Integrating Simulation and Testing for Superior Superalloy Manufacturing

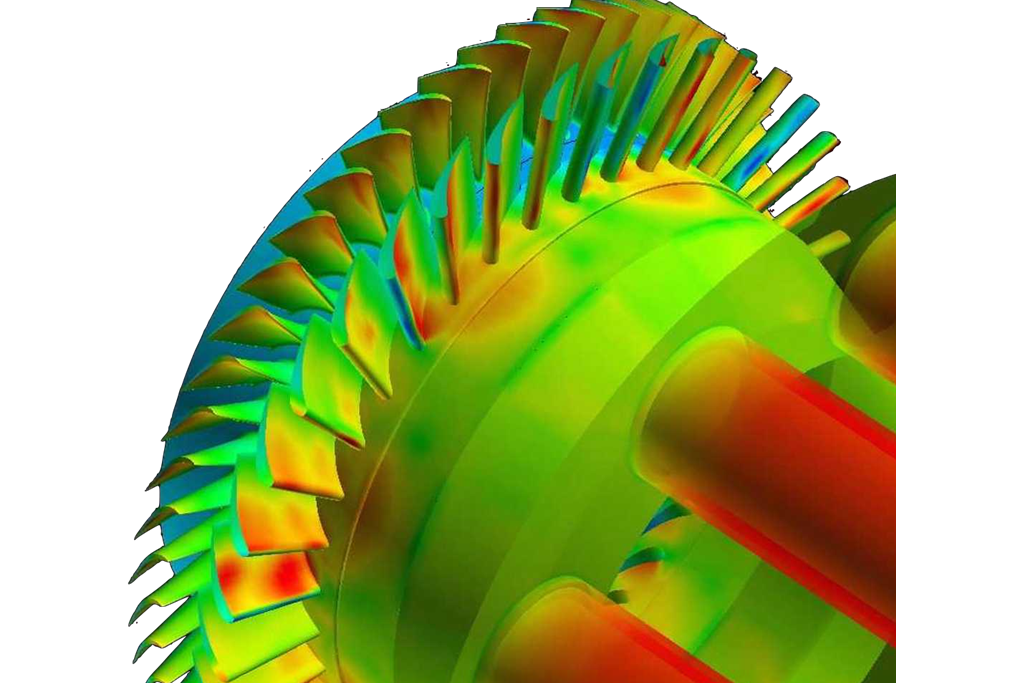

Superalloy parts are critical components in industries where performance and reliability are paramount. These parts must be capable of withstanding extreme conditions such as high temperatures, mechanical stress, and corrosive environments. Superalloys, typically based on nickel, cobalt, or iron, exhibit exceptional strength and resistance to oxidation and thermal creep, making them indispensable in aerospace, power generation, and defense applications. To achieve the high standards required for these demanding applications, manufacturers integrate advanced simulation techniques and testing protocols to optimize part design and manufacturing processes. This blog delves into the different manufacturing processes used for superalloy parts, the benefits of various superalloys, post-processing methods, testing techniques, and their applications across industries.

Different Superalloy Part Manufacturing Processes

The production of superalloy parts involves various processes, each suited to specific types of components and performance requirements.

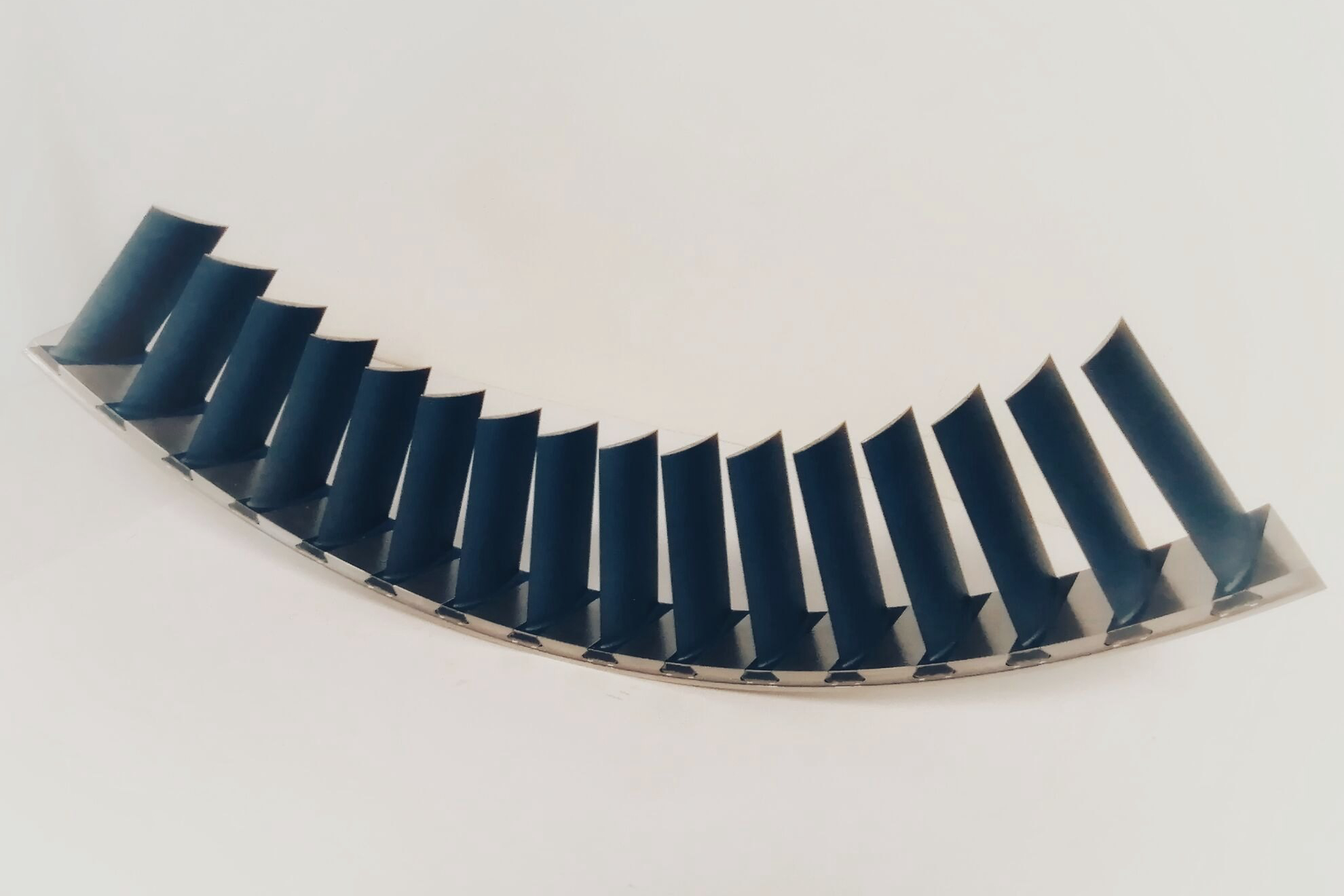

