Microscopic and SEM Analysis in Single Crystal Blade Casting

Single crystal turbine blades are critical in industries requiring high-performance materials, such as aerospace and aviation, power generation, and military and defense. These blades are typically cast using the single crystal casting process, which forms a continuous crystal structure that improves strength, fatigue resistance, and performance under extreme temperatures. However, the casting process is complex, and even minor defects, like inclusions or grain boundary imperfections, can compromise the blade’s performance.

Therefore, microscopic and scanning electron microscopy (SEM) analysis is crucial in detecting these defects, ensuring the final product meets the required quality standards. This blog delves into the casting process, suitable alloys, post-processing methods, and the importance of microscopic and SEM analysis in detecting defects within single-crystal turbine blades.

Overview of Single Crystal Blade Casting Process

Single crystal casting is a specialized technique used primarily to manufacture high-performance components such as turbine blades. The process begins with creating a ceramic shell mold designed to withstand the extreme temperatures encountered during casting. The mold is then filled with molten superalloy, typically under vacuum or controlled atmospheres to minimize contamination, as seen in vacuum investment casting.

One of the defining characteristics of single-crystal casting is the directional solidification process. Directional solidification refers to the controlled cooling of the molten metal, which encourages the formation of a single, continuous crystal structure. The molten alloy cools from the bottom up by maintaining a specific temperature gradient, with the crystal structure growing in the same direction. This process eliminates grain boundaries—regions where cracks or fractures are more likely to form under stress—resulting in a material with superior mechanical properties, such as resistance to fatigue, creep, and high-temperature degradation. This controlled cooling process is critical for creating complex, high-performance superalloy directional casting components.

While single crystal casting yields materials with excellent performance characteristics, the process is inherently prone to defects. Inclusions—unwanted particles such as oxides, sulfides, or solidified droplets—can form during casting, leading to weak points in the material. Such inclusions can drastically affect the mechanical properties of turbine blades, making it essential to detect and eliminate them early in manufacturing. X-ray or ultrasonic testing helps identify these inclusions before they affect the final product.

Suitable Superalloys for Single Crystal Blade Casting

The performance of turbine blades heavily depends on selecting the appropriate superalloys. These alloys must exhibit exceptional strength and durability at high temperatures and resistance to oxidation and corrosion. Several alloys are commonly used in single-crystal casting due to their outstanding high-temperature properties:

CMSX Series

Alloys in the CMSX Series, such as CMSX-4, CMSX-10, and CMSX-486, are specifically formulated for single-crystal applications. They are well-known for their superior creep resistance, which allows turbine blades to withstand constant thermal stress for extended periods. These alloys also demonstrate excellent high-temperature strength, which is critical for parts exposed to extreme operating conditions in turbine engines.

Rene Alloys

René alloys, such as Rene 41, Rene 80, and Rene N5, are high-performance alloys designed for turbine blades. These alloys offer enhanced oxidation resistance and high strength at elevated temperatures, which makes them particularly suitable for aerospace and power generation applications. They also have excellent weldability, which is beneficial during post-processing, such as welding or repairs.

Inconel Alloys

Inconel alloys, such as Inconel 738, Inconel 939, and Inconel X-750, are popular choices for turbine blades due to their superior high-temperature performance. Inconel alloys offer excellent oxidation resistance, which helps protect turbine blades from the corrosive effects of high-heat environments. These alloys are commonly used in gas turbines for power plants and aerospace applications.

Single Crystal Alloys

Single crystal alloys, such as PWA 1484, CMSX-2, and SC180, are specifically engineered for high-performance turbine blades. These materials are tailored to provide superior resistance to thermal fatigue and creep under extreme temperatures. They are commonly used in both commercial and military jet engines.

Post-Processing for Single Crystal Blade Castings

After casting, single crystal turbine blades undergo several post-processing steps to improve their material properties and prepare them for use in high-stress environments. These post-processing methods are designed to address any residual defects and optimize the material's overall performance.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is a post-casting process that involves subjecting the turbine blade to high pressure and temperature in an inert gas environment. This process eliminates any internal porosity or voids that can arise from gas entrapment during casting. HIP enhances the density of the blade, improving its mechanical properties and resistance to cracking or failure under high stress.

Heat Treatment

Heat treatment is used to refine the microstructure of the turbine blade, improving its strength and resistance to high-temperature degradation. By controlling the heating and cooling rates, manufacturers can optimize the size and distribution of precipitates in the alloy, which directly influences the material’s performance. Heat treatment also helps increase the creep resistance of the material, an important factor for parts exposed to sustained high temperatures.

