Optimizing Manufacturing Process for Blade Durability

In high-performance industries like aerospace, power generation, and defense, turbine blades face some of the most extreme operational conditions. These components are subjected to intense mechanical stresses, high temperatures, and corrosive environments. The durability of these blades is crucial for ensuring long-term performance, reliability, and safety. The single crystal casting process is one of the most advanced methods for producing turbine blades with the durability needed to withstand these harsh conditions.

The manufacturing process of single-crystal turbine blades plays a crucial role in achieving their exceptional durability. By carefully controlling the casting parameters, engineers can create blades with superior mechanical properties, such as enhanced fatigue and creep resistance at high temperatures. Choosing the right superalloy for the specific application is also critical, with materials like Inconel and Hastelloy being widely used for their outstanding performance in extreme environments.

Optimizing the casting process, selecting the right superalloys, and employing post-processing techniques such as heat treatment and Hot Isostatic Pressing (HIP) can significantly improve turbine blade durability. Furthermore, rigorous material testing and analysis ensure that the blades meet the stringent standards required for high-performance applications.

Combining advanced manufacturing techniques, precise material selection, and thorough testing, turbine blades can achieve the durability required for safe and efficient operation in the harshest environments.

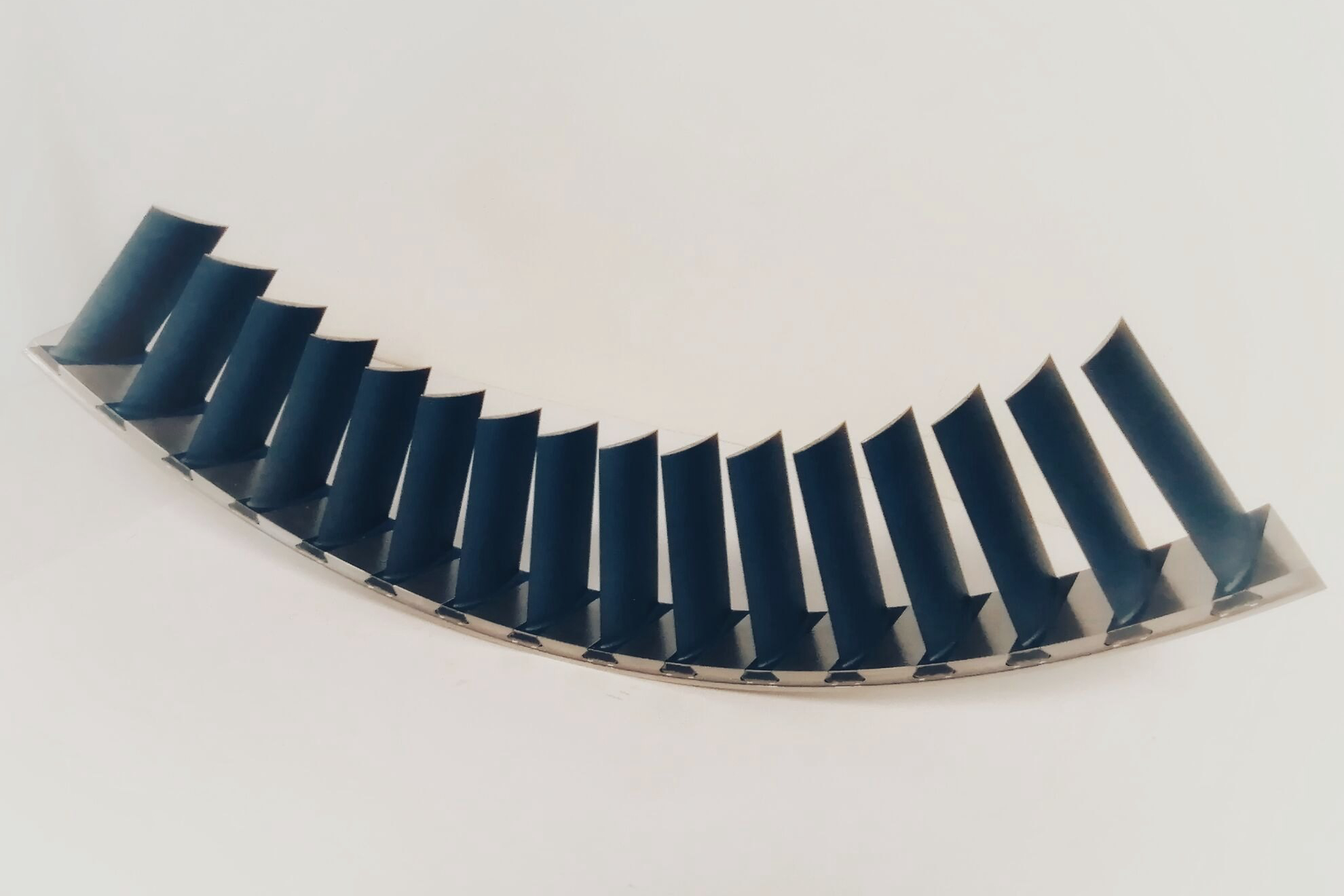

Casting Process for Single Crystal Turbine Blades

Single crystal casting is a highly specialized process that results in turbine blades with a continuous, defect-free crystal structure. This starkly contrasts traditional polycrystalline casting, where grains and grain boundaries can create weak points in the material. In single crystal casting, the blade is formed with a single, continuous crystal throughout, eliminating the vulnerabilities caused by grain boundaries.

The process begins with careful preparation of the alloy, followed by directional solidification—a controlled cooling process that encourages the formation of a single crystal from the molten metal. This is achieved by carefully controlling the mold's cooling rate and temperature gradients. The temperature must be controlled to ensure that the crystal grows in the desired direction. This process is critical because improper cooling or temperature gradients can lead to defects that affect the blade's strength and performance.

In the casting process, precise alloy composition control is essential. The alloy's chemical composition must be finely tuned to achieve the desired mechanical properties. This typically means incorporating high levels of nickel, chromium, aluminum, and other elements that improve high-temperature strength, oxidation resistance, and fatigue resistance for turbine blades. By controlling the amount and distribution of these elements, manufacturers ensure the blade can withstand extreme thermal and mechanical stresses without failing.

