Precision High-Temperature Alloy Components for Subsea Valve Supply

High-temperature alloy components are indispensable in critical industries that face extreme operational conditions, such as subsea oil and gas exploration. In such environments, where high pressure, elevated temperatures, and corrosive seawater are typical, the materials must be durable and withstand harsh conditions. Among the best materials for this purpose are superalloys, which offer superior strength, resistance to corrosion, and the ability to maintain performance even in extreme environments.

Subsea valves, used in offshore drilling and subsea pipeline systems, must perform reliably under such demanding circumstances. This blog delves into the role of superalloy materials in subsea valve components, explaining why they are essential, how they are manufactured, and how rapid prototyping techniques ensure precision in the final products.

Superalloy Subsea Valve Components

Subsea valves are critical components in subsea oil and gas infrastructure. These valves control the flow of oil, gas, and other fluids, often in deep-sea conditions where pressures can exceed 20,000 psi, and temperatures can range from freezing to several hundred degrees Celsius. The challenges of such environments demand components that can withstand:

High pressure: Valves must remain sealed and operational under extreme pressure.

High temperatures: As subsea production systems deal with high-temperature fluids, the materials must retain their strength at elevated temperatures.

Corrosive environments: Seawater is highly corrosive, and valves must resist saltwater and other chemicals that can accelerate material degradation.

Superalloys are engineered to thrive in these conditions. Their ability to resist oxidation, maintain mechanical strength, and withstand thermal creep makes them the ideal material for subsea valves. In this context, superalloy subsea valve components ensure the safety and longevity of offshore equipment.

Typical Superalloys Used in Subsea Valve Components Manufacturing

The performance of subsea valves largely depends on the choice of material. Superalloys used for subsea valve components are chosen based on their specific properties, such as resistance to corrosion, oxidation, high temperature, and mechanical stress. Let's look at the typical superalloys used in subsea valve manufacturing:

Inconel Alloys: Inconel 625 is known for its exceptional resistance to oxidation and corrosion at elevated temperatures, making it ideal for subsea valve components exposed to harsh saltwater environments. The alloy's high strength and resistance to chloride-induced stress corrosion cracking further enhance its suitability for subsea applications. Inconel 718, on the other hand, is valued for its excellent mechanical properties, including high strength, creep resistance, and fatigue strength, making it suitable for valves that endure extreme mechanical stress and temperature variations in deep-sea environments.

Hastelloy Alloys: Hastelloy C-276 provides outstanding resistance to pitting, crevice corrosion, and stress corrosion cracking, especially in aggressive environments like seawater. Its high resistance to various chemicals and high temperatures makes Hastelloy alloys a preferred choice for long-term subsea applications exposed to highly corrosive substances.

Monel Alloys: Monel 400 offers high resistance to seawater and is highly effective at preventing stress corrosion cracking in chloride-rich environments. The combination of high strength and excellent corrosion resistance makes Monel 400 ideal for subsea valve components.

Titanium Alloys: Titanium alloys, particularly Ti-6Al-4V, are prized for their excellent strength-to-weight ratio and resistance to corrosion in chloride environments like seawater. Titanium alloys maintain high mechanical properties at elevated temperatures and are often used where weight reduction is critical without sacrificing performance.

Manufacturing Process and Equipment of Superalloy Subsea Valve Components

To meet the demanding requirements of subsea valve components, superalloys must undergo advanced manufacturing processes to ensure precision and reliability. Various processes, such as casting, machining, and additive manufacturing, produce complex, high-quality subsea valve components.

Vacuum investment casting is one of the primary methods used to produce subsea valve components made from superalloys. This method begins with creating a detailed wax pattern of the valve component coated with a ceramic shell. The mold is then heated, causing the wax to melt away, leaving behind a hollow cavity in the shape of the component.

The mold is subsequently filled with molten superalloy poured under vacuum conditions. The vacuum environment prevents oxidation and reduces the risk of gas inclusions, ensuring high-quality castings with minimal defects. Once the casting has cooled, it is removed from the shell and subjected to additional post-processing treatments such as heat and machining.

