WAAM 3D Printing for Large High-Temperature Alloy Structures

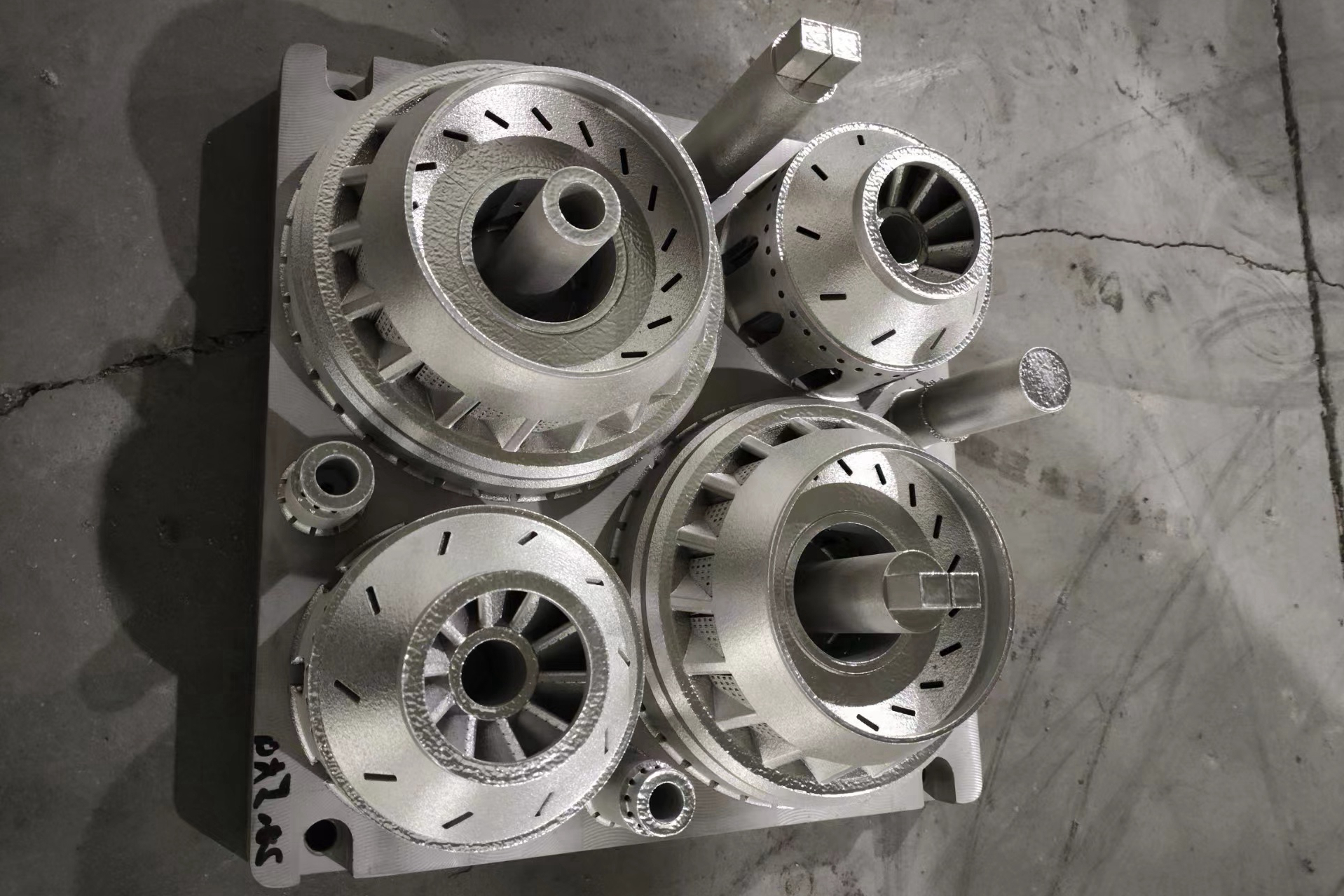

Wire Arc Additive Manufacturing (WAAM) is an advanced 3D printing technique that utilizes an electric arc welding process to deposit metal wire, layer by layer, to build large-scale, high-performance structures. Unlike traditional manufacturing methods, WAAM enables the production of highly complex geometries with relatively low material waste and high deposition rates. It makes it especially valuable for the fabrication of large, high-temperature alloy parts used in industries where superior mechanical properties and resistance to extreme conditions are crucial.

WAAM has seen increased adoption in aerospace, power generation, oil and gas, and chemical processing, where components must endure high temperatures, corrosive environments, and extreme mechanical stress. Large-scale parts from high-performance materials like Inconel, Monel, Hastelloy, and Titanium are critical to these sectors. WAAM facilitates the efficient fabrication and repair of such parts, allowing for faster production times, reduced costs, and improved material utilization.

