Stress Relief in Castings: Key to Dimensional Stability

Introduction

Superalloy castings are crucial in high-performance industries such as aerospace, power generation, and petrochemical processing, where components endure intense stress and extreme temperatures. These superalloys, often based on nickel, cobalt, or iron, provide outstanding mechanical strength, resistance to thermal degradation, and corrosion resistance, making them ideal for turbine blades, engine components, and other critical parts.

In these high-stakes applications, maintaining dimensional stability is a priority. When dimensional stability is compromised, even a minor shift can cause components to fail. For instance, a turbine blade that deforms under high stress may disrupt airflow, reducing engine efficiency or causing severe mechanical failure. Hence, achieving and maintaining dimensional accuracy is essential to ensure these parts' reliability, safety, and lifespan.

One critical process to attain dimensional stability in superalloy castings is stress relief. This heat treatment minimizes residual stress, redistributes internal strains, and enhances the material's structural integrity. By understanding stress relief and its benefits, manufacturers can produce parts that perform consistently under demanding conditions, contributing to high-performance systems' long-term reliability and safety.

Understanding Stress in Superalloy Castings

Residual or internal stress occurs when stress is "locked" into the material during manufacturing processes, such as casting, forming, or machining. In superalloy castings, residual stresses often arise during the rapid cooling and solidification phase. As different casting regions cool at varying rates, thermal gradients develop, causing material parts to contract at different rates. It creates stress within the material, which remains even after cooling. These stresses can lead to deformation, cracking, and premature failure if not relieved.

Factors Contributing to Residual Stress in Superalloy Castings

Temperature Changes

High thermal gradients between the core and surface of a casting caused differential contraction, creating significant stress in regions with abrupt cooling. Heat treatment can help relieve these stresses, ensuring dimensional stability.

Material Composition

Superalloys with complex alloying elements respond to thermal changes differently. For example, some elements in nickel-based superalloys may segregate during cooling, leading to localized stresses.

