Inconel 600

Basic Introduction

Inconel 600 is a nickel-chromium alloy designed to withstand extreme environmental conditions. This superalloy is known for maintaining its structural integrity and performance under high temperatures, oxidation, and corrosive atmospheres. It is a versatile material utilized in many industries, including aerospace, nuclear, power generation, chemical processing, and marine, due to its ability to perform across a wide temperature range—from cryogenic conditions to over 1093°C (2000°F).

The alloy's non-magnetic properties and solid solution-strengthened structure ensure that it remains durable and reliable, even under long-term exposure to high stress, heat, and corrosive media. Inconel 600 finds frequent application in components such as furnace equipment, heat exchangers, gas turbine parts, and reactor vessels. Its resistance to heat, chemical damage, and environmental stress makes it indispAbout Inconel 600 Superalloy

Material Name and Equivalent Names: Inconel 600 is known by other names like Alloy 600, Nicrofer 3716, Ferrochronin 600, and Haynes 600. It corresponds to UNS N06600 in the American standard system, ASTM B163 and B167 standards, DIN/EN 2.4816, and GB/T 15059: GH600 in Chinese standards.

Inconel 600 Basic Introduction

Inconel 600 is a nickel-based superalloy renowned for its excellent corrosion and oxidation resistance at high temperatures. Its high nickel content of around 72% offers remarkable strength and stability even in harsh chemical and thermal environments.

This alloy is widely used in aerospace, chemical processing, marine, and energy generation due to its ability to withstand cryogenic and elevated temperatures. Its high thermal fatigue resistance and mechanical strength also make it suitable for applications such as heat exchangers, turbines, and reactor components.ensable for industries that operate in harsh conditions, requiring materials that can tolerate extremes without compromising performance.

Alternative Superalloys of Inconel 600

Some alternative materials to Inconel 600 include Inconel 625, Inconel 718, and Hastelloy C-276. Inconel 625 offers superior corrosion resistance and strength for marine applications, while Inconel 718 provides better mechanical properties under extreme pressure and temperatures, which is ideal for aerospace components. Hastelloy C-276, on the other hand, is better suited for aggressive chemical environments requiring excellent pitting resistance.

Each alternative offers specialized advantages depending on the intended environment, with trade-offs between tensile strength, corrosion resistance, and heat tolerance. This makes Inconel 600 an optimal choice when chemical and mechanical stability are necessary across a broad temperature range.

Inconel 600 Design Intention

The design of Inconel 600 aims to provide an alloy capable of withstanding harsh chemical environments, such as those involving acidic and alkaline solutions, while also exhibiting thermal stability. The high nickel content ensures resistance to oxidation and corrosion, while chromium contributes to stability under oxidizing conditions. Manganese and copper enhance resistance to corrosion in marine environments.

This alloy’s versatility allows it to operate effectively across a broad temperature range—from cryogenic levels to 700°C—making it a top choice in applications requiring thermal fatigue resistance, high mechanical strength, and long-term creep performance.

Inconel 600 Chemical Composition

The components of Inconel 600 play critical roles in achieving its exceptional properties. Nickel (Ni) provides oxidation resistance and maintains ductility. Chromium (Cr) enhances corrosion resistance and thermal stability, while iron (Fe) contributes to strength. Copper (Cu) and manganese (Mn) offer additional corrosion resistance, particularly in marine environments.

Element | Composition (%) |

|---|---|

Nickel (Ni) | 72 |

Chromium (Cr) | 14.0 – 17.0 |

Iron (Fe) | 6.0 – 10.0 |

Manganese (Mn) | ≤ 1.0 |

Copper (Cu) | ≤ 0.5 |

Inconel 600 Physical Properties

Inconel 600 is known for its excellent density, high melting point, and thermal conductivity, making it ideal for high-temperature environments. The following table summarizes its fundamental physical properties:

Property | Value |

|---|---|

Density (g/cm³) | 8.47 |

Melting Point (°C) | 1370 |

Thermal Conductivity (W/(m·K)) | 14.9 |

Modulus of Elasticity (GPa) | 205 |

Metallographic Structure of Inconel 600 Superalloy

Inconel 600 has an austenitic face-centered cubic (FCC) structure, which provides superior mechanical properties and resistance to thermal fatigue. The FCC lattice offers excellent ductility and toughness, which helps prevent brittle fracture under stress.

The microstructure remains stable over long exposure to high temperatures, ensuring consistent performance. Inconel 600 also shows minimal grain boundary precipitation, enhancing its corrosion resistance in chemically aggressive environments and making it suitable for nuclear and chemical reactor applications.

