What is X-ray Checking?

Introduction of X-ray

X-ray checking is a non-destructive testing (NDT) method that allows the internal structure of components to be analyzed without causing damage. It offers precise and reliable insights into defects such as voids, cracks, and inconsistencies, ensuring product quality and safety.

In precision engineering, X-ray inspection is pivotal in providing high-resolution imaging of critical parts. It is instrumental in industries where performance and durability are non-negotiable, such as aerospace and automotive, ensuring that each part meets stringent specifications.

What Is X-ray Checking?

X-rays are a form of electromagnetic radiation that penetrates solid objects, enabling the inspection of internal structures. X-ray machines generate X-rays that pass through a material and are captured by a detector. The resulting image reveals internal irregularities, such as cracks, porosity, or incomplete welds.

X-ray checking is commonly used to inspect complex mechanical components and high-temperature alloys, such as turbine blades, automotive parts, and aerospace components. It ensures that these parts are free of defects that could compromise their performance or lifespan.

How Does an X-ray Work?

An X-ray machine consists of several key components: an X-ray tube, a detector, and image processing software. The X-ray tube generates the X-ray beam, which passes through the inspected object. The detector captures the transmitted rays, and the software processes the data to create a detailed image.

As X-rays penetrate an object, different materials absorb varying amounts of radiation, which creates contrast in the resulting image. This allows engineers to detect hidden defects and assess the quality of internal features.

Types of X-ray Machines

Digital Radiography (DR): Provides immediate results with high image quality and is often used in automotive and aerospace applications.

Computed Tomography (CT): Offers 3D imaging for highly detailed analysis, ideal for complex parts in industries like aerospace and medical.

Fluoroscopy: Used for real-time imaging to inspect moving parts or dynamic operations, such as in pharmaceutical or food packaging.

Portable X-ray Systems: Compact and mobile field inspection solutions, often used in oil and gas or military applications.

Benefits of X-ray Checking

High Precision: X-ray machines achieve micron-level accuracy, making them ideal for critical component inspection.

Improved Efficiency: Automated X-ray systems reduce the time and effort involved in manual inspections, streamlining the testing process.

Data Integration: Results from X-ray inspections can be directly fed into analysis software, enabling detailed data analytics and reporting.

Consistency and Reliability: Automated X-ray systems minimize human error, ensuring reliable and repeatable measurements.

Versatility: X-ray checking accommodates a variety of industries and geometries, from automotive parts to complex turbine blades.

Applications of X-ray Checking in Different Industries

Aerospace and Aviation: X-ray inspection is crucial for identifying cracks or voids in turbine blades, ensuring flight safety and component reliability.

Power Generation: In gas turbines and other high-temperature components, X-ray testing helps detect internal defects, preventing catastrophic failures.

Oil and Gas: X-ray inspection ensures the integrity of critical components such as valves and pipelines exposed to extreme environments.

Energy: X-ray checking plays a role in inspecting renewable energy equipment, such as wind turbine components.

Marine: Ensures the durability of marine components by identifying internal defects that could lead to corrosion or wear.

Mining: Inspects high-strength mining tools and parts to ensure they withstand abrasive environments.

Automotive: Critical components like engine parts and transmission systems undergo X-ray checks to ensure safety and performance.

Chemical Processing: X-ray checks verify the integrity of pressure vessels and heat exchangers.

Pharmaceutical and Food: X-ray systems monitor packaging and inspect products to prevent contamination.

Military and Defense: Ensures the reliability of military equipment by detecting defects in critical components.

Nuclear: X-ray testing is vital in inspecting reactor components, ensuring they meet stringent safety standards.

X-ray Testing in Custom Superalloy Parts Manufacturing

Superalloy Vacuum Investment Casting

Vacuum Investment Casting offers precise shaping for superalloys with minimal contamination. It is widely used for turbine blades and aerospace components requiring high-performance alloys.

Vacuum Investment Casting must undergo an X-ray inspection to detect micro-cracks, porosity, or shrinkage defects invisible to surface-level inspections, ensuring product reliability under extreme stress.

