What is CFD Analysis, and How Does Superalloy Parts Manufacturing Benefit from It?

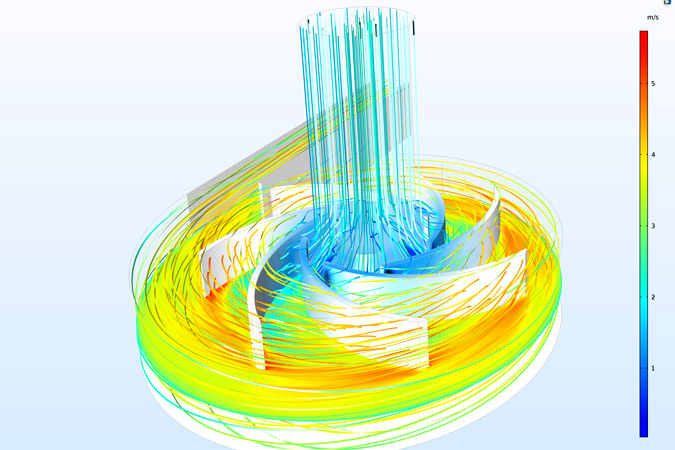

Computational Fluid Dynamics (CFD) is a powerful tool for simulating and analyzing fluid flow, heat transfer, and associated physical phenomena in engineering applications. In superalloy manufacturing, CFD ensures that casting, forging, machining, and 3D printing achieve the highest quality and performance standards. CFD allows engineers to visualize the flow of materials, temperature distributions, and other crucial process parameters. This ensures that critical components used in aerospace, energy, and chemical industries are produced with minimal defects and optimal efficiency. The use of CFD has become increasingly significant in superalloy production, where precise control over heat treatment, material flow, and solidification is crucial for achieving the desired properties of high-temperature-resistant parts.

Overview of Superalloy Parts and Processes Requiring CFD Analysis

In superalloy manufacturing, a wide range of processes benefit from CFD analysis. The precision required for these processes and the necessity of defect-free components make CFD a crucial step. Vacuum Investment Casting relies on CFD to simulate uniform mold filling, preventing issues like porosity and ensuring consistent part quality. Single Crystal Casting uses CFD to manage the directional solidification required to form single crystals without grain boundaries.

Equiaxed Crystal Casting benefits from CFD simulations that help control cooling rates, resulting in uniform grain structures. Directional Casting also utilizes CFD to control thermal gradients and optimize the solidification process for improved mechanical properties.

