Precision and Tight Tolerances in CNC Machining of Alloys

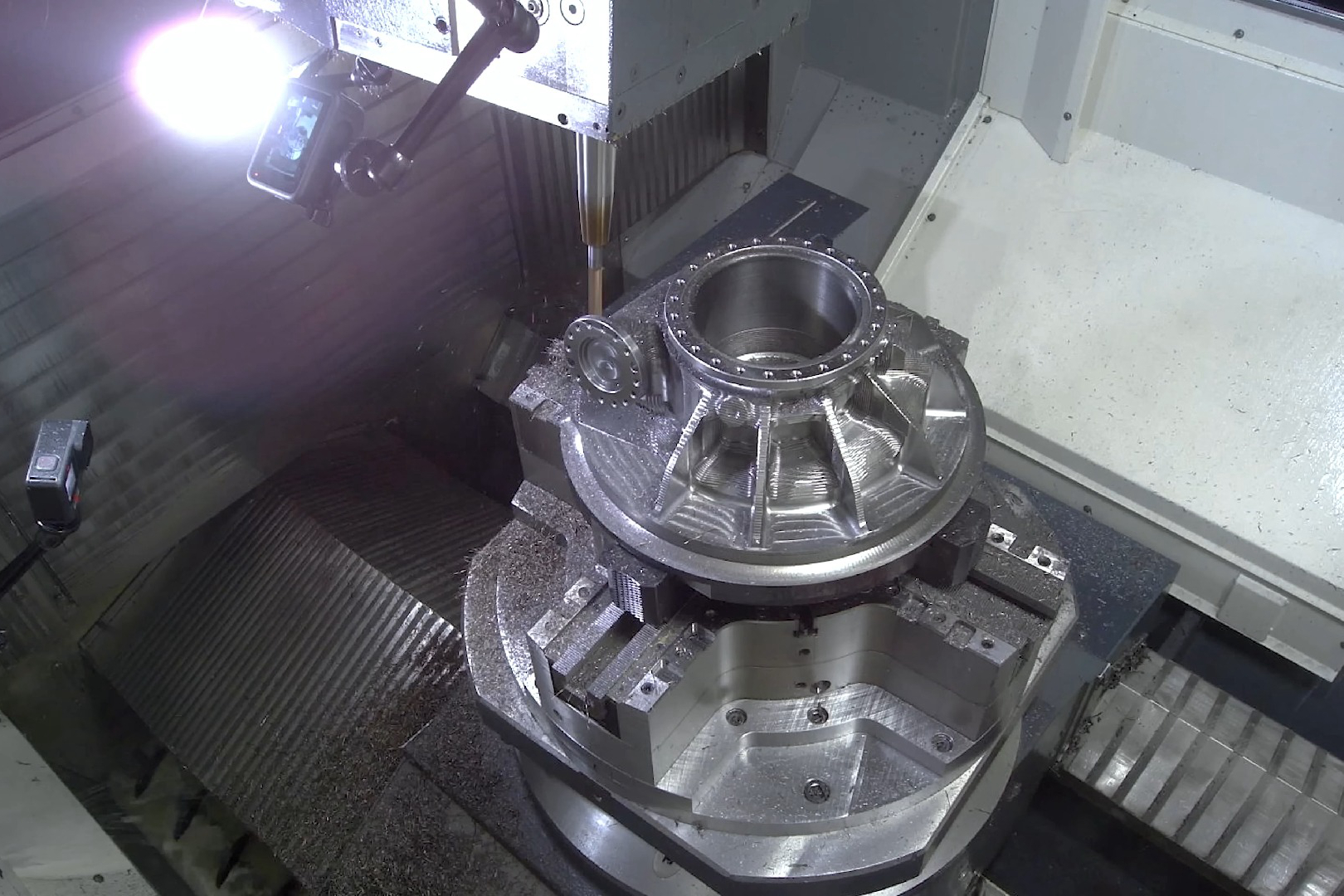

At Neway Precision Works, we specialize in processing high-temperature alloys and superalloys, which are integral to critical applications in aerospace, power generation, defense, and more. One of the key technologies we utilize to achieve high precision and tight tolerances in superalloy parts is CNC machining (Computer Numerical Control). This blog delves into how CNC machining ensures exceptional accuracy, reliability, and performance for superalloy parts and its role in manufacturing advanced components used in demanding environments.

Introduction to CNC Machining for Superalloy Parts

In industries such as aerospace and power generation, where components are exposed to extreme temperatures and mechanical stresses, precision is non-negotiable. Manufacturing parts from superalloys like Inconel, CMSX, Monel, Hastelloy, and Titanium alloys demands the utmost accuracy in material handling and machining. CNC machining offers an efficient and reliable solution for achieving this precision, making it a vital process in producing critical superalloy components.

