Managing Low-Angle Boundary Defects in Blade Casting

Low-angle boundary (LAB) defects are an inherent challenge in manufacturing single crystal castings, particularly in high-performance turbine blades used in critical industries like aerospace, power generation, and defense. These defects can significantly impact cast components' mechanical properties, longevity, and reliability. Therefore, controlling these defects is crucial for ensuring the optimal performance of the final part.

This blog will delve into the causes of LAB defects, methods for managing them during the casting process, suitable superalloys for minimizing these issues, and post-processing approaches to refine the casting. Additionally, we will explore the testing and analysis techniques used to detect LAB defects and their importance in various industries.

Understanding Low-Angle Boundary Defects in Single Blade Casting

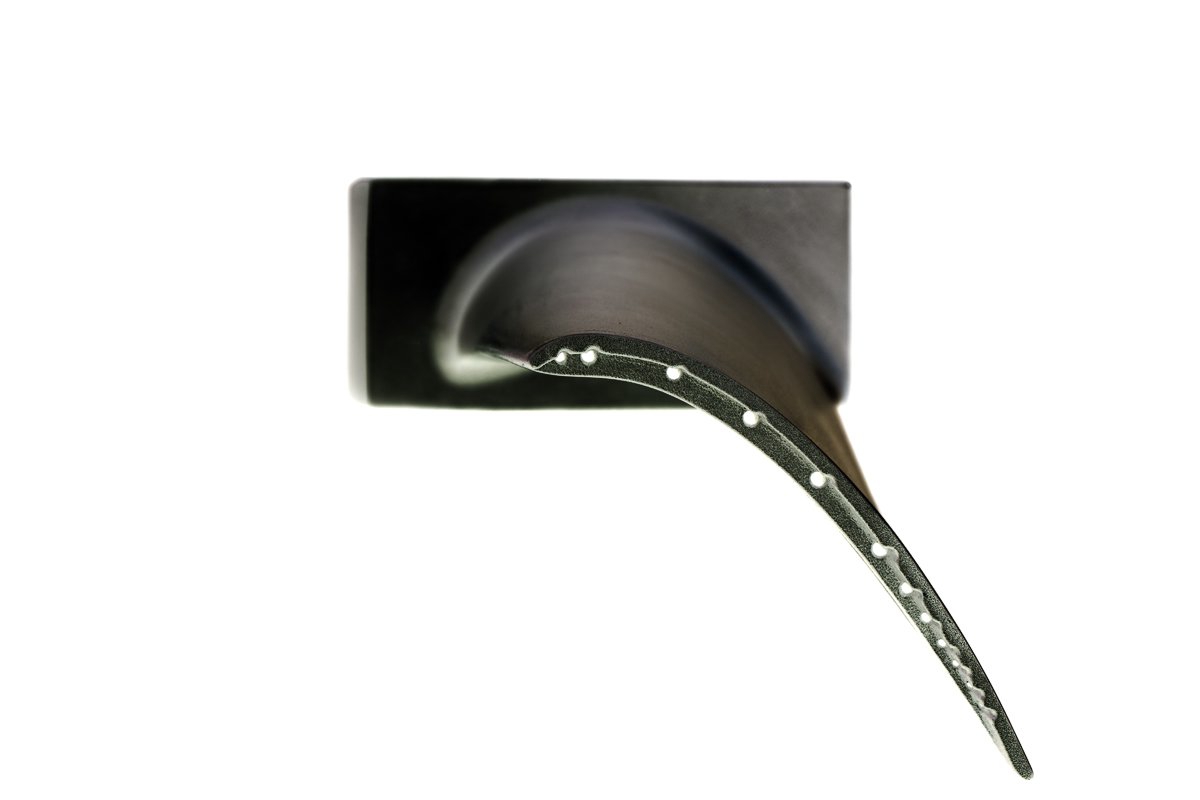

Low-angle boundary (LAB) defects arise during the directional solidification process in single crystal casting. These defects manifest as misalignments in the crystal structure, where the grain boundaries are not perfectly aligned at low angles, causing a deviation from the ideal single crystal structure. Unlike high-angle grain boundaries, which are more easily detected, LAB defects present unique challenges. They often remain hidden and are difficult to identify with standard testing methods once they cause significant issues with the mechanical properties of the casting.

The formation of LAB defects is typically linked to thermal gradients, cooling rates, and misalignment during the solidification process. As the molten metal solidifies, imperfections can occur if the temperature distribution is uneven or if the cooling rate is too rapid or slow. In many cases, LAB defects are more likely to occur at the interface between the mold and the casting or within regions where the heat transfer is irregular.

