Rene 77

About Rene 77 Superalloy

Name and Equivalent Names

Rene 77, recognized by UNS N07777, is a nickel-chromium-based superalloy. It conforms to the standards of ASTM B637, DIN/EN 2.4683, and GB/T 14992 (GH4043). It is also listed under AMS 5972 and ASME SB-637, making it a widely recognized material for high-temperature applications.

Rene 77 Basic Introduction

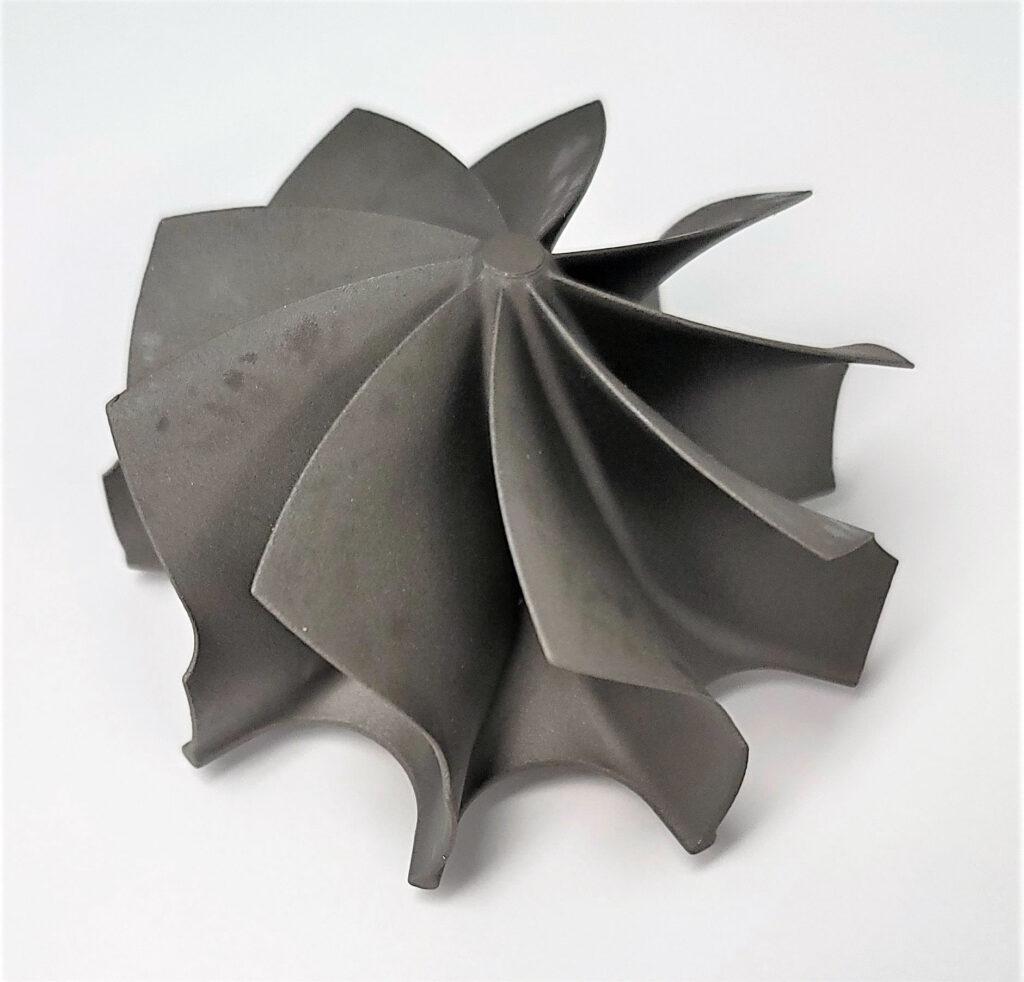

Rene 77 is a nickel-based superalloy optimized for high mechanical strength, excellent creep resistance, and fatigue strength at elevated temperatures. This alloy is used in demanding environments where components, such as gas turbines and aerospace engines, must withstand thermal cycling and mechanical stress.

Rene 77 offers a long service life, maintaining its properties for over 15,000 hours at 900°C. Its composition includes aluminum, titanium, and molybdenum, which contribute to its strength and stability under extreme conditions, making it an excellent choice for industrial applications.

Alternative Superalloys of Rene 77

Inconel 738, Inconel 718, and Hastelloy X are common alternatives to Rene 77. Inconel 738 offers excellent oxidation resistance at high temperatures, while Inconel 718 provides superior corrosion resistance. Hastelloy X is known for its excellent thermal stability and weldability, and it is often used in aerospace applications. These alloys serve similar high-temperature functions, with selection depending on specific performance and environmental needs.

Rene 77 Design Intention

Rene 77 was designed to address the need for high creep strength and thermal fatigue resistance in applications subjected to elevated temperatures. The alloy is intended for use in components that experience significant thermal cycling, such as turbine blades and structural aerospace parts. Its chemical composition balances mechanical strength with oxidation resistance, ensuring durability and performance in harsh environments.

Rene 77 Chemical Composition

Rene 77's chemical composition provides excellent thermal stability and strength. Nickel forms the base, while chromium ensures oxidation resistance. Aluminum and titanium strengthen the alloy through precipitation hardening, while molybdenum and cobalt enhance creep resistance.

Element | Content (wt%) |

|---|---|

Nickel (Ni) | Balance |

Chromium (Cr) | 15 |

Cobalt (Co) | 16 |

Molybdenum (Mo) | 4.75 |

Aluminum (Al) | 5.75 |

Titanium (Ti) | 3.5 |

Tungsten (W) | 3.5 |

Iron (Fe) | Max 0.5 |

Rene 77 Physical Properties

Rene 77 offers high density and thermal conductivity, making it effective in heat-resistant applications. Its high modulus of elasticity ensures structural stability under stress.