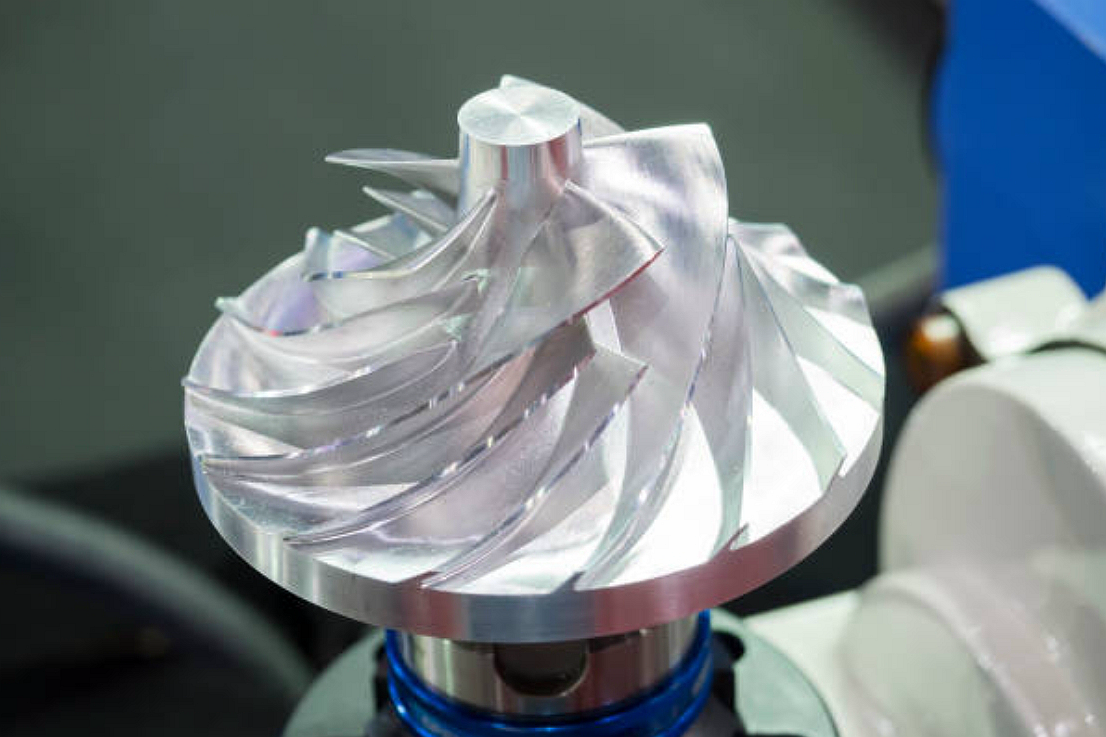

CNC machining allows manufacturers to produce parts with extremely tight tolerances and complex geometries. For example, components such as turbine blades, combustion chambers, nozzle rings, and various other engine and power plant parts require high precision to ensure they perform reliably over extended periods under harsh conditions. In this blog, we will explore the various benefits of CNC machining, particularly for superalloy castings, and how Neway ensures that every part meets the demanding standards required for optimal performance.

Materials Used in CNC Machining of Superalloy Parts

At Neway, we work with a wide range of superalloys and special alloys with excellent properties for high-temperature and high-stress applications. These include Inconel alloys (such as Inconel 718 and Inconel 625), CMSX single crystal, Monel, Hastelloy, and various Titanium alloys. Each of these materials has unique properties that make them ideal for aerospace, power generation, and other critical applications:

Inconel Alloys:

Known for their excellent heat and oxidation resistance, Inconel alloys (especially Inconel 718) are widely used in gas turbines, rocket engines, and other aerospace components that withstand extreme temperatures.

CMSX Alloys:

Single crystal alloys, such as CMSX-10 and CMSX-486, are primarily used for turbine blades in jet and gas turbines, where superior creep resistance and mechanical properties are required.

Monel Alloys:

These nickel-copper alloys are prized for their corrosion resistance and are often used in marine and chemical applications where parts are exposed to harsh environments. Monel 400 and Monel K500 are prime examples of this class.

Hastelloy Alloys:

With outstanding resistance to corrosion and oxidation, Hastelloy alloys are used in applications where components must endure high temperatures and aggressive chemical environments, such as in chemical processing industries. Materials like Hastelloy C-276 are commonly used in such demanding environments.

Titanium Alloys:

Titanium alloys like Ti-6Al-4V are known for their strength-to-weight ratio, making them essential for aerospace and automotive industries where light but durable components are needed.

Each of these materials poses unique challenges in machining due to their high strength, toughness, and resistance to wear and heat. However, CNC machining can handle these challenges, providing the accuracy and precision required for producing high-performance components.