Inconel 600 Mechanical Properties

The mechanical properties of Inconel 600 reflect its suitability for high-performance applications requiring strength and thermal fatigue resistance. Below is a summary of key mechanical data:

Property | Value |

|---|---|

Tensile Strength (MPa) | 550 – 690 |

Yield Strength (MPa) | 240 – 300 |

Hardness (HRC) | 80 – 85 HRB |

Elongation (%) | 30 – 35 |

Creep Rupture Life | ~10,000 hrs at 600°C / 140 MPa |

Fatigue Strength (MPa) | 220 – 320 |

Thermal Fatigue Resistance | High up to 700°C |

Key Features of Inconel 600 Superalloy

1. Exceptional Corrosion Resistance: Inconel 600 offers excellent resistance to oxidizing and reducing environments, making it suitable for chemical reactors, nuclear applications, and marine equipment. Its performance remains stable even under aggressive conditions involving acids and alkalis.

2. High-Temperature Strength: With a tensile strength range of 550–690 MPa, Inconel 600 retains mechanical integrity across a wide temperature range, making it ideal for aerospace, power generation, and heat exchanger components.

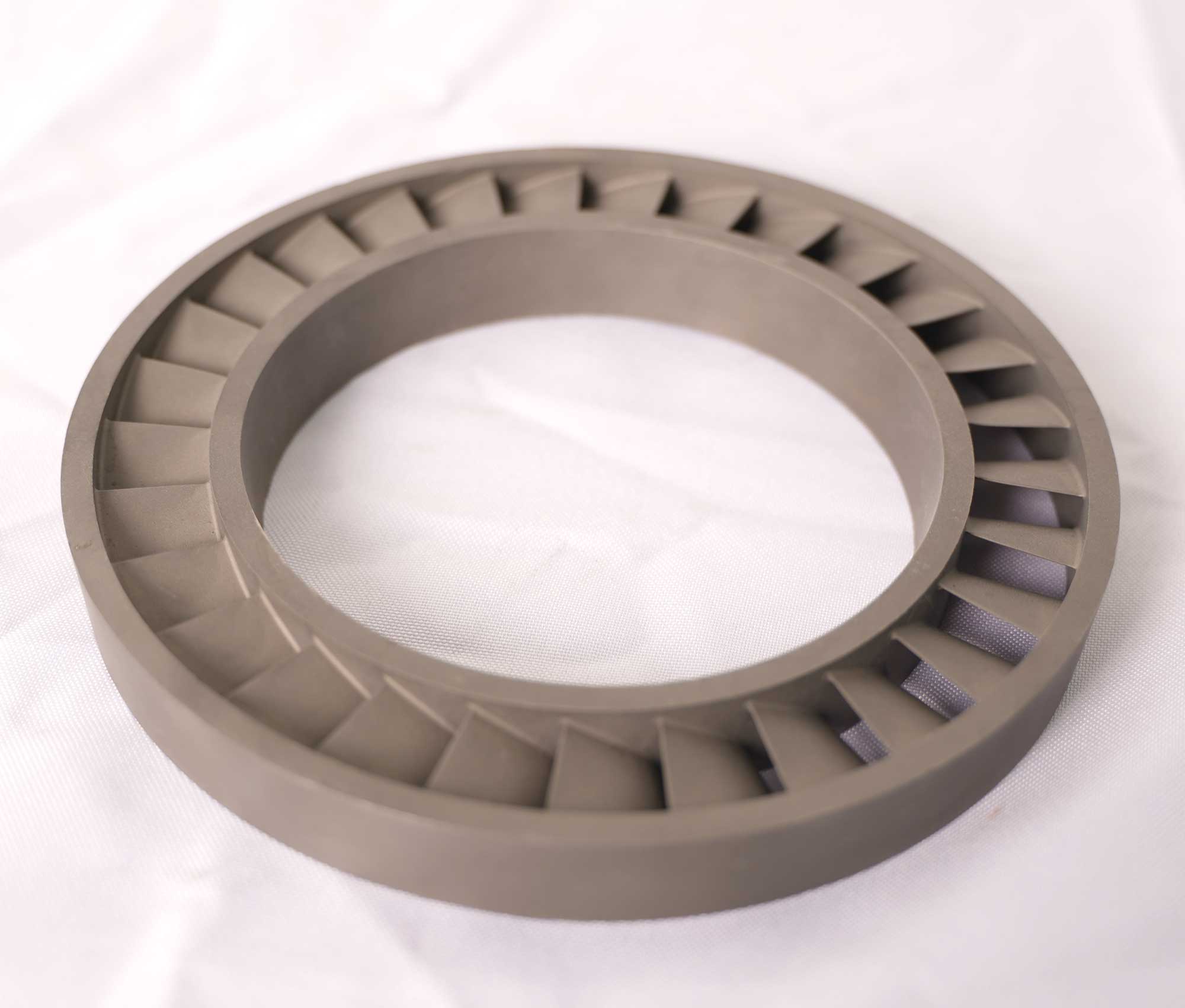

3. Superior Thermal Fatigue Resistance: This alloy maintains stability under cyclical thermal loads, resisting thermal fatigue up to 700°C. It is commonly used in turbine blades and reactor components exposed to fluctuating temperatures.

