Post Processing for High-Quality Superalloy Component Finishing

Post-Processing in Superalloy Manufacturing

In manufacturing high-performance superalloy components, post-processing is a critical step in ensuring the final product meets stringent industry standards. Superalloys, such as Inconel, Hastelloy, Rene, and titanium alloys, are extensively used in demanding applications across aerospace, power generation, automotive, and oil & gas industries due to their exceptional high-temperature properties. However, post-processing is necessary to enhance their mechanical properties, dimensional accuracy, surface finish, and overall reliability to optimize these materials for their intended use. This process can include heat treatment, machining, polishing, coating, and specialized testing to maximize the material’s potential.

Different manufacturing processes such as Vacuum Investment Casting, Single Crystal Casting, Equiaxed Crystal Casting, Directional Casting, Powder Metallurgy, Forging, CNC Machined parts, and 3D Printed parts each require distinct post-processing techniques tailored to the characteristics and performance demands of the component.

Post-Processing for Different Superalloy Manufacturing Processes

Superalloy parts are produced using various manufacturing methods, each with unique post-processing requirements. Let's look at how post-processing applies to different processes:

Vacuum Investment Casting: After the casting process, components often undergo post-processing, such as Hot Isostatic Pressing (HIP), heat treatment, and CNC machining. HIP helps eliminate internal porosity and improves material density, particularly important for components subjected to high pressures, such as turbine blades and combustor liners. Heat treatment further optimizes the microstructure and mechanical properties, while machining ensures the part meets tight tolerances.

Single Crystal Casting: Used primarily for high-performance turbine blades in aerospace and power generation, single crystal casting creates components with superior creep resistance and thermal stability. Post-processing methods such as controlled heat treatment and precision machining refine the crystal structure and remove any defects that may have formed during the casting process. Proper heat treatment is also essential to relieve stresses and ensure dimensional stability in high-temperature environments.

Equiaxed Crystal Casting: Post-processing steps such as heat treatment and machining help increase fatigue resistance and toughness for components like turbine rotors and other high-stress parts. Heat treatment processes like solution annealing or aging refine the microstructure, while machining removes excess material and refines the part to its final dimensions.

Directional Casting: This process is commonly used to create turbine blades and other components requiring a specific grain structure to enhance strength and thermal fatigue resistance. Post-processing techniques, including heat treatment and machining, are applied to ensure proper grain alignment and improve mechanical properties like tensile strength and fatigue resistance.

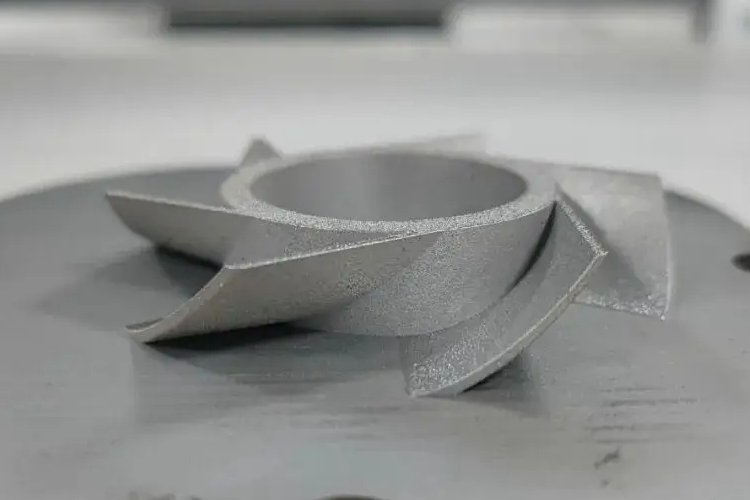

Powder Metallurgy Turbine Discs: For parts such as turbine discs and other components that need to maintain high strength at elevated temperatures, post-processing techniques like sintering, HIP, and CNC machining are employed. These processes help optimize the material's density, remove porosity, and refine its mechanical properties.

Superalloy Precision Forging: Superalloy forging processes often require heat treatment and machining after forging to achieve the desired strength, hardness, and dimensional accuracy. Heat treatment can refine the grain structure, while machining ensures that the final part meets tight tolerance requirements, essential for parts used in turbines and engines.

