Inconel 738C

About Inconel 738C Superalloy

Inconel 738C, or Alloy 738C, conforms to ASTM B637 and DIN EN 2.4652 standards. It shares similarities with Inconel 738 but includes slight chemical adjustments for enhanced cyclic load resistance. In China, it aligns with GB/T 14992: GH738C.

This alloy consists mainly of nickel (Ni), chromium (Cr), and cobalt (Co), with additional elements such as aluminum (Al), titanium (Ti), and tungsten (W). These enhance its mechanical and thermal fatigue properties, making it suitable for extreme temperatures and high-stress applications.

Inconel 738C Basic Introduction

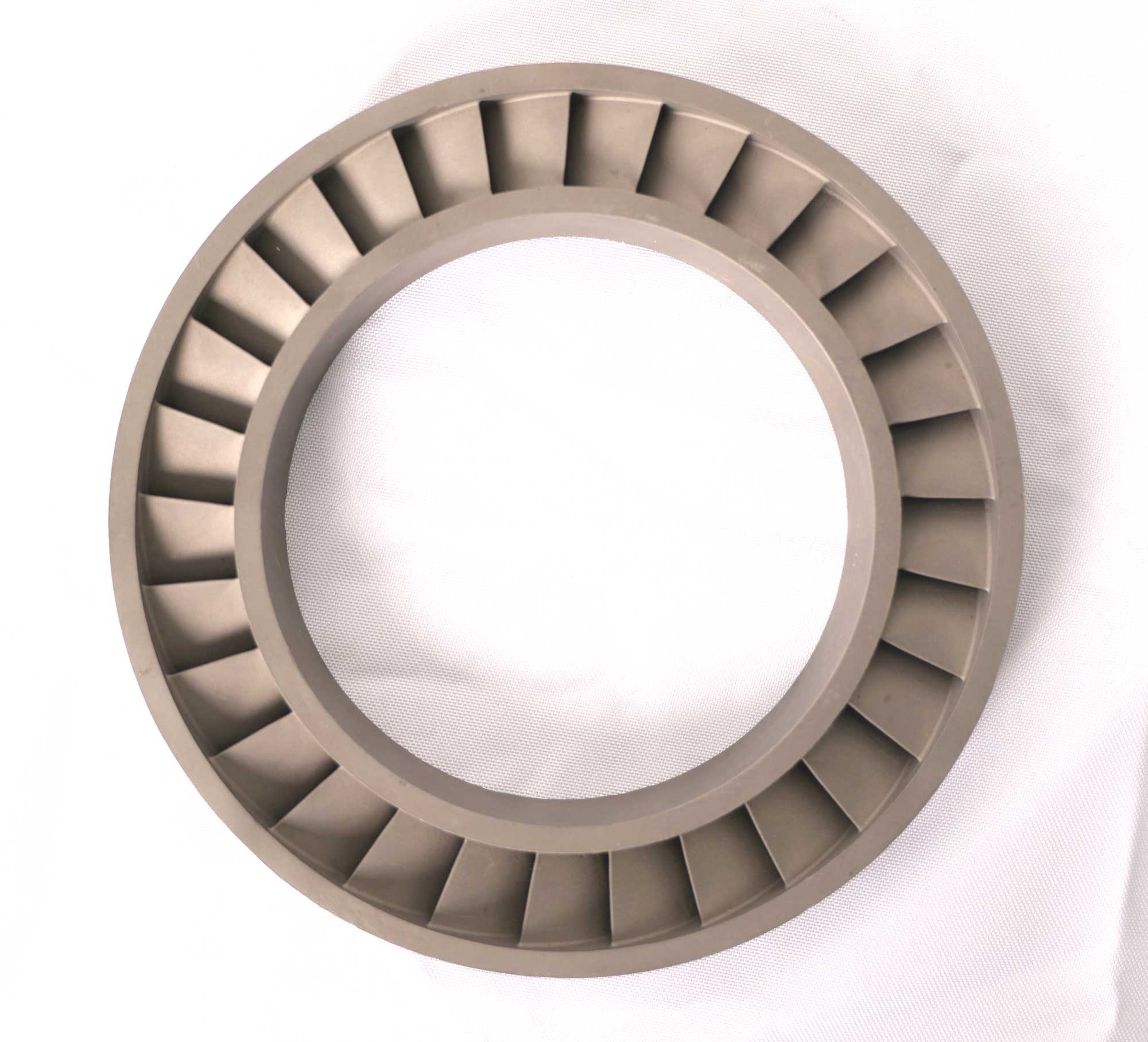

Inconel 738C is a high-performance superalloy that maintains mechanical integrity under elevated temperatures and intense operational loads. Its chemical composition ensures a balance of strength, oxidation resistance, and thermal fatigue performance, making it ideal for turbine blades, nozzles, and hot-section components.

