What is Carbon Sulfur Analyzer Checking?

Introduction of Carbon Sulfur Analyzer

Concept of Carbon Sulfur Analyzer Checking

Carbon Sulfur Analyzer (CSA) checking is vital for measuring carbon and sulfur levels in metals and alloys. These two elements significantly impact the material's strength, corrosion resistance, and performance. CSA helps manufacturers ensure product quality and compliance with industry standards by accurately determining their concentrations.

Role of Carbon Sulfur Analyzer in Precision Engineering

In precision engineering, materials must meet strict chemical composition requirements to function reliably in extreme conditions. CSA is widely applied to validate the elemental composition of components used in aerospace, automotive, and power generation industries. It ensures that carbon and sulfur levels remain within specified ranges to maintain structural integrity and avoid premature failures.

What Is Carbon Sulfur Analyzer Checking?

Definition and Operation of Carbon Sulfur Analyzer Machines

A Carbon Sulfur Analyzer is a specialized machine that detects and quantifies solid materials' carbon and sulfur content, particularly metals and alloys. The analyzer combusts the sample in an oxygen-rich environment, measuring the emitted gases to determine the elemental concentrations.

Common Parts and Products Inspected by Carbon Sulfur Analyzers

Carbon Sulfur Analyzers are commonly used to inspect high-temperature alloys, steel components, precision-forged parts, and turbine blades. These materials require stringent chemical composition control to ensure long-term durability and performance in demanding environments, such as aerospace engines and power plants.

How Does a Carbon Sulfur Analyzer Work?