Superalloy Directional Casting

Directional casting is another process often used to produce high-performance subsea valve components. In this technique, the solidification of the molten superalloy is controlled to form a microstructure with favorable properties. The direction of solidification is carefully managed to produce uniform grain structures that improve the mechanical properties of the final component.

This method is particularly advantageous for subsea valve components, as it can enhance the alloy's resistance to high-pressure fatigue and thermal stresses, ensuring that the components can withstand the harsh conditions of subsea operations.

Powder metallurgy (PM) is an advanced technique for manufacturing high-strength, complex components. Fine metal powders are blended, compacted into molds, and sintered at high temperatures to form solid parts. The resulting superalloy parts exhibit superior wear resistance, fine-grained microstructures, and uniform properties, making them ideal for the harsh environments encountered by subsea valves.

Powder metallurgy is particularly useful when designing intricate subsea valve components with complex geometries that may be difficult to achieve using traditional casting methods.

CNC machining achieves the acceptable tolerances and surface finishes required in subsea valve components. CNC machines precisely cut, mill, and shape superalloy components to specifications, ensuring that the final parts fit together correctly and perform optimally in subsea systems.

This process is essential for producing high-precision valve components with complex shapes, such as valve seats, actuators, and other critical parts. CNC machining also helps to achieve smooth surface finishes, reducing the potential for corrosion and improving the durability of the components.

Superalloy Additive Manufacturing

Additive manufacturing, particularly Selective Laser Melting (SLM) and Laser Metal Deposition (LMD), is a growing technique in producing subsea valve components. Additive manufacturing builds components layer by layer, providing high precision and the ability to create complex geometries that would be difficult or impossible to produce using traditional methods.

SLM allows for high material efficiency, minimal waste, and the ability to produce custom valve components in a relatively short timeframe. It also enables high-performance superalloys, such as Inconel, Hastelloy, and titanium, to manufacture robust subsea valve components.

Testing Methods and Equipment in Superalloy Subsea Valve Components QC

Ensuring the quality of subsea valve components is essential for ensuring safety and operational reliability. The extreme operating conditions in subsea environments demand that these components undergo stringent testing to confirm that they meet the necessary standards.

X-ray Inspection

X-ray inspection is a widely used non-destructive testing (NDT) method that allows manufacturers to detect internal defects within superalloy subsea valve components, such as porosity, cracks, or inclusions. Using X-ray imaging, the internal structure of the component can be examined without causing any damage to the part. This testing method is essential for ensuring valve components' structural integrity before being put into service.

Ultrasonic Testing

Ultrasonic testing uses high-frequency sound waves to assess the thickness and integrity of subsea valve components. Manufacturers can identify flaws, such as cracks or voids, by measuring the time it takes for sound waves to travel through the material and return to the sensor. Ultrasonic testing is particularly effective at identifying subsurface defects that may not be visible on the surface.

Tensile and Fatigue Testing

Tensile testing is used to determine the mechanical properties of the superalloy, such as tensile strength, yield strength, and flexibility. Fatigue testing simulates the cyclic loading and unloading that subsea valve components undergo during operation, helping to ensure they can withstand repeated stresses without failure. These tests are critical in assessing the durability of the components in real-world subsea conditions, where repeated cycles of pressurization and depressurization can lead to component failure over time.

Chemical Composition Analysis

The chemical composition of the superalloy is analyzed using methods such as Optical Emission Spectroscopy (OES) or X-ray Fluorescence (XRF). The alloy's composition directly influences its mechanical properties, corrosion resistance, and high-temperature performance. Ensuring that the composition of the material aligns with the specified requirements is a vital part of the quality control process, with ICP-OES playing a pivotal role in confirming alloy consistency.