This alloy performs well in demanding environments, offering long-term stability at temperatures up to 982°C. Its excellent fatigue resistance ensures durability during cyclic operations, making it a preferred choice in the aerospace and energy industries.

Alternative Superalloys of Inconel 738C

Alternative materials to Inconel 738C include Inconel 738, Inconel 625, and Rene 80, each offering specific advantages. Inconel 625 excels in corrosion resistance but lacks the high-temperature strength of 738C. Rene 80 is another alternative with excellent creep strength, suitable for turbine components but with more complex processing requirements.

Other potential substitutes are Nimonic 90 and Hastelloy X, both known for their strength and oxidation resistance. However, Inconel 738C remains superior for applications requiring a balance of fatigue resistance, thermal stability, and mechanical strength.

Inconel 738C Design Intention

Inconel 738C is designed to withstand extreme thermal cycles and mechanical loads, making it a reliable choice for high-performance engines. The alloy focuses on providing long-term creep resistance at elevated temperatures, allowing it to perform efficiently in gas turbines and jet engines.

The alloy's composition ensures oxidation resistance, even during prolonged exposure to harsh environments. With enhanced fatigue resistance, Inconel 738C meets the needs of applications requiring durable components that can endure continuous cyclic operations under stress.

Inconel 738C Chemical Composition

Inconel 738C’s composition includes nickel (Ni) as the base element, providing high-temperature stability and chromium (Cr) for oxidation resistance. Aluminum (Al) and titanium (Ti) contribute to the alloy's strength by forming gamma-prime precipitates. The addition of tungsten (W) improves the material’s creep resistance.

Element | Weight % |

|---|---|

Nickel (Ni) | 60.0 – 65.0 |

Chromium (Cr) | 15.5 – 16.5 |

Aluminum (Al) | 3.4 – 3.8 |

Titanium (Ti) | 3.4 – 3.8 |

Tungsten (W) | 1.5 |

Iron (Fe) | Balance |

Inconel 738C Physical Properties

Inconel 738C exhibits excellent thermal stability and mechanical properties, ensuring reliability in extreme environments.

Property | Value |

|---|---|

Density (g/cm³) | 8.12 |

Melting Point (°C) | 1300 |

Thermal Conductivity (W/m·K) | 10.7 |

Modulus of Elasticity (GPa) | 210 |

Metallographic Structure of Inconel 738C

Inconel 738C exhibits a microstructure reinforced by gamma-prime (γ′) precipitates, contributing to its strength and thermal stability. These precipitates form through aluminum, titanium, and nickel alloying, providing enhanced resistance to creep and stress rupture at elevated temperatures.

Additionally, carbide phases, primarily MC-type carbides, further improve the alloy's mechanical properties. These structures prevent grain boundary sliding, which is essential for applications such as turbine blades, where mechanical loads and temperature fluctuations are common.

Inconel 738C Mechanical Properties

Inconel 738C offers superior mechanical properties, making it ideal for high-temperature and cyclic loading applications.

Property | Value |

|---|---|

Tensile Strength (MPa) | 1100 |

Yield Strength (MPa) | 900 |

Fatigue Strength (MPa) | 450 |

Hardness (HRC) | Rockwell C40-45 |

Elongation (%) | 10 – 12 |

Elastic Modulus (GPa) | ~210 |

Key Features of Inconel 738C Superalloy

High-Temperature Strength Inconel 738C offers exceptional strength at temperatures up to 982°C, ensuring reliable performance under extreme thermal conditions. This makes it an excellent choice for turbine blades and exhaust systems.

Creep Resistance With a design focus on creep resistance, Inconel 738C maintains structural integrity during extended exposure to elevated temperatures, ensuring long service life.

Fatigue Resistance This alloy is highly resistant to cyclic loads, making it suitable for applications involving continuous thermal cycling, such as jet engines and gas turbines.

Oxidation and Corrosion Resistance The alloy provides excellent resistance to oxidation and corrosion, even in harsh environments, ensuring reliability in aerospace and marine applications.

Mechanical Durability Inconel 738C maintains high tensile strength and hardness over prolonged operational cycles, ensuring mechanical durability in challenging conditions.

