Superalloy Firearm Accessories Processing Plant

Induction of Superalloy Firearm Accessories

The demand for high-performance firearm accessories is paramount in today's highly specialized industries, particularly defense, law enforcement, and competitive shooting. The ability of a firearm to withstand extreme conditions—whether in combat, high-stakes law enforcement operations, or competitive shooting—is often determined by the quality and durability of its components. It is where superalloy firearm accessories come into play.

Superalloy materials, such as Stellite, Nimonic, and Titanium alloys, offer exceptional heat, wear, and corrosion resistance. These characteristics are essential for parts facing intense thermal and mechanical stresses during use. At Neway Precision Works, we provide high-temperature alloy processing services with advanced manufacturing technologies and processes that ensure the highest quality superalloy components. This blog will explore the world of superalloy firearm accessories, their manufacturing processes, benefits, and applications.

Superalloy firearm accessories are precision-engineered components designed to operate in high-temperature, high-stress environments. These components are made from specialized alloys known for their strength, corrosion resistance, and thermal stability. They are commonly used in critical parts of firearms exposed to intense forces, such as barrels, receivers, triggers, and gas blocks.

Firearm accessories manufactured from superalloys are designed to perform reliably under the most demanding conditions. Whether it's the extreme temperatures generated in rapid fire, the corrosive effects of environmental exposure, or the constant friction of moving parts, superalloys provide the durability needed for firearm longevity and high performance.

The materials most often used in manufacturing superalloy firearm accessories include Stellite, Nimonic, and Titanium alloys. These materials are chosen for their exceptional mechanical properties, including high strength at elevated temperatures, superior wear resistance, and excellent corrosion resistance.

Superalloys Used In Superalloy Firearm Accessories

Stellite Alloys

Stellite alloys are cobalt-based superalloys renowned for their excellent wear resistance and ability to perform under extreme temperatures. They are widely used in manufacturing firearm components exposed to constant friction and thermal stress. Stellite is particularly valuable for parts such as gas parts, muzzle brakes, and barrel liners.

Stellite 6, one of the most common grades, offers outstanding wear, hardness, and corrosion resistance, making it ideal for high-stress parts such as firearm components exposed to repeated firing cycles. Stellite 12 provides even more excellent resistance to corrosion and oxidation, which is particularly beneficial for components subjected to high temperatures. Stellite 21, known for its high-temperature stability and ability to retain hardness, is often used in aerospace and military applications. It is a suitable choice for firearm accessories exposed to high heat.

Nimonic Alloys

Nimonic alloys are a group of high-strength superalloys engineered explicitly for extreme-temperature applications, such as gas turbines and other high-performance components. They exhibit outstanding creep resistance, oxidation resistance, and thermal stability, making them an ideal choice for firearm components that require superior performance under high-temperature conditions.

Nimonic 75 is one of the most commonly used grades in the Nimonic family. It offers excellent creep resistance at elevated temperatures, making it ideal for firearm parts like triggers and gas that experience high stress and temperatures. Nimonic 90 is another popular grade, offering even more excellent oxidation resistance and tensile strength. Nimonic 263 is widely used in high-performance applications where resistance to high-temperature creep and oxidation is crucial, such as components that require a long service life under extreme conditions.

Titanium Alloys

Titanium alloys are known for their excellent strength-to-weight ratio, high corrosion resistance, and ability to withstand elevated temperatures. These properties make them ideal for firearms where strength and lightness are required. Titanium alloys are commonly used in firearm parts such as frames, receivers, and barrels, where reducing weight while maintaining structural integrity is a priority.

Ti-6Al-4V (Grade 5) is the most widely used titanium alloy, offering a balance of strength, corrosion resistance, and lightweight properties. Ti-13V-11Cr-3Al is another grade used in applications that require additional strength and fatigue resistance. Ti-6Al-7Nb is a titanium alloy designed for medical and aerospace applications, but it is also used in firearm components where corrosion resistance and high strength are needed.