Thermal Barrier Coatings (TBC)

Thermal Barrier Coatings (TBC) are ceramic coatings applied to turbine blades to protect them from extreme heat during operation. The coatings act as an insulating layer, reducing the temperature experienced by the superalloy substrate and extending the life of the component. TBCs also reduce oxidation and erosion, which are common causes of turbine blade failure.

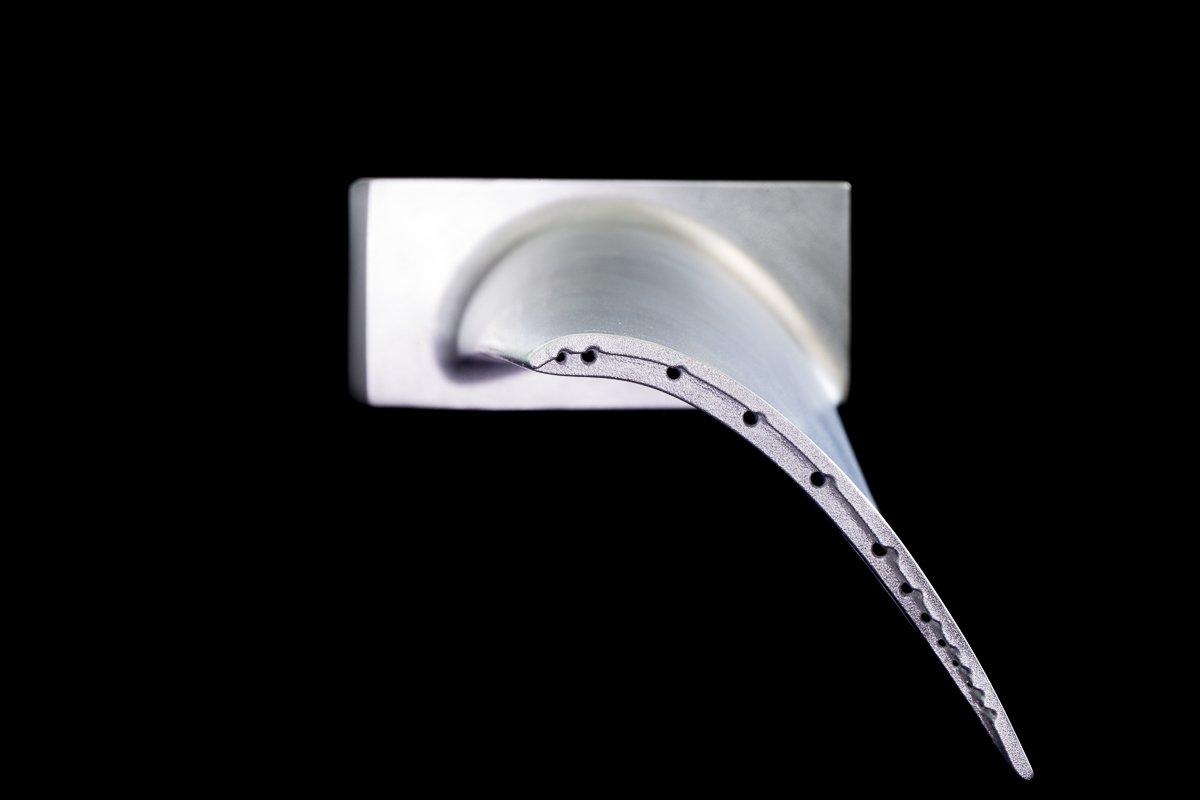

Superalloy CNC Machining and EDM

After casting, the turbine blade is typically subjected to CNC machining to achieve the final shape and geometry. This process ensures that the blade meets the required dimensional tolerances. For intricate features, such as cooling holes or internal channels, Electrical Discharge Machining (EDM) is often used. EDM allows for the precise machining of complex geometries without affecting the material's structural integrity.

Superalloy Welding

In some cases, welding may be required to repair casting defects or to join components. The welding process must be carefully controlled to ensure that the thermal cycles do not affect the material properties of the superalloy.

Testing Methods for Inclusion Detection

In addition to microscopic and SEM analysis, several other testing methods are used to ensure the quality of single-crystal turbine blades.

Tensile Testing:

Tensile testing is used to evaluate the mechanical properties of the turbine blade, such as its strength and ductility. By applying a controlled tensile load to the sample, engineers can determine how the material behaves under stress and identify any weaknesses caused by inclusions or other defects.

X-ray Testing:

X-ray testing is a non-destructive technique used to detect internal inclusions and voids. By passing X-rays through the material and capturing the resulting image, engineers can identify any internal defects that may not be visible on the surface. This method is beneficial for detecting inclusions deep within the casting.

