Refining Microstructures with Heat Treatment in Alloys

Introduction to Heat Treatment

Heat treatment is an essential post-processing technique that significantly enhances superalloy components' durability, strength, and performance. Heat treatment can improve superalloys' structural integrity by applying controlled heating and cooling processes, often used in high-stress, high-temperature environments. Industries like aerospace, power generation, and chemical processing rely heavily on these enhancements, operating under extreme mechanical and thermal stresses.

The durability and lifespan of superalloy components can be significantly extended through heat treatment. This process helps relieve internal stresses, refines grain structure, and optimizes alloy homogeneity, enabling these components to withstand operational stress and repeated thermal cycles. Heat treatment is crucial for achieving long-term reliability and efficiency in applications where maintenance and downtime are costly.

What is Heat Treatment in Alloy Castings?

Definition and Purpose of Heat Treatment for Superalloy Castings

Heat treatment refers to a series of processes in which alloy castings are subjected to specific temperature cycles to alter and improve their properties. Standard methods include annealing, solution treatment, aging, quenching, and stress-relieving treatments. Each technique serves a unique purpose, addressing distinct characteristics within the alloy to optimize it for real-world applications. The process sequence typically involves

heating the component to a target temperature,

holding it for a specified time and

cooling it at a controlled rate to refine its internal structure.

Heat treatment's primary goal is to enhance superalloy components' performance, longevity, and resilience. By restructuring the alloy's internal grain structure and homogenizing its composition, heat treatment reduces the risk of warping, cracking, and fatigue. It enables superalloy parts to maintain strength, toughness, and stability even when exposed to extreme heat, mechanical loads, or environmental stressors. Heat treatment enhances the component's immediate mechanical properties and ensures that these properties are retained over time, increasing the component's operational life.

How Heat Treatment Enhances the Durability and Life of Superalloy Components

Heat treatment enhances durability by reducing internal stresses, refining the microstructure, and creating a more uniform distribution of elements within the alloy. It strengthens the material and ensures it can withstand mechanical and thermal fatigue. Components like turbine blades, combustion chambers, and gas turbine nozzles undergo continuous high-stress cycles that would lead to degradation without the stability and resilience provided by heat treatment.

Specifically, heat treatment processes like annealing and aging increase fatigue resistance by relieving residual stresses accumulated during the initial casting, forging, or machining processes. When stresses are left unaddressed, they can weaken the alloy over time, resulting in microcracks or fractures. By relieving these stresses, heat treatment ensures that the alloy remains structurally intact, minimizing the risk of premature failure. Additionally, heat treatment improves the alloy's ability to resist creep—deformation due to prolonged exposure to high temperatures—which is essential for parts that operate under constant thermal loads.

Understanding Microstructure in Superalloy Parts

What is Microstructure?

Microstructure is the arrangement and distribution of grains, phases, and other microscopic features within a material. In metals and alloys, microstructure is pivotal in determining fundamental properties like strength, toughness, creep resistance, and corrosion resistance. The grain structure, phase composition, and uniformity of the microstructure influence how the alloy will perform under various stresses and environments. For superalloys, achieving a refined microstructure with uniform grain boundaries and minimal defects is essential for optimal mechanical performance.

Importance of Microstructure in Superalloys

In superalloys, the microstructure is especially critical for durability, high-temperature stability, and corrosion resistance. Delicate, uniform grain structures enhance the alloy's strength and fatigue resistance, allowing it to withstand cyclic stresses encountered in applications like gas turbines and jet engines. A refined microstructure also improves creep resistance—essential for components exposed to prolonged high temperatures, such as turbine blades, where deformation can occur over time. Manufacturers can ensure that superalloy parts maintain mechanical and chemical stability by refining the microstructure, making them suitable for extreme operational conditions.

Overview of Heat Treatment in Superalloys

Types of Heat Treatment Processes

Heat treatment is a critical post-processing technique to refine the microstructure of superalloy parts. Here are several standard heat treatment methods:

Annealing: Involves heating the alloy to a specified temperature, then cooling it slowly to relieve internal stresses and achieve a uniform grain structure, enhancing material consistency.

