Nickel-Based Alloy Cooking Equipment Modules Supplier

Induction of Cooking Equipment Modules

In commercial and industrial kitchens, cooking equipment must endure extreme conditions such as high temperatures, humidity, and frequent cleaning with aggressive agents. Cooking equipment modules made from high-performance nickel-based alloys are essential in these settings due to their exceptional resistance to heat, corrosion, and wear. These materials maintain their integrity under demanding conditions, ensuring that equipment operates safely, efficiently, and for long periods. Nickel-based alloys, especially superalloys like Inconel, Hastelloy, and Monel, are the materials of choice for producing components that need to handle intense cooking environments, offering unmatched durability and reliability.

Superalloys Used in Cooking Equipment Modules

The selection of high-performance superalloys for cooking equipment modules is crucial for achieving the heat resistance, corrosion resistance, and longevity required in commercial and industrial kitchens. Three primary types of superalloys commonly used are Inconel, Hastelloy, and Monel. Each brand has specific grades that are especially suited to meet the rigorous demands of food preparation and processing environments.

Inconel Alloys

Inconel is a family of nickel-chromium-based alloys renowned for its outstanding resistance to oxidation and high temperatures. Inconel alloys are particularly well-suited for cooking equipment exposed to continuous high-heat conditions. Some commonly used grades include:

Inconel 600: This alloy is highly resistant to oxidation and corrosion, particularly at elevated temperatures. Inconel 600 is often used in cooking modules where high heat exposure and resilience against chemical interactions are required.

Inconel 625: Known for its excellent fatigue strength and oxidation resistance, Inconel 625 is ideal for components exposed to fluctuating temperatures, such as oven liners or grill components.

Inconel 718: With high strength and corrosion resistance at elevated temperatures, Inconel 718 is commonly used in high-performance cooking modules, especially where parts need to maintain mechanical integrity over extended periods.

Hastelloy Alloys

Hastelloy alloys offer outstanding resistance to corrosion and high-temperature environments, making them ideal for cooking equipment that encounters aggressive substances, such as acidic food ingredients and cleaning agents.

Hastelloy C-276: This alloy is highly resistant to pitting and stress corrosion cracking, which is essential for cooking equipment in industrial kitchens where acidic foods and harsh cleaning chemicals are used.

Hastelloy C-22: Known for its versatility, Hastelloy C-22 provides excellent resistance to oxidizing and non-oxidizing acids. It is suitable for equipment components exposed to various culinary ingredients and chemicals.

Hastelloy X: This grade combines high-temperature strength and oxidation resistance, making it suitable for parts that frequently encounter high temperatures, such as grills, fryers, and other heat-intensive modules.

Monel Alloys

Monel alloys, primarily nickel-copper-based, offer exceptional corrosion resistance, particularly in acidic and marine environments. Their robustness makes them well-suited for cooking equipment modules requiring strength and corrosion resistance.

Monel 400: Known for its superior resistance to corrosion in acidic and alkaline environments, Monel 400 is frequently used in components that come into contact with acids or corrosive food ingredients.

Monel K500: By adding age-hardening properties, Monel K500 combines the corrosion resistance of Monel 400 with greater strength, making it suitable for high-stress cooking applications where both durability and corrosion resistance are paramount.

Monel 404: This alloy is particularly resistant to hydrofluoric acid, making it a specialized choice for cooking equipment exposed to aggressive chemicals or acidic foods in industrial kitchens.

These superalloy families enable manufacturers like Neway Precision Works to create components that excel in challenging kitchen environments, where equipment must perform reliably under constant stress and high temperatures.

