Superalloy Marine Engine Components Manufacturer

Superalloy Marine Engine Components: Manufacturing, Materials, and Applications

Superalloys are crucial in designing and manufacturing marine engine components, ensuring reliability, strength, and performance in the harshest environments. From the extreme temperatures in propulsion systems to the corrosive forces of seawater, superalloys are engineered to withstand demanding conditions, enhancing the overall efficiency and longevity of marine engines. This blog will explore the critical aspects of superalloy marine engine components, including the materials, manufacturing processes, post-processing techniques, and rapid prototyping methods integral to producing high-performance marine engine parts.

Introduction to Superalloy Marine Engine Components

Marine engines operate in an environment that demands unparalleled durability and performance. The constant exposure to high pressures, high temperatures, and corrosive seawater requires materials that maintain their structural integrity and offer high resistance to wear, corrosion, and fatigue. Superalloys, a class of high-performance materials, are specifically designed to meet these requirements. Composed primarily of nickel, cobalt, and iron-based alloys, superalloys are highly resistant to oxidation and creep, making them ideal for high-temperature applications such as turbine blades, combustion chambers, and exhaust systems in marine engines.

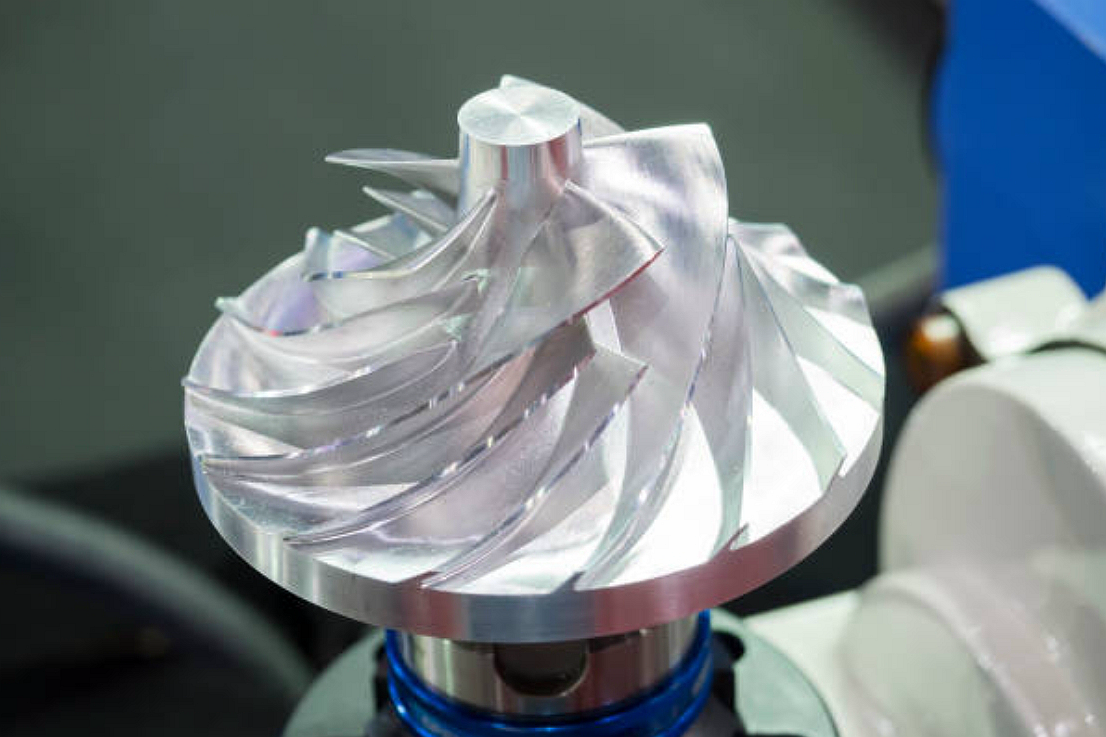

Marine engine components, such as turbine blades, impellers, combustion chambers, and other critical parts, are often made from these advanced materials to ensure efficiency and durability. The performance and longevity of these components are paramount for the entire system's reliability, as any failure can lead to costly downtime and extensive repairs. Superalloy parts are thus vital for modern marine propulsion systems, which power everything from naval ships and submarines to commercial cargo ships and luxury cruise liners.