Solution Treatment: In this process, the alloy is heated to dissolve unwanted phases, followed by rapid cooling to retain a single-phase structure. This technique is crucial for maintaining phase stability in high-temperature superalloys.

Aging: Aging is a controlled heating and cooling process that precipitates specific phases within the microstructure, enhancing hardness and strength, especially in fatigue-resistant components.

Quenching: This involves rapid cooling to trap desirable phases within the microstructure, increasing hardness and tensile strength, which is vital for high-stress applications.

Stress-Relieving: This process reduces residual stresses induced during casting or machining, preventing warping or cracking in service.

Each heat treatment process is designed to induce specific changes in the alloy's microstructure, optimizing its properties for high-performance applications.

Purpose of Heat Treatment for Microstructure Refinement

Heat treatment refines the microstructure of superalloys by precisely controlling grain size and phase distribution and eliminating defects like voids and microcracks. These refinements enhance mechanical strength, corrosion resistance, and thermal stability. Each heat treatment method has a unique impact: solution treatment removes unwanted phases while aging induces the precipitation of beneficial phases to improve hardness and durability. This precise microstructural control allows manufacturers to tailor superalloy components to specific operational requirements, ensuring they meet demanding performance standards in extreme environments.

Benefits of Refining Microstructures with Heat Treatment

Enhanced Mechanical Strength

Refined microstructures achieved through heat treatment contribute to higher tensile strength and load-bearing capacity. Heat treatment strengthens superalloys by reducing grain size and achieving a uniform grain structure, enabling them to resist mechanical stresses effectively. It is essential for components like turbine blades, which must endure extreme centrifugal forces without deforming, maintaining structural integrity and performance.

Improved Creep Resistance

Creep resistance is a material's ability to resist gradual deformation under constant stress at high temperatures. Heat treatment processes such as aging and solution treatment improve creep resistance by refining grain structure and precipitating phases that inhibit grain boundary sliding. This enhancement is critical for high-temperature applications like gas and steam turbines, where components are subjected to prolonged heat and stress.

Increased Fatigue Life

Heat-treated superalloy parts exhibit increased fatigue life, which can withstand more loading and unloading cycles before failure. Refined microstructures resist crack initiation and propagation more effectively, which is especially important in cyclic stress environments. This benefit is essential for rotating components in engines and turbines, where fatigue resistance directly affects performance and longevity.

Superior Corrosion and Oxidation Resistance

Heat treatment can refine the microstructure to create more effective alloys that resist oxidation and corrosion. Processes like annealing and aging promote a homogeneous structure, minimizing weak points that might otherwise succumb to corrosive elements. This enhanced resistance is crucial for superalloy parts used in oil, gas, and marine environments, where exposure to harsh chemicals and oxidizing environments is expected.

Enhanced Thermal Stability

Refined microstructures help superalloy components maintain their integrity under fluctuating thermal conditions. Heat treatment allows the alloy to resist phase transformations or structural changes better when exposed to high temperatures. This stability is essential for applications such as combustion chambers and turbine nozzles, where rapid temperature changes are routine.

Heat Treatment Techniques for Microstructure Refinement

Solution Treatment and Aging

Solution treatment involves heating the alloy to a temperature where undesirable phases dissolve, followed by rapid cooling to retain a single-phase structure. Aging is then applied to precipitate beneficial phases, which enhance hardness and strength. Together, these processes refine the microstructure, balancing strength and ductility and ensuring the alloy can endure demanding operational conditions. This combination is crucial for applications requiring durability and resilience, such as turbine components.

Annealing

Annealing heats the alloy to a designated temperature, followed by slow cooling to relieve internal stresses and achieve a uniform grain structure. This process enhances ductility, reducing brittleness and making components more resilient in high-stress applications. The improved toughness provided by annealing is valuable in superalloy components that withstand impact or cyclic loading without fracturing.

Quenching and Tempering

Quenching involves rapid cooling, typically in water or oil, to lock in desired phases and increase the alloy's hardness. Tempering follows quenching to reduce brittleness by reheating the alloy at a lower temperature. This technique creates an optimal balance between hardness and ductility, making it ideal for applications requiring strength and resilience, such as high-performance engine components and structural parts in aerospace.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) applies high pressure and temperature to densify the microstructure and remove internal voids. HIP significantly enhances mechanical properties like tensile strength and fatigue resistance by eliminating potential points of failure. This technique is especially beneficial for superalloy components produced through additive manufacturing, as it ensures a uniform, dense structure critical for performance in high-stress and high-temperature environments.

Typical Applications and Industries of Heat Treatment

Heat Treatment Applications in Different Industries

Heat treatment is widely applied across industries that require durable and reliable superalloy components. Some typical applications include:

Aerospace: Turbine blades, combustion chambers, exhaust components, and airframe parts in jet engines benefit from heat treatment for enhanced high-temperature resilience, durability, and resistance to thermal fatigue.

Power Generation: Heat treatment is applied to turbine blades, casings, and high-performance components in gas and steam turbines. It improves creep resistance, extends component life, and ensures stable operation under constant high-temperature conditions.

Oil and Gas: Parts such as drill bits, high-pressure valves, and extraction equipment in corrosive or high-stress environments require heat treatment to increase strength, corrosion resistance, and operational lifespan.

Marine and Chemical Processing: Superalloy components exposed to saltwater or aggressive chemicals rely on heat treatment for maximum corrosion resistance and durability, critical for long-term use in marine or processing applications.

Benefits of Heat Treatment for These Applications

Heat treatment provides several key advantages, such as improved operational life, reduced maintenance costs, and enhanced safety. In aerospace, for instance, components experience fewer failures and require less frequent replacement, essential in applications where downtime is highly costly and disruptive. In power generation, heat treatment improves the creep resistance of turbine parts, allowing for longer service intervals and reduced operational costs. These benefits demonstrate the importance of heat treatment in sustaining performance, efficiency, and reliability in industries that demand top-tier durability from their components.

Inspection and Quality Control of Heat-Treated Microstructures

Common Inspection Techniques

Metallographic Analysis: Examines grain structure and phase distribution to confirm that the desired microstructure has been achieved.

X-Ray Diffraction: Identifies phases within the alloy to verify that heat treatment has produced the correct structure.

Scanning Electron Microscopy (SEM): Provides detailed images of the microstructure, identifying defects or inconsistencies.

Hardness Testing: Measures surface hardness to ensure heat treatment improves mechanical properties.

Importance of Quality Control

Quality control is critical in heat-treated superalloy parts to verify that microstructural refinement has been achieved as intended. Each inspection method targets specific properties, ensuring the alloy has met its intended application's mechanical and structural requirements. By detecting any deviations early, manufacturers can prevent failures in the field, reducing downtime and maintenance costs.

What Superalloy Parts Need Heat Treatment

Heat treatment is necessary for various superalloy parts to enhance their durability and performance. Here are some common examples:

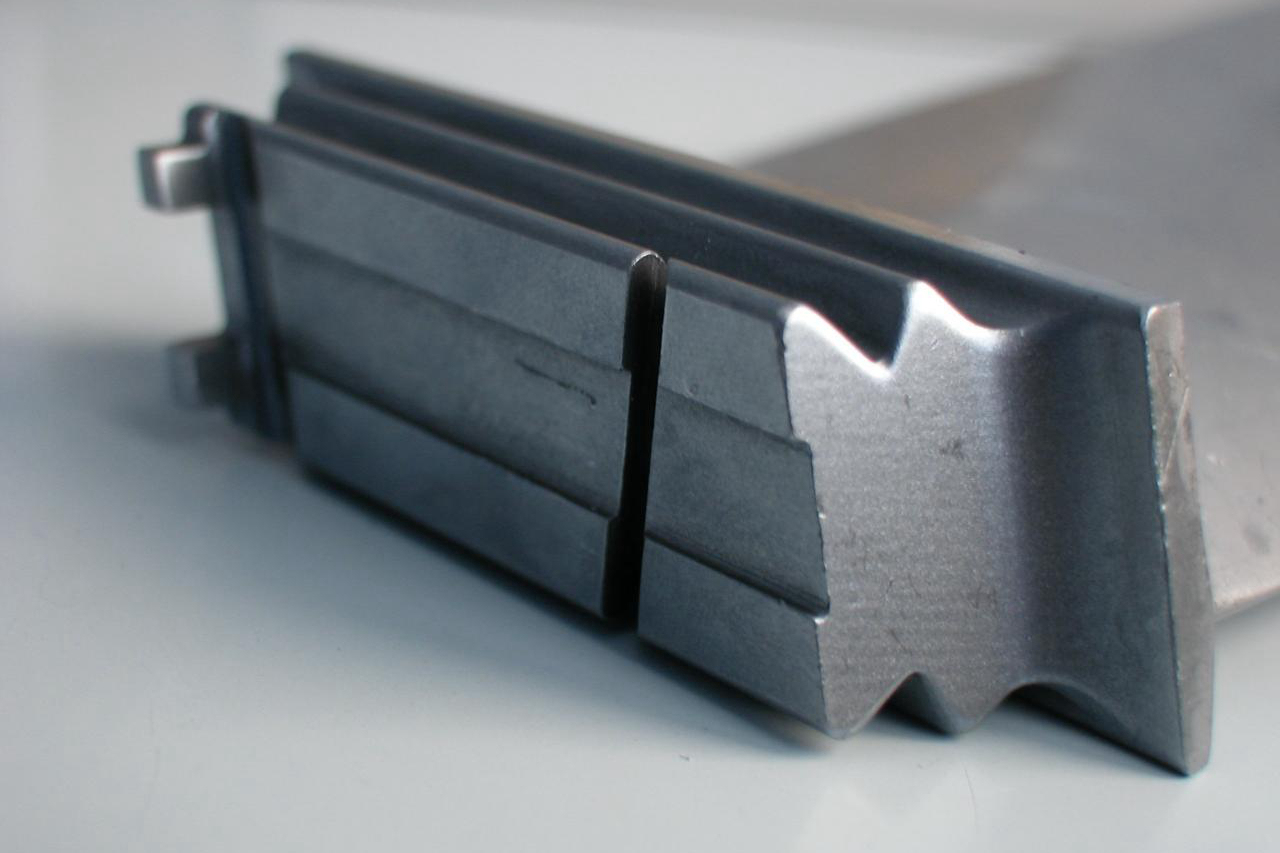

Vacuum Investment Castings: These castings benefit from heat treatment to improve strength and resistance to high temperatures.

Single Crystal Castings: Heat treatment is essential to ensure the optimized grain structure, which is crucial for high-stress applications.

Equiaxed Crystal Castings: Heat treatment refines the uniform grain structure, enhancing durability under thermal stress.

Directional Castings: This casting type requires heat treatment to align grain structures for enhanced mechanical properties.

Special Alloy Castings: Tailored heat treatment ensures these castings meet specific performance standards.

Powder Metallurgy Superalloy Parts: Heat treatment is applied to achieve optimal density and structural integrity.

Precision Forging Parts: Heat treatment improves strength and refines grain flow in these forged parts.

CNC Machined Superalloy Parts: Post-machining heat treatment enhances mechanical properties and reduces residual stress.

3D Printed Superalloy Components: Heat treatment stabilizes the microstructure and improves mechanical consistency.

Each component benefits from refined microstructures, achieved through heat treatment processes tailored to their specific requirements.

Heat Treatment FAQs

What are the main types of heat treatment processes for superalloy parts?

How does heat treatment improve fatigue resistance in superalloy components?

What is the role of microstructure in corrosion resistance?

How long does a typical heat treatment cycle take for superalloys?

What is the difference between HIP and other heat treatment methods?