The design of the mold and the cooling process also significantly influence the blade's durability. The mold promotes smooth, uniform solidification and prevents defects such as voids, cracks, and inclusions. Optimizing the mold design and the casting parameters helps to achieve a high-quality, durable single-crystal structure.

Choosing the Right Superalloys for Durability in Single Crystal Casting

Selecting the right superalloy is crucial for producing turbine blades with superior durability. Different superalloys offer varying degrees of resistance to high temperatures, corrosion, and mechanical stress. The composition and characteristics of these superalloys are tailored to specific applications and performance requirements.

CMSX Series

The CMSX series of alloys are widely used in single crystal casting for turbine blades due to their excellent high-temperature strength, creep resistance, and thermal fatigue resistance. Alloys such as CMSX-10, CMSX-2, and CMSX-4 offer remarkable mechanical properties at elevated temperatures, making them ideal for jet engine turbine blades. These alloys are typically based on a nickel matrix with the addition of elements like rhenium and tantalum to enhance their creep resistance and oxidation resistance. CMSX alloys are designed to withstand extreme thermal conditions while maintaining structural integrity.

Rene Alloys

Another set of superalloys commonly used in turbine blades is Rene alloys, such as Rene 41, Rene 65, and Rene 104. These alloys are known for their excellent high-temperature strength and long-term durability. Rene alloys typically comprise nickel, chromium, and elements like tungsten and molybdenum. These alloys offer outstanding resistance to creep and fatigue, making them particularly suitable for high-stress applications. The precise composition of these alloys allows for optimal performance under high-temperature conditions and is critical in ensuring long-lasting durability in turbine blades.

Inconel Alloys

Inconel alloys, such as Inconel 718, Inconel X-750, and Inconel 738C, are another category of materials commonly used for turbine blades. Inconel alloys are primarily nickel-based, adding elements such as aluminum, titanium, and molybdenum to improve their strength and oxidation resistance. Inconel alloys are well-known for their ability to withstand high temperatures, making them ideal for use in gas turbines and steam turbines. They also offer good resistance to oxidation and corrosion, which is crucial in harsh operating environments. Inconel alloys are popular for turbine blades in aerospace and power generation applications due to their high strength-to-weight ratio and reliability.

