Rene 41

About Rene 41 Superalloy

Name and Equivalent Names

Rene 41, identified by UNS N07041, is a nickel-chromium superalloy. It conforms to multiple standards, such as ASTM B637, DIN/EN 2.4973, GB/T 14992 (GH4133), and AMS 5719. It is also recognized by ASME SB-637, ISO 15156, and NACE MR0175, ensuring broad usage in various industries.

Rene 41 Basic Introduction

Rene 41 is a high-performance nickel-based superalloy known for its outstanding mechanical properties and thermal stability. With a blend of chromium, cobalt, molybdenum, and other strengthening elements, it is engineered to withstand extreme temperatures and stress conditions.

Designed for aerospace and gas turbine applications, Rene 41 offers excellent oxidation and thermal fatigue resistance, even at temperatures up to 982°C. Its ability to retain mechanical strength over long durations makes it a reliable material for combustion chambers, afterburners, and turbine components.

Alternative Superalloys of Rene 41

Comparable alternatives to Rene 41 include Inconel 718, Inconel 738, and Hastelloy X, which offer excellent strength at elevated temperatures. Inconel 718 provides superior corrosion resistance and creep strength. Inconel 738 excels in oxidation resistance, making it suitable for turbine blades. Hastelloy X, widely used in jet engines, offers exceptional thermal stability. Each alloy is selected based on specific operating conditions, providing manufacturers with versatile options for high-temperature environments.

Rene 41 Design Intention

Rene 41 was designed for applications requiring high mechanical strength and oxidation resistance at elevated temperatures. It addresses the need for materials with excellent creep resistance, allowing them to maintain structural integrity in harsh environments over long periods. This superalloy is tailored for aerospace components and gas turbines, where the combination of tensile strength, fatigue resistance, and stability under thermal stress is essential for safety and performance.

Rene 41 Chemical Composition

The chemical composition of Rene 41 contributes to its superior thermal and mechanical properties. Nickel provides a strong base, while chromium enhances oxidation resistance. Cobalt and molybdenum improve creep strength, and aluminum and titanium aid in precipitation hardening for long-term durability.

Element | Content (wt%) |

|---|---|

Nickel (Ni) | Balance |

Chromium (Cr) | 18.0 – 20.0 |

Cobalt (Co) | 10.0 – 12.0 |

Molybdenum (Mo) | 9.0 – 10.5 |

Aluminum (Al) | 1.4 – 1.6 |

Titanium (Ti) | 3.0 – 3.3 |

Iron (Fe) | Max 3.0 |

Silicon (Si) | Max 0.5 |

Rene 41 Physical Properties

Rene 41’s density ensures lightweight components, while its high melting point allows operation at extreme temperatures. Its modulus of elasticity provides excellent stiffness, and thermal conductivity ensures efficient heat dissipation.

Property | Value |

|---|---|

Density (g/cm³) | 8.36 |

Melting Point (°C) | 1400 |

Thermal Conductivity (W/m·K) | 11.2 |

Modulus of Elasticity (GPa) | 215 |

Metallographic Structure of Rene 41 Superalloy

Rene 41 exhibits a precipitation-hardened microstructure, where gamma-prime (γ') precipitates strengthen the nickel matrix. The uniform distribution of γ phases enhances the alloy's resistance to creep deformation, ensuring stability under thermal stress.

Grain boundary strengthening is critical in minimizing grain boundary sliding and enhancing the material's resistance to cracking. The alloy’s metallographic structure ensures durability over prolonged exposure to high temperatures, making it a prime candidate for aerospace and turbine components operating in extreme conditions.

Rene 41 Mechanical Properties

Rene 41 offers excellent tensile strength and fatigue resistance, with superior creep rupture life at high temperatures. Its fracture toughness ensures reliability in demanding environments, while high hardness and ductility contribute to long service life.

Property | Value |

|---|---|

Tensile Strength (MPa) | 1170 – 1280 |

Yield Strength (MPa) | 1030 – 1100 |

Creep Strength (982°C) | Effective for long durations |

Hardness (HRC) | 30 – 35 |

Elongation (%) | 8 – 10 |

Elastic Modulus (GPa) | 210 |

Key Features of Rene 41 Superalloy

1. Exceptional High-Temperature Strength

Rene 41 provides excellent tensile and yield strength at elevated temperatures, making it ideal for aerospace and gas turbine components. It maintains structural integrity even at temperatures up to 982°C.

2. Superior Creep Resistance

The alloy exhibits high creep strength, essential for components exposed to constant stress at elevated temperatures. It ensures long-term reliability, offering over 10,000 hours of creep rupture life at 982°C.

3. Excellent Thermal Fatigue Resistance

Rene 41 resists thermal fatigue under cyclic temperature fluctuations, making it highly suitable for gas turbines, combustion chambers, and jet engines where such conditions are expected.

4. Outstanding Oxidation Resistance

The high chromium content ensures excellent oxidation resistance, protecting the alloy from degradation in extreme environments. This feature extends the service life of components operating at high temperatures.

5. High Fracture Toughness and Durability

Rene 41 exhibits remarkable fracture toughness, ensuring reliable performance in demanding environments. Its combination of hardness and ductility minimizes the risk of mechanical failure.