Typical Superalloy Part Manufacturing Process

The manufacturing process for superalloy firearm accessories involves several vital stages that ensure the highest precision, performance, and reliability. These processes include vacuum investment casting, powder metallurgy, and precision forging. Each technique has advantages, ensuring that the resulting parts meet the demanding requirements of firearm applications.

Vacuum Investment Casting

Vacuum investment casting is one of the most advanced and precise methods for manufacturing high-performance superalloy components. This technique involves creating a mold using a wax pattern and then coated with a ceramic shell. The wax is removed in a dewaxing process, and the mold is filled with molten superalloy under a vacuum to ensure the purity of the material and prevent oxidation.

Superalloy single crystal casting, superalloy equiaxed crystal casting, and superalloy directional casting are commonly used in vacuum investment casting for firearm accessories. Single crystal casting is particularly valuable for producing turbine blades and similar high-performance parts, as it minimizes defects and improves the material's strength. Equiaxed crystal casting, which involves creating a uniform grain structure, ensures superior toughness and resistance to fatigue. Directional casting allows for controlled solidification, producing parts with specific directional properties for high-strength applications.

Powder Metallurgy

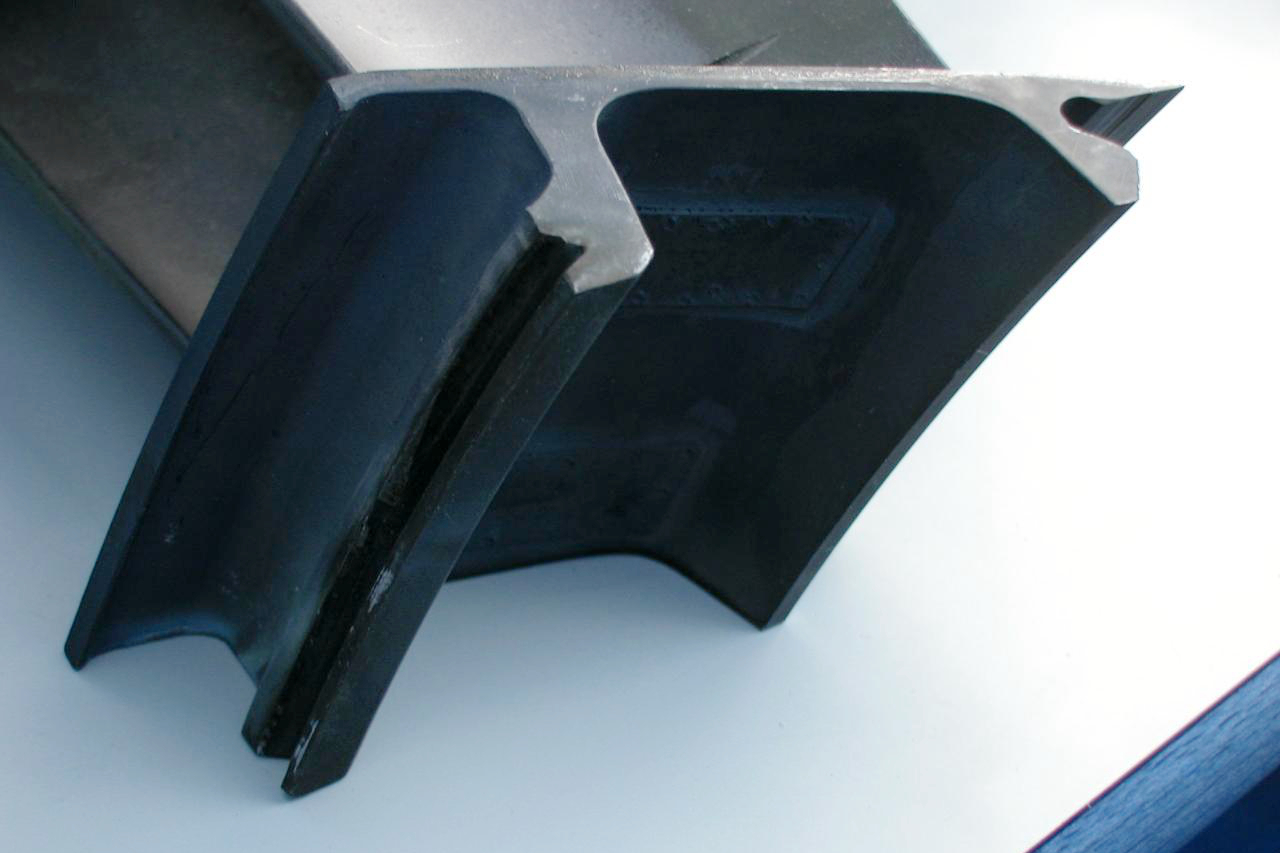

Powder metallurgy is a highly efficient process for manufacturing superalloy parts with complex geometries. In this process, fine powder of the desired superalloy is compacted into molds and then sintered at high temperatures to create a solid part. This method is ideal for producing firearm components that require intricate shapes or high uniformity, such as gas blocks and muzzle brakes.

The critical advantage of powder metallurgy is its ability to produce components with excellent mechanical properties, minimal waste, and high material efficiency. The powder's fine grain structure improves toughness, wear resistance, and dimensional accuracy, crucial for firearm parts that must withstand repeated use.

Precision Forging

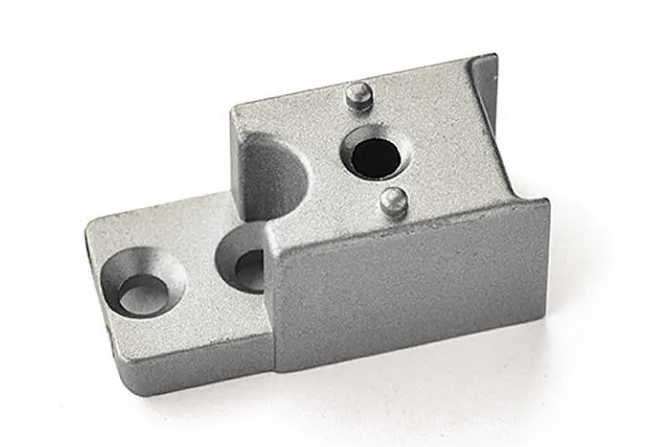