Single Crystal Alloys

In addition to CMSX and Rene alloys, other advanced single-crystal alloys, such as PWA 1480, Rene N5, and CMSX-10, are increasingly used in turbine blades. These alloys are engineered to provide superior creep resistance, oxidation resistance, and thermal stability. The precise control of trace elements in these alloys allows manufacturers to fine-tune their properties to meet the demanding requirements of turbine blade applications. Single crystal alloys with their carefully controlled composition, offer exceptional mechanical properties and extended service life in extreme environments.

Choosing the suitable alloy for a specific application is critical to achieving the required balance of durability, strength, and high-temperature performance. Manufacturers must carefully consider the turbine blade's operating conditions, performance demands, and the material's ability to resist oxidation, corrosion, and mechanical stress.

Post-Processing Techniques to Enhance Blade Durability

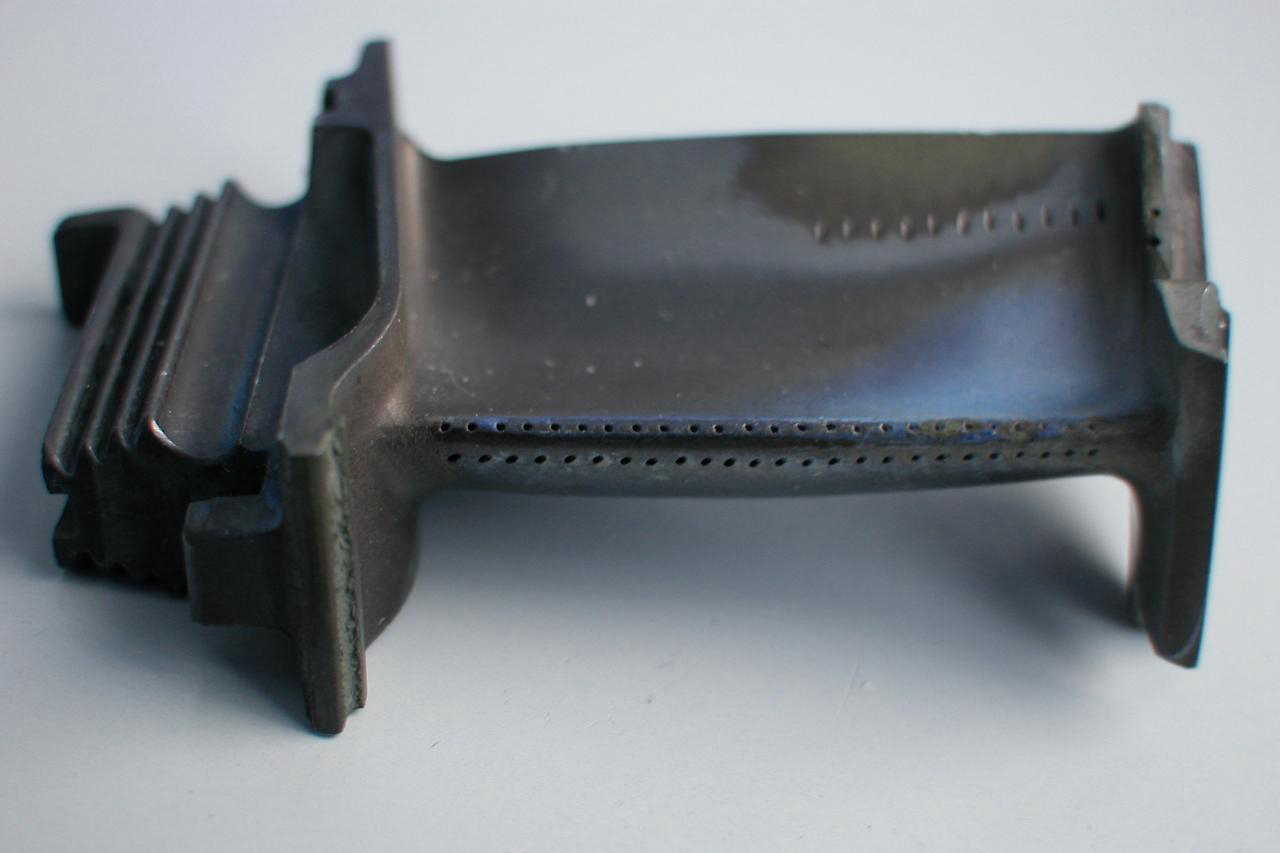

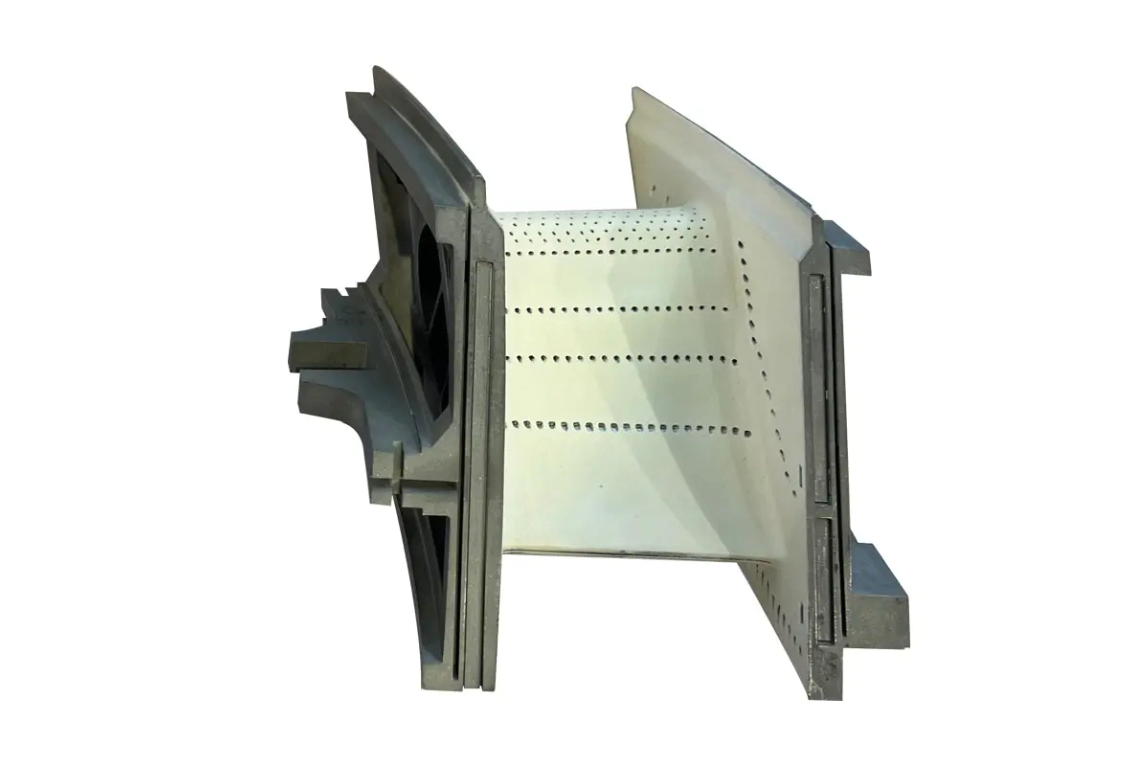

Once the turbine blade has been cast using the single crystal method, a series of post-processing steps are employed to enhance its durability. These processes help refine the material's properties and eliminate any defects that may have formed during casting.

Heat Treatment