Typical Superalloys Used in Marine Engine Components Manufacturing

The selection of the right superalloy is critical to ensuring that marine engine components meet the specific requirements of their applications. The main superalloys manufacturing marine engine parts are typically nickel-based and cobalt-based due to their superior high-temperature strength, corrosion, and fatigue resistance.

Nickel-Based Superalloys

Nickel-based superalloys, such as Inconel, Hastelloy, and Nimonic, are commonly used in marine engine components due to their excellent high-temperature properties and resistance to thermal degradation. Inconel alloys, such as Inconel 718, are often used in turbine blades, combustion chambers, and other engine parts subjected to extreme heat. These alloys provide superior resistance to oxidation, creep, and thermal fatigue, making them ideal for high-performance applications in the marine industry.

Hastelloy alloys, primarily nickel and molybdenum-based, are highly resistant to corrosion and are frequently used in seawater-resistant components like pumps and valves. Nimonic alloys, another subset of nickel-based superalloys, are known for their high strength at elevated temperatures. They are commonly used in critical engine components such as turbine blades and discs.

Cobalt-Based Superalloys

Cobalt-based superalloys, such as Stellite and Haynes alloys, are known for their excellent wear and corrosion resistance, particularly in highly corrosive marine environments. These alloys are used in parts like bearings, seals, and valve seats, providing exceptional resistance to erosion and pitting, even in seawater and other harsh chemicals.

Manufacturing Process and Equipment for Superalloy Marine Engine Components

Manufacturing superalloy marine engine components involves various processes, each chosen based on the material properties required and the part's complexity. At Neway Precision Works Ltd., we use a range of advanced casting, forging, machining, and additive manufacturing techniques to produce high-performance marine engine components. Each method ensures the necessary material properties and allows for producing parts that can withstand the extreme conditions of marine environments.

Vacuum Investment Casting

Vacuum Investment Casting (VIC) is one of the most common methods of manufacturing complex superalloy parts for marine engine components. VIC is ideal for producing intricate geometries and achieving precise tolerances, making it well-suited for high-performance components such as turbine blades, combustion chambers, and impellers. The process involves creating a wax pattern of the desired part coated with a ceramic shell. The wax is melted in a vacuum, and molten superalloy is poured into the shell to form the final part. VIC offers an excellent surface finish and minimal porosity, ensuring that marine engine components are durable and reliable.

Single Crystal and Directional Solidification Casting

For highly demanding applications such as turbine blades, Single Crystal Casting (SX) and Directional Solidification Casting (DS) are often used to produce parts with superior material properties. Single Crystal Casting produces components with a continuous grain structure, which helps to eliminate grain boundaries that could weaken the material under high stress. This method is ideal for parts that experience extreme temperatures and high mechanical stresses, as it improves high-temperature strength and resistance to thermal fatigue.

Directional Solidification Casting is another method to enhance the mechanical properties of superalloy marine engine components. By controlling the direction in which the material solidifies, directional solidification minimizes the formation of unwanted grains, which can significantly improve the strength and fatigue resistance of the final part.

