Superalloy Transmission Component Assemblies Manufacturing Hub

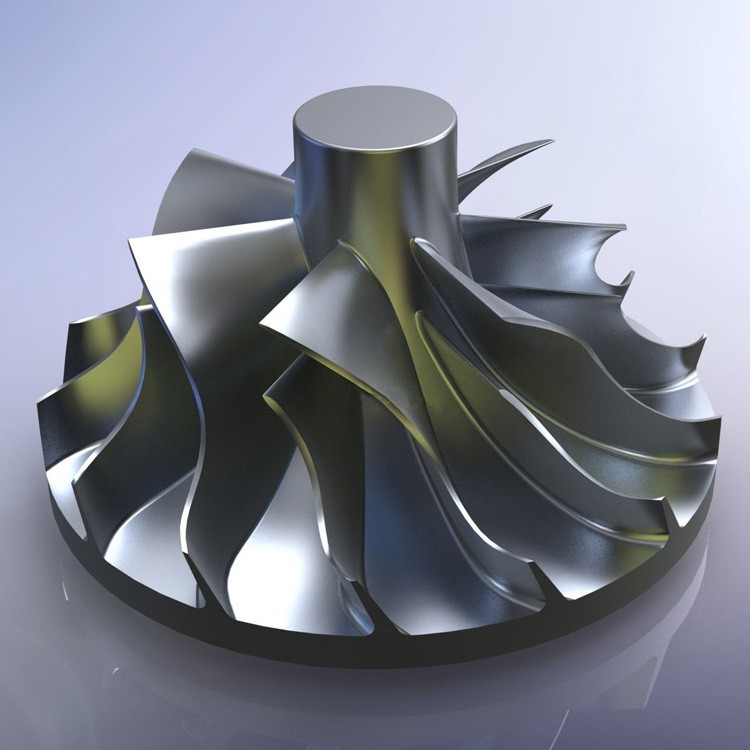

Transmission systems are critical to the functionality and efficiency of various machines across industries like aerospace, automotive, power generation, and defense. These systems, composed of multiple assemblies, are responsible for transferring power effectively, managing mechanical loads, and ensuring consistent performance. Among the many materials used for these vital assemblies, superalloys are among the most reliable. Due to their excellent mechanical properties, high-temperature stability, and resistance to wear and corrosion, superalloys are often the material of choice for high-performance transmission components.

In this blog, we will explore the different aspects of manufacturing superalloy transmission component assemblies—ranging from materials, manufacturing techniques, and prototyping methods to post-processing, quality inspection, and industry applications. Whether you are in aerospace, automotive, or another sector requiring high-quality transmission assemblies, understanding the benefits of superalloy components is critical to optimizing performance.

Induction of Transmission Component Assemblies

Transmission component assemblies transmit mechanical power from one system to another. In critical industries such as aerospace and automotive, these components must be designed to withstand extreme temperatures, high loads, friction, and constant operational stress. These transmission components include gears, couplings, shafts, and bearings, which must function efficiently under the demanding conditions of their respective applications.

To fulfill these rigorous requirements, manufacturers often turn to superalloys—a group of advanced materials known for their high mechanical strength, oxidation resistance, and ability to retain properties at high temperatures. Superalloys are generally based on nickel, cobalt, or iron, offering specific advantages. These materials are essential in aerospace, where reliability and performance can mean the difference between mission success and failure.

Superalloys Used in Transmission Component Assemblies

Superalloys are high-performance alloys engineered to maintain mechanical properties even in extreme environments. Three primary types of superalloys are used in transmission component manufacturing: nickel-based, cobalt-based, and iron-based. Here, we explore the three fundamental categories of superalloys commonly used, along with three corresponding grades for each.

Nickel-Based Superalloys

Nickel-based superalloys are widely used in high-temperature applications due to their ability to maintain strength, oxidation resistance, and creep resistance. They are commonly employed for critical transmission components such as shafts, gears, and couplings.

Inconel 718: Known for its strength, durability, and oxidation resistance, Inconel 718 is used for high-performance applications such as turbine shafts and aerospace gears.

Inconel 625: Featuring excellent fatigue resistance and strength, Inconel 625 is often used in components exposed to extreme thermal and mechanical stress.

