Wind Power Attachments High Strength Material Provision For Renewable Energy Plants

Introduction to Wind Power Attachments

Wind Power Attachments are critical components in wind turbine systems, providing the structural strength and reliability required to convert wind energy into electricity efficiently. These attachments connect various parts of the wind turbine, such as the rotor, nacelle, tower, and blades, ensuring the system operates safely and effectively under extreme conditions. Wind Power Attachments must withstand harsh environmental forces, including high winds, thermal fluctuations, and corrosive elements, making selecting suitable materials for their construction essential.

Wind power is one of the most promising renewable energy sources in the fight against climate change. With the growing demand for wind energy, developing robust and reliable turbine components, such as Wind Power Attachments, has become critical to ensuring wind energy systems' successful operation and longevity. These attachments are engineered to handle the high stress and fatigue cycles caused by fluctuating wind speeds, making them crucial for maintaining system stability and ensuring optimal performance.

High-Temperature Alloys for Wind Power Attachments

The manufacture of Wind Power Attachments requires materials that can offer high strength and excellent resistance to wear corrosion and temperature variations. High-temperature alloys are ideal for this purpose, as they possess the necessary mechanical properties to ensure durability and reliability under demanding conditions. These alloys are designed to maintain structural integrity despite exposure to extreme temperatures, high mechanical loads, and corrosive environmental elements.

Some of the most commonly used alloys for Wind Power Attachments include Inconel, Hastelloy, Stellite, and Titanium alloys. These materials are preferred due to their high tensile strength, excellent corrosion resistance, and ability to resist creep and fatigue at elevated temperatures. The properties of these alloys make them suitable for manufacturing critical wind turbine components that must endure constant exposure to harsh weather conditions while maintaining performance over extended service lives.

Typical Superalloys Used in Wind Power Attachments Manufacturing

Wind Power Attachments are often manufactured using high-strength superalloys for optimal performance and longevity. The following are some of the most commonly used superalloys in the production of Wind Power Attachments:

Inconel Alloys: Inconel grades such as Inconel 625 and Inconel 718 are used due to their excellent mechanical strength, oxidation resistance, and fatigue resistance. These alloys are particularly useful for components that experience high stress and fluctuating loads, as they maintain structural integrity in extreme conditions. Inconel 718, in particular, provides exceptional resistance to creep and rupture, making it a popular choice for wind turbine attachments that require high reliability over extended periods.

Hastelloy Alloys: Hastelloy alloys are used in applications with critical corrosion resistance. Hastelloy X is commonly employed for wind power components exposed to environmental factors like moisture and salt spray, ensuring longevity and minimal degradation. Hastelloy alloys maintain their strength and resistance to oxidation in high-temperature environments, which makes them ideal for offshore wind turbine applications where the components are constantly exposed to corrosive marine environments.

Stellite Alloys: Known for their exceptional hardness and resistance to wear, Stellite alloys are used in parts that require resistance to abrasion and thermal degradation. Stellite 6, for example, offers excellent wear resistance, making it suitable for use in wind power attachments that experience high friction and wear over time. The alloy's hardness allows it to withstand the abrasive forces exerted by wind and mechanical operations.

Titanium Alloys: Titanium alloys, such as Ti-6Al-4V, are used in wind power attachments for their high strength-to-weight ratio. They are ideal for components that endure fatigue and fluctuating forces without adding significant weight to the turbine structure. Titanium alloys are also known for their outstanding corrosion resistance, which is particularly beneficial in offshore wind turbine installations where exposure to seawater can lead to rapid material degradation if unsuitable materials are used.

Manufacturing Process and Equipment of Wind Power Attachments

The manufacturing of Wind Power Attachments involves various processes, including casting, forging, CNC machining, and additive manufacturing. Each of these processes is chosen based on the specific requirements of the attachment, such as the need for precise geometries, mechanical strength, and material properties.

Casting and Forging: Casting processes like Vacuum Investment Casting produce complex shapes that are strong and resistant to environmental factors. This process ensures that the alloy maintains its properties and that the final product is free from defects like porosity or inclusions. Isothermal Forging enhances the material's grain structure, improving its strength and fatigue resistance. Isothermal forging allows for consistent material properties throughout the component, making it ideal for Wind Power Attachments that experience high cyclic loads.