Property | Value |

|---|---|

Density (g/cm³) | 8.73 |

Melting Point (°C) | 1395 |

Thermal Conductivity (W/m·K) | 12 |

Modulus of Elasticity (GPa) | 210 |

Metallographic Structure of Rene 77 Superalloy

Rene 77 features a γ-phase nickel matrix with γ' (gamma prime) precipitates, enhancing high-temperature strength and creep resistance. The γ' phase prevents dislocation movement, which improves the alloy’s mechanical stability during long-term exposure to stress.

Adding tungsten, cobalt, and molybdenum strengthens the grain boundaries, ensuring excellent fatigue resistance. This structure allows Rene 77 to maintain mechanical properties in cyclic temperature environments, reducing the risk of thermal fatigue and ensuring long service life for critical components.

Rene 77 Mechanical Properties

Rene 77 offers exceptional creep strength, fatigue resistance, and high tensile strength. It performs well under mechanical stress and thermal cycling, with a long creep rupture life at elevated temperatures.

Property | Value |

|---|---|

Tensile Strength (MPa) | 1000–1200 |

Yield Strength (MPa) | ~900 |

Creep Strength | High at elevated temperatures |

Hardness (HRC) | 35–40 |

Elongation (%) | 10–12 |

Elastic Modulus (GPa) | 210 |

Key Features of Rene 77 Superalloy

1. Superior Creep Resistance

Rene 77 maintains high creep strength, allowing components to withstand stress at elevated temperatures over extended periods. This property makes it ideal for gas turbines and aerospace engines.

2. Excellent Thermal Fatigue Resistance

The alloy performs well under thermal cyclic conditions, ensuring reliability in environments where components undergo rapid heating and cooling, such as in power generation and aviation.

3. High Mechanical Strength

With tensile strengths between 1000 and 1200 MPa, Rene 77 offers excellent structural integrity, ensuring safety and performance in critical applications.

4. Long Service Life at High Temperatures

Rene 77 provides over 15,000 hours of service life at 900°C, making it highly reliable for continuous operation in harsh environments.

5. Oxidation and Corrosion Resistance

Chromium content ensures excellent oxidation resistance, protecting components from degradation under high temperatures and corrosive environments, making the alloy ideal for energy and industrial sectors.

Rene 77 Superalloy’s Machinability

Rene 77 is suitable for Vacuum Investment Casting because of its high-temperature stability and ability to produce precision components with excellent surface quality.

The alloy is not typically used in Single Crystal Casting due to its polycrystalline structure, which makes it more effective in applications requiring uniform grain formations.

Rene 77 performs well in Equiaxed Crystal casting because it offers excellent creep resistance with evenly distributed grains, essential for components under cyclic loads.

Superalloy Directional Casting is a potential option for Rene 77, but its use is limited since the alloy's strengths are better utilized in equiaxed applications.

Rene 77 is not ideal for Powder Metallurgy Turbine Disc manufacturing due to challenges in powder processing and the limited need for powdered forms of this alloy.

The alloy is well-suited for Superalloy Precision Forging, allowing the production of solid and heat-resistant components with reliable mechanical properties.

Superalloy 3D Printing is not widely used for Rene 77 due to difficulties maintaining uniform mechanical properties during additive manufacturing.

Thanks to its high strength and thermal resistance, Rene 77 can be efficiently processed using CNC Machining, allowing precise component fabrication.

Superalloy Welding with Rene 77 is challenging but feasible with specialized techniques to prevent cracking and maintain mechanical integrity.

The alloy benefits significantly from Hot Isostatic Pressing (HIP), enhancing its mechanical properties by eliminating internal porosity and ensuring uniform strength.

Rene 77 Superalloy Applications

In Aerospace and Aviation, Rene 77 is used for turbine blades and structural components, offering superior performance under high thermal loads and cyclic stress.

In the Power Generation industry, Rene 77 finds application in gas turbines, where its thermal fatigue resistance ensures long service life in harsh conditions.

In Oil and Gas applications, Rene 77 provides reliable performance in high-pressure valves and drilling equipment exposed to extreme temperatures and corrosive environments.

Rene 77 supports Energy production by maintaining performance in turbines and heat exchangers, ensuring efficiency under continuous operation.

The Marine industry benefits from Rene 77’s corrosion resistance, which ensures durability in propulsion systems and exhaust components exposed to seawater.

In Mining, Rene 77 is used for wear-resistant parts such as drill bits and pump components, ensuring high reliability in abrasive conditions.

Rene 77 supports Automotive applications, particularly in high-performance exhaust systems, where its ability to withstand thermal cycling is crucial.

In Chemical Processing, Rene 77 provides stability in reactors and heat exchangers exposed to extreme temperatures and chemical environments.

In the pharmaceutical and food industries, Rene 77 ensures the safe operation of critical equipment, such as valves, thanks to its corrosion resistance and mechanical stability.

In Military and Defense, Rene 77 is used in jet engines and missile components, providing strength and reliability in demanding conditions.

The Nuclear industry leverages Rene 77 for reactor components that withstand radiation and extreme heat without degradation.

When to Choose Rene 77 Superalloy

Rene 77 is ideal for applications requiring long-term performance under extreme heat and mechanical stress. This alloy is perfect for custom superalloy parts used in aerospace, power generation, and marine environments where thermal fatigue and creep resistance are critical.

For industries like chemical processing and oil and gas, Rene 77 offers corrosion resistance and mechanical reliability, ensuring durability in harsh environments. It is particularly effective in aerospace engines and turbines that experience frequent thermal cycling. When extended service life is required, especially at high temperatures, Rene 77 delivers exceptional performance and stability, making it a preferred material for demanding industrial applications.