Inconel 738C Superalloy’s Machinability

Based on industry standards, Inconel 738C is compatible with Vacuum Investment Casting due to its excellent high-temperature properties and oxidation resistance. This casting method ensures precise, complex shapes for turbine components, leveraging the alloy’s creep resistance.

However, Inconel 738C is not suitable for Single Crystal Casting. Its metallurgical structure relies on a combination of gamma-prime precipitates and carbides, optimized for equiaxed and directional casting, rather than single-crystal structures.

Inconel 738C performs well in Equiaxed Crystal Casting because of its stable microstructure, ensuring reliable mechanical performance across complex geometries. This method aligns with the alloy’s intended use in turbine blades and hot-section parts.

The alloy also suits Directional Casting, where grain structure aligns with operational stress paths, further enhancing fatigue and creep resistance for aerospace applications.

Inconel 738C is not ideal for Powder Metallurgy Turbine Disc manufacturing due to processing challenges and the limited availability of powdered forms for this specific alloy.

Due to its high-temperature strength, Inconel 738C is unsuitable for Precision Forging. Its hardness and stiffness make forging difficult, leading to higher tool wear and reduced forging precision.

Superalloy 3D Printing is not recommended for Inconel 738C due to the difficulty in maintaining uniform microstructure across layers, which is essential for performance at elevated temperatures.

The alloy is compatible with CNC Machining, which uses advanced tools and techniques to manage tool wear and surface integrity. Its hardness and strength require careful machining strategies for efficiency.

Superalloy Welding with Inconel 738C presents challenges, such as cracking and microstructural degradation. Specialized techniques like preheating and post-weld heat treatment are necessary.

Finally, Inconel 738C benefits from Hot Isostatic Pressing (HIP), improving its density, reducing porosity, and enhancing mechanical properties, making it even more reliable for high-stress applications.

Inconel 738C Superalloy Applications

Aerospace and Aviation: In the aerospace industry, Inconel 738C is used for turbine blades, vanes, and combustor components due to its ability to withstand high thermal cycles. Aerospace and Aviation rely on its excellent fatigue resistance.

Power Generation: Inconel 738C is widely applied in gas turbines and power plants where thermal efficiency is critical. It performs well in turbines exposed to extreme temperatures. Power Generation applications include turbine blades and heat exchangers.

Oil and Gas: In the oil and gas industry, Inconel 738C’s oxidation resistance makes it suitable for downhole tools and gas turbines used in offshore platforms. Oil and Gas operations benefit from its durability.

Energy: In energy production, including renewable sectors, Inconel 738C ensures reliable turbines and heat recovery systems operation. Energy applications often include steam and gas turbines.

Marine: In the marine sector, Inconel 738C components withstand saltwater environments and high operational temperatures. Marine applications include turbine engines for naval vessels.

Mining: Inconel 738C is used for high-performance machinery operating in extreme conditions, such as high-temperature smelters. Mining tools benefit from its corrosion and wear resistance.

Automotive: Inconel 738C is used in turbochargers and exhaust systems for high-performance vehicles. Automotive applications demand materials that perform well under extreme conditions.

Chemical Processing: Inconel 738C's resistance to oxidation and corrosion is essential in chemical plants. Chemical Processing applications include heat exchangers and reactors.

Pharmaceutical and Food: High purity and corrosion resistance make Inconel 738C suitable for food processing equipment and pharmaceutical reactors. Pharmaceutical and Food industries rely on it for reliable performance.

Military and Defense: Inconel 738C is applied in military aircraft engines and missile systems, providing thermal stability and fatigue resistance. Military and Defense benefit from its reliability in harsh conditions.

Nuclear: In nuclear plants, Inconel 738C provides reliable performance for turbine blades and control rod components exposed to high radiation and heat. Nuclear sectors depend on it for safety and durability.

When to Choose Inconel 738C Superalloy

Choose Inconel 738C for applications requiring exceptional thermal stability, fatigue resistance, and creep strength. This superalloy is ideal for gas turbines, jet engines, and high-temperature exhaust systems where mechanical performance and corrosion resistance are critical. Its reliable service life ensures durability under continuous operational stress.

If you need custom superalloy parts, Inconel 738C offers an optimized thermal fatigue resistance and mechanical integrity balance. This alloy guarantees consistent performance in challenging environments for aerospace, marine, and energy industries. Visit Custom superalloy parts for tailored solutions designed to meet specific engineering needs.