Industries and Applications of Superalloy Subsea Valve Components

Superalloy subsea valve components are primarily used in the oil and gas industry, where their resistance to high pressure, temperature, and corrosion is vital. However, these components are also applicable in other sectors that require high-performance valves for demanding environments, such as:

Offshore Oil and Gas: Subsea valves control the flow of hydrocarbons in deep-sea drilling operations, pipeline systems, and offshore rigs.

Nuclear Power: Subsea valve components may be used in subsea cooling systems or nuclear reactors, where high-temperature and high-pressure capabilities are crucial.

Chemical Processing: Subsea valves in chemical processing plants require resistance to aggressive chemicals and corrosive environments.

Typical Post-Process of Superalloy Subsea Valve Components

Once the superalloy subsea valve components have been manufactured, they typically undergo several post-processing steps to ensure optimal performance. These processes include:

Heat Treatment: Heat treatment relieves internal stresses, improves hardness, and enhances material properties like tensile strength and creep resistance.

Surface Treatment: Surface coatings, such as thermal barrier coatings (TBC) or laser cladding, can improve corrosion and wear resistance.

Polishing and Machining: Final machining processes, such as polishing, help achieve the desired surface finish and dimensions, ensuring the components are smooth and defect-free.

Rapid Prototyping and Verify of Superalloy Subsea Valve Components

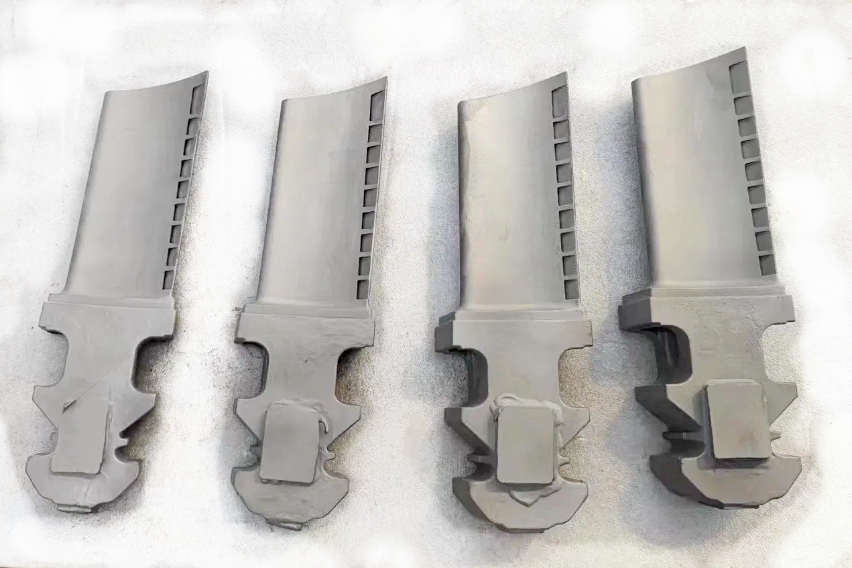

Rapid Prototyping Process: Superalloy 3D Printing and CNC Machining

Rapid prototyping methods, such as superalloy 3D printing and CNC machining, are essential in subsea valve component manufacturing. These methods allow manufacturers to quickly iterate on designs, produce functional prototypes, and verify part fitment before mass production. 3D printing of superalloys offers significant advantages in terms of part complexity, material efficiency, and time savings, while CNC machining ensures precision and accuracy in the final product.

Importance of Verifying Samples

Verifying prototypes and samples is crucial to ensure that the final subsea valve components meet design specifications and can withstand operational conditions. Testing prototypes before mass production can help identify potential issues, prevent costly mistakes, and confirm that the materials and manufacturing processes will deliver the required performance.

FAQs about Superalloy Subsea Valve Components Manufacturing

What superalloys are most commonly used in subsea valve components?

How does vacuum investment casting contribute to the manufacturing of subsea valve components?

What are the main benefits of additive manufacturing in subsea valve production?

How do heat treatments improve the performance of subsea valve components?

What are the key challenges in manufacturing subsea valve components from superalloys?