Precision Machining of Hard Alloys with EDM

Electrical Discharge Machining (EDM) for Hard Alloy Components

Electrical Discharge Machining (EDM) is an advanced post-processing technique that has become essential for machining hard alloys, especially superalloys used in high-temperature and high-stress applications. EDM’s ability to create intricate geometries and precise dimensions on challenging materials makes it invaluable across aerospace, power generation, defense, and chemical processing.

Unlike traditional machining methods, EDM is a non-contact, thermal-based process that uses electrical discharges to remove material, resulting in excellent tolerances and high-quality finishes. This article explores the unique capabilities of EDM for hard alloy components, examining suitable materials, specific applications, comparisons with other post-processing techniques, inspection methods, and industry relevance.

Typical Superalloys Suitable for EDM

EDM is ideally suited for a range of superalloys, known for their high resistance to temperature, corrosion, and wear. These characteristics make superalloys difficult to machine with conventional methods, but they are perfect for EDM due to their ability to handle hard materials precisely and without mechanical stress. Below are typical superalloys that benefit from EDM, organized by brand and grade:

Inconel Alloys:

Inconel 718: Known for its excellent strength and resistance to oxidation and corrosion, Inconel 718 is a preferred choice in gas turbine and jet engine components.

Inconel 625: With outstanding fatigue and oxidation resistance, this alloy is frequently used in high-stress applications where flexibility and strength are essential.

Inconel X-750: This high-temperature alloy resists oxidation and corrosion and is used in various aerospace applications, including nuclear reactors.

Inconel 738C: With excellent creep resistance, this alloy is widely used for turbine blades and other high-temperature sections in gas turbines.

CMSX Series:

CMSX-10: This alloy offers superb creep strength, making it ideal for turbine blades and other high-stress aerospace components.

CMSX-486: Known for its high strength and stability, CMSX-486 is used for hot-section components exposed to extreme temperatures.

CMSX-6: This single-crystal alloy is designed for applications requiring exceptional thermal stability, such as rotating turbine parts.

CMSX-7: With remarkable creep resistance, CMSX-7 is commonly used in turbines and industrial gas turbines.

Monel Alloys:

Monel K500: This alloy combines excellent corrosion resistance with high strength, making it suitable for marine applications and chemical processing equipment.

Monel 400: Known for its resistance to seawater corrosion, Monel 400 is widely used in marine environments.

Monel R-405: This alloy’s enhanced machinability makes it popular for precision equipment in the oil and gas industry.

Monel 450: This alloy’s strength and corrosion resistance are ideal for pump and heat exchanger applications.

Hastelloy Alloys:

Hastelloy C-276: With exceptional resistance to pitting and stress corrosion, Hastelloy C-276 is extensively used in chemical processing applications.

Hastelloy B-2: This alloy is ideal for hydrochloric acid processing due to its resistance to reducing environments.

Hastelloy X: This high-temperature alloy is frequently used in jet engines and gas turbines.

Hastelloy G-35: Its superior resistance to corrosive environments makes it an excellent choice for chemical and petrochemical processing.

Which Superalloy Parts Require EDM

Electrical Discharge Machining (EDM) is essential for post-processing hard alloy components that require high precision and complex geometries, particularly in applications where traditional machining would struggle or introduce unwanted stress. Below are some superalloy parts that commonly undergo EDM processing:

Vacuum Investment Castings

This category includes single crystal castings, equiaxed crystal castings, directional castings, and special steel investment castings. These parts are often found in high-temperature environments like gas turbines and jet engines, where their intricate geometries are best refined through EDM. EDM allows precise modifications to these castings, ensuring tight tolerances and detailed shapes without compromising the integrity of the cast structure.

Precision Forged Superalloy Parts

Parts such as isothermal forged, rough forged, and free-forged superalloy components require EDM’s precision to achieve the final specifications. These parts are commonly used in aerospace and power generation, where strength and resilience are critical. EDM allows for precise contouring of forged parts without mechanical stress, resulting in high-strength parts with superior finishes.

Powder Metallurgy Parts

Components created through powder metallurgy processes benefit from EDM’s non-contact machining, which preserves the structural integrity of brittle or complex powder-based parts. EDM is beneficial for adding intricate features or refining dimensions on parts that would otherwise be challenging to machine.

CNC Machined Superalloy Parts

While CNC machining can achieve a high level of accuracy, EDM can further refine parts, especially for complex internal features and tight tolerances. EDM is also useful when a CNC-machined part needs finishing or additional detailing to meet stringent requirements.