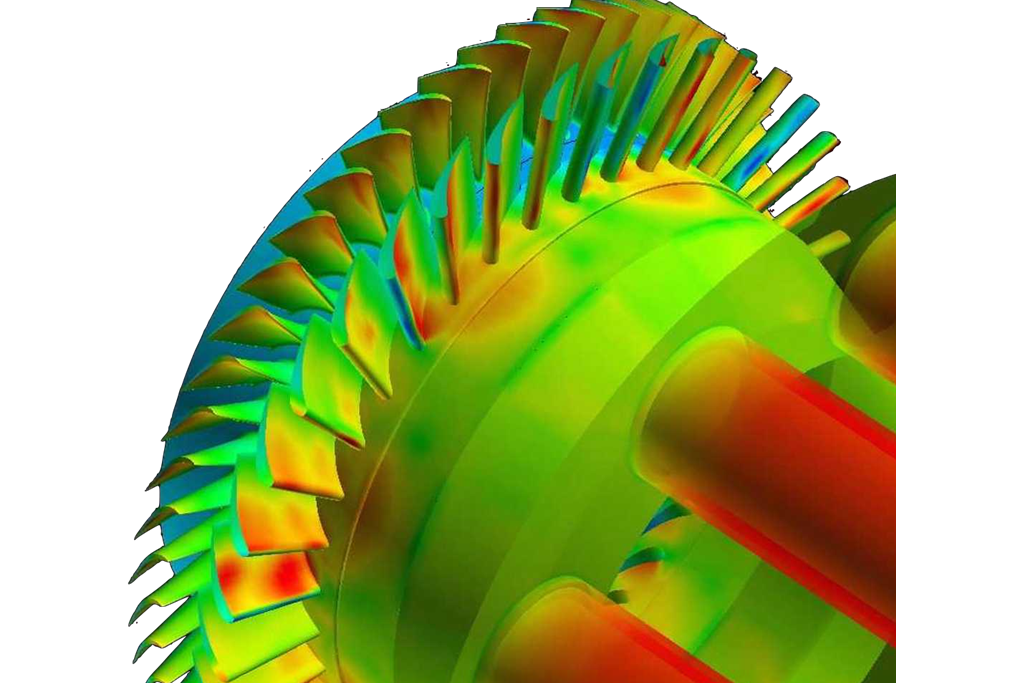

Typical Superalloy Part Manufacturing Process

Producing superalloy parts for cooking equipment modules requires specialized manufacturing processes that ensure precision, durability, and heat resistance. The primary methods include vacuum investment casting, powder metallurgy, and precision forging.

Vacuum Investment Casting

Vacuum investment casting is ideal for creating complex shapes with high dimensional accuracy and a fine surface finish, making it suitable for cooking equipment modules that demand precision and durability. In this process, a wax model of the part is coated with a ceramic shell, which is then heated to remove the wax, creating a mold. The mold is filled with molten superalloy under vacuum conditions, ensuring high density and minimizing contamination.

Superalloy Single Crystal Casting: Single crystal casting produces parts with a uniform crystalline structure, reducing the risk of thermal fatigue and improving high-temperature performance. This process suits components that require exceptional structural integrity, such as burners or heat exchangers. Microstructure refinement enhances creep resistance, which is vital for high-stress environments.

Superalloy Equiaxed Crystal Casting: Equiaxed casting creates parts with a uniform crystal structure, enhancing toughness and resistance to cyclic thermal stresses. It is ideal for cooking equipment subjected to constant temperature changes. Grain structure control ensures improved fatigue resistance for temperature-sensitive applications.

Superalloy Directional Casting: Directional casting controls crystal growth in a specific direction, giving the alloy greater mechanical strength in that orientation. This technique is proper for parts that encounter directional stresses, such as oven racks and rotisserie components. Directional solidification enhances mechanical properties and reliability under stress.

Unique Steel Investment Casting: Special steel alloys may also be used in investment casting to produce high-strength, corrosion-resistant parts, providing additional options for custom applications in cooking equipment. This casting option supports tailored solutions for components with unique durability requirements.

The vacuum investment casting process ensures that each component meets stringent quality standards, resulting in cooking equipment modules that are robust, reliable, and resistant to high temperatures and corrosion.

Powder Metallurgy

Powder metallurgy is another effective method for manufacturing superalloy parts. Fine metal powders are compacted and sintered to form a dense, solid material. Powder metallurgy allows for producing parts with complex shapes, high density, and consistent microstructures, offering precise control over material properties.

This method is particularly advantageous for components in cooking equipment that require uniformity, high wear resistance, and strength. Powder metallurgy enables manufacturers to create intricate parts with minimal porosity and high durability, making it suitable for applications where reliability and resistance to abrasion are essential. Powder preparation techniques enhance uniformity, ensuring consistent performance and longevity in high-wear components.

Precision Forging

Precision forging shapes superalloy materials through controlled deformation, enhancing their mechanical properties and ensuring strength and stability. Several forging techniques are commonly used for high-performance cooking equipment modules:

Rough Forging: Rough forging is used to create the initial shape of the component, providing a solid foundation for further refinement. This process suits more significant parts that require high durability, such as grills and oven racks.

Free Forging: Free forging allows greater flexibility in shaping complex geometries, making it ideal for custom cooking equipment modules with unique designs. The benefits of free forging include improved mechanical strength and shape adaptability, which are essential for custom modules.

Isothermal Forging: Isothermal forging maintains a consistent temperature throughout the process, minimizing material deformation and improving mechanical properties. This technique benefits parts that require high thermal stability, such as heating elements and burners. Isothermal forging benefits ensure enhanced strength and resilience in high-heat applications.

These forging methods ensure that cooking equipment modules are durable, resilient, and capable of withstanding the intense conditions of commercial kitchens. Precision forging advantages offer reliability and strength, meeting the high standards in the food service industry.

Cooking Equipment Modules Manufacturing

Manufacturing high-performance cooking equipment modules requires precision techniques, including vacuum investment casting, powder metallurgy, and precision forging. Each process is selected based on the specific requirements of the part, such as temperature resistance, corrosion resistance, and dimensional accuracy.