Superalloy Single Crystal Casting

Single Crystal Casting eliminates grain boundaries, enhancing mechanical strength and creep resistance in aerospace turbine blades. This method ensures durability under high temperatures.

Single Crystal Casting requires X-ray inspection to confirm the absence of defects, such as voids or misaligned crystal structures, which could compromise mechanical performance.

Superalloy Equiaxed Crystal Casting

Equiaxed Crystal Casting produces components with a uniform grain structure, providing better thermal and mechanical stability. It is commonly used for gas turbine discs.

Equiaxed Crystal Casting benefits from X-ray inspection to identify porosity and structural inconsistencies, ensuring component integrity in high-temperature applications.

Superalloy Directional Casting

Directional Casting aligns grains along a preferred orientation, enhancing strength in high-stress applications like jet engines.

Superalloy Directional Casting undergoes X-ray inspection to detect defects that might develop during cooling, preventing premature failure under operational loads.

Special Superalloy Casting

Special Alloy Casting involves unique alloy compositions tailored for high-performance applications such as aerospace or nuclear reactors.

Special Alloy Casting requires X-ray testing to ensure internal consistency, avoiding undetected flaws that could lead to catastrophic failures.

Superalloy Powder Metallurgy Turbine Disc

Powder Metallurgy offers precise control over the microstructure, producing highly durable turbine discs.

Powder Metallurgy Turbine Disc relies on X-ray testing to identify internal voids and ensure proper consolidation during the sintering process.

Superalloy Precision Forging

Precision Forging provides excellent mechanical properties by shaping alloys under controlled conditions. It is used for components like turbine shafts.

Superalloy Precision Forging needs X-ray inspection to validate the structural integrity of forged components, ensuring reliability under heavy loads.

Superalloy Isothermal Forging

Isothermal forging maintains uniform temperatures during forging, ensuring minimal grain growth and improved fatigue resistance.

Isothermal Forging benefits from X-ray testing to identify any internal defects introduced during the process, safeguarding performance.

Superalloy Hot Isostatic Pressing (HIP)

HIP uses high temperature and pressure to remove porosity in castings and powder components, increasing material density.

Hot Isostatic Pressing (HIP) requires X-ray inspection to verify that no residual voids remain, ensuring high-quality finished products.

Superalloy Welding

Welding joins critical components, especially in aerospace and power applications, requiring high-strength seams.

Superalloy Welding undergoes X-ray inspection to identify hidden defects, such as cracks or voids within weld joints, ensuring structural stability.