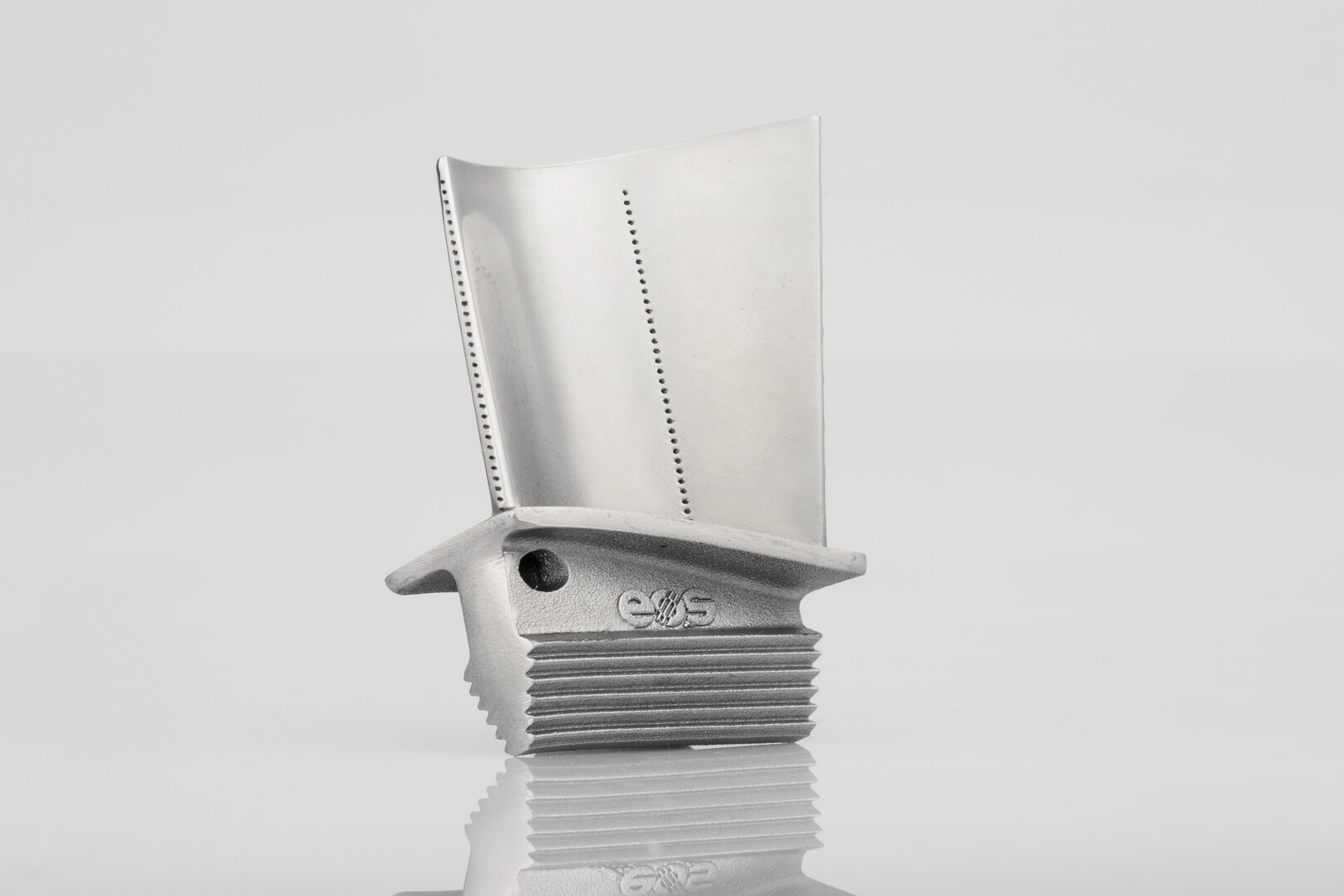

3D Printed Superalloy Parts

Additive manufacturing allows for creating intricate superalloy parts, but EDM is often required as a post-processing step to smooth and refine these parts for optimal performance. EDM ensures that 3D-printed superalloy parts meet the specifications for high-stress applications.