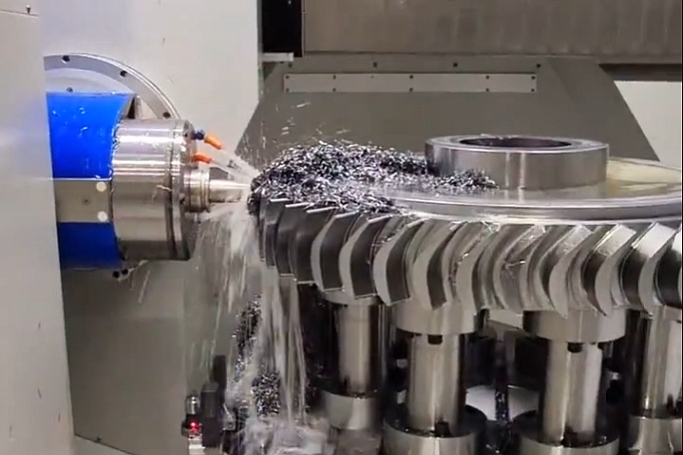

Superalloy CNC Machining: CNC machining is commonly used for precision parts that require fine surface finishes and tight dimensional tolerances. After machining, components may undergo additional treatments like polishing, coating, or heat treatment to improve wear resistance, reduce stress concentrations, and enhance performance in high-temperature environments.

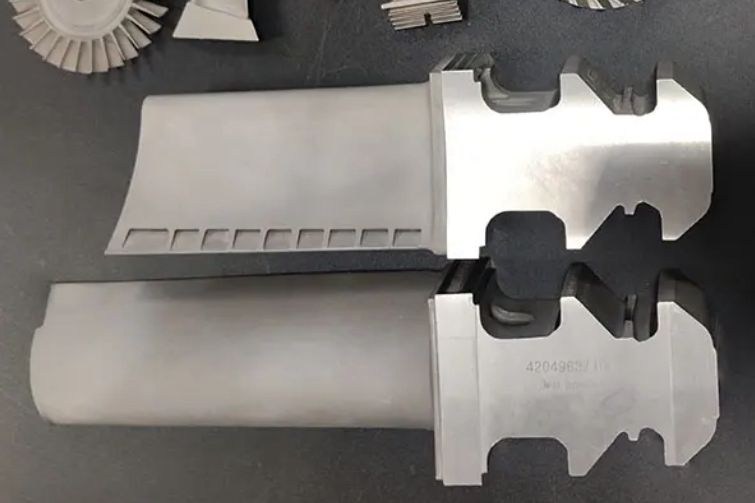

Superalloy 3D Printing: In additive manufacturing, post-processing ensures that 3D-printed superalloy parts achieve the necessary strength and surface quality. This can include heat treatment to improve material properties and machining to achieve precise dimensions. Post-processing also includes surface finishing treatments like polishing or coating to enhance the part's functionality and appearance.

Benefits of Post-Processing for Different Superalloys

Each type of superalloy benefits from specific post-processing techniques that enhance its performance, ensuring reliability and durability in high-stress environments. Below are the key benefits of post-processing for different superalloys:

Inconel Alloys

Inconel alloys, such as Inconel 718 and Inconel 625, are known for their excellent resistance to oxidation and corrosion in high-temperature environments. Post-processing methods like heat treatment and Hot Isostatic Pressing (HIP) enhance their creep resistance, fatigue life, and mechanical strength. These processes ensure that Inconel components meet the rigorous performance standards required for applications in gas turbines, jet engines, and other critical high-temperature environments.

Hastelloy and Monel Alloys

Both Hastelloy and Monel alloys are highly regarded in the chemical processing and marine industries for their superior corrosion resistance. Post-processing techniques such as heat treatment, surface coatings, and polishing help enhance their resistance to oxidation, corrosion, and wear. These treatments optimize their performance in aggressive chemical environments, making them ideal for use in reactors, heat exchangers, and marine components.

Titanium Alloys

Titanium alloys, such as Ti-6Al-4V and Ti-10V-2Fe-3Al, are used in aerospace, medical, and automotive industries for their light weight and excellent corrosion resistance. Post-processing treatments like heat treatment improve their fatigue resistance and strength, while surface finishing techniques such as polishing or coating enhance their biocompatibility for medical implants and wear resistance for aerospace components.

Rene Alloys

Rene alloys such as Rene 104 and Rene 41 are designed to withstand extreme high-temperature and high-stress conditions. Post-processing methods like heat treatment and Hot Isostatic Pressing (HIP) are employed to improve tensile strength and resistance to thermal fatigue and eliminate internal porosity, ensuring that parts like turbine blades perform optimally in jet engines and other high-performance aerospace applications.

Stellite Alloys

Stellite alloys are renowned for their wear resistance, making them ideal for components such as valves, pumps, and cutting tools. Post-processing treatments like heat treatment, surface coating, and polishing significantly improve their hardness, wear resistance, and toughness, ensuring these components maintain their integrity under high-stress and high-wear conditions in industrial and aerospace environments.

Comparison of Post-Processing Techniques

Post-processing techniques vary, and their application varies based on the manufacturing process and material requirements. Here’s a comparison of the most common post-processing methods:

Heat Treatment

One of the most common post-processing techniques, heat treatment helps refine the microstructure of superalloys and optimize properties such as tensile strength, hardness, and creep resistance. The specific heat treatment process (e.g., solution annealing, aging, or quenching) varies depending on the alloy and desired properties.

