Superalloy Packaging Machine Accessories Processing Plant

Induction of Packaging Machine Accessories

Packaging machine accessories are essential in industrial settings where machines must perform efficiently under high wear, heat, and chemical exposure. These accessories include parts like sealing jaws, rollers, nozzles, and other critical components that contribute to the smooth functioning of packaging machines. In high-performance industries such as food processing, pharmaceuticals, and consumer goods manufacturing, these parts must withstand constant use and exposure to aggressive cleaning agents. Superalloys, such as Inconel, Hastelloy, and Monel, are frequently chosen for these applications due to their durability, corrosion resistance, and high-temperature stability. These materials ensure that packaging machine accessories endure intense operational demands while maintaining reliability and longevity.

Superalloys Used in Packaging Machine Accessories

Selecting the material for packaging machine accessories is essential to ensure they meet performance requirements under challenging conditions. Three leading superalloy families—Inconel, Hastelloy, and Monel—are commonly used due to their exceptional resistance to heat, corrosion, and mechanical stress.

Inconel Alloys

Inconel alloys, primarily composed of nickel and chromium, are highly resistant to oxidation and maintain strength at elevated temperatures, making them ideal for packaging machine parts exposed to continuous heat. Commonly used Inconel grades include:

Inconel 625: Known for its excellent fatigue strength, oxidation resistance, and weldability, Inconel 625 is frequently used in components that experience temperature cycling and high-stress conditions. It also withstands many corrosive environments, making it a versatile choice for parts that must perform under demanding conditions.

Inconel 718: This alloy provides high strength, durability, and resistance to oxidation and corrosion, making it ideal for packaging machine components that must endure heavy loads and extended operating times. Its mechanical properties ensure durability, especially in applications that require consistent performance over long periods.

Inconel 600: Known for its resistance to both heat and corrosion, Inconel 600 is commonly used in parts exposed to fluctuating temperatures and various chemicals. Its ability to withstand oxidation makes it particularly suited to components in packaging machines that operate at high temperatures.

Hastelloy Alloys

Hastelloy alloys are designed to resist corrosion in aggressive environments, making them ideal for applications in the food and pharmaceutical industries where cleaning agents and acidic substances are commonly encountered.

Hastelloy C-276: Known for its exceptional resistance to pitting, stress corrosion cracking, and oxidation, Hastelloy C-276 is frequently used in components exposed to harsh cleaning agents. Its durability in oxidizing and reducing environments makes it suitable for various applications in packaging machines.

Hastelloy C-22: This alloy provides outstanding resistance to oxidizing and non-oxidizing acids, making it ideal for parts that may come into contact with various chemicals. Its versatility in handling different environments makes Hastelloy C-22 valuable in packaging accessories for the pharmaceutical and chemical processing industries.

Hastelloy X: Known for its high-temperature strength and oxidation resistance, it is often used in applications where parts face extreme heat. Its strength and stability make it a preferred material for heat-sensitive packaging machine accessories.

Monel Alloys

Monel alloys, primarily nickel-copper alloys, are known for their excellent corrosion resistance, especially in acidic and marine environments. Their durability makes them well-suited for packaging machine components exposed to wet or corrosive conditions.

Monel 400: Known for its outstanding resistance to seawater and various acids, Monel 400 is often used in parts that need to withstand acidic cleaning agents and saline environments. Its mechanical properties make it a reliable choice for high-stress applications.

Monel K500: By adding age-hardening properties, Monel K500 combines the corrosion resistance of Monel 400 with enhanced strength, making it suitable for high-stress packaging machine components that also require protection against corrosion.

Monel 404: This alloy is particularly resistant to hydrofluoric acid, making it ideal for parts exposed to aggressive chemicals in food processing or pharmaceutical packaging machines.

These superalloy families provide Neway Precision Works with the ability to manufacture packaging machine accessories that deliver durability, resistance, and performance in demanding industrial environments.

Typical Superalloy Part Manufacturing Process

Manufacturing superalloy packaging machine accessories require specialized processes that ensure precision, strength, and heat resistance. The primary manufacturing methods include vacuum investment casting, powder metallurgy, and precision forging.

Vacuum Investment Casting

Vacuum investment casting is an ideal method for creating complex shapes with high dimensional accuracy and surface finish, making it well-suited for superalloy components in packaging machines. The process begins by creating a wax model of the desired part coated with a ceramic shell. After removing the wax, the mold is filled with molten superalloy in a vacuum chamber, reducing contamination and producing dense, high-quality parts.

Superalloy Single Crystal Casting: This technique produces parts with a single crystal structure, eliminating grain boundaries and improving creep resistance. It is suitable for components that require exceptional high-temperature stability. Microstructure refinement further enhances creep resistance, which is crucial for maintaining stability in high-stress applications.