Inconel X-750: Inconel X-750 offers a great combination of tensile strength and thermal resistance, making it ideal for gear assemblies and couplings used in aerospace and industrial powertrains.

Cobalt-Based Superalloys

Cobalt-based superalloys are known for their superior wear resistance, especially when components are exposed to friction, heat, and corrosion.

Stellite 6B: Stellite 6B is a cobalt-chromium alloy with excellent hardness, making it perfect for high-stress applications like gears and bearings in industrial and aerospace transmissions.

Stellite 21: Stellite 21 provides wear resistance and high-temperature strength, making it ideal for components subjected to aggressive environments.

Stellite 25: With its superior toughness, Stellite 25 is used for gears and components that must withstand heavy loads while maintaining dimensional integrity.

Iron-Based Superalloys

Iron-based superalloys offer a cost-effective solution for many applications that demand high strength and stability, especially in automotive and industrial environments.

Nimonic 75: This iron-nickel alloy provides a balance of toughness and resistance to oxidation, making it suitable for gears and shafts that operate at high temperatures.

Nimonic 90: Nimonic 90 is known for its tensile strength and fatigue resistance and is frequently used in automotive transmission systems.

Nimonic 263: This superalloy combines excellent thermal stability with fatigue resistance, making it ideal for high-temperature automotive components.

Transmission Component Assemblies Manufacturing Process

Manufacturing superalloy transmission component assemblies requires various advanced methods to achieve the necessary strength, precision, and reliability. These include vacuum investment casting, powder metallurgy, and precision forging, each offering specific benefits in producing components for high-performance applications.

Vacuum Investment Casting

Vacuum Investment Casting is particularly effective for producing complex, high-precision superalloy components. The vacuum environment prevents oxidation and ensures minimal porosity, producing components that meet the highest quality standards.

Superalloy Single Crystal Casting

Superalloy Single Crystal Casting allows for the growth of a single crystal within the component, which eliminates grain boundaries and reduces the chances of failure due to thermal fatigue. It is used for components exposed to high stresses, such as turbine blades and key transmission elements.

Equiaxed Crystal Casting

Equiaxed Crystal Casting allows crystals to grow uniformly, providing a balanced microstructure that enhances toughness and strength. This method is used for gears and couplings that need balanced mechanical properties.

Directional Casting

Directional Casting aligns grains in a specific direction by controlling the solidification process, enhancing mechanical properties. This method is beneficial for turbine shafts and other transmission parts.

Special Steel Investment Casting

Special Steel Investment Casting is also used for specific applications, providing strength, wear resistance, and good fatigue life for less critical components.

Powder Metallurgy

Powder Metallurgy (PM) is an efficient and effective manufacturing method for high-performance transmission components. In this process, powdered metal is compacted and sintered to create solid, dense parts with highly uniform properties.

Powder metallurgy allows manufacturers to control the material's microstructure, resulting in superior mechanical performance. The process also ensures minimal material waste, making it highly cost-effective. Powder metallurgy is suitable for producing small, complex components that require high dimensional accuracy and strength, such as small gears and bearing housings.

Precision Forging

Precision Forging is a critical process in manufacturing superalloy transmission component assemblies. Forging involves shaping the metal under compressive forces to enhance its mechanical properties and produce a durable part.

Rough Forging

Rough Forging is the initial stage, where the material is shaped into a rough form before further refinement. Rough Forging provides the foundation for high-strength parts.

Free Forging

Free Forging involves shaping the metal without the use of dies, allowing for flexibility in creating unique geometries. This process is commonly used to produce customized transmission components in small batches.

Isothermal Forging

Isothermal Forging is carried out at a constant temperature, which helps preserve the alloy's microstructure and minimizes defects. It is ideal for producing parts that require precise geometry and strength, such as aerospace gears and couplings.

Prototyping and Low Volume Production for Superalloy Transmission Component Assemblies

Rapid prototyping and small-batch production are critical to developing high-performance transmission component assemblies. These methods enable engineers to validate their designs quickly and identify any necessary adjustments before scaling to total production. Prototyping is also essential for industries that require highly customized components or want to iterate quickly.