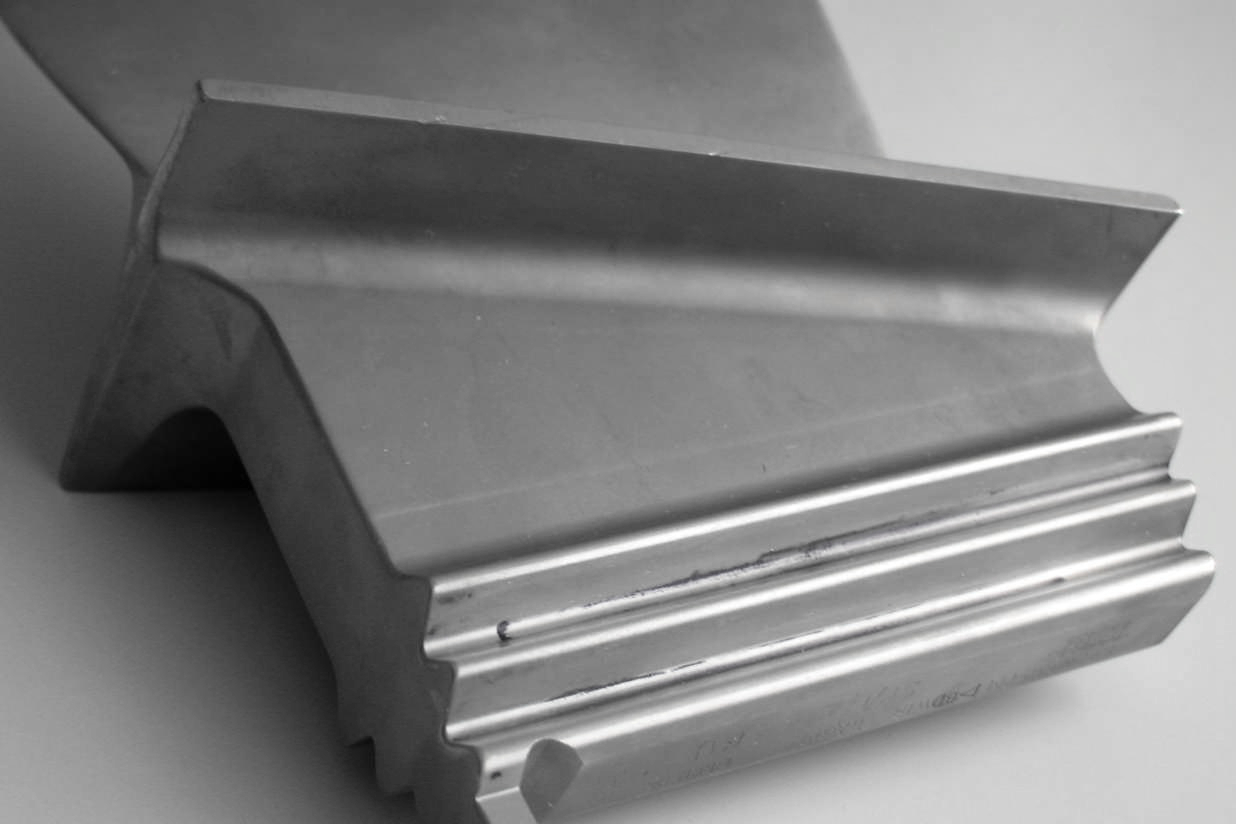

Superalloy Forging and CNC Machining

Superalloy forging involves the application of heat and pressure to shape the material into the desired component, improving its strength and grain structure. Forging creates high-strength marine engine components such as shafts, gears, and casings. The forging process ensures that the material maintains a uniform grain structure, providing excellent toughness and resistance to fatigue.

After forging, superalloy components are further refined using Superalloy CNC Machining. CNC machining uses computer-controlled equipment to shape and finish parts to tight tolerances precisely. This process is critical for producing complex geometries and high-accuracy components, ensuring that marine engine parts meet the rigorous specifications for high-performance applications.

Additive Manufacturing

Additive Manufacturing, specifically Selective Laser Melting (SLM), is gaining popularity in the marine industry for producing complex superalloy components. AM technologies allow for the rapid production of parts directly from digital files, creating intricate geometries and internal structures that would be impossible to achieve with traditional manufacturing methods. For example, turbine blades with cooling channels or other complex features can be produced using SLM 3D printing. AM also allows faster prototyping and small-batch production, which is particularly useful for reducing lead times and testing new designs.

Testing Methods and Equipment in Superalloy Marine Engine Components QC

Quality control (QC) ensures that marine engine components meet the high-performance standards for marine applications. Several advanced testing methods are employed to verify the integrity and performance of superalloy parts before they are deployed in marine engines.

X-ray Inspection: This non-destructive testing method detects internal defects, such as voids and cracks, that could compromise the structural integrity of superalloy components. X-ray inspection ensures that the parts are free from hidden defects that could lead to failure under operational conditions. Industrial CT scanning is another method that enhances the detection of such hidden flaws.