Superalloy Equiaxed Crystal Casting: This process creates parts with a uniform crystal structure, which enhances toughness and fatigue resistance. It is ideal for packaging machine accessories that face continuous cyclic stresses. Equiaxed crystal casting advantages include improved fatigue resistance and durability under cyclic loads.

Superalloy Directional Casting: Directional casting controls crystal growth to produce parts with superior mechanical properties along a specific axis, making them highly durable under directional stresses. Directional solidification provides enhanced mechanical properties and reliability along stress-prone axes.

Unique Steel Investment Casting: Special steel alloys can also be used in vacuum investment casting for components that require additional strength and durability, allowing for versatile applications in packaging machine accessories. This casting flexibility supports customized solutions to meet specific operational needs.

Powder Metallurgy

Powder metallurgy is another essential process for producing superalloy components. This method involves compressing fine metal powders into molds and then sintering them at high temperatures to create dense, solid parts. Powder metallurgy is beneficial for creating complex shapes and high-density materials, offering precise control over material properties.

Powder metallurgy is particularly valuable for packaging machine accessories that need uniformity, high wear resistance, and consistent performance. Components produced through powder metallurgy exhibit minimal porosity and excellent durability, making them suitable for applications where reliability and corrosion resistance are essential. Precise particle size control ensures consistent microstructure, which is critical for maintaining durability under continuous use.

Precision Forging

Precision forging shapes superalloy materials through controlled deformation, enhancing mechanical properties like strength and stability. This method is commonly used to create packaging machine accessories that require robust durability and resistance to wear.

Rough Forging: Used to form the initial shape of more significant components, rough forging provides a strong foundation for further refinement and is suitable for heavy-duty parts.

Free Forging: Free forging offers flexibility in shaping complex components, making it possible to produce custom parts without restrictive dies, which is advantageous for packaging machines with unique requirements. Free forging benefits include reduced porosity and customized shape adaptability.

Isothermal Forging: This process maintains a consistent temperature throughout forging, ensuring a uniform grain structure and reducing deformation. It is particularly beneficial for components that need stability under constant use. Isothermal forging advantages ensure high resilience, making parts reliable under continuous stress.

These forging techniques are designed to produce packaging machine accessories that can withstand high stress, high temperatures, and frequent operational cycles.