For components exposed to high temperatures and corrosive environments, vacuum investment casting is often the preferred method due to its ability to produce dense, defect-free parts with excellent surface finish. This casting process reduces porosity and improves component integrity, essential for high-performance parts used in demanding kitchen environments.

Powder metallurgy is ideal for creating parts with complex shapes and uniform microstructures, offering high precision and consistency in material properties. The process ensures minimal porosity and enhances wear resistance, making it suitable for reliable and durable components under frequent use and exposure to high temperatures.

Precision forging enhances the strength and durability of components that endure heavy use and frequent temperature changes. Forging techniques like isothermal and free forging improves grain structure, which is crucial for maintaining the mechanical properties of parts under cyclic stresses and heat. It ensures that components maintain structural integrity and longevity in high-stress cooking environments.

Together, these methods ensure that cooking equipment modules meet the high standards of quality and performance expected in commercial and industrial kitchens, offering enhanced strength, corrosion resistance, and reliability for high-demand applications.

Prototyping for Cooking Equipment Modules

Prototyping is essential in developing cooking equipment modules, allowing manufacturers to test and refine designs before committing to full-scale production. Prototyping is particularly valuable for custom or small-batch orders, enabling rapid adjustments based on testing results.

3D Printing Service

3D printing, also known as additive manufacturing, is a flexible and cost-effective prototyping method allowing manufacturers to create complex parts quickly. For cooking equipment modules, 3D printing provides a rapid way to test new designs and ensure they meet performance requirements before production.

Superalloy 3D Printing

Superalloy 3D printing is specialized for high-performance applications, using powdered superalloys to create parts layer by layer. This method is ideal for producing functional prototypes or small production runs of cooking equipment modules, enabling manufacturers to explore various designs and functionalities efficiently.

Superalloy CNC Machining

CNC machining offers precision and versatility for low-volume production and prototyping, allowing manufacturers to create detailed parts with tight tolerances. This method is suitable for producing high-quality prototypes of cooking equipment modules, ensuring they meet exact specifications and performance requirements.

Cooking Equipment Modules Post-Process

Post-processing is crucial to achieving the desired mechanical and thermal properties of cooking equipment modules. Common post-processing steps include:

Hot Isostatic Pressing (HIP): HIP improves material density and eliminates internal voids, enhancing the component’s strength and durability. This process is essential for parts exposed to high temperatures and mechanical stress.

Heat Treatment: Heat treatment optimizes the mechanical properties of superalloys, increasing hardness and improving resistance to wear and fatigue. This process is essential for components that undergo frequent temperature cycling, ensuring long-term performance and durability.

Surface Finishing: Surface finishing, such as polishing or coating, provides corrosion resistance and a smooth surface, which is critical for hygiene in cooking equipment modules.

These post-processing techniques ensure that cooking equipment modules are durable, reliable, and able to withstand the intense conditions of commercial and industrial kitchens.

Cooking Equipment Modules Quality Inspection

Quality inspection is critical to verify that each cooking equipment module meets industry durability, precision, and safety standards. Advanced testing methods ensure the structural integrity and accuracy of each part:

X-ray Inspection: X-ray inspection identifies internal defects such as voids or cracks, ensuring the component is structurally sound. This non-destructive method is essential for confirming the integrity of components used in high-stress environments.

Coordinate Measuring Machine (CMM): CMM provides precise measurements, verifying that each part meets the specified dimensions and tolerances required for high-performance applications, similar to dimensional accuracy verification critical in applications requiring exact specifications.

Metallographic Microscopy: This method examines the microstructure of superalloys, ensuring consistent grain structure and phase distribution for high-temperature stability and corrosion resistance, similar to metallographic analysis used to verify material properties in superalloy components.

These quality inspection methods help maintain the reliability and safety of cooking equipment modules, ensuring that each component performs as expected in demanding kitchen environments.

Industry Applications of Cooking Equipment Modules

High-performance cooking equipment modules are essential in industries where equipment must endure high temperatures, frequent cleaning, and exposure to harsh ingredients and cleaning agents. Key applications include:

Commercial Kitchens: Restaurants and hotels rely on durable, heat-resistant equipment modules to handle heavy use and maintain food safety standards.

Food Processing: Food processing plants use equipment to resist corrosion from acidic ingredients and withstand frequent cleaning cycles. Nickel-based alloy components ensure durability and efficiency.

Specialized Culinary Equipment: High-end culinary equipment manufacturers use nickel-based alloys to create components that deliver reliability, safety, and longevity in residential and professional kitchens.

These industries depend on high-performance cooking equipment modules to maintain quality, efficiency, and safety in challenging kitchen environments.

FAQs about Cooking Equipment Modules Manufacturing

What are the most suitable superalloys for cooking equipment modules?

How does powder metallurgy improve cooking equipment component production?

Why is Hot Isostatic Pressing (HIP) important in manufacturing high-temperature parts?

What quality inspection methods are used to verify cooking equipment modules?

How does CNC machining benefit prototyping for cooking equipment modules?