CNC Machining: CNC machining is essential for achieving tight tolerances and precision in Wind Power Attachments. Using 5-axis CNC machining ensures that the components meet stringent dimensional requirements, providing the accuracy needed for optimal turbine performance. This precision is essential for parts that require complex geometries, such as attachment brackets, where any deviation from the design could compromise the overall safety and efficiency of the wind turbine.

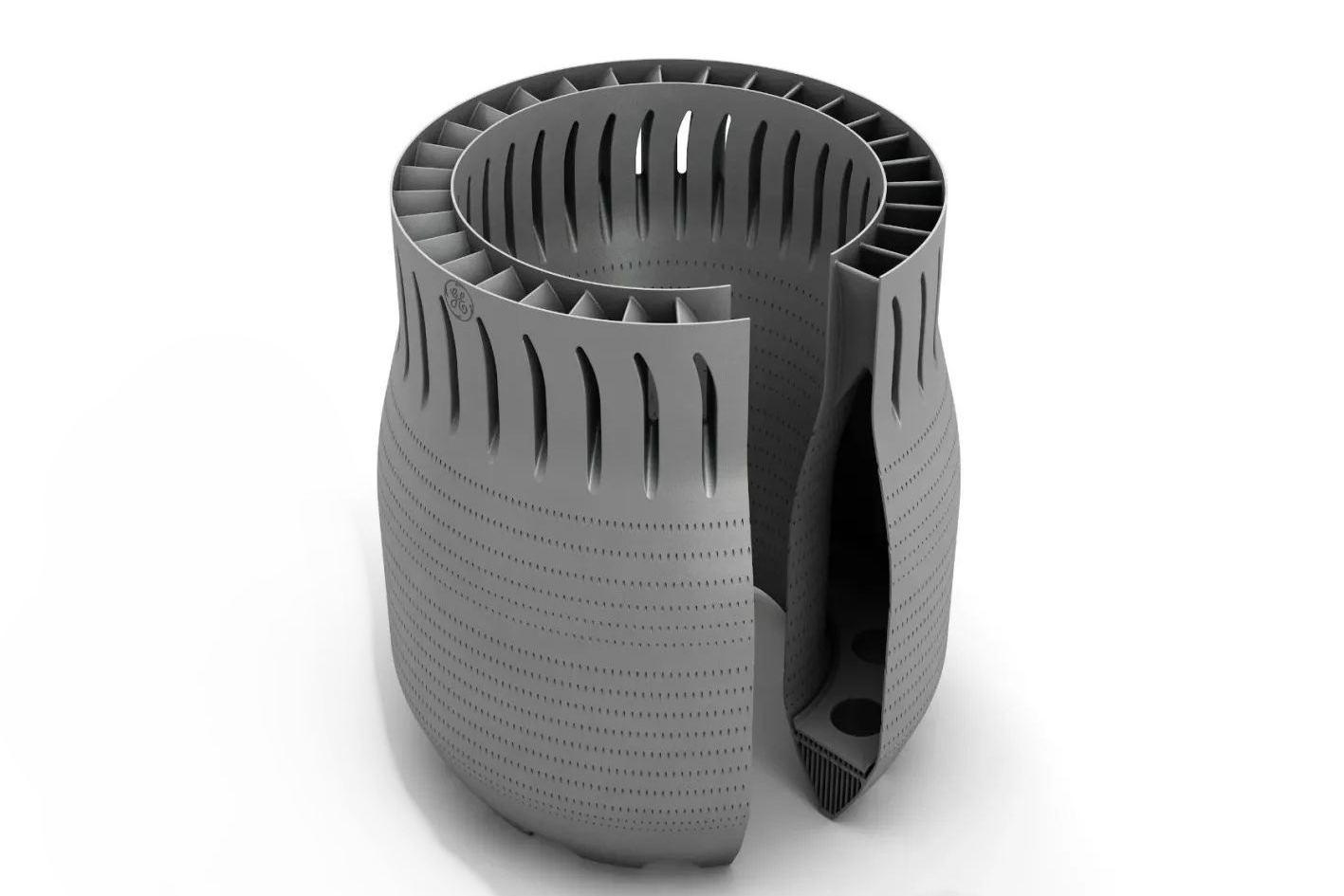

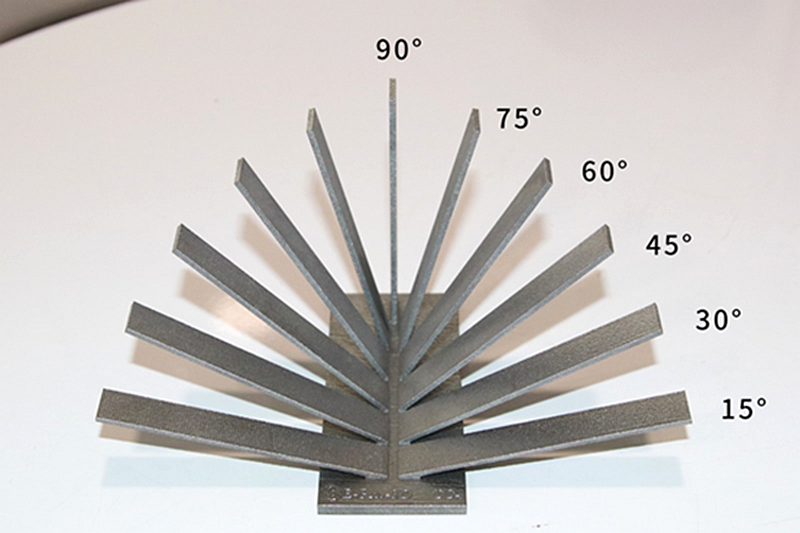

Additive Manufacturing: Additive manufacturing techniques like Selective Laser Melting (SLM) are increasingly used for prototyping and producing complex parts. This technology allows rapid prototyping, making developing and testing new designs for Wind Power Attachments easier. SLM offers significant flexibility in part design, enabling the creation of intricate lattice structures that can reduce weight while maintaining strength. Additionally, SLM is beneficial for producing lightweight, high-strength components that can be customized for specific applications.

Testing Methods and Equipment for Quality Control

Quality control is crucial in manufacturing Wind Power Attachments, as they are responsible for maintaining the integrity of the wind turbine system. Several testing methods ensure the attachments meet the required strength, durability, and reliability specifications.

Non-Destructive Testing (NDT)

Non-destructive testing methods, such as ultrasonic testing and X-ray inspection, detect internal defects, such as cracks or voids, without damaging the components. Ultrasonic testing is beneficial for assessing the internal structure of forged or cast components, ensuring no hidden flaws could lead to premature failure. X-ray inspection provides detailed imaging of the internal features, allowing for the identification of any porosity or structural weaknesses.

Mechanical Testing

Mechanical testing, including tensile testing, fatigue testing, and creep testing, is conducted to assess the mechanical properties of the components. These tests help determine whether the Wind Power Attachments can withstand the forces they will be subjected to during their service life. Fatigue testing is essential, as it simulates the fluctuating loads the attachments will face due to wind gusts. In contrast, tensile testing measures the maximum load the material can handle before failure.