4. Long Creep Life: Inconel 600 has excellent creep resistance, offering ~10,000 hours of performance at 600°C under 140 MPa stress. This ensures reliability in high-temperature applications like gas turbines and pressure vessels.

5. Versatile Applications Across Industries: Thanks to its balance of mechanical and corrosion resistance properties, Inconel 600 finds applications in aerospace, marine, chemical processing, and nuclear power. Its machinability makes it compatible with CNC machining, welding, and heat treatment.

Inconel 600 Superalloy’s Machinability

Inconel 600 can be used in Vacuum Investment Casting due to its oxidation resistance and ability to retain strength at high temperatures. Its compatibility with precision molds makes it ideal for critical aerospace and industrial components.

However, Single Crystal Casting is not recommended for Inconel 600 because the alloy lacks the required microstructural properties to benefit from this process, typically used for high-stress turbine blades requiring single-crystal orientation.

Equiaxed Crystal Casting is a suitable process for Inconel 600, as it ensures uniform grain structure and provides good mechanical properties at elevated temperatures. This casting method is effective for industrial components that demand thermal stability.

Inconel 600 is not ideal for Superalloy Directional Casting, as it is primarily intended for components with sufficient equiaxed grains. Directional casting suits alloys requiring enhanced creep resistance along specific orientations.

Inconel 600 is incompatible with Powder Metallurgy Turbine Disc applications, as it lacks the microstructural features and specific strength required for such applications, which demand materials optimized for high creep strength.

Inconel 600 can be processed using Superalloy Precision Forging. Its toughness and mechanical properties allow it to withstand forging, making it suitable for high-strength parts.

Inconel 600 is rarely used for Superalloy 3D Printing due to its complex microstructure, which makes it challenging to print while retaining optimal mechanical properties.

It is widely applied in CNC Machining. Its machinability, though demanding, is manageable with appropriate tooling and cooling techniques. The alloy’s stability makes it ideal for precision machining of complex parts.

Inconel 600 supports Superalloy Welding but requires pre-heating and post-welding heat treatment to prevent cracking. Proper control ensures high-strength, corrosion-resistant welds.

While Hot Isostatic Pressing (HIP) can enhance the density and mechanical properties of certain alloys, it is not commonly applied to Inconel 600 due to its already favorable mechanical properties and minimal porosity.

Inconel 600 Superalloy Applications

In the Aerospace and Aviation industry, Inconel 600 is used for heat exchangers, engine components, and jet engine seals due to its high-temperature stability and corrosion resistance.

In power generation, Inconel 600 is found in turbines, heat exchangers, and reactor cores. Its high creep resistance ensures durability under continuous thermal stress.

For Oil and Gas, Inconel 600 is applied in downhole equipment, risers, and sour gas environments, where sulfide corrosion resistance is crucial.

In the Energy industry, the alloy is used in nuclear reactors and geothermal systems, benefiting from its ability to withstand oxidation and chemical exposure over time.

In Marine applications, Inconel 600 resists seawater corrosion and is used in exhaust systems, valves, and heat exchangers on ships and submarines.

Mining applies it in pumps, valves, and wear-resistant components exposed to abrasive and corrosive environments.

In the Automotive sector, Inconel 600 is used for exhaust manifolds and turbochargers, where high-temperature performance and resistance to oxidation are required.

In Chemical Processing, Inconel 600 is used for heat exchangers, reactors, and piping systems exposed to acidic and alkaline environments.

For Pharmaceuticals and Food, it is suitable for sterile equipment like valves and heat exchangers, where corrosion resistance is necessary for product safety.

In Military and Defense, Inconel 600 is used in missile components, jet engines, and defense systems requiring reliable performance under extreme conditions.

In the Nuclear industry, it plays a role in reactor control systems and heat exchangers, providing stability under radioactive exposure and high temperatures.

When to Choose Inconel 600 Superalloy

Inconel 600 is ideal when high corrosion resistance, mechanical strength, and thermal stability are essential. Industries that deal with extreme environments—such as Aerospace and Aviation, Oil and Gas, and Nuclear—benefit from the alloy's ability to perform reliably under fluctuating temperatures. Its compatibility with custom superalloy parts allows engineers to design components that meet exact specifications.

Additionally, Inconel 600 offers a blend of oxidation resistance and mechanical integrity, making it suitable for Power Generation and Chemical Processing applications. Its superior performance under stress and heat ensures long-lasting components, minimizing maintenance and downtime across various industries.