The ability to manufacture large, complex parts quickly and cost-effectively transforms how industries approach the production of critical components. The high deposition rates inherent to WAAM make it an ideal choice for producing significant components that would otherwise be too time-consuming or costly to produce with conventional manufacturing techniques. As industries continue to push the boundaries of performance and efficiency, WAAM is set to play an increasingly important role in the future of high-temperature alloy manufacturing.

Manufacturing Process of WAAM 3D Printing

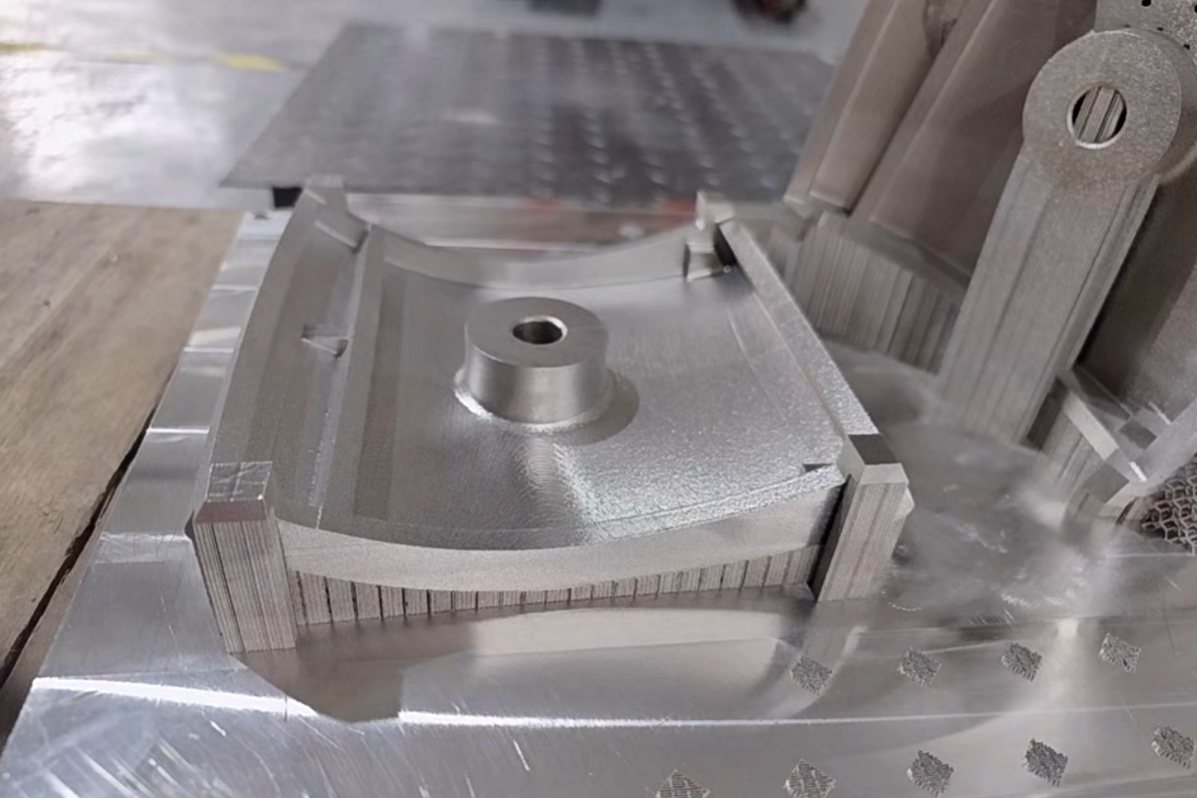

The WAAM 3D printing begins with a metal wire fed into a welding torch. The torch produces an electric arc that melts the wire; as it melts, the material is deposited layer by layer onto a substrate or existing component. This layer-by-layer deposition is controlled with high precision, allowing for creating parts with intricate geometries. The process uses a variety of welding techniques, including Gas Metal Arc Welding (GMAW), Tungsten Inert Gas (TIG) welding, or Plasma Arc Welding (PAW), depending on the specific material and desired properties.

One of the key advantages of WAAM is its ability to handle large parts. Unlike traditional 3D printing technologies, which often struggle with larger-scale components, WAAM is particularly suited for producing sizable structures made from high-temperature alloys. The process can deposit metal wire much faster, making it ideal for applications where speed and efficiency are critical. Furthermore, because WAAM uses a heat source to melt the material, it also allows for the direct bonding of high-performance alloys, like Inconel and Titanium, without needing complex pre-treatment steps.