Chemical Composition Verification

Techniques like Glow Discharge Mass Spectrometry (GDMS) are used to verify the chemical composition of the alloys, ensuring that the materials meet the required corrosion resistance and strength standards. GDMS provides highly accurate data on trace elements, which is critical for ensuring that the superalloys have the suitable properties for optimal performance.

Industries and Applications of Wind Power Attachments

Wind Power Attachments are primarily used in the renewable energy sector, specifically in wind turbine manufacturing. They play a key role in ensuring the structural stability of wind turbines, which are crucial for producing clean, renewable energy. These components are responsible for securely attaching various parts of the turbine, such as the rotor hub, nacelle, tower, and blades, ensuring the turbine can withstand regular and extreme weather conditions.

Wind Power Attachments are also used in offshore wind farms, where corrosion resistance is critical due to the harsh marine environment. Offshore wind turbines are subjected to higher stress levels than their onshore counterparts, as they must contend with waves, saltwater, and powerful winds. In these applications, Wind Power Attachments made from high-performance alloys such as Inconel and Hastelloy ensure the longevity and reliability of the turbine structures, contributing to efficient and consistent energy production.

Post-processing and Surface Treatments for Wind Power Attachments

Post-processing and surface treatments are essential for improving the performance and lifespan of Wind Power Attachments. These treatments help enhance the components' resistance to corrosion, fatigue, and wear, ultimately ensuring the safety and reliability of wind energy systems.

Heat Treatment: This process helps refine the alloy's grain structure, enhance mechanical properties, and relieve internal stresses that may have developed during manufacturing. Heat treatment ensures the attachments maintain strength and toughness, even when subjected to high loads and temperature variations.