Glow Discharge Mass Spectrometry (GDMS):

GDMS is used to assess trace inclusions in the alloy matrix. This technique involves sputtering a small area of the sample and analyzing the emitted ions to determine the material's elemental composition. GDMS is particularly effective for detecting contaminants and inclusions that could affect the performance of the turbine blade.

Ultrasonic Testing:

Ultrasonic testing uses high-frequency sound waves to detect internal inclusions and voids. By sending sound waves through the material and analyzing the reflections, engineers can identify any defects that may be present. Ultrasonic testing is a non-destructive method that can be used to inspect the entire volume of the casting.

Coordinate Measuring Machine (CMM):

CMMs are used to verify the dimensions and geometry of the turbine blade. By comparing the measured dimensions to the design specifications, engineers can identify any external casting defects that may have occurred during the manufacturing process.

Microscopic and SEM Analysis for Defect Detection

Once the turbine blades are cast and post-processed, the next step is to conduct detailed microscopic analysis and scanning electron microscopy (SEM) to identify potential defects, such as inclusions, voids, and cracks, that could compromise the performance of the blade.

Microscopic Analysis: Metallographic microscopy involves preparing the surface of the turbine blade by grinding and polishing it to a smooth finish, followed by etching to reveal the microstructure. This analysis helps identify various defects, including inclusions, porosity, and other irregularities in the material. Inclusions are often made of oxide or sulfide particles and can significantly impact the mechanical properties of the blade, especially its fatigue resistance.

Metallographic analysis focuses on examining the grain structure and identifying any anomalies that could cause weak spots in the casting. Since single crystal casting eliminates grain boundaries, detecting microstructural defects is crucial for ensuring the blade’s structural integrity.

Scanning Electron Microscopy (SEM): SEM provides high-resolution imaging that is invaluable in detecting smaller inclusions and defects not visible under optical microscopy. SEM works by scanning the surface of the material with a focused beam of electrons, producing detailed images of the microstructure. SEM is particularly useful for identifying defects at the sub-micron level that can’t be seen using conventional microscopy.

One of the key advantages of SEM is its ability to conduct energy-dispersive X-ray spectroscopy (EDS) alongside imaging. EDS allows for elemental analysis of the material, providing information about the composition of inclusions or other defects. This is vital for identifying the source of contamination or impurities in the casting process.

SEM also enables fractography analysis, which helps examine the failure mechanisms of materials under stress. This is particularly useful for understanding the impact of inclusions or other microstructural defects on the turbine blade's overall performance.

Industry Applications for Single Crystal Castings

Single crystal castings are used in many industries requiring high-performance, high-temperature components.

Aerospace and Aviation

One of the most critical applications for single-crystal turbine blades is in the aerospace and aviation industry. Turbine blades are critical components in jet engines, where they are exposed to extreme temperatures and high rotational speeds. The integrity of these blades is essential for the safe and efficient operation of aircraft engines, making microscopic and SEM analyses crucial for quality control.

Power Generation

In the power generation industry, single crystal turbine blades are used in gas turbines to generate electricity. These turbines operate at high temperatures and pressures, requiring components that can withstand harsh conditions without losing performance. Single crystal castings provide the strength and reliability needed for efficient power generation, minimizing maintenance and maximizing uptime.

Military and Defense

Military applications also rely heavily on single-crystal turbine blades. These components are used in jet engines for military aircraft, as well as in missile systems and other defense equipment. The reliability of these blades is critical for the performance of military hardware, and advanced testing methods are used to ensure they meet the required standards. Military and defense applications demand the highest levels of precision and durability to maintain operational readiness.

Marine and Energy

Single crystal turbine blades are also used in marine propulsion systems and energy generation equipment. These components must operate reliably in challenging environments exposed to high temperatures, pressures, and corrosive conditions. Advanced superalloys and rigorous quality control processes ensure that these blades can perform effectively in such demanding applications, especially for long-term durability in marine settings.

Automotive

In the automotive industry, single crystal castings are used in high-performance engine components, particularly in performance cars and racing applications. The ability of single crystal superalloys to withstand high temperatures and mechanical stress makes them ideal for turbochargers, exhaust systems, and other components where reliability and performance are paramount, ensuring vehicles can reach their peak potential in high-demand conditions.

FAQs:

What are the benefits of using SEM analysis in single-crystal blade casting?

How does Hot Isostatic Pressing (HIP) improve the quality of single crystal castings?

What types of defects can be detected through microscopic analysis?

Why is directional solidification important in single-crystal casting?

What are the main applications of single-crystal turbine blades in the aerospace industry?