LAB defects in turbine blades can lead to problems like reduced fatigue resistance, impaired creep properties, and lower overall mechanical strength. Since turbine blades often operate in extreme conditions involving high temperatures and mechanical stresses, the performance of these parts can be compromised by such defects. Therefore, mitigating these defects through careful casting processes and proper selection of superalloys is crucial.

Techniques for Managing Low-Angle Boundary Defects

Managing LAB defects requires a comprehensive approach that involves controlling the thermal environment during casting, optimizing mold design, and refining the solidification process. Several techniques are employed to minimize the formation of low-angle boundaries and ensure that the final casting maintains its single-crystal integrity. Techniques like single crystal casting ensure high-performance parts for aerospace and power generation industries.

Optimized Solidification Process

The solidification process must be carefully controlled to ensure uniform crystal growth and prevent the formation of LAB defects. This is achieved by controlling the thermal gradient during the cooling phase. Directional solidification is a widely used technique in single-crystal casting, where heat is gradually removed from the mold to guide the growth of the crystal structure in a particular direction.

Advances in furnace technology have made it possible to control temperature profiles more precisely, ensuring a consistent cooling rate throughout the casting. By using a controlled heat removal process, it is possible to avoid creating irregular cooling patterns that lead to the formation of misaligned crystals.

Seeding and Crystal Growth Control

Introducing a seed crystal at the start of the casting process can significantly reduce the likelihood of LAB defects. A well-prepared seed ensures that the crystals will grow in a specific direction, minimizing any misalignment during the solidification phase. By ensuring that the primary crystal grows uniformly, LAB defects can be reduced or eliminated.

Further control of the crystal growth direction can be achieved through advanced techniques like controlled temperature gradients and optimized mold materials. Careful attention to the seed’s orientation can guide the crystal growth in the desired direction, reducing the chances of misalignment. Superalloy single crystal casting is an essential technique in maintaining crystal integrity.

Mold Design Innovations

The design of the casting mold is another critical factor in controlling LAB defects. Mold geometry and material selection are pivotal in ensuring that the thermal environment during solidification is stable and uniform. Modern molds are designed to distribute heat evenly across the casting, preventing temperature gradients that may contribute to forming LAB defects.

Advanced mold materials with high thermal conductivity can help maintain even cooling rates. Mold designs that minimize abrupt temperature changes and allow for gradual heat dissipation effectively reduce the risk of crystal misalignment and low-angle boundary formation. For example, vacuum investment casting provides a controlled thermal environment ideal for minimizing defects.

Casting Environment Control

Controlling the casting environment is essential to maintaining high-quality single-crystal castings. Vacuum or inert gas environments are commonly employed to prevent contamination and oxidation, which can cause defects in the crystal structure. Controlling the atmosphere within the mold can also help reduce the formation of defects by maintaining a stable thermal environment.

Temperature stability is another critical aspect of the casting process. Fluctuations in temperature can cause uneven solidification, leading to the formation of low-angle boundaries. Therefore, employing real-time monitoring systems to track and adjust the temperature during casting is critical in managing LAB defects. Advanced casting techniques can be employed to improve the precision of the casting process further.

Suitable Superalloys for Low-Angle Boundary Control

Certain superalloys are particularly well-suited to managing low-angle boundary (LAB) defects in single crystal casting. These alloys are chosen based on their chemical composition and ability to form a stable single crystal structure during solidification. The following superalloys are commonly used in single crystal casting and have been optimized to reduce LAB formation:

Inconel Alloys

Inconel alloys, such as Inconel 713, Inconel 718, and Inconel 738, are commonly used in high-temperature applications and are well-known for their excellent oxidation and corrosion resistance. These alloys exhibit good solidification behavior, making them ideal for turbine blades and other critical components. The likelihood of LAB defects in these alloys can be minimized by controlling the solidification rate.

CMSX Series

The CMSX series, including CMSX-4, CMSX-10, and CMSX-486, are particularly effective at controlling low-angle boundary formation. These alloys are designed for high-performance applications, such as turbine blades in jet engines, where single crystal structures are essential. Their composition is optimized to promote uniform crystal growth, reducing the potential for defects during casting.

Rene Alloys

Rene alloys, such as Rene 104 and Rene 88, are high-performance nickel-based superalloys designed for turbine blades and other high-temperature applications. These alloys have excellent resistance to creep and fatigue, and their casting properties allow for better control over the formation of low-angle boundaries. Rene alloys are often used in military and aerospace applications, where the ability to prevent LAB defects is crucial for maintaining component reliability.