The WAAM process also provides flexibility in terms of material choice. By using metal wire as the feedstock, WAAM can easily accommodate a range of high-temperature alloys, including those with complex compositions, ensuring that the printed parts meet the stringent performance criteria required for extreme conditions. This versatility makes WAAM a valuable tool for repairing damaged components, enabling the restoration of critical parts that might otherwise require costly replacements. In addition, the ability to combine WAAM with other techniques like superalloy CNC machining or superalloy precision forging allows for the creation of high-performance parts capable of withstanding extreme environments.

Suitable Printing Materials for WAAM 3D Printing

The materials used in WAAM (Wire Arc Additive Manufacturing) 3D printing are a key factor in determining the performance and application of the printed parts. High-temperature alloys, such as Inconel, Monel, Hastelloy, and Titanium, are often used in industries where parts are subjected to extreme environments. These materials offer exceptional strength and thermal and corrosion resistance, making them ideal for power generation, aerospace, and chemical processing applications.

Inconel Alloy

Inconel alloys are a group of nickel-chromium-based superalloys known for their excellent resistance to oxidation, corrosion, and high-temperature creep. These alloys are often used in demanding applications, such as turbine blades, combustion chambers, and exhaust systems in the aerospace and power generation industries. Inconel alloys, including Inconel 600, Inconel 718, and Inconel 625 have high strength and are resistant to thermal fatigue, making them ideal for repairing or manufacturing parts exposed to high heat.

Monel Alloy

Monel alloys, including Monel 400 and Monel K500, are known for their exceptional corrosion resistance, especially in marine environments. These alloys are typically used in applications that require resistance to saltwater, such as marine engine components, valve parts, and heat exchangers. Monel’s resistance to pitting, crevice corrosion, and stress corrosion cracking makes it a reliable material for underwater and chemical processing applications.

Hastelloy Alloy

Hastelloy alloys, such as Hastelloy C-276 and Hastelloy C-22, are a family of nickel-based alloys designed to withstand high temperatures and aggressive chemical environments. These materials are commonly used in chemical processing, power generation, and nuclear energy, where resistance to corrosive environments is crucial. Hastelloy’s ability to resist stress corrosion cracking and maintain structural integrity under extreme conditions makes it ideal for applications like reactor vessel components, distillation systems, and heat exchangers.

Titanium Alloy

Titanium alloys, such as Ti-6Al-4V, Ti-3Al-2.5Sn, and Ti-6Al-2Sn-4Zr, are prized for their excellent strength-to-weight ratio, corrosion resistance and ability to perform at high temperatures. These alloys are frequently used in aerospace and automotive applications, where performance and weight reduction are key factors. Titanium’s resistance to oxidation, high tensile strength, and low density make it ideal for manufacturing components like jet engine parts, structural components, and automotive engine parts. Titanium alloys are also used in medical devices due to their biocompatibility.

Here’s your content with embedded anchor text referencing the relevant post-processing services:

Post-Processing for WAAM 3D Printed Parts

Once the WAAM printing process is complete, post-processing is often necessary to ensure the printed parts meet the required mechanical and thermal properties. Several post-processing techniques are commonly used to enhance the strength, durability, and surface finish of WAAM 3D-printed parts.

Heat Treatment

Heat treatment is one of the most common post-processing steps for WAAM parts, particularly when working with high-temperature alloys. Heat treatment processes, such as solution annealing, aging, and stress relief, help optimize the material's microstructure, improving its strength, ductility, and resistance to fatigue. By adjusting the temperature and time during heat treatment, manufacturers can achieve the desired material properties tailored to the specific application.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) removes any residual porosity left from the additive manufacturing process. This post-processing technique involves placing the printed part in a high-pressure, high-temperature environment, which compacts the material and eliminates voids, improving its overall density. HIP enhances the mechanical properties of the material, such as tensile strength and fatigue resistance, making the part more suitable for high-performance applications.

Superalloy CNC Machining and EDM

Once the part is printed, precise CNC machining or Electrical Discharge Machining (EDM) may be used to achieve the final geometries and surface finish required for the component. This post-processing step ensures that the part meets the tight tolerances and specifications necessary for its intended application. CNC machining and EDM allow for fine-tuning complex geometries, ensuring all features are produced to the correct dimensions.

Surface Treatment and Coatings

Surface treatment is another important post-processing step, especially for parts exposed to high temperatures and harsh environments. Thermal Barrier Coatings (TBC) are often applied to high-temperature alloy parts to provide an insulating layer that protects the component from thermal degradation. These coatings help extend the part's lifespan by reducing the oxidation rate and thermal cycling damage. Other surface treatments, such as shot peening or coating with corrosion-resistant materials, can also be applied to improve the wear resistance and longevity of the printed part.

Testing and Quality Control for WAAM Parts

Ensuring the quality and performance of WAAM 3D printed parts is critical, particularly when they are used in high-stakes applications such as aerospace, power generation, and chemical processing. Several testing methods are employed to verify the material properties and ensure that the parts meet the required mechanical strength, thermal resistance, and dimensional accuracy standards.

