to prevent cracking during welding, making it suitable for repairs of turbine blades.

Hot Isostatic Pressing (HIP) enhances the mechanical properties of Inconel 738 by eliminating casting porosities, further improving fatigue life and creep resistance.

Inconel 738 Superalloy Applications

In the Aerospace and Aviation industry, Inconel 738 is used in turbine blades and jet engines due to its excellent strength at elevated temperatures.

For Power Generation, the alloy is employed in gas turbines and combustors, maintaining structural integrity over long cycles of high-temperature operations.

In the Oil and Gas industry, Inconel 738 components, such as gas compressors and exhaust systems, withstand corrosive and high-pressure environments.

In Energy, the alloy is favored for applications requiring excellent creep resistance and long-term thermal stability, such as industrial turbines.

The Marine sector uses Inconel 738 for exhaust components and other systems exposed to corrosive marine conditions, ensuring longevity in harsh environments.

In Mining, the alloy’s resistance to wear and corrosion makes it suitable for high-performance drilling equipment and valves.

In the Automotive industry, Inconel 738 is utilized in high-performance exhaust systems and turbochargers to withstand extreme heat.

In Chemical Processing, the alloy is used in heat exchangers and reactors, maintaining structural integrity under corrosive conditions.

In the Pharmaceutical and Food industries, Inconel 738 ensures hygienic operations and reliable performance in equipment exposed to steam and cleaning agents.

Military and Defense applications rely on Inconel 738 for components that need high fatigue strength, such as missile engines and defense aircraft.

In the Nuclear sector, the alloy’s high temperature and corrosion resistance make it suitable for heat exchangers and reactor components.

When to Choose Inconel 738 Superalloy

Inconel 738 is optimal for custom superalloy parts when long-term thermal resistance and fatigue strength are essential. It performs exceptionally well in environments requiring mechanical integrity and oxidation resistance at high temperatures, such as aerospace and energy applications.

This alloy is ideal for extreme thermal cycling components, including gas turbines, combustion chambers, and marine exhaust systems. Inconel 738 offers an outstanding balance of creep strength, corrosion resistance, and fatigue performance for manufacturers seeking reliable and durable solutions in demanding industries.