Rene Superalloy Equiaxed Crystal Casting Production Company

Overview of Rene Superalloy

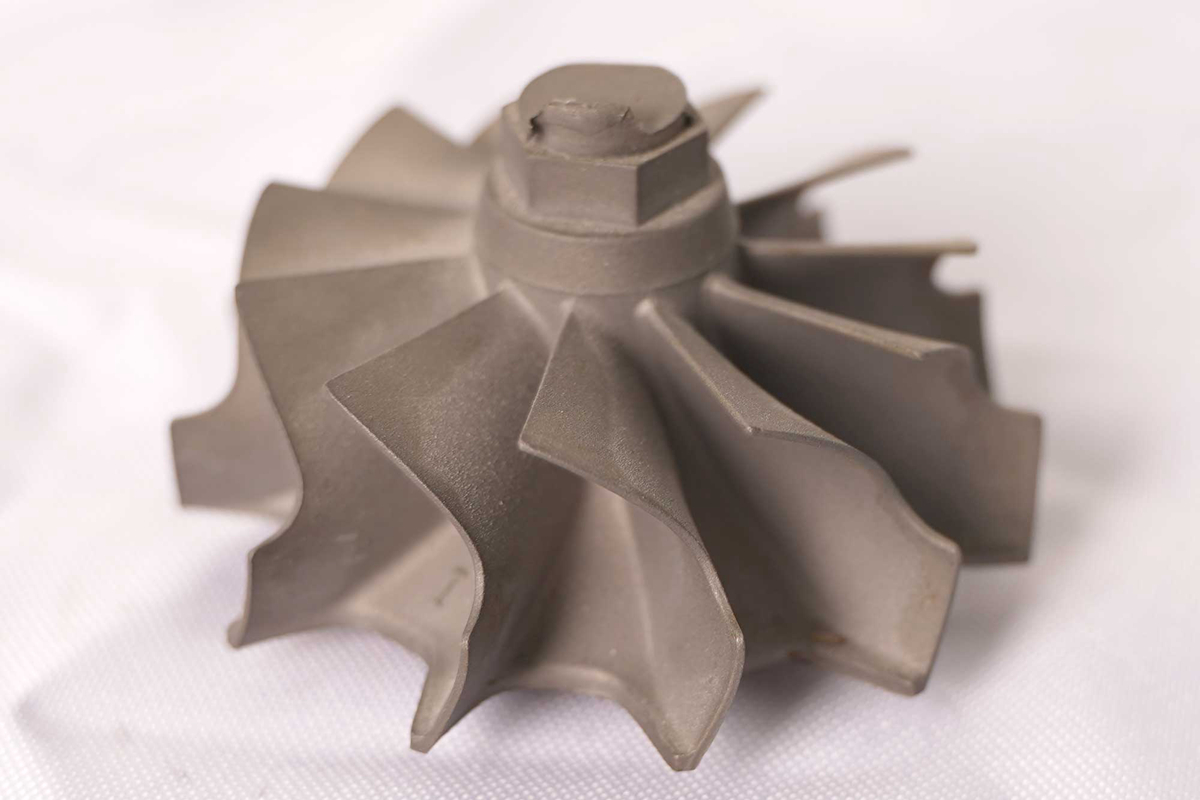

Rene superalloys are a series of nickel-based alloys designed for extreme conditions, particularly where high strength, corrosion resistance, and thermal stability are essential. These materials are crucial for applications that demand performance under intense heat and pressure, such as in the aerospace, power generation, and military sectors. The main distinguishing feature of Rene superalloys is their ability to maintain structural integrity at high temperatures, making them a preferred choice in high-performance applications, including gas turbines, jet engines, and other critical components exposed to extreme environments.

Rene superalloys are typically composed of a base of nickel, with significant additions of chromium, cobalt, and other elements to improve their resistance to oxidation, corrosion, and thermal degradation. These alloys are primarily used in turbine blades, combustor liners, and other parts that operate at high temperatures, where standard alloys would rapidly degrade.

Popular grades of Rene superalloy include Rene 104, Rene 108, and Rene 142, each offering unique properties for different industrial applications. Rene 104, for instance, is known for its high strength and excellent creep resistance at elevated temperatures, making it ideal for turbine blades. Rene 108 is optimized for use in gas turbines due to its good oxidation resistance and strength at high temperatures. These materials are capable of withstanding the harshest operating conditions, making them essential to various sectors where reliability and durability are paramount.

More Equiaxed Crystal Casting Superalloys

While Rene superalloys are known for their exceptional high-temperature properties, there are several other superalloy brands that offer equiaxed crystal casting capabilities. Each of these superalloys is formulated to provide superior performance in specific industrial applications, such as gas turbines, heat exchangers, and components for power generation.

Superalloy Brand 1: Inconel Alloys

Inconel 718: Known for its high strength and excellent weldability, Inconel 718 is often used in aerospace, power generation, and chemical processing.

Inconel 738: This alloy has excellent resistance to high-temperature oxidation and is often used in gas turbine components.

Inconel 925: A nickel-chromium superalloy with enhanced resistance to pitting and crevice corrosion, ideal for harsh marine environments.

Superalloy Brand 2: CMSX Series

CMSX-10: Known for its exceptional creep strength and resistance to oxidation, CMSX-10 is often used in jet engine components.

CMSX-4: A popular choice for high-temperature turbine applications due to its superior thermal stability and low thermal expansion.