Precision forging is another critical process used in producing superalloy firearm components. This process involves shaping the material using mechanical force, with the benefit of maintaining the material's strength while achieving intricate geometries. Precision forging can be applied through various techniques, including rough, accessible, and isothermal forging.

Rough forging is typically used to form the basic shape of the part, which is then refined using free forging. Free forging is when the material is heated and shaped without using molds, allowing for greater flexibility in achieving complex shapes. Isothermal forging, a more advanced technique, involves applying pressure to the material while maintaining a consistent temperature throughout the forging process, ensuring uniformity and reducing the risk of defects.

For firearm accessories, precision forging is particularly beneficial for parts such as barrels, bolts, and frames, where strength, durability, and resistance to wear are critical.

Superalloy Firearm Accessories Manufacturing

The most suitable manufacturing process for superalloy firearm accessories largely depends on the parts' specific requirements. For example, precision forging is often the best choice for components that require complex geometries and high strength, such as firearm frames and bolts. The ability to forge parts to precise tolerances ensures they fit together perfectly and perform reliably under extreme conditions.

In contrast, vacuum investment casting is ideal for parts that must maintain structural integrity under high temperatures, such as barrel liners and gas parts. The ability to produce components with minimal porosity and excellent material properties makes casting an excellent choice for high-performance firearm parts.

Prototyping for Superalloy Firearm Accessories

Prototyping is an essential step in the development of any firearm accessory. Before full-scale production, prototypes are used to test and refine designs, ensuring the final product meets the required specifications. Prototyping allows manufacturers to evaluate the parts' form, fit, and function before committing to mass production, reducing the risk of defects and costly revisions. At Neway Precision Works, we offer rapid prototyping services for superalloy firearm accessories.