Post-Processing of CNC-Machined Superalloy Parts

After CNC machining, several post-processing techniques are applied further to enhance the performance and quality of superalloy parts. These include:

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is a process used to improve superalloy parts' density and mechanical properties. It is particularly effective in removing internal porosity, which could otherwise reduce the strength and fatigue resistance of the part. After CNC machining, parts are subjected to HIP at high temperatures and pressures, eliminating porosity and ensuring a uniform material structure. The benefits of HIP include improved material integrity and enhanced performance in demanding applications.

Heat Treatment

Heat treatment is a critical step for enhancing the mechanical properties of CNC-machined superalloy components. It improves properties such as tensile strength, fatigue resistance, and creep resistance. The heat treatment process ensures that superalloy parts can withstand the extreme operating conditions typically encountered in aerospace, energy, and defense industries. Heat treatment optimizes the performance and durability of high-temperature alloy parts through aging and solution annealing.

Surface Finishing

CNC-machined superalloy parts undergo various surface finishing operations to achieve the necessary surface properties. Techniques like polishing, grinding, and shot peening improve wear resistance, reduce surface roughness, and enhance fatigue life. Surface finishing improves the appearance and enhances the performance and longevity of superalloy components, ensuring they meet the high standards required for aerospace and industrial applications.

Coating

Components such as turbine blades may undergo thermal barrier coating (TBC) or other coatings that improve heat resistance for added protection. It is essential for parts exposed to high temperatures and oxidizing environments. TBC application helps extend the life of critical components, like turbine blades, by protecting them from thermal degradation and oxidation.

Testing and Inspection of CNC-Machined Superalloy Parts

Testing and inspection are essential to ensure that CNC-machined superalloy parts meet stringent quality standards and can perform reliably under extreme conditions. Neway employs a range of advanced testing methods to verify the quality and integrity of each part:

Coordinate Measuring Machine (CMM)

Coordinate Measuring Machines (CMM) are used to measure the precise dimensions of CNC-machined parts to ensure they meet the required tolerances. CMM ensures that the parts adhere to tight specifications, which is crucial in industries like aerospace and defense.

Scanning Electron Microscopy (SEM)

Scanning Electron Microscopy (SEM) provides detailed images of a part's surface, helping to detect micro-defects that may not be visible to the naked eye. SEM is vital for identifying surface and sub-surface flaws that could affect the part's performance under operational stresses.

X-ray and Metallographic Microscopy

X-ray inspection and Metallographic Microscopy are used to identify internal defects such as voids, cracks, and porosity, which could compromise the performance of the superalloy part. These techniques are critical for ensuring that parts are free from hidden defects, which could lead to premature failure in high-stress applications.

Tensile Testing

Tensile testing ensures that superalloy parts can withstand the mechanical stresses they encounter in service. This test measures the ultimate tensile strength (UTS) and yield strength, ensuring the material behaves as expected under load.

Fatigue and Creep Testing

These tests simulate long-term use and high-temperature conditions, ensuring that parts maintain structural integrity over time. Fatigue testing and creep testing are crucial to determine how superalloy parts will perform under cyclic stresses and at elevated temperatures, which is vital for parts in turbine engines and other high-performance applications.

Industry Applications for CNC-Machined Superalloy Parts

Superalloy components are used in various industries where performance, reliability, and precision are critical. Some of the key sectors include:

Aerospace

CNC-machined turbine blades, nozzle rings, and combustion chambers are essential for jet engines and other high-performance aerospace systems. Aerospace and Aviation components such as these require high-temperature alloys for durability and resistance to extreme thermal and mechanical stresses. These parts are integral to jet propulsion systems, and CNC machining ensures the precision required for applications like superalloy jet engine components.

Power Generation

Gas and steam turbines use precision-machined superalloy components to maintain efficiency and durability. These high-performance materials are critical for turbine blades and heat exchangers. The power generation industry benefits from superalloy parts like superalloy heat exchanger parts, which must withstand high pressures and corrosive environments. These high-strength, heat-resistant components enhance Power Generation systems.

Oil and Gas

Subsea equipment, valves, and pumps made from superalloys must perform reliably under high pressures and temperatures. Superalloy pump components, such as those in subsea drilling operations, are essential for long-term performance in extreme environments. The oil and gas sector depends on superalloy materials for critical parts like high-temperature alloy pump components, ensuring operational reliability, corrosion resistance, and wear resistance.

Defense

Military and space exploration components require high-precision, high-strength materials to operate in extreme conditions. These industries depend on high-performance superalloy parts, including superalloy missile segments and armor system parts, engineered for optimal strength, reliability, and longevity in high-stress environments. The military and defense sector requires components capable of withstanding extreme conditions, from high temperatures to mechanical shocks.

FAQs

What is the typical tolerance range for CNC-machined superalloy parts?

How does CNC machining improve the performance of turbine blades?

What are the key benefits of CNC machining for complex geometries in superalloy parts?

How does post-processing, like HIP and heat treatment, enhance the performance of CNC-machined superalloy parts?

What are the most common industries that rely on CNC-machined superalloy components?