Scanning Electron Microscopy (SEM): SEM is employed to examine the microstructure of superalloy parts at a very high resolution. This test is beneficial for identifying surface defects, studying the grain structure, and understanding how the material will perform under different environmental conditions. It is essential for assessing fracture analysis of materials.

Tensile and Fatigue Testing: Tensile testing measures the strength and elongation properties of the material, while fatigue testing evaluates how the material performs under cyclic loading. These tests ensure that marine engine components can withstand the mechanical stresses encountered during regular operation. Dynamic and static fatigue testing helps predict component longevity under stress.

Creep Testing: Creep testing measures a material's ability to resist deformation under constant stress at high temperatures. This test is crucial for components like turbine blades operating at elevated temperatures for extended periods. High-temperature stability testing is also critical for ensuring long-term performance in harsh environments.

Typical Post-Processing of Superalloy Marine Engine Components

Once the superalloy parts have been manufactured, several post-processing steps are applied to optimize their performance and extend their service life.

Heat treatment processes, such as solution treatment, aging, and stress relieving, enhance the mechanical properties of superalloy components. For example, heat treatment can increase the hardness and tensile strength of turbine blades and other marine engine components, making them more resistant to wear and deformation. It is crucial for improving the durability and extending the service life of high-performance marine parts.

Thermal Barrier Coatings (TBCs) are applied to high-temperature components like turbine blades and exhaust components to reduce heat transfer and protect the substrate material from thermal degradation. TBC helps improve the efficiency of marine engines by reducing fuel consumption and increasing the lifespan of engine components. TBC enhances performance by protecting against thermal cycling, especially under harsh marine operating conditions.

HIP is a post-processing technique that eliminates cast parts' porosity and improves the material's overall density and mechanical properties. It is particularly effective in superalloy turbine blades, ensuring their strength and durability in harsh marine environments. By enhancing material integrity and eliminating internal voids, HIP ensures that the components perform reliably over long periods, even in the most demanding conditions.

Rapid Prototyping and Verification of Superalloy Marine Engine Components

Rapid prototyping and verification play a vital role in developing marine engine components. New technologies like 3D printing (additive manufacturing) and CNC machining allow for fast and cost-effective prototyping of complex superalloy parts. These techniques enable engineers to test and refine designs quickly, reducing development cycles and lead times. Selective Laser Melting (SLM) technology further improves the precision of prototyping, allowing for complex geometries and tight tolerances often required in marine engine parts.

Marine engine components, such as turbine blades, impellers, and combustion chambers, are often made of high-performance alloys like Inconel or Hastelloy, which are difficult to fabricate using traditional methods. However, 3D printing of superalloy materials enables the rapid production of such parts with lower costs and quicker turnaround times. Advanced techniques like WAAM (Wire and Arc Additive Manufacturing) are used to create larger structures, further enhancing efficiency in the manufacturing process.

Importance of Verifying Samples

Verifying the performance of prototype components is essential to ensure that they meet the necessary specifications. Verification tests may include mechanical testing, thermal analysis, and environmental testing to simulate real-world conditions. Testing processes, such as heat treatment and hot isostatic pressing (HIP), are often employed to evaluate the durability and strength of the components. Furthermore, material testing ensures that the final parts exhibit the necessary properties to withstand extreme conditions, such as high temperatures and mechanical stress.

Verifying sample parts ensures that only the most durable and high-performing components are used in the final production process. SLM 3D Printing and other additive technologies provide rapid iteration and allow for adequate testing of these prototypes in real-world simulations before moving to mass production. The process ensures that each part is thoroughly tested for material integrity and can perform optimally in the demanding marine engine environment.

FAQs About Superalloy Marine Engine Components Manufacturing

What are the critical characteristics of superalloy materials used in marine engines?

How does additive manufacturing benefit the production of marine engine components?

What is the most common superalloy used for marine turbine blades?

What are the advantages of using vacuum investment casting for marine engine components?

How do you ensure the quality of superalloy marine engine components?