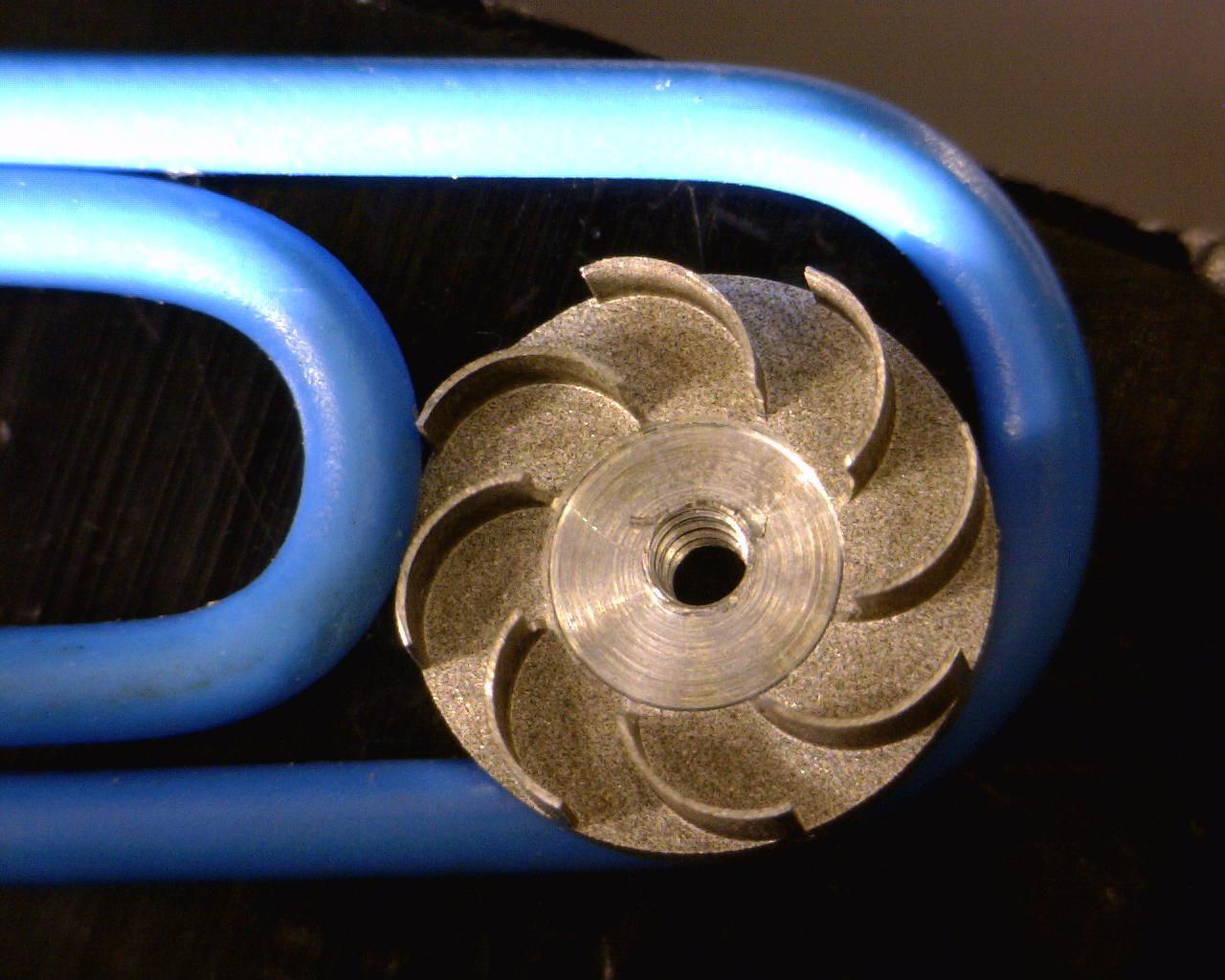

Powder Metallurgy Turbine Discs involve CFD to analyze powder flow during compaction and sintering, ensuring homogeneous properties in the final product. Forging processes, including isothermal and precision forging, use CFD to predict material flow and minimize forging defects.

In CNC Machining, CFD helps optimize coolant flow, ensuring consistent tool life and preventing heat-induced defects in superalloy components. Finally, 3D Printing of Superalloys (Additive Manufacturing) leverages CFD to ensure uniform material deposition and eliminate weak areas or voids during printing, leading to more vital parts with fewer internal flaws.

Benefits of Different Superalloys from CFD Analysis

CFD analysis provides distinct advantages for different types of superalloys used in high-temperature and high-stress applications.

Inconel Alloys

Inconel Alloys, such as Inconel 718 and Inconel 625, are known for their high strength and oxidation resistance. CFD simulations help optimize the mold filling and solidification processes, ensuring that complex geometries are properly formed without internal voids or cold shuts. This optimization is critical to meet the performance demands of aerospace turbine components.