Complex Geometry

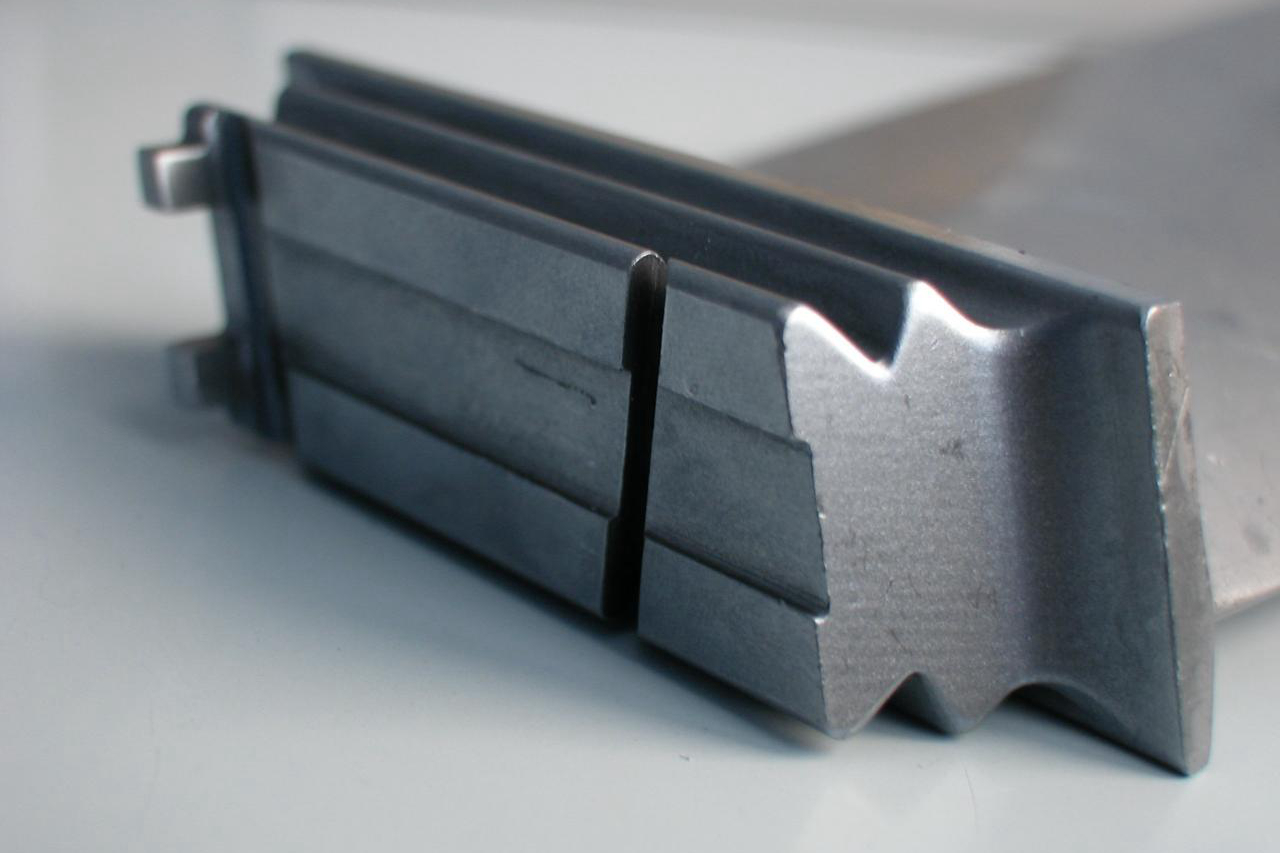

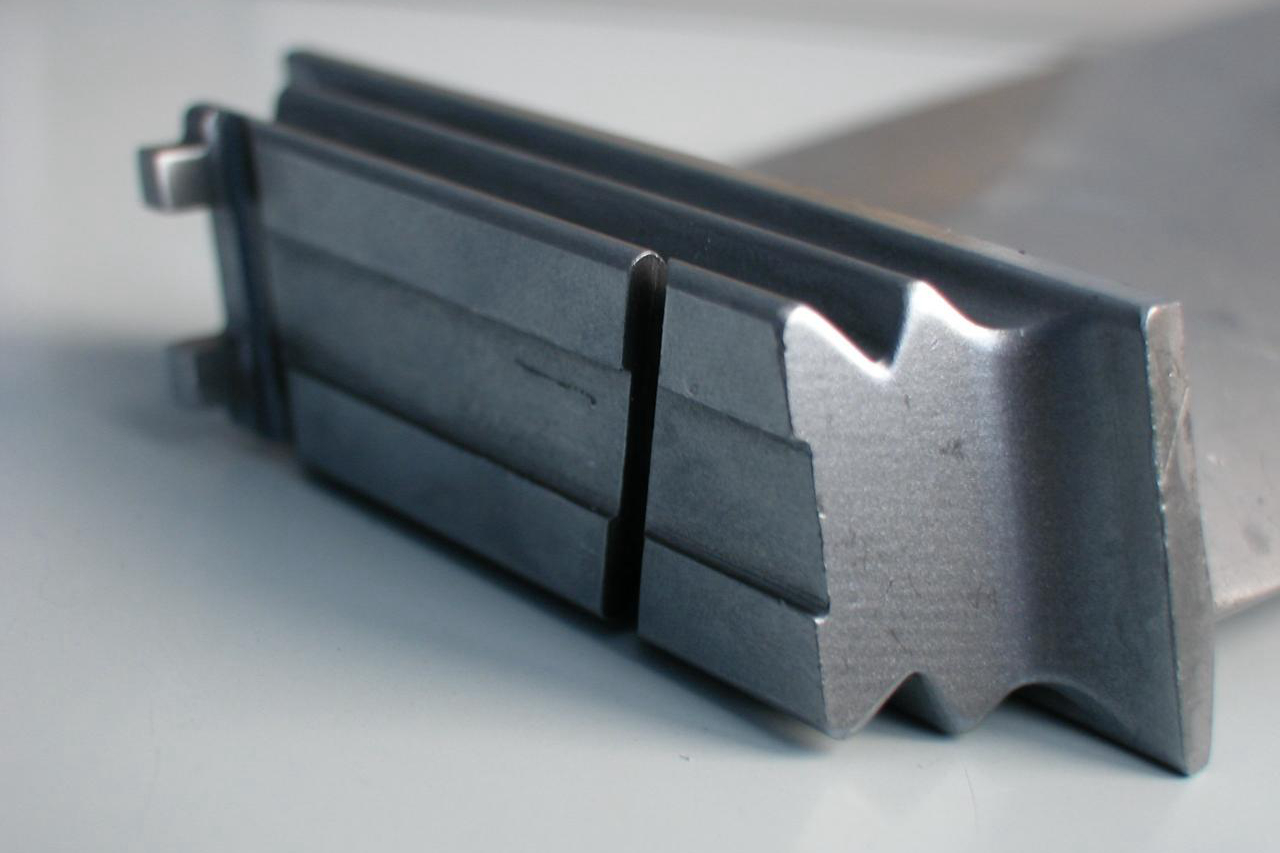

Intricate or asymmetrical part geometries lead to uneven cooling rates. Thin sections cool faster than thicker areas, creating regions of varying stress within the same component. Manufacturers can mitigate these effects and improve dimensional stability by refining casting techniques and applying stress-relief methods.