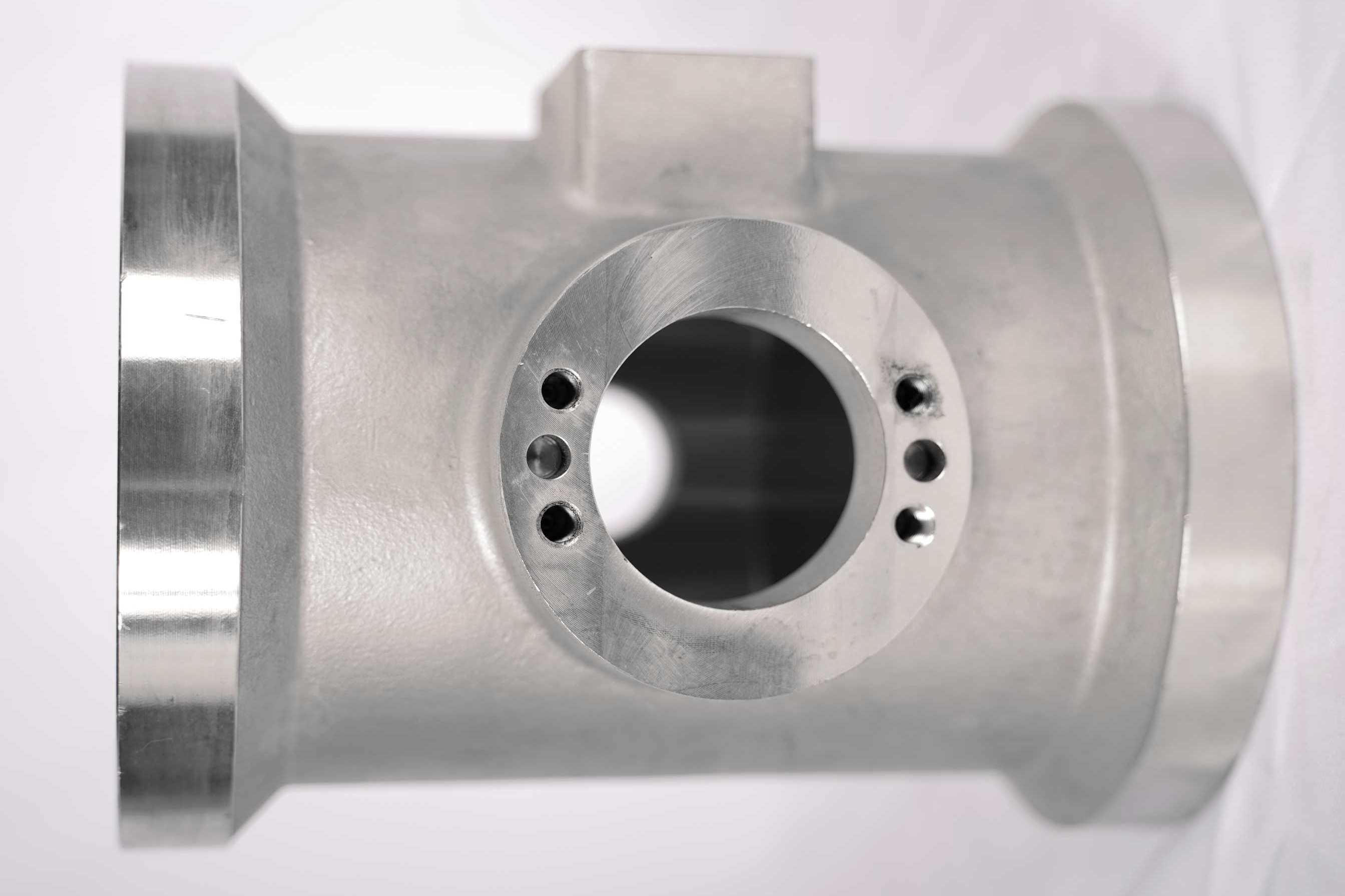

Packaging Machine Accessories Manufacturing

To meet the rigorous demands of packaging machine applications, the manufacturing process for superalloy packaging machine accessories relies on precision and advanced techniques. Vacuum investment casting is frequently used for its ability to create defect-free parts with excellent dimensional accuracy. Powder metallurgy is ideal for complex geometries that require uniform microstructure and high density, while precision forging provides additional strength and wear resistance for components that experience frequent mechanical stress.

By combining these techniques, Neway Precision Works can produce packaging machine accessories that meet strict quality standards, ensuring performance, durability, and reliability. Each process is selected based on the specific needs of the part, whether it requires high-temperature resistance, corrosion resistance, or structural strength.

Prototyping for Packaging Machine Accessories

Prototyping is vital in developing packaging machine accessories, allowing manufacturers to test and refine designs before committing to full-scale production. Prototyping is particularly valuable for custom or low-volume orders, where adjustments may be necessary to meet specific requirements. One advanced technique for rapid prototyping is 3D printing, which can be applied to packaging machine accessories to assess form, fit, and function before moving forward with larger production runs.

3D Printing Service

3D printing, also known as additive manufacturing, is a flexible and cost-effective method for prototyping. It allows manufacturers to produce complex parts layer by layer, enabling rapid testing and refinement. For packaging machine accessories, superalloy 3D printing provides a quick way to validate designs and ensure they meet functional requirements before final production. With this technology, manufacturers can produce parts with the precision needed for high-performance applications, all while keeping production times short.

Superalloy 3D Printing

Superalloy 3D printing is specialized for high-performance applications, using powdered superalloys to create detailed parts in a controlled environment. This method is ideal for functional prototypes and small production runs, offering the precision necessary to evaluate design effectiveness. SLM 3D printing, for instance, delivers precise, durable superalloy parts with excellent mechanical properties, which is critical when producing packaging machine accessories that must endure harsh operational conditions.

Superalloy CNC Machining

CNC machining is widely used for low-volume production and prototyping, offering precision and reliability. CNC machining ensures that prototypes meet exact specifications and allows for high-quality production of packaging machine accessories that require tight tolerances and detailed features. CNC machining also enables manufacturers to create parts with complex geometries, ensuring each accessory performs optimally under demanding conditions.

Packaging Machine Accessories Quality Inspection

Quality inspection is critical to verify that each packaging machine accessory meets industry standards for performance and durability. Advanced testing methods ensure that each part is free from defects and meets design specifications:

X-ray Inspection

X-ray inspection detects internal flaws such as voids or cracks, ensuring the component is structurally sound. It is similar to how industrial CT technology is used for internal defect detection in superalloy components, ensuring no hidden weaknesses in high-performance materials like superalloys. This method also validates packaging machine accessories for structural integrity, ensuring they meet rigorous quality standards.