CMSX Series Single Crystal Alloys

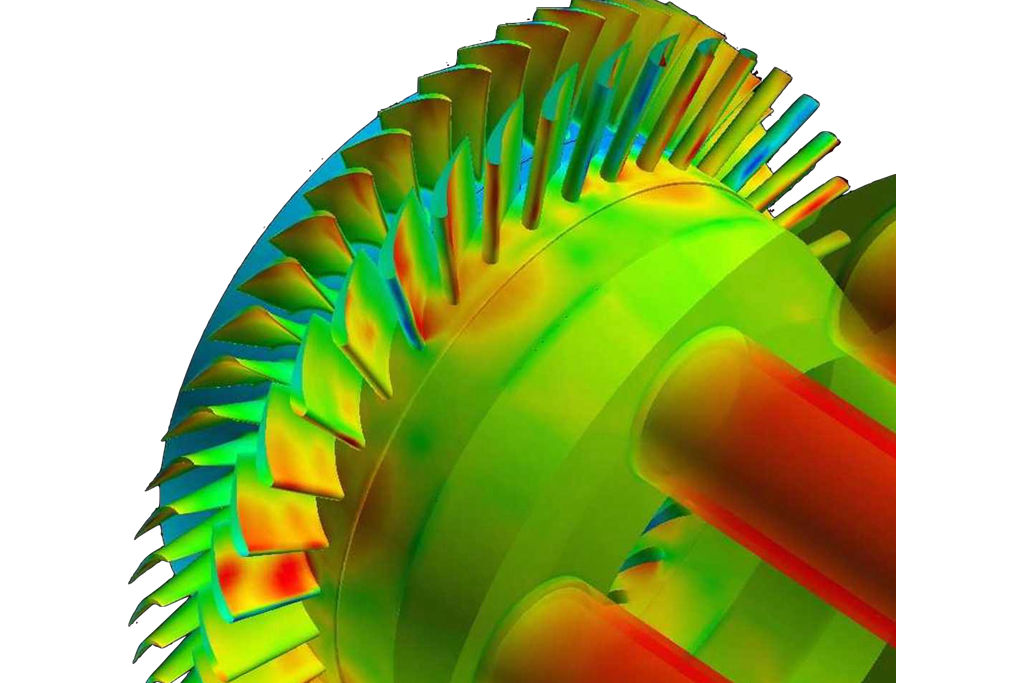

For CMSX Series Single Crystal Alloys, CFD analysis is crucial for ensuring that the temperature gradients during solidification are controlled precisely to grow a defect-free single crystal. Single crystal components are primarily used in turbine blades, where eliminating grain boundaries is essential for increasing creep resistance. CFD also helps in predicting how to adjust cooling rates and thermal gradients to achieve uniform crystal growth throughout the component.

Monel and Hastelloy Alloys

Monel and Hastelloy Alloys benefit from CFD in managing casting and post-casting thermal processes. These alloys are used in applications with essential corrosion resistance, such as chemical processing equipment. CFD ensures that defects like porosity are minimized during casting, thereby enhancing corrosion resistance. CFD also helps fine-tune heat treatment processes to achieve the optimal material properties needed in these aggressive environments.

Titanium Alloys

Titanium Alloys, such as Ti-6Al-4V, are often used in aerospace for their excellent strength-to-weight ratio and corrosion resistance. CFD is essential in simulating heat distribution during casting and forging, ensuring consistent temperature management. This is crucial to maintain strength and toughness while avoiding the formation of undesirable phases or defects.

Rene Alloys

For Rene Alloys, used primarily in gas turbines, CFD aids in optimizing cooling rates during forging and powder metallurgy processes. Rene alloys are prized for their high-temperature strength and oxidation resistance, and CFD ensures that the forging and sintering processes are optimized to yield these desired properties.

Stellite and Nimonic Alloys

Stellite and Nimonic Alloys also benefit significantly from CFD, particularly in optimizing wear resistance and oxidation control. These alloys are used in high-wear applications like cutting tools and turbine engine components. CFD helps model thermal conductivity and cooling processes to enhance mechanical properties like wear resistance, which is vital for extending the service life of these parts.

Comparison of CFD Benefits Across Post-Processing Methods

Different post-processing methods in superalloy manufacturing, such as Hot Isostatic Pressing (HIP), Heat Treatment, and Thermal Barrier Coating (TBC), each benefit uniquely from CFD analysis.

Hot Isostatic Pressing (HIP)

For Hot Isostatic Pressing, CFD allows for a detailed analysis of pressure and temperature distribution throughout the part, ensuring uniform densification. This helps eliminate any remaining internal voids, thereby improving the superalloy components' fatigue life and overall durability.

Heat Treatment

In Heat Treatment, CFD modeling predicts the temperature gradients within the superalloy during heating and cooling cycles. Accurate modeling of these gradients is crucial for optimizing the microstructure, minimizing residual stresses, and reducing the risk of cracking. Manufacturers can ensure consistent and repeatable results by understanding how the heat treatment process impacts different sections of the part.

Thermal Barrier Coating (TBC)

For Thermal Barrier Coating, CFD is used to analyze the coating process and ensure uniform coverage. The thermal barrier must be applied consistently to protect the underlying superalloy from high operating temperatures. CFD simulations help understand the deposition of coatings and identify potential issues like uneven layers or improper adhesion, which could reduce the effectiveness of the thermal barrier.

Superalloy Welding

Superalloy Welding also benefits from CFD by allowing engineers to predict the impact of welding heat input on the part's microstructure and properties. CFD modeling helps ensure that welding does not introduce unacceptable residual stresses or cause changes in grain size that could compromise the alloy's mechanical performance.

Electrical Discharge Machining (EDM)

Finally, Electrical Discharge Machining (EDM) uses CFD to simulate fluid flow in the dielectric medium, impacting the final cut's quality. CFD ensures that debris is effectively removed during machining, resulting in a smoother finish and reducing the risk of thermal cracking in the superalloy component.