Importance of Dimensional Stability in Superalloy Components

Dimensional stability is critical in high-performance components because it ensures that parts retain their original geometry and fit within specified tolerances, even under extreme operating conditions. In applications such as jet engines and gas turbines, any dimensional deviation due to thermal or mechanical stress can severely impact performance and safety.

Consequences of Dimensional Instability

Warping

When residual stress is not adequately relieved, superalloy castings may warp over time, leading to misalignment with other components, decreased efficiency, and increased wear. This deformation compromises the component's precision and functionality.

Cracking

Internal stresses, particularly in areas with high-stress concentration, increase the likelihood of cracking. Once a crack forms, it can propagate under load, potentially causing catastrophic failure. Stress-relief processes like heat treatment help prevent these critical failures by minimizing residual stress.

Reduced Component Life

High residual stress levels lead to premature wear and fatigue, reducing the component's lifespan l and leading to more frequent replacements. Ensuring material integrity through proper post-processing methods, like HIP, helps extend the operational life of these parts.

Real-World Impact

In the aerospace industry, even a slight dimensional shift in turbine blades can disrupt airflow, lowering fuel efficiency and increasing engine stress. In power generation, deformation in turbine blades can lead to higher operational costs and unplanned maintenance due to efficiency losses and safety risks. The integrity of dimensional stability in superalloy components is essential to maintaining high performance, safety, and cost-efficiency in these critical applications.

What is Stress Relief in Superalloy Castings?

Stress relief is a controlled heat treatment process that reduces internal stresses within a superalloy casting. Applying heat gives the material storms the energy to rearrange themselves, redistributing and reducing residual stress to achieve dimensional stability.

Essential Techniques Used in Stress Relief

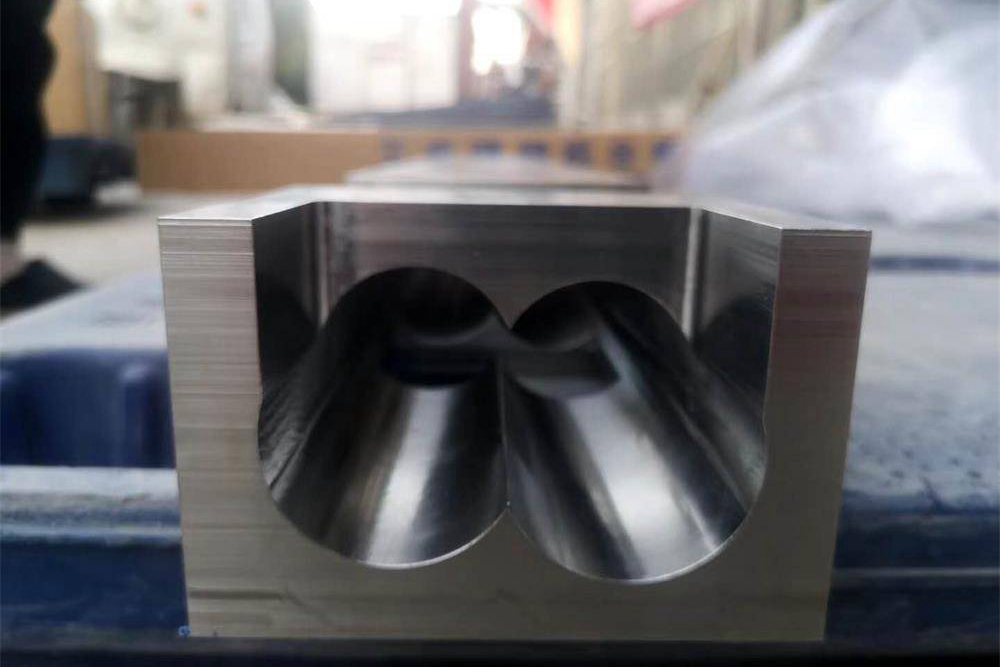

Vacuum Heat Treatment

Vacuum heat treatment is conducted in a vacuum furnace to prevent oxidation and contamination, which is particularly effective for superalloys prone to surface reactions that can weaken the material.