Coordinate Measuring Machine (CMM)

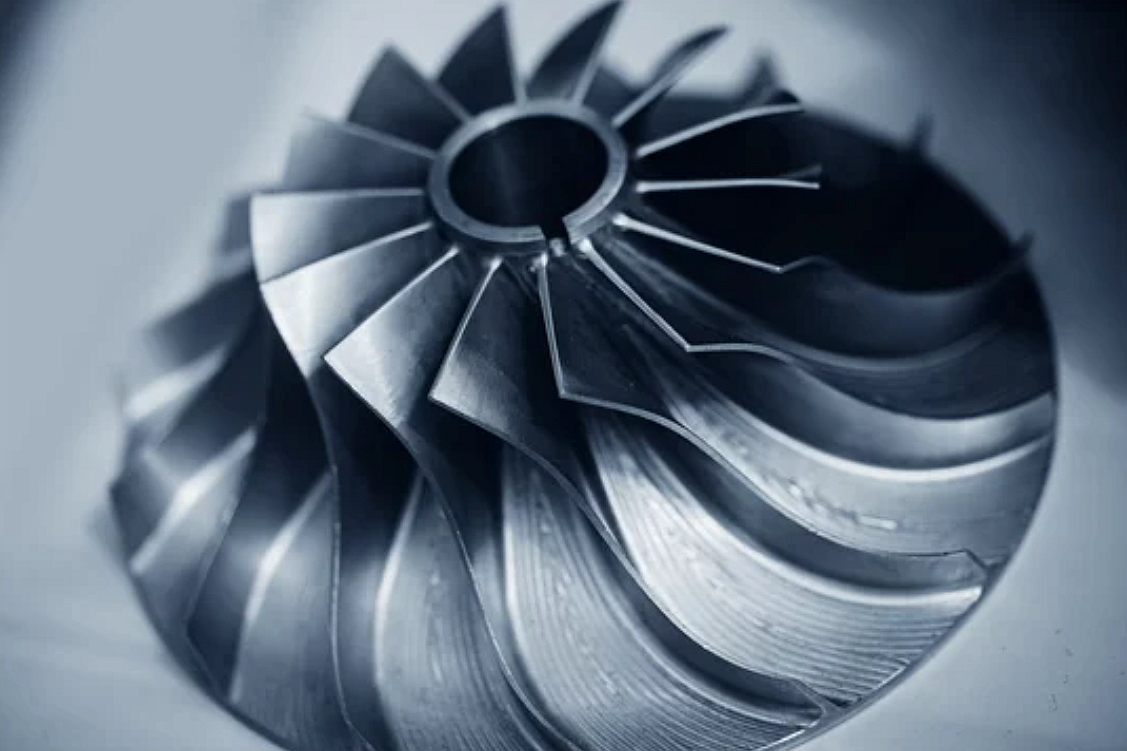

The CMM provides precise dimensional measurements, confirming that each part meets the required tolerances. It is especially relevant compared to other quality control methods used in superalloy precision machining for parts like turbine blades, where exact dimensional measurements are critical to ensure proper fit and function. In turbine blade manufacturing or packaging machine accessories, achieving precise measurements is vital to maintaining product consistency.

Metallographic Microscopy

Metallographic microscopy is a technique used to examine the microstructure of superalloys, verifying grain structure and phase distribution. It is particularly relevant for grain structure analysis in superalloys, which ensures that materials can withstand high-stress, high-temperature environments. When inspecting packaging machine accessories made from advanced alloys, examining the grain structure ensures that the parts are solid and resilient, much like the critical role of superalloy testing in turbine engines and other high-performance applications.

These inspection techniques help maintain the quality and reliability of packaging machine accessories, ensuring they perform as expected in demanding environments. Similarly, high-performance components in aerospace and energy sectors undergo rigorous inspections using advanced techniques like dynamic and static fatigue testing to confirm long-term durability and performance.

Industry Applications of Packaging Machine Accessories

Superalloy packaging machine accessories are essential in industries where reliability, corrosion resistance, and high performance are paramount:

Food Processing: Packaging equipment must handle constant cleaning and exposure to acidic or salty substances. Superalloy accessories provide the necessary resistance to corrosion and wear.

Pharmaceuticals: Pharmaceutical packaging equipment must meet stringent cleanliness and chemical resistance standards. Superalloy components ensure durability and hygiene in these sensitive applications.

Consumer Goods: Packaging machines for consumer goods require parts that can handle high speeds and repeated use without degradation. Superalloy accessories offer the strength and durability needed for long-lasting performance.

Under challenging conditions, these industries rely on superalloy packaging machine accessories to maintain efficiency, safety, and reliability.

FAQs about Packaging Machine Accessories Manufacturing

What are the best superalloys for packaging machine accessories?

How does powder metallurgy improve superalloy packaging component production?

Why is Hot Isostatic Pressing (HIP) important in post-processing packaging accessories?

What quality inspection methods are used for packaging machine accessories?

How does CNC machining support prototyping for packaging accessories?