Hot Isostatic Pressing (HIP): HIP is used to eliminate porosity and improve the density and strength of cast parts, ensuring that the components can withstand high stress and fatigue during their operational life. The use of HIP in post-processing helps reduce the likelihood of crack initiation and propagation, significantly improving the fatigue life of the components.

Coatings: Corrosion-resistant coatings, such as Thermal Barrier Coatings (TBC) and anti-corrosion paints, are applied to protect the attachments from environmental degradation, particularly in offshore applications where saltwater exposure is a concern. TBCs are typically ceramic-based coatings that help insulate the base material from high temperatures, reducing thermal stress and extending component life.

Rapid Prototyping and Verification of Wind Power Attachments

Rapid Prototyping Process

Rapid prototyping is integral to developing Wind Power Attachments, allowing manufacturers to test and refine designs before full-scale production. This approach accelerates the product development cycle, enabling faster iteration and validation of design concepts, which is critical in the highly competitive renewable energy sector.

3D Printing

Superalloy 3D printing, such as Selective Laser Melting (SLM), produces prototypes for quick testing and validation. This process allows for the creation of complex geometries that can be tested under real-world conditions. Using 3D Printing for rapid prototyping significantly reduces the time required to move from concept to prototype, allowing manufacturers to identify potential issues early in the design process.

CNC Machining

CNC machining is also used in prototyping to produce high-precision components identical to their production counterparts, ensuring that the prototypes accurately represent the final product. CNC machining allows for the production of prototypes with tight tolerances, ensuring that they meet the performance requirements before moving on to mass production.

Importance of Verifying Samples

Verifying samples is crucial to ensure that the Wind Power Attachments perform as expected in real-world applications. Testing prototype components for mechanical strength, durability, and resistance to environmental factors allows manufacturers to identify and address any issues early in the development process. Verifying samples through rigorous testing methods, such as tensile and fatigue testing, provides valuable data that helps optimize the design and manufacturing processes, ensuring that the final components meet or exceed industry standards.

Verifying the prototypes also helps identify the optimal material selection and heat treatment processes to achieve the best strength, weight, and corrosion resistance combination. This step is essential to minimize the risk of failure in critical applications and ensure the longevity and reliability of wind energy systems.

Five Common FAQs About Wind Power Attachments Manufacturing

What Materials Are Commonly Used in Wind Power Attachments?

High-temperature alloys such as Inconel, Hastelloy, Stellite, and Titanium are commonly used for their excellent strength, corrosion resistance, and durability. These alloys are designed to maintain performance even when exposed to extreme temperatures and mechanical stresses.

How Is Corrosion Resistance Achieved in Wind Power Attachments?

Corrosion resistance is achieved through high-performance alloys and protective coatings, such as Thermal Barrier Coatings (TBC) and anti-corrosion paints. These coatings protect the metal from harsh environmental conditions, including exposure to moisture, salt spray, and fluctuating temperatures.

What Testing Methods Are Used for Quality Control?

Non-destructive testing (NDT), mechanical testing, and chemical composition verification are used to ensure the quality and reliability of Wind Power Attachments. NDT methods like ultrasonic testing and X-ray inspection help detect internal defects, while mechanical testing assesses properties like tensile strength, fatigue resistance, and creep behavior.

Why Is Rapid Prototyping Important in Manufacturing Wind Power Attachments?

Rapid prototyping allows for testing and validating new designs, helping reduce lead times, identify issues early, and improve the final product's performance. Manufacturers can optimize the design by creating and testing prototypes using additive manufacturing and CNC machining before moving to full-scale production, minimizing costs and delays.

What Are the Benefits of Post-Processing for Wind Power Attachments?

Post-processing methods like heat treatment and HIP improve the mechanical properties, strength, and reliability of Wind Power Attachments, ensuring they can endure harsh operational environments. Surface treatments such as coatings enhance corrosion resistance, making the components suitable for onshore and offshore wind applications.

Wind Power Attachments are essential components that contribute to the efficiency and reliability of renewable energy plants. By utilizing high-strength alloys, advanced manufacturing processes, and thorough quality control measures, manufacturers can produce components that help maximize the performance and longevity of wind turbines. At Neway Precision Works Ltd, our expertise in high-temperature alloys and cutting-edge manufacturing technologies ensures that our Wind Power Attachments meet the rigorous demands of the renewable energy sector. Our commitment to innovation and quality helps drive the advancement of renewable energy technology, contributing to a sustainable and greener future for all.