Components of a Carbon Sulfur Analyzer

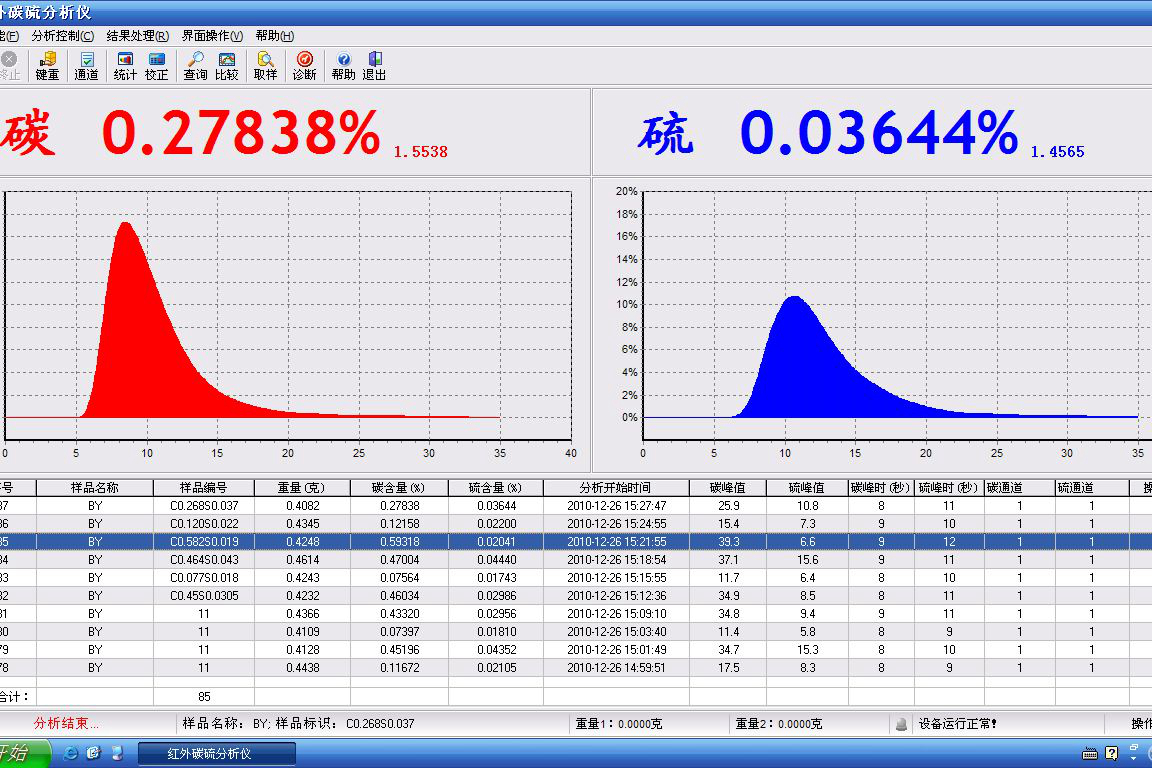

A typical Carbon Sulfur Analyzer comprises a high-temperature furnace, an oxygen supply system, gas detection cells, and a data processing unit. The furnace burns the sample, releasing carbon dioxide (CO₂) and sulfur dioxide (SO₂) gases, which are then detected by sensors.

Capturing Data and Producing Results

As the sample combusts, the emitted gases pass through infrared or thermal conductivity detectors that measure their concentrations. The data is collected and analyzed in real time, generating a report that indicates the exact levels of carbon and sulfur in the material.

Types of Carbon Sulfur Analyzer Machines

Combustion-Based Carbon Sulfur Analyzers: These are the most common types, and they are ideal for analyzing metals and alloys by burning the sample in an oxygen environment.

Induction Furnace Carbon Sulfur Analyzers: These are best suited for materials that require rapid heating and combustion, providing quick and accurate results.

Infrared Carbon Sulfur Analyzers: These analyzers use infrared sensors to detect the emitted gases, ensuring precise measurements for small sample sizes.

Portable Carbon Sulfur Analyzers: Designed for field use, these analyzers offer flexibility by enabling on-site measurements.

Benefits of Carbon Sulfur Analyzer Checking

High Precision: Accurately measures carbon and sulfur content, ensuring materials meet exacting standards for performance.

Improved Efficiency: Automates the analysis process, reducing the time required to assess material quality.

Data Integration: Results can be seamlessly integrated into reporting and compliance tracking software systems.

Consistency and Reliability: Reduces human error by automating measurements, ensuring reliable and repeatable results.

Versatility: Suitable for various materials, including steel, high-temperature alloys, and precision-forged components.

Applications of Carbon Sulfur Analyzer Checking in Different Industries

Aerospace and Aviation: Ensures carbon and sulfur content in turbine blades and engine components remain within specifications, preventing material degradation.

Power Generation: Validates the chemical composition of high-temperature alloys used in power plant turbines to ensure reliability.

Oil and Gas: Confirms material integrity by analyzing carbon and sulfur levels in corrosion-resistant pipelines and drilling equipment.

Energy: Monitors the elemental composition of components used in renewable energy systems to maintain efficiency.

Marine: Analyzes shipbuilding materials to ensure corrosion resistance, extending the lifespan of marine components.

Mining: Ensures the durability of mining equipment by controlling carbon and sulfur content in wear-resistant alloys.

Automotive: Validates the chemical composition of engine and exhaust components to meet emissions regulations and enhance performance.

Chemical Processing: Prevents contamination by analyzing the purity of materials used in reactors and piping systems.

Pharmaceutical and Food: Inspects stainless steel components used in food processing equipment to ensure hygiene and durability.

Military and Defense: Ensures critical components' reliability by analyzing high-strength alloys' chemical composition.

Nuclear: Validates the elemental composition of materials used in nuclear reactors to ensure safety and compliance.

Carbon Sulfur Analyzer Testing in Custom Superalloy Parts Manufacturing

Superalloy Vacuum Investment Casting

Vacuum Investment Casting creates complex shapes with excellent surface finish, which is suitable for high-stress applications like turbine blades. Carbon Sulfur Analyzer testing ensures the material’s carbon and sulfur content remains within strict tolerances, preventing defects such as cracking or corrosion under extreme operating conditions.