Non-Destructive Testing (NDT)

Non-destructive testing methods, such as X-ray inspection, ultrasound, and computed tomography (CT) scanning, are commonly used to detect internal defects like voids, cracks, or inclusions that may compromise the integrity of the printed part. These techniques allow manufacturers to evaluate the part without damaging it, ensuring any potential issues are identified before the part is delivered.

Mechanical Testing

Tensile testing, hardness testing, and fatigue testing are commonly used to evaluate the mechanical properties of WAAM parts. These tests assess the material's strength, ductility, and fatigue resistance under stress. The results help ensure that the part will perform reliably under the demanding conditions it will face in its intended application.

Material Composition Testing

The chemical composition of the printed part is also tested to verify that it matches the specifications for the selected alloy. Techniques like Glow Discharge Mass Spectrometer (GDMS) and Inductively Coupled Plasma Optical Emission Spectrometer (ICP-OES) are used to analyze the material's elemental composition and ensure it meets the required standards.

Microstructural Analysis

Scanning Electron Microscopy (SEM) and Metallographic Microscopy are used to examine the microstructure of WAAM printed parts. These techniques help identify defects in the material’s grain structure or undesirable phases that may affect its performance. This type of analysis is crucial for ensuring that the part’s properties align with the expectations for high-temperature and high-stress applications.

Thermal Performance Testing

Simultaneous Thermal Analysis (STA) is often employed to assess the printed part's heat resistance and thermal stability. This test evaluates the material’s ability to withstand thermal cycling and high-temperature exposure, which is particularly important for components used in aerospace, power generation, and chemical processing environments.

Industries and Applications of WAAM 3D Printing for High-Temperature Alloy Parts

WAAM 3D printing is transforming the manufacturing of large, complex, and high-performance components used in industries where durability and resistance to extreme conditions are paramount. Below are some key industries and applications where WAAM technology is making a significant impact:

Aerospace and Aviation

WAAM 3D printing manufactures turbine blades, engine components, and exhaust systems for aerospace applications. WAAM technology enhances performance and reduces the cost of manufacturing aircraft components by enabling the production of lightweight yet durable parts with complex geometries. Significant structural components such as wing spars and fuselage parts are also being printed using WAAM, reducing lead times and material waste. Superalloy exhaust system parts can be manufactured efficiently using this technology, ensuring high performance and reduced production costs.

Power Generation

WAAM manufactures turbine blades, combustion chambers, and heat exchangers in the power generation sector. The ability to quickly print large parts with high-temperature alloys like Inconel and Hastelloy reduces production costs and improves power plant components' efficiency. The ability to print large and durable components in-house reduces dependency on traditional casting methods, enhancing flexibility and cost-efficiency.

Oil and Gas

WAAM is increasingly used to repair and manufacture large, corrosion-resistant parts for the oil and gas industry. Components such as valves, pumps, and downhole tools are printed using materials like Monel and Inconel, which offer excellent resistance to corrosion and high temperatures. It makes WAAM an ideal technology for extending the life of critical parts in harsh operating environments. For example, pump components can be fabricated quickly, reducing downtime in the oil extraction process.

Chemical Processing

Chemical reactors, heat exchangers, and piping systems often require components made from high-performance alloys. WAAM allows for creating complex geometries and significant components with the required resistance to corrosive chemicals and high temperatures, making it ideal for use in the chemical processing industry. High-temperature alloys like Hastelloy and Inconel can be utilized to ensure the durability and efficiency of critical components such as reactor vessel components and piping systems.

Marine

The marine industry uses WAAM to manufacture significant engine components, heat exchangers, and offshore structures. Monel and Inconel alloys are commonly used for their superior resistance to seawater corrosion, ensuring that marine components can withstand the harsh conditions of the ocean environment. Superalloy heat exchanger parts are essential in ensuring the longevity of maritime systems exposed to corrosive conditions.

Automotive

WAAM technology is also being explored in the automotive industry to produce lightweight, high-performance components such as exhaust systems and engine parts. Titanium and Inconel alloys are frequently used for their high strength-to-weight ratios and thermal stability, helping to improve vehicle performance while reducing overall weight. With superalloy transmission component assemblies, manufacturers are able to push the boundaries of performance in high-demand automotive environments.

FAQs

What are the key benefits of using WAAM for manufacturing large, high-temperature alloy parts?

How does WAAM compare to traditional manufacturing methods for large parts?

Can WAAM 3D printing be used to repair high-temperature alloy components?

What are the challenges involved in using WAAM for high-performance alloy parts?

What post-processing steps are necessary for WAAM 3D-printed parts to meet industry standards?