Hot Isostatic Pressing (HIP)

HIP is often applied to parts that require maximum material density and structural integrity. It removes internal porosity and defects, improving fatigue resistance and overall strength. It is particularly beneficial for cast parts and parts made from powder metallurgy.

CNC Machining

CNC machining is critical for achieving the precise dimensions required in many superalloy components. After machining, components may undergo surface finishing treatments, such as polishing, to improve surface smoothness and reduce friction.

Surface Coatings

For high-temperature applications, surface coatings like thermal barrier coatings (TBC) or protective coatings can enhance corrosion and wear resistance. These coatings are often used in turbine blades, jet engine parts, and other components exposed to extreme conditions.

Polishing and Grinding

Polishing and grinding achieve smooth, defect-free surfaces on superalloy parts. This is essential in applications where surface finish can impact performance, such as in aerospace turbine blades or medical implants.

Post-Processing Testing and Quality Control

Post-processing testing is essential to ensure that superalloy components meet the required specifications for performance and reliability. Several testing methods are used to assess the quality of post-processed parts:

Dimensional Accuracy: Coordinate Measuring Machines (CMM) are often used to verify that post-processed components meet dimensional tolerances. CMM testing helps ensure the final product’s accuracy, which is crucial in high-precision applications like aerospace. Precision measurement techniques, such as water immersion ultrasonic inspection, also play an important role in confirming the dimensional stability of the components.

Mechanical Testing: Tensile testing, fatigue testing, and hardness testing are standard methods to assess the mechanical properties of superalloy components after post-processing. These tests help verify the material’s strength, flexibility, and resistance to wear and fatigue. These evaluations ensure that the superalloy parts perform reliably under operational stress and temperature conditions.

Material Integrity Testing: Techniques like X-ray inspection and ultrasonic testing help detect internal defects, such as porosity or inclusions, that may have been missed during the initial manufacturing process. These methods ensure the integrity of the component, particularly in critical applications like turbine blades or engine parts. Non-destructive testing preserves the structure of the superalloy while providing essential information about its quality.

Surface Integrity Testing: Scanning Electron Microscopy (SEM) and profilometry are used to assess the surface finish of superalloy components. These tests help identify microstructural defects that could affect the part’s performance, such as cracks, voids, or surface oxidation. By using advanced techniques like EBSD analysis, manufacturers can further investigate the crystallographic orientation and phase distribution, ensuring that surface defects do not compromise the component’s structural integrity.

Industry Applications and Benefits of Post-Processing

Post-processing plays a vital role in ensuring that superalloy components meet the rigorous demands of various industries. Some of the key applications include:

Aerospace and Aviation

Post-processing is essential for turbine blades, combustor liners, and engine parts, which must withstand extreme temperatures and pressures. Heat treatment, Hot Isostatic Pressing (HIP), and surface coatings are commonly applied to improve performance and ensure the longevity of these components. These treatments help enhance the fatigue resistance and durability of critical components like superalloy jet engine components.

Power Generation

Superalloy components used in gas turbines and other high-temperature power generation equipment require precise post-processing to improve mechanical properties and reduce wear. Post-processing ensures the efficiency and durability of power generation systems. For example, superalloy heat exchanger parts benefit from treatments that optimize their resistance to thermal cycling and corrosion, which is crucial for maintaining system performance over extended periods.

Oil & Gas

Superalloy parts used in oil drilling and refining equipment must resist corrosion and high pressures. Post-processing methods like surface coatings and heat treatment enhance the material’s resistance to aggressive environments, ensuring reliability and safety. High-temperature alloy pump components in oil and gas operations, for instance, are treated to extend their lifespan and improve performance under harsh conditions.

Automotive and Marine

High-performance components such as exhaust systems, valve seats, and marine propulsion parts benefit from post-processing treatments that improve wear, strength, and corrosion resistance. For instance, superalloy transmission component assemblies are subjected to heat treatment and surface coatings that enhance their durability, enabling them to withstand the high stress and thermal conditions encountered in automotive and marine applications.

Medical

Superalloy components used in medical devices, such as implants and surgical tools, require precise post-processing to ensure biocompatibility, strength, and precision. Heat treatment and surface finishing are critical to achieving the desired performance and safety standards. Post-processing ensures that components such as superalloy surgical tools meet the high standards required for medical applications, including durability, precision, and resistance to wear.

FAQs

What are the most common post-processing techniques used in superalloy manufacturing?

How does heat treatment improve the properties of superalloy components?

Why is Hot Isostatic Pressing (HIP) used in the post-processing of superalloy components?

What role does CNC machining play in the finishing of superalloy components?

How does post-processing impact the performance and lifespan of superalloy parts in aerospace applications?