Role of CFD Analysis in Testing Superalloy Components

CFD (Computational Fluid Dynamics) plays a crucial role in testing and validating superalloy components by simulating operational conditions and enhancing physical testing. These simulations improve testing efficiency, guide quality assurance, and help optimize component designs.

Tensile and Fatigue Testing Augmentation

CFD simulations predict stress points and regions most likely to fail under tensile and fatigue conditions. These insights enhance the efficiency of physical tests by identifying areas of concern and optimizing testing protocols. Integrating CFD analysis with fatigue testing enables engineers to anticipate failure modes and refine components to meet performance standards.

Thermal Analysis

CFD is particularly valuable for thermal analysis, allowing manufacturers to simulate the thermal behavior of superalloy parts under operational conditions. Simulations predict how components respond to thermal cycling and steady-state high temperatures. These predictions are cross-referenced with thermal physical property tests to validate performance. This approach ensures the reliability of parts like turbine blades and engine components operating under extreme thermal stress.

Defect Visualization and X-ray/CT Scan Complements

CFD complements X-ray and CT scan inspections by simulating the solidification process during casting to identify defect-prone areas, such as porosity or shrinkage cavities. Comparing CFD results with X-ray or CT data verifies whether the manufacturing process avoided these flaws, enhancing quality assurance.

Dynamic and Static Fatigue Testing

CFD simulations model the loads and thermal conditions components face during operation, aiding in dynamic and static fatigue testing. By simulating cyclic loading conditions, CFD helps identify failure-prone areas, enabling engineers to modify designs or manufacturing processes to increase fatigue life. This proactive approach improves reliability in critical applications, such as aerospace and power generation.

CFD is an invaluable tool for integrating simulation with physical testing, optimizing superalloy component performance, and ensuring quality in high-stress applications.

Industry Applications and Benefits of CFD in Superalloy Manufacturing

CFD analysis is critical across various industries that depend on superalloy components to perform reliably under extreme conditions.

Aerospace and Aviation

In the Aerospace and Aviation sector, CFD is essential in optimizing the manufacturing of turbine blades and other engine components. These parts must withstand extreme temperatures and stress, and CFD ensures that the casting, forging, and coating processes yield components that meet stringent requirements. Components like superalloy jet engine components greatly benefit from CFD optimization in their design and manufacturing processes.

Power Generation

In Power Generation, particularly in gas and steam turbines, superalloy components must function under high-temperature and high-pressure conditions for prolonged periods. CFD helps ensure these parts have minimal defects and optimal microstructure, increasing efficiency and lifespan. For example, applying CFD in manufacturing superalloy heat exchanger parts helps optimize thermal performance and minimize potential areas of failure.

Oil and Gas

In the Oil and Gas industries, CFD controls flow behavior while manufacturing valves, fittings, and other components that must resist both high-pressure and corrosive environments. Superalloy components such as high-temperature alloy pump components are optimized using CFD to withstand harsh conditions, ensuring reliability and safety over prolonged operational periods.

Automotive

Although less common, automotive applications involve superalloy components in high-performance engines and turbochargers. CFD helps optimize the heat treatment and casting processes to produce lightweight and thermally stable parts, essential for achieving maximum performance. Parts such as superalloy transmission component assemblies benefit from CFD to ensure efficient and reliable performance in high-stress environments.

Chemical and Energy Industries

In the Chemical Processing and Energy industries, CFD aids in designing superalloy components that resist aggressive corrosion while ensuring structural integrity. Components like heat exchangers, mixers, and reaction vessels require a precise manufacturing process that guarantees both durability and resistance to harsh chemicals, all of which CFD simulations support.

Military and Defense

The Military and Defense sector also benefits from CFD in superalloy manufacturing, as components for rockets, propulsion systems, and other defense-related technologies require highly reliable, durable, and temperature-resistant materials. CFD analysis ensures these parts can handle the extreme environments they are subjected to without compromising on performance, enhancing the capabilities of components like superalloy armor system parts.

FAQs

What are the key benefits of using CFD analysis in single crystal superalloy casting?

How does CFD help in optimizing post-processing methods like HIP and heat treatment?

In which industries is CFD analysis most beneficial for superalloy components?

What role does CFD play in minimizing casting defects like porosity and inclusions?

How does CFD simulation complement physical testing methods for superalloy parts?