Superalloy Single Crystal Casting

Single Crystal Casting eliminates grain boundaries, improving thermal and mechanical performance in jet engine components. Carbon and sulfur analysis ensures that even trace amounts of these elements do not weaken the crystal structure, maintaining performance at high temperatures.

Superalloy Equiaxed Crystal Casting

Equiaxed Crystal Casting produces materials with evenly distributed grains, balancing strength and flexibility. Carbon Sulfur Analyzer testing verifies elemental consistency, ensuring the part performs reliably under mechanical stress and temperature fluctuations.

Superalloy Directional Casting

Superalloy Directional Casting aligns grain structures to optimize high-temperature strength. Accurate carbon and sulfur measurements prevent chemical inconsistencies that could cause thermal fatigue or performance degradation.

Special Superalloy Casting

Special Alloy Casting creates customized components tailored to specific operational environments. Carbon Sulfur Analyzer testing ensures that chemical compositions meet precise requirements, avoiding contamination that could compromise the part’s performance.

Superalloy Powder Metallurgy Turbine Disc

Powder Metallurgy Turbine Disc offers superior mechanical properties by eliminating casting defects. Carbon and sulfur content verification ensures that impurities do not disrupt the material’s integrity, which is essential for high-stress applications.

Superalloy Precision Forging

Superalloy Precision Forging refines grain structures, enhancing strength and fatigue resistance. Carbon Sulfur Analyzer testing ensures the material meets chemical specifications, preventing potential structural weaknesses.

Superalloy Isothermal Forging

Isothermal Forging maintains uniform temperature during forging, producing parts with consistent properties. Carbon Sulfur Analyzer testing detects any chemical deviations that could compromise the performance of these precision components.

Superalloy Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) improves mechanical properties by eliminating internal voids. Carbon and sulfur analysis ensures no unwanted chemical changes occur during the HIP process, safeguarding long-term reliability.

Superalloy Welding

Superalloy Welding joins components exposed to high temperatures and harsh conditions. Carbon Sulfur Analyzer testing ensures welded joints do not introduce elemental inconsistencies that could weaken the structure.

Superalloy CNC Machining

Superalloy CNC Machining creates precision parts with minimal waste. Carbon and sulfur analysis ensures that material composition remains intact throughout the machining process, maintaining part integrity.

Superalloy 3D Printing

Superalloy 3D Printing enables rapid manufacturing of complex parts without molds. Carbon Sulfur Analyzer testing ensures printed components meet chemical specifications, avoiding performance issues due to elemental inconsistencies.

When to Choose Carbon Sulfur Analyzer Testing

Material Qualification Manufacturers use CSA to certify raw materials, ensuring the carbon and sulfur content meets industry standards before production.

Quality Control during Production Carbon Sulfur Analyzer testing ensures that materials maintain consistent chemical compositions throughout manufacturing.

Failure Analysis In the event of component failure, CSA helps identify chemical inconsistencies that could have contributed to the issue.

Regulatory Compliance CSA is essential to meet regulatory standards for aerospace, automotive, and energy industries, where chemical accuracy is critical.

Supplier Verification Manufacturers use CSA to verify the chemical integrity of materials provided by suppliers, minimizing risks in the production process.

FAQs about Carbon Sulfur Analyzer Checking

What is the purpose of Carbon Sulfur Analyzer testing? CSA measures materials' carbon and sulfur content to meet chemical specifications and performance requirements.

Which industries rely on Carbon Sulfur Analyzer testing? Industries such as aerospace, automotive, power generation, and chemical processing depend on CSA to ensure material quality.

How accurate is Carbon Sulfur Analyzer testing? CSA provides highly accurate results, detecting even trace amounts of carbon and sulfur in metals and alloys.

Can Carbon Sulfur Analyzers test non-metallic materials? CSA can analyze materials like ceramics and polymers, although it is most commonly used for metals and alloys.

How long does it take to perform a Carbon Sulfur Analyzer test? The testing process is quick, typically taking a few minutes per sample, making it ideal for both quality control and production environments.