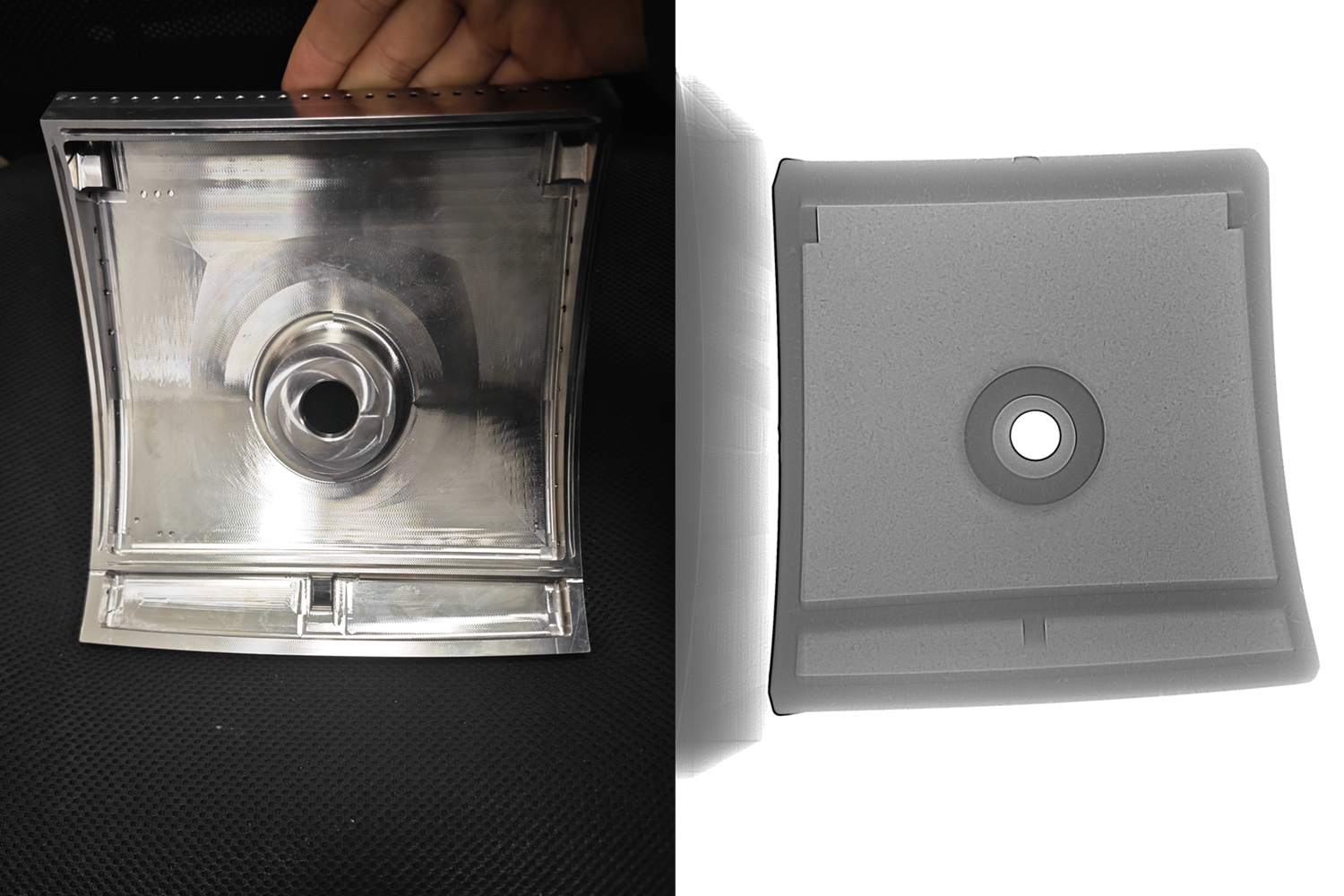

Superalloy CNC Machining

CNC Machining shapes alloys into precise components with complex geometries, often used in aerospace and automotive industries.

Superalloy CNC Machining requires X-ray testing to detect subsurface defects or stress concentrations introduced during machining.

Superalloy 3D Printing

3D Printing creates intricate superalloy components layer by layer, enabling custom designs.

Superalloy 3D Printing requires X-ray inspection to ensure layer consistency and detect voids that could affect mechanical performance.

When to Choose X-ray Testing?

Critical Safety Components: X-ray inspection is essential for components in aerospace, nuclear, and military applications, where failure is not an option.

Complex Geometries: Parts with intricate internal structures, such as 3D-printed components, require X-ray inspection to confirm internal integrity.

High-Temperature Applications: Components subjected to extreme heat, such as turbine blades, need X-ray testing to detect thermal stress defects.

New Manufacturing Processes: Novel manufacturing methods like powder metallurgy require X-ray testing to ensure consistency and quality.

Failure Analysis: X-ray inspection is used during failure investigations to uncover hidden defects that may have contributed to a breakdown.

FAQs about X-ray Checking

What types of defects can X-ray detect? X-ray testing can identify voids, cracks, porosity, incomplete welds, and internal stress concentrations.

Is X-ray inspection safe for operators? Modern X-ray machines are designed with shielding and safety protocols to minimize radiation exposure to operators.

How long does X-ray inspection take? The inspection time depends on the part’s complexity, but digital radiography often provides immediate results.

What materials can be inspected using X-ray? X-ray inspection works on metals, ceramics, composites, and polymers used across aerospace, automotive, and medical industries.

How does X-ray compare to other NDT methods? X-ray testing offers superior imaging for internal defects compared to other NDT methods like ultrasound or magnetic particle inspection.