CMSX-6: Another alloy in this series designed for critical aerospace applications, offering a balance between high strength and oxidation resistance.

Superalloy Brand 3: Nimonic Alloys

Nimonic 75: One of the most widely used grades, offering excellent oxidation resistance and strength at high temperatures.

Nimonic 90: Provides better fatigue resistance than Nimonic 75, making it ideal for turbine components.

Nimonic 263: Designed for use in extreme high-temperature environments, Nimonic 263 has excellent resistance to both thermal fatigue and oxidation.

Inspection for Equiaxed Crystal Castings

Inspection is a critical part of the manufacturing process for equiaxed crystal castings, as these parts often operate in environments where failure is not an option. Advanced inspection techniques ensure the integrity and performance of these superalloy components. Common inspection methods for equiaxed crystal castings include:

Key Inspection Methods

Coordinate Measuring Machine (CMM) Checking:

The CMM is used to measure the physical dimensions of the cast part to ensure it matches the design specifications. This precision measurement ensures that the part will fit perfectly in its intended application, preventing any misalignment in critical systems like gas turbines or aerospace engines. CMM checks are essential for ensuring that superalloy parts meet strict dimensional tolerances.

X-ray inspection is used to detect internal defects such as porosity, cracks, or voids that might not be visible on the surface. This method ensures that the part is free of internal flaws that could compromise its structural integrity. X-ray checking is crucial for ensuring the reliability of superalloy castings in high-stress environments, such as gas turbine engines.

Metallographic microscopy is used to examine the grain structure of the casting. For equiaxed crystal castings, it’s crucial to verify that the crystals are evenly distributed and that there are no impurities or inclusions that could affect the material’s properties. This inspection helps to ensure that the casting has the desired mechanical properties for its intended application.

Scanning Electron Microscopy (SEM):

SEM is used for detailed surface and microstructural analysis. This technique can identify the morphology of the grain boundaries, which is important for understanding how the material will behave under stress and high temperatures. By utilizing SEM, manufacturers can identify microscopic defects that could lead to part failure in demanding applications.

Tensile Testing:

Tensile testing measures the material’s strength and ductility by applying a pulling force. This test is vital for confirming that the casting can withstand the mechanical loads it will encounter in real-world applications, such as in aerospace engines or power plant turbines. Tensile testing helps ensure that equiaxed crystal castings maintain structural integrity under extreme conditions.

By using these advanced inspection methods, manufacturers can ensure that equiaxed crystal castings meet the stringent performance and safety standards required for critical applications in industries like aerospace, power generation, and chemical processing. These inspections help detect defects early, ensuring that only high-quality components are used in mission-critical environments.

Superalloy Equiaxed Crystal Casting Applications

Equiaxed crystal castings of Rene superalloys and other high-performance superalloys are essential in industries where components must operate under extreme temperatures and stresses. This casting process provides enhanced strength, durability, and thermal stability, making it ideal for critical applications across aerospace, power generation, oil and gas, marine, automotive, and military sectors.

Aerospace and Aviation

In the aerospace and aviation industry, superalloy components such as turbine blades, combustion chambers, and nozzle components are crucial for jet engines. These components require high strength, oxidation resistance, and thermal stability to withstand the extreme conditions they face in operation. Equiaxed crystal casting provides the ideal combination of properties for these critical parts, ensuring the performance and reliability of modern aerospace engines.

Power Generation

Gas turbines in power generation plants operate at very high temperatures, demanding components that offer exceptional durability and efficiency. Components like turbine blades, nozzle rings, and heat exchangers are commonly produced using equiaxed crystal casting. The superior mechanical properties of these castings ensure that they can withstand thermal cycling and high-stress environments, essential for reliable power generation.

Oil and Gas

In the oil and gas industry, superalloy components are used in harsh environments where equipment must resist high pressure, temperature, and corrosion. Components such as valves, pumps, and heat exchangers are made from Rene superalloys and other high-performance materials using equiaxed crystal casting. These castings ensure that equipment performs efficiently and lasts longer, reducing downtime and maintenance in challenging oil extraction and processing conditions.

Marine

Marine engines, particularly those used in power plants and large ships, require components that resist both extreme temperatures and corrosion. Superalloy castings, including equiaxed crystal castings, are often used for parts like turbine blades and reactor vessel components. These castings help marine engines perform reliably in aggressive environments, ensuring the longevity and efficiency of the systems they power.

Automotive

In the automotive sector, high-performance engines used in racing and sports cars demand components capable of withstanding extreme conditions. Superalloy components, particularly those made using equiaxed crystal casting, provide a cost-effective solution for these applications. These castings offer the durability and heat resistance required in automotive engines subjected to high thermal stresses during high-speed operations.

Military and Defense

In military and defense applications, such as military engines, missiles, and aircraft, superalloys like Rene are used for their ability to withstand elevated temperatures and extreme mechanical stresses. Equiaxed crystal castings play a crucial role in ensuring the performance and reliability of these components, which are subjected to the harshest operational conditions. These castings are essential for the functionality of advanced defense systems.

FAQs

What are the main advantages of using Rene superalloys in equiaxed crystal casting?

How do equiaxed crystal castings compare to single crystal castings?

What industries benefit most from Rene superalloy equiaxed crystal castings?

What are the main challenges in equiaxed crystal casting of Rene superalloys?

How is quality control ensured in the production of equiaxed crystal castings?