3D Printing Service

Additive manufacturing, or 3D printing, allows manufacturers to create complex components layer by layer, directly from digital models. This technique is precious in prototyping, as it allows the creation of intricate designs and reduces the time and cost involved in tooling and molds.

3D printing is especially beneficial for producing lightweight, high-strength components for aerospace and automotive applications, where superalloy transmission parts often need to meet strict weight and performance standards.

Superalloy 3D Printing

Using superalloy powders, 3D printing can create components that possess all of the mechanical properties of cast or forged superalloys. It enables manufacturers to produce prototypes and small-batch parts with the same performance characteristics as production components.

Superalloy 3D printing is beneficial for producing parts like gears, couplings, and complex housings that require strength and precision.

Superalloy CNC Machining

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that allows for high precision. CNC machining is used to refine prototypes, perform detailed finishing on cast or forged parts, and achieve the tight tolerances required in transmission component assemblies.

CNC machining is ideal for low-volume production because it offers the flexibility to create custom designs without investing in expensive tooling. It is commonly used to produce complex superalloy parts that require detailed finishing.

Transmission Component Assemblies Post-Process

Post-processing is a crucial stage in manufacturing superalloy transmission components, ensuring that each part meets the required performance criteria. The most common post-processing methods include:

Heat Treatment: Heat treatment processes like aging, annealing, and quenching are used to improve the material properties, such as strength, toughness, and resistance to thermal fatigue. Heat treatment is essential for aerospace transmission components.

Hot Isostatic Pressing (HIP): HIP eliminates any porosity in the material, ensuring a more uniform microstructure and enhancing the mechanical properties of the finished part. HIP is particularly valuable for safety-critical parts.

Surface Coating: Thermal barrier coatings (TBC) improve surface resistance to oxidation, corrosion, and wear. Surface coatings help extend transmission components' life in harsh environments.

Machining and Polishing: After casting or forging, final machining and polishing operations are performed to achieve the desired surface finish and dimensional accuracy.

Transmission Component Assemblies Quality Inspection

Quality assurance is critical in manufacturing transmission components, especially in high-performance applications like aerospace and automotive industries. Various advanced inspection methods are employed to ensure that each part meets the highest standards of quality and reliability.

Coordinate Measuring Machine (CMM): CMM measures the geometric dimensions of each component with high precision, ensuring that tight tolerances are met, as seen in dimensional accuracy verification of equiaxed crystal casting parts.

X-ray Inspection: X-ray inspection detects internal defects like porosity or voids that could compromise the component's strength or performance, similar to preserving integrity in superalloy castings through non-destructive X-ray testing.

Ultrasonic Testing: Ultrasonic testing is a non-destructive technique used to identify subsurface flaws or inconsistencies in the material, ensuring its integrity; much like water immersion, ultrasonic inspection benefits superalloy CNC-machined parts.

Tensile Testing: Tensile testing evaluates the strength and elasticity of the material by stretching it until it breaks. It helps determine the component's ability to withstand operational stresses, akin to measuring tensile strength in superalloy components using universal testing machines.

Industry Applications of Transmission Component Assemblies

Superalloy transmission components are used in industries that demand high performance, reliability, and durability. Some of the key industries where these components are commonly applied include:

Aerospace: Transmission assemblies used in aircraft engines, turbine systems, and helicopter drivetrains require superalloys to withstand high temperatures and mechanical stresses.

Automotive: High-performance automotive applications, such as sports cars and heavy-duty vehicles, require transmission components resistant to thermal cycling, wear, and fatigue.

Power Generation: Gas turbines and other power generation systems rely on transmission components that maintain mechanical integrity under extreme conditions.

Oil and Gas: Equipment used in oil and gas extraction and processing requires transmission assemblies capable of withstanding corrosive environments, high pressure, and temperature variations.

Defense and Military: Military vehicles, fighter jets, and naval vessels require high-strength, durable transmission components made from superalloys to ensure their reliability in harsh environments.

FAQs About Transmission Component Assemblies Manufacturing

What are the main benefits of using superalloys in transmission component assemblies?

How does vacuum investment casting improve the quality of transmission components?

What role does powder metallurgy play in creating high-performance transmission parts?

How can 3D printing accelerate the prototyping of transmission component assemblies?

What are the most expected quality inspection techniques in transmission component assembly manufacturing?