Rene 41 Superalloy’s Machinability

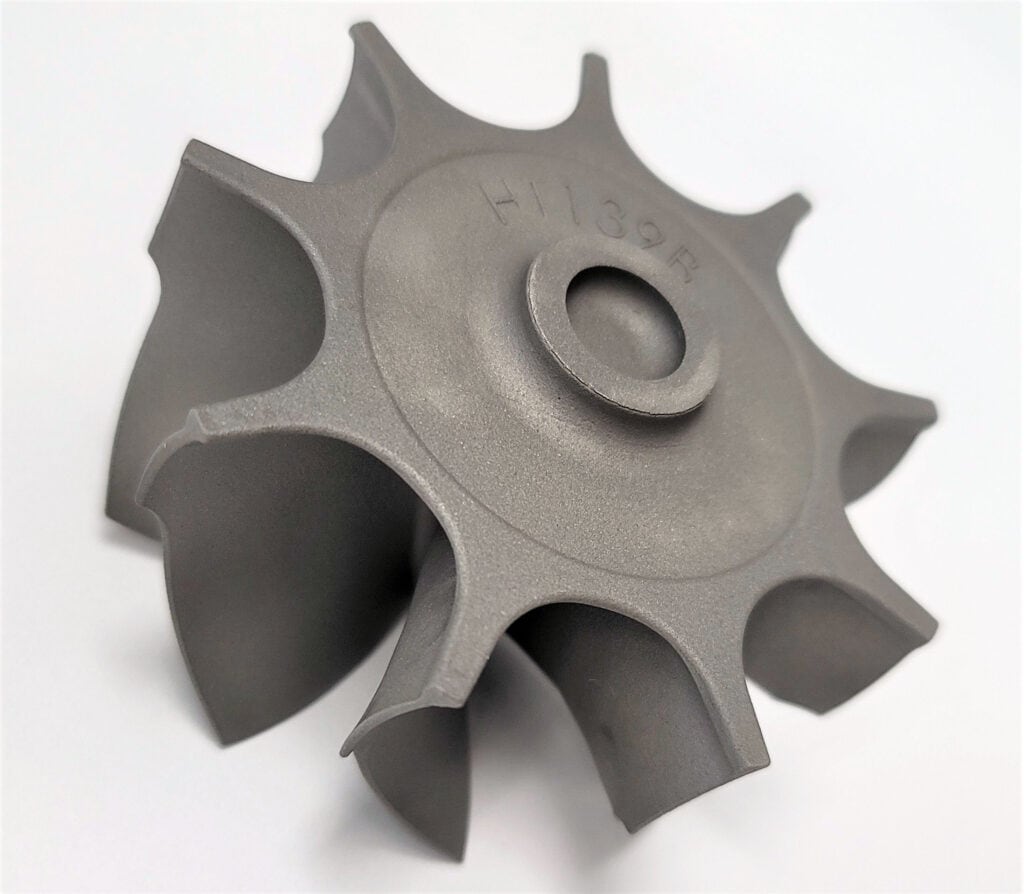

Rene 41 can be effectively used in Vacuum Investment Casting due to its excellent thermal stability, making it suitable for producing high-precision parts under controlled environments.

The alloy is not typically used for Single Crystal Casting because its composition is optimized for high-strength polycrystalline structures rather than single-crystal applications.

Rene 41 is compatible with Equiaxed Crystal casting due to its ability to maintain strength in polycrystalline form, allowing it to perform well in components with uniform grain structures.

While it has excellent mechanical properties, Rene 41 is less preferred for Superalloy Directional Casting since directional grain structures are not the primary focus of this alloy's applications.

The alloy is not ideal for Powder Metallurgy Turbine Discs due to challenges in powder processing and limited applications in this form.

Rene 41 performs well in Superalloy Precision Forging, enabling the creation of solid and heat-resistant components through hot forging techniques.

Although possible, Superalloy 3D Printing is less commonly used for Rene 41 due to its complex material properties, which may require advanced printing systems.

Rene 41 is suitable for CNC Machining due to its high tensile strength and durability, which allow precise and accurate machining with specialized tools.

Superalloy Welding of Rene 41 is challenging but achievable with proper preheating and post-weld heat treatment, reducing the risks of cracking and deformation.

Rene 41 can benefit from Hot Isostatic Pressing (HIP) to eliminate porosity, enhancing cast and forged components' mechanical properties and structural integrity.

Rene 41 Superalloy Applications

In Aerospace and Aviation, Rene 41 is used for combustion chambers, afterburners, and turbine blades, providing strength and oxidation resistance at high temperatures.

For Power Generation, the alloy finds application in gas turbines and exhaust components, ensuring long-term durability in extreme thermal environments.

In the Oil and Gas industry, Rene 41 is used for downhole tools and flanges due to its resistance to corrosion and high-temperature fatigue.

The alloy supports Energy production with applications in turbines, where heat resistance and creep strength are essential for efficiency.

In the Marine industry, Rene 41 is utilized in exhaust systems and propulsion components due to its ability to withstand corrosive environments and thermal cycles.

Rene 41 is used in Mining for wear-resistant tools and pump components, offering toughness in abrasive and high-pressure environments.

In Automotive applications, the alloy is used in high-performance exhaust systems and turbocharger components, where heat resistance is critical.

The Chemical Processing industry benefits from Rene 41’s resistance to oxidation and corrosion in chemical reactors and heat exchangers.

Rene 41 is also used in Pharmaceutical and Food processing, especially in valves and seals where corrosion resistance is crucial.

In Military and Defense, the alloy is employed for missile components and jet engines, providing reliability in harsh environments.

The Nuclear industry uses Rene 41 for reactor components, offering strength and corrosion resistance under radiation and high temperatures.

When to Choose Rene 41 Superalloy

Rene 41 should be chosen for applications requiring a balance of strength, heat, and oxidation resistance. It is ideal for custom superalloy parts in harsh environments, such as aerospace engines, gas turbines, and marine systems. Additionally, when long-term durability and creep resistance are necessary at temperatures up to 982°C, Rene 41 excels. For industries where performance under extreme thermal fatigue is essential, such as power generation and defense, Rene 41 offers excellent mechanical properties and service life. Its resistance to oxidation makes it the go-to material for high-temperature environments, ensuring minimal degradation over time.