Heat treatment is a crucial post-processing step that optimizes the mechanical properties of turbine blades. After casting, the blades undergo heat cycles that relieve internal stresses and ensure the material achieves its desired strength and stability. Heat treatment allows the alloy to develop the optimal microstructure for high-temperature strength, fatigue resistance, and oxidation resistance. Manufacturers can improve the material’s overall durability and performance by carefully controlling the heat treatment parameters.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is another crucial post-processing technique that improves the material’s integrity and uniformity. This process involves applying high-pressure gas at elevated temperatures to the turbine blade. HIP helps eliminate any internal porosity, which can be a potential point of failure. Applying uniform pressure also ensures that the material is densified, improving its overall mechanical properties. HIP is instrumental in enhancing the durability of turbine blades by ensuring that no defects or voids are present within the material.

Thermal Barrier Coating (TBC)

One of the most critical post-processing techniques for improving turbine blades' durability is applying a thermal barrier coating (TBC). These coatings protect the turbine blades from extreme heat and oxidation during operation. TBCs help reduce the temperature that the blade experiences, effectively lowering the thermal load on the material. By reducing thermal cycling and oxidation, TBCs increase the blade's lifespan and enhance its resistance to thermal fatigue. The coating material is carefully chosen to ensure it bonds well with the base alloy and provides long-lasting protection.