Superalloy 3D Printing

Using advanced techniques like superalloy 3D printing, we can quickly produce accurate prototypes that can be tested and modified. It allows manufacturers to produce complex, high-performance parts for firearm accessories with tight tolerances and intricate geometries, ideal for functionality and durability. Superalloy 3D printing provides a cost-effective solution for low-volume production and rapid iteration of designs.

Superalloy CNC Machining

For prototypes that require a high level of precision, superalloy CNC machining offers exceptional finishing and tight tolerance capabilities. CNC machining is ideal for producing parts with detailed features and complex shapes, ensuring that each prototype meets the specifications for reliable performance. It also allows quick adjustments, minimizes lead time, and facilitates faster product development.

Utilizing these advanced manufacturing technologies ensures our clients receive high-quality prototypes for superalloy firearm accessories optimized for functionality and performance.

Superalloy Firearm Accessories Post-Process

Post-processing is critical in enhancing superalloy firearm accessories' mechanical properties and performance. Post-processing techniques include heat treatment, surface finishing, and coating, which are crucial in improving the final components' durability, hardness, and corrosion resistance.

Heat Treatment

Heat treatment processes such as Hot Isostatic Pressing (HIP) and vacuum heat treatment ensure that the material is uniformly heated and defects-free. Hot Isostatic Pressing (HIP) helps eliminate porosity and enhances the strength and integrity of the components. Vacuum heat treatment ensures precise control over the heating process, which improves material properties without introducing unwanted contaminants.

Surface Finishing

Surface treatments like nitriding and thermal barrier coatings increase the wear resistance of parts, which is particularly beneficial for components subjected to frequent friction or extreme temperatures, such as firing pins and barrels. Surface quality improvement through advanced finishing techniques ensures that parts are durable and corrosion-resistant, even under harsh conditions.

Coating

Thermal barrier coatings (TBC) are often applied to enhance the component's resistance to heat and thermal cycling. Thermal barrier coatings (TBC) protect components from extreme temperatures, making them ideal for firearm accessories exposed to high friction and thermal stress, such as barrels and gas pistons.

These post-processing techniques ensure that superalloy firearm accessories are durable, reliable, and capable of withstanding the rigorous demands of firearm applications.

Superalloy Firearm Accessories Quality Inspection

Quality control ensures that superalloy firearm components meet the highest performance and reliability standards. At Neway Precision Works, we employ various advanced testing methods to verify the integrity of our parts, including X-ray inspection, ultrasonic testing, and metallographic analysis.

Mechanical testing, such as tensile and fatigue testing, helps us ensure that the components can withstand the stresses they encounter in real-world applications. We also use Coordinate Measuring Machines (CMM) and Scanning Electron Microscopes (SEM) to inspect the precision and microstructure of each part, ensuring they meet the strict tolerances required for high-performance firearm accessories.

By combining advanced non-destructive testing with mechanical and microstructural analysis, we guarantee that our superalloy firearm components deliver superior quality, ensuring they can withstand extreme conditions while maintaining peak performance.

Industry Applications of Superalloy Firearm Accessories

Superalloy firearm accessories are essential in industries that require critical performance and reliability under extreme conditions. These include:

Military and Defense: Superalloy components are used in firearms and weapon systems where durability, resistance to wear, and reliability are crucial.

Law Enforcement: Firearm accessories made from superalloys are used by law enforcement agencies that rely on firearms for public safety.

Competitive Shooting: Competitive shooters use high-performance accessories made from superalloys to gain an edge in precision and durability.

Custom Firearms: Enthusiasts and manufacturers of custom firearms often rely on superalloy components for specialized performance.

These industries depend on superalloy firearm accessories to ensure durability, precision, and reliability under the most demanding conditions.

FAQs about Superalloy Firearm Accessories Manufacturing

What are the key benefits of using superalloys in firearm accessories?

How do Stellite alloys improve the performance of firearm components?

What is the role of precision forging in firearm accessory manufacturing?

Can you prototype superalloy firearm accessories using 3D printing technology?

How does post-processing affect the performance of superalloy firearm parts?