Isothermal Annealing

Isothermal annealing involves holding the material at a specific temperature for a set time, allowing it to reach equilibrium and gradually relieve stress. This technique is helpful for intricate parts with complex geometries, as it allows for uniform stress reduction without introducing new residual stress.

Effect on Crystal Structure and Grain Orientation

The stress relief process refines the crystal structure, aligns grains, reduces defects, and improves the overall stability and performance of the superalloy. Proper alignment of grains enhances creep resistance and other mechanical properties crucial for high-temperature applications.

Benefits of Stress Relief for Superalloy Castings

Stress relief offers numerous benefits for superalloy castings, enhancing the reliability and durability of components in high-performance applications.

Enhanced Dimensional Stability

Stress relief minimizes shape distortion, ensuring the casting maintains its intended dimensions even under thermal and mechanical stresses, which is essential in applications like turbine components.

Improved Mechanical Properties

Relieving residual stress enhances the material's flexibility and resistance to cracking, enabling it to withstand extreme operational loads without failure.

Extended Component Life

By eliminating internal stresses, stress relief reduces the likelihood of fatigue failure, significantly extending the lifespan of components, particularly in aerospace and power generation applications.

Increased Resistance to High-Temperature Deformation

Stress relief enhances the material's ability to retain its form and resist deformation under high temperatures. Parts like turbine blades and jet engines must be exposed to extreme heat.

For example, stress-relieved turbine blades in jet engines last longer and maintain precise aerodynamic shapes, improving fuel efficiency and operational performance.

Challenges in Stress Relief for Superalloy Castings

While stress relief is essential, it is not without challenges:

Over-Relieving Stress

Excessive stress relief can lead to undesirable grain growth, impacting the alloy's strength and hardness. Careful control is essential to avoid over-processing.

Precision Requirements

Superalloy stress relief requires precise temperature control and timing to ensure the process achieves the desired effects without introducing new stresses.

Cost and Time Constraints

The process can be resource-intensive, especially for large-scale production. Balancing cost and time with quality requirements is often challenging. Simulation software can help reduce inefficiencies, but the resource demands are still significant.

These challenges highlight the importance of advanced technology and precise control in stress relief processes to maintain quality and cost-effectiveness.

Advances in Stress Relief Techniques for Superalloys

Recent advancements in stress relief processes have improved precision, control, and efficiency:

Computer-Controlled Heat Treatments

Automated systems with real-time temperature monitoring ensure precise control, reducing the risk of over- or under-relieving stress. This approach is often coupled with vacuum heat treatment for improved process accuracy.

Process Simulation

Simulation software models the stress relief process, allowing engineers to optimize heating and cooling schedules for different superalloys. It reduces trial-and-error, improving efficiency and reducing waste. Process simulation also helps predict potential issues in advance, improving outcomes.

Emerging Materials and Alloys

Some modern superalloys are engineered with lower intrinsic residual stress, reducing the need for extensive stress relief. These materials are beneficial in applications where dimensional stability is critical. Their use streamlines the production process and reduces the reliance on intensive stress relief treatments.

These innovations enable manufacturers to produce high-quality, stress-relieved superalloy components with improved performance and longevity.

Applications and Case Studies: Stress Relief in Action

Stress relief is essential across several industries, ensuring the reliability, performance, and longevity of superalloy components:

Aerospace

In aerospace, jet engines contain numerous superalloy components that face extreme heat and mechanical stress. Stress relief prevents warping and dimensional shifts, ensuring consistent performance and extending the operational life of critical parts like turbine blades, combustion chambers, and airframe components.

Power Generation

Gas turbines operate under high temperatures and cyclic stresses. Stress-relieved superalloy components in turbines improve efficiency by maintaining dimensional stability and reducing operational costs. The process enhances the durability of turbine blades, discs, and nozzles, resulting in longer service intervals and minimized downtime.

Petrochemical

In the petrochemical industry, superalloys are used in equipment that withstand corrosive and high-temperature environments. Stress relief treatments enhance the stability and reliability of components such as valves, pumps, and reactor parts, minimizing the risk of failure and downtime, which is crucial in maintaining continuous operations.

Stress Relief in Superalloy Castings FAQs

Why is stress relief crucial for superalloy castings in high-performance applications?

What are the primary techniques used in stress relief for superalloys?

How does stress relief impact the mechanical properties of superalloy castings?

What challenges do manufacturers face during the stress relief process for superalloys?

How does stress relief contribute to the extended lifespan of superalloy components?