Superalloy Welding and Repair

Even after extensive post-processing, turbine blades may require repairs or modifications during service life. Superalloy welding techniques repair damaged areas of the blades while ensuring the integrity of the material’s composition. The welding process must be carefully controlled to prevent disruption of the alloy's properties. Properly executed welding and repair techniques can extend the blade’s service life without compromising its durability.

Testing and Quality Control for Durability Assurance

Once the turbine blades are manufactured and post-processed, rigorous testing is performed to ensure they meet durability requirements. These tests simulate real-world operating conditions and help manufacturers assess the blade’s performance over time.

Non-Destructive Testing (NDT)

Non-destructive testing (NDT) is an essential part of the quality control process for turbine blades. Techniques like X-ray, CT scanning, and ultrasonic testing detect internal defects, such as cracks, voids, or inclusions, that may compromise the blade’s durability. These tests ensure that the blades meet the necessary quality standards before they are used in operational systems.

Tensile and Fatigue Testing

Tensile testing assesses the blade's strength under mechanical stress and measures its ability to resist deformation. Fatigue Testing in Superalloy Components simulates the cyclic stresses the turbine blades experience during their service life. By testing the blade's resistance to fatigue, manufacturers can predict its long-term performance and identify potential failure points before the blades are put into operation.

Creep Testing

Creep testing is another critical test for turbine blades. Creep refers to the slow deformation of the material under constant stress at elevated temperatures. Turbine blades are subjected to creep testing to ensure they can maintain their structural integrity over long periods of operation in high-temperature environments.

Glow Discharge Mass Spectrometer (GDMS)

The Glow Discharge Mass Spectrometer (GDMS) is used to measure the composition of the superalloys precisely. This technique ensures that the alloy’s composition matches the required specifications and that the materials are free from any trace elements that could affect the blade’s durability. Composition Verification with GDMS helps confirm material quality and consistency for optimized performance.

Scanning Electron Microscopy (SEM)

Finally, scanning electron microscopy (SEM) is used to analyze the microstructure of the turbine blades. SEM allows manufacturers to examine the grain boundaries, crystal structure, and surface condition of the blades at a microscopic level. This helps ensure the uniformity of the single crystal structure and identifies any defects or weaknesses that could compromise durability. SEM for Microstructural Analysis plays a crucial role in the final inspection and ensures blades meet rigorous durability standards.

Industry Applications and the Role of Manufacturing Process Optimization

Optimizing the manufacturing process for turbine blade durability is crucial across various industries. In aerospace and aviation, turbine blades are critical components in jet engines, which must withstand extreme mechanical and thermal stresses. The manufacturing processes used to create these components, such as superalloy jet engine components, are essential for ensuring durability and high performance in the harsh conditions encountered during flight.

Power generation industries rely on durable turbine blades for gas and steam turbines, ensuring continuous and reliable power production. Optimizing manufacturing processes such as casting and heat treatment increases the efficiency and reliability of turbine blades in these critical systems. For example, superalloy heat exchanger parts are optimized for durability in power plants, where they must endure extreme thermal stresses over long operational periods.

In the military and defense sectors, turbine blades are used in high-performance military aircraft and systems requiring maximum reliability under extreme conditions. For example, optimized manufacturing processes for superalloy missile segments and armor system parts ensure critical components perform reliably even in the most demanding environments.

Turbine blades are also essential in marine propulsion systems and offshore oil platforms, where durability is critical to surviving harsh environments. Oil and gas applications, such as superalloy pump system assemblies, benefit from optimized manufacturing processes that enhance component longevity in extreme conditions.

In energy and renewable systems like wind turbines, single crystal turbine blades with optimized manufacturing processes ensure long-lasting, high-performance operation. These turbines rely on carefully controlled manufacturing to ensure high efficiency and durability in fluctuating environmental conditions.

FAQs

What factors affect the durability of turbine blades made from single crystal casting?

How does the directional solidification process contribute to the strength of turbine blades?

Why is precise composition control important in producing durable turbine blades?

What role does thermal barrier coating play in increasing turbine blade durability?

How do testing methods like creep and fatigue help predict turbine blade longevity?