Comparison with Other Post-Processing Methods

Electrical Discharge Machining (EDM) offers unique advantages over other post-processing methods, particularly in its non-contact, thermal-based material removal approach. Here’s how EDM compares to other standard techniques:

EDM vs. CNC Machining

CNC machining is effective for shaping and drilling but needs help with complex internal geometries, especially in hard alloys. EDM provides a higher degree of precision for intricate shapes and acceptable tolerances without introducing mechanical stress, making it ideal for superalloys that are difficult to machine with conventional methods. This capability is critical for parts requiring complex cooling channels or internal structures in aerospace and energy applications.

EDM vs. Laser Machining

Laser machining is a fast and precise process, but it can cause thermal stress, leading to microcracking in superalloys. EDM’s non-contact, non-thermal approach avoids these issues, enabling stress-free machining for sensitive components. This ability to machine without inducing thermal damage is essential to maintaining structural integrity for high-stress superalloy parts.

EDM vs. Grinding

Grinding is a surface-finishing process that is challenging to use on complex or internal geometries in superalloys. EDM allows for precision material removal in intricate profiles that grinding cannot achieve, making it a superior choice for detailed finishing. It is precious for components that require high tolerance and fine details in hard-to-reach areas.

EDM vs. Water Jet Cutting

While water jet cutting is suitable for flat or semi-flat profiles, it cannot handle internal geometries or fine details as effectively as EDM. EDM offers the flexibility to machine intricate internal features with high precision, making it more versatile for superalloy applications. This versatility is beneficial for manufacturing high-performance parts with complex internal designs.

How to Detect High-Temperature Alloy Parts After EDM

Inspection and testing of EDM-processed superalloy parts are crucial for ensuring quality and adherence to specifications. The following techniques are commonly used:

Coordinate Measuring Machine (CMM) Testing

CMM testing measures precise dimensions to verify that EDM-machined parts meet tight tolerances. This process ensures that each part complies with design specifications for dimensional accuracy.

X-ray Testing

X-ray inspections detect any internal voids or defects that may have formed during EDM processing, ensuring high standards of quality and reliability, particularly for aerospace and defense applications.

Metallographic Microscopy

Metallographic microscopy allows for examining the microstructure to verify structural integrity after EDM processing. It provides insights into grain structure and phase consistency, identifying unwanted changes.

Scanning Electron Microscopy (SEM)

SEM provides high-resolution imaging for detecting surface imperfections and microcracks that may result from EDM. This level of inspection is essential for assessing potential impact on performance.

Tensile Testing

Tensile testing assesses the strength and elasticity of the part to ensure it meets the mechanical performance requirements. This test is crucial for verifying that the EDM process has not compromised the alloy’s integrity.

Surface Roughness Testing

As EDM can produce different surface finishes, surface roughness testing ensures that parts meet the required specifications for surface quality. Maintaining optimal surface roughness is vital for parts exposed to high-stress environments.

Industry and Application

EDM-processed superalloy components are critical in various industries, particularly where extreme environments and precision engineering are required. Here’s a look at the primary industries and applications for EDM-machined complex alloy components:

Aerospace and Aviation

EDM enables the precision machining of turbine blades, jet engine components, and exhaust systems. These parts must withstand high temperatures and stress, making EDM’s stress-free, precise machining ideal for aerospace applications, such as superalloy jet engine components.

Power Generation

Superalloy parts in gas and steam turbines, heat exchangers, and nuclear reactors benefit from EDM’s ability to handle complex shapes and exacting tolerances. It is essential for high-pressure, high-temperature operations, where components like superalloy heat exchanger parts must perform reliably under demanding conditions.

Military and Defense

EDM is used for processing armor systems, missile components, and other critical equipment where durability and reliability are paramount. Its precision capabilities are crucial for manufacturing superalloy armor system parts and missile components, which require tight tolerances for high-stress environments.

Chemical Processing

Superalloy components that resist corrosion and high temperatures are vital in chemical processing, where EDM ensures these parts meet the necessary precision for safe, efficient operation in corrosive environments.

Oil and Gas

Superalloy parts in downhole tools, pumps, and control valves endure harsh environments. EDM’s precision machining ensures these components, such as high-temperature alloy pump components, can withstand extreme conditions in the field, ensuring durability and performance under high pressure.

FAQs

What is the maximum thickness of a complex alloy component that EDM can process?

How does EDM’s material removal rate compare to other post-processing methods?

Can EDM handle both large and small-scale superalloy components?

How long does EDM take for intricate, complex alloy components?

What are the benefits of EDM for precision machining compared to laser cutting?