Single Crystal Alloys

Other single crystal alloys, including PWA 1480 and CMSX-2, are suitable for preventing low-angle boundary defects. These alloys are designed for advanced turbine blades, vanes, and other critical components that must maintain their integrity under extreme conditions. Their properties, including improved thermal stability and resistance to high-temperature deformation, make them ideal for controlling LAB defects.

Post-Processing Approaches for LAB Defect Management

Post-processing techniques are often employed to address any remaining defects and refine the material properties once a casting has been produced. These processes can help eliminate or mitigate the effects of LAB defects and improve the component's overall performance.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is a post-processing technique that uses high temperature and pressure to eliminate residual porosity and improve the material's integrity. While HIP is not explicitly designed to address LAB defects, it can help reduce the impact of any remaining defects by consolidating the material and improving its mechanical properties. Using advanced HIP technology ensures that the overall material structure is refined, helping to mitigate the effect of LAB-related issues.

Heat Treatment for Microstructure Refinement

Controlled heat treatment cycles can be used to refine the microstructure of the casting and relieve stresses that may contribute to LAB defects. These heat treatments can help promote a more uniform crystal structure by reducing misalignments and ensuring the crystals align correctly. By controlling the cooling rate during precision heat treatment, the possibility of residual LAB defects can be minimized, enhancing the material's mechanical and thermal properties.

Surface Treatments and Coatings

Surface treatments, such as coating the casting with high-performance thermal barrier coatings, can help mitigate the effects of any existing LAB defects. These coatings not only protect the surface of the casting from oxidation and wear but can also enhance the component's resistance to high-temperature deformation, which is particularly beneficial in the presence of LAB defects. Modern TBC application methods ensure that coatings are applied evenly, reducing the impact of any surface irregularities and improving the overall durability of the component.

Testing and Analysis for Low-Angle Boundary Defect Detection

Detecting low-angle boundary (LAB) defects requires advanced testing and analysis techniques. Several non-destructive testing (NDT) methods are used to identify these defects without damaging the casting.

Non-Destructive Testing (NDT)

X-ray inspection, computed tomography (CT) scanning, and ultrasonic testing are commonly employed to detect internal defects in single-crystal castings. These methods allow for identifying misalignment in the crystal structure and help pinpoint areas where LAB defects may be present. Manufacturers can use these methods to gain high-resolution images and real-time data for defect detection and process optimization.

Electron Backscatter Diffraction (EBSD)

Electron Backscatter Diffraction (EBSD) is a powerful technique used to analyze the orientation of crystals within a material. This method can reveal misalignments in the crystal structure, including low-angle boundaries. Engineers can understand the microstructure and identify potential defects by examining the diffraction patterns. EBSD data helps refine casting processes and improve component quality.

Mechanical Testing

Mechanical testing, including tensile and creep tests, assesses the impact of LAB defects on the material’s mechanical properties. Components suspected of having LAB defects can be subjected to these tests to determine their strength, fatigue resistance, and performance under high-temperature conditions. These tests ensure that parts meet the necessary standards for high-performance applications.

Industry Applications and the Importance of LAB-Free Single Crystal Blades

In aerospace, power generation, and military defense industries, single crystal castings with minimal LAB defects are essential for ensuring the reliability and longevity of critical components. These industries require components that can withstand extreme temperatures and mechanical stresses without failure, making managing LAB defects a high priority.

Aerospace

In aerospace, for example, turbine blades made from high-performance superalloys must be defects-free to operate efficiently in harsh environments within jet engines. Ensuring these single crystal turbine blades are LAB-free is crucial for maintaining engine performance and safety under extreme conditions.

Power Generation

Similarly, power generation turbines rely on the integrity of their blades to maintain operational efficiency and minimize downtime. LAB-free components in turbines enhance their ability to endure high temperatures and mechanical loads, contributing to long-term reliability. Power generation turbines, therefore, depend on defect-free single crystal castings to ensure optimal performance and reduce maintenance needs.

Military

Military applications, where turbine blades and other critical components are used in engines, also require defect-free casting to ensure the reliability of propulsion systems. Components for military and defense systems must meet stringent performance standards, and controlling LAB defects is crucial to ensuring durability and operational efficiency in high-risk environments.

FAQs

What causes low-angle boundary defects in single crystal castings?

How can mold design help minimize low-angle boundary defects?

Which superalloys are best for preventing low-angle boundary defects?

What post-processing techniques are effective for managing LAB defects?

How is Electron Backscatter Diffraction (EBSD) used to detect LAB defects?