Preparation of Single Crystal Guide Blades and Multiple Integrated Casting Service

Single crystal guide blades are indispensable in high-performance turbine systems, where they manage airflow, enhance efficiency, and ensure long-term reliability. These blades are used in critical applications such as aerospace engines, power generation turbines, and advanced defense systems. Their ability to withstand extreme temperatures and mechanical stress is directly tied to their defect-free single crystal structure.

The production of these advanced components is a complex and demanding process. It requires precise casting techniques, high-performance superalloys, and rigorous quality control. Multiple integrated casting services further streamline this process by combining various production stages into a cohesive operation, enhancing efficiency and quality.

The Single Crystal Casting Process

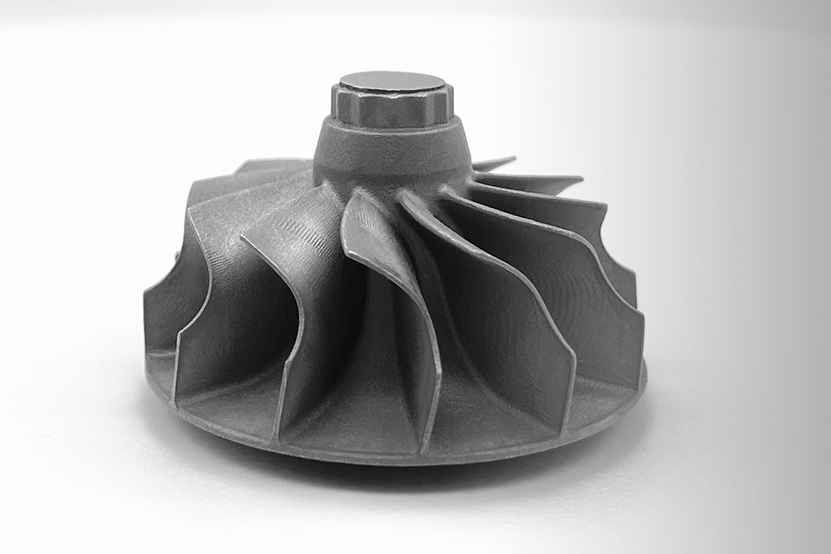

Producing single-crystal guide blades begins with sophisticated casting methods that ensure uniform crystal structures and minimize defects. Each step in the casting process is critical to achieving the desired mechanical and thermal properties.

Vacuum investment casting is a cornerstone of single crystal production. This process occurs in a vacuum environment to prevent oxidation and contamination, which can degrade the material’s properties. The molten superalloy is poured into a pre-designed ceramic mold, allowing for the precise replication of intricate guide blade geometries. Advanced techniques in vacuum investment casting ensure high-quality results, particularly for components used in demanding environments.

Directional solidification ensures the formation of a single crystal structure. By creating a controlled temperature gradient, the molten alloy can solidify in a single direction, promoting the growth of a uniform crystal. Innovations in directional solidification, such as improved cooling systems and advanced thermal controls, reduce the risk of grain boundary formation, enhancing the blade’s mechanical performance and longevity.

Seeding techniques play a vital role in guiding crystal growth. A seed crystal is introduced at the base of the mold to initiate the formation of a single crystal. The alignment and integrity of the seed are critical, as any deviation can lead to secondary grains or defects. Precise seeding methods, in conjunction with superalloy single crystal casting, ensure the production of high-quality turbine components with uniform properties.

Simultaneous casting processes are increasingly used to enhance efficiency and reduce production time. By integrating multiple casting operations into a single workflow, manufacturers can produce guide blades and other turbine components more cost-effectively while maintaining stringent quality standards. Processes like superalloy CNC machining are often employed post-casting to achieve these high-performance parts' precision and surface finish.

Suitable Single Crystal Casting Superalloys

The performance of single crystal guide blades is highly dependent on the superalloys used in their construction. These materials are engineered for extreme environments, offering high-temperature strength, oxidation resistance, and exceptional mechanical properties.

Inconel Alloys

Inconel alloys are a common choice for guide blade casting. Alloys such as Inconel 738 and Inconel 713 provide excellent thermal fatigue and oxidation resistance, making them ideal for turbine applications. However, achieving a defect-free single crystal structure with these alloys requires precise control of cooling rates and solidification conditions.

CMSX Series

The CMSX superalloys, including CMSX-4 and CMSX-10, are specifically designed for single crystal applications. Even in the most demanding environments, these alloys offer superior creep resistance and thermal stability. Advances in CMSX alloy compositions, such as reduced segregation and improved grain boundary resistance, have further enhanced their suitability for guide blade casting.

Rene Alloys

Rene alloys, such as Rene 104 and Rene 88, are another preferred option for high-performance guide blades. These alloys are known for their exceptional thermal fatigue resistance and high-temperature strength. However, the complexity of their composition and casting process requires meticulous attention to detail.

Specialized single-crystal alloys

Specialized single crystal alloys, such as PWA 1484 and CMSX-2, are tailored for specific turbine applications. These materials are optimized for durability, thermal stability, and long-term reliability. Their use demands advanced casting techniques and stringent quality control for consistent performance.

Post-Processing for Single Crystal Guide Blades

Post-processing plays a crucial role in refining the properties of single-crystal guide blades and ensuring their performance under extreme conditions. Each post-processing step addresses specific challenges related to structural integrity and mechanical properties.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is a critical step in eliminating porosity and improving the density of the material. This process involves applying high pressure and temperature to the cast component, which closes internal voids and strengthens the material. However, maintaining the single crystal structure during HIP requires precise pressure and temperature control.

Heat Treatment

Heat treatment enhances the mechanical properties of guide blades, such as tensile strength, ductility, and creep resistance. The heat treatment process must be carefully tailored to each alloy to avoid unwanted grain recrystallization or microstructural inconsistencies.

Surface Finishing and Coating

Surface finishing and coating processes, including applying Thermal Barrier Coatings (TBC), protect guide blades from oxidation and thermal damage. TBCs reduce heat transfer and extend the service life of the component. Advanced application techniques, such as plasma spraying, ensure a consistent and durable coating.

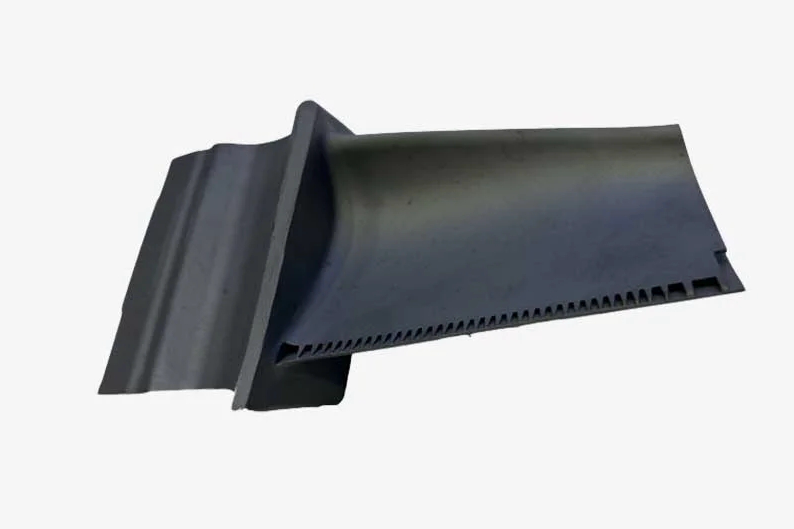

CNC Machining and Deep Hole Drilling

CNC machining and deep hole drilling are employed to achieve the precise geometries and internal cooling channels required for guide blades. These processes demand high levels of precision to avoid dimensional inaccuracies or damage to the blade structure. Creating intricate cooling channels is particularly challenging due to the tight tolerances and complex designs.

Testing and Quality Assurance

Rigorous testing ensures that single crystal guide blades meet the highest quality and performance standards. Testing methods are designed to identify defects, evaluate mechanical properties, and verify compliance with design specifications.

Metallographic Microscopy and SEM

Metallographic microscopy and Scanning Electron Microscopy (SEM) are used to examine the microstructure of guide blades. These techniques provide detailed insights into the crystal structure, allowing manufacturers to detect defects such as grain misalignments or inclusions.

X-ray and CT Scanning

X-ray testing and industrial CT scanning are critical for inspecting the internal integrity of guide blades. These non-destructive testing methods can identify internal voids, cracks, or inclusions that may not be visible on the surface. Industrial CT scanning is particularly valuable for verifying the accuracy of cooling channels and other complex internal features.

Fatigue and Tensile Testing

Fatigue and tensile testing simulate the real-world stresses that guide blades will encounter in service. These tests assess the component’s ability to withstand thermal cycling, mechanical loads, and prolonged use under extreme conditions. Accurate simulation of operational environments is essential for reliable results.

Electron Backscatter Diffraction (EBSD)

Electron Backscatter Diffraction (EBSD) testing provides a detailed crystal orientation and alignment analysis. This technique ensures that the single crystal structure meets the design specifications and identifies any deviations that could impact performance.

Industry Applications and Integrated Casting Services

Single crystal guide blades are used across various industries where their ability to withstand harsh environments and optimize performance is critical. Integrated casting services play a vital role in meeting the specific demands of these industries.

Aerospace and Aviation

In aerospace and aviation, single crystal guide blades are vital to jet engines. They optimize airflow, enhance efficiency, and improve the engine’s resistance to thermal fatigue. Integrated casting services streamline the production of these complex components, ensuring consistent quality and performance in aerospace and aviation applications.

Power Generation

The power generation industry relies on guide blades for gas and steam turbines. These components are essential for maximizing energy output and minimizing emissions. Power generation facilities depend on integrated casting services to meet high production demands while maintaining stringent quality standards for long-term efficiency and reliability.

Oil and Gas

In oil and gas, guide blades are used in compressors and pumps operating in harsh environments. The durability and reliability of single crystal guide blades are critical in these applications, where components are subjected to extreme pressures and temperatures. Oil and gas operations benefit from integrated casting services to produce high-performance blades that endure demanding operating conditions.

Defense and Military

Defense and military applications require guide blades for advanced propulsion systems and other critical technologies. These components must meet rigorous performance standards, withstanding extreme conditions and high stress. Military and defense sectors rely on integrated casting services to ensure the production of reliable, high-quality components for mission-critical systems.

FAQs

What are the benefits of using integrated casting services for single crystal guide blade production?

How do CMSX and Rene alloys enhance the performance of single crystal guide blades?

What role does directional solidification play in preventing crystal defects during casting?

Why is Hot Isostatic Pressing (HIP) critical in the post-processing of guide blades?

What testing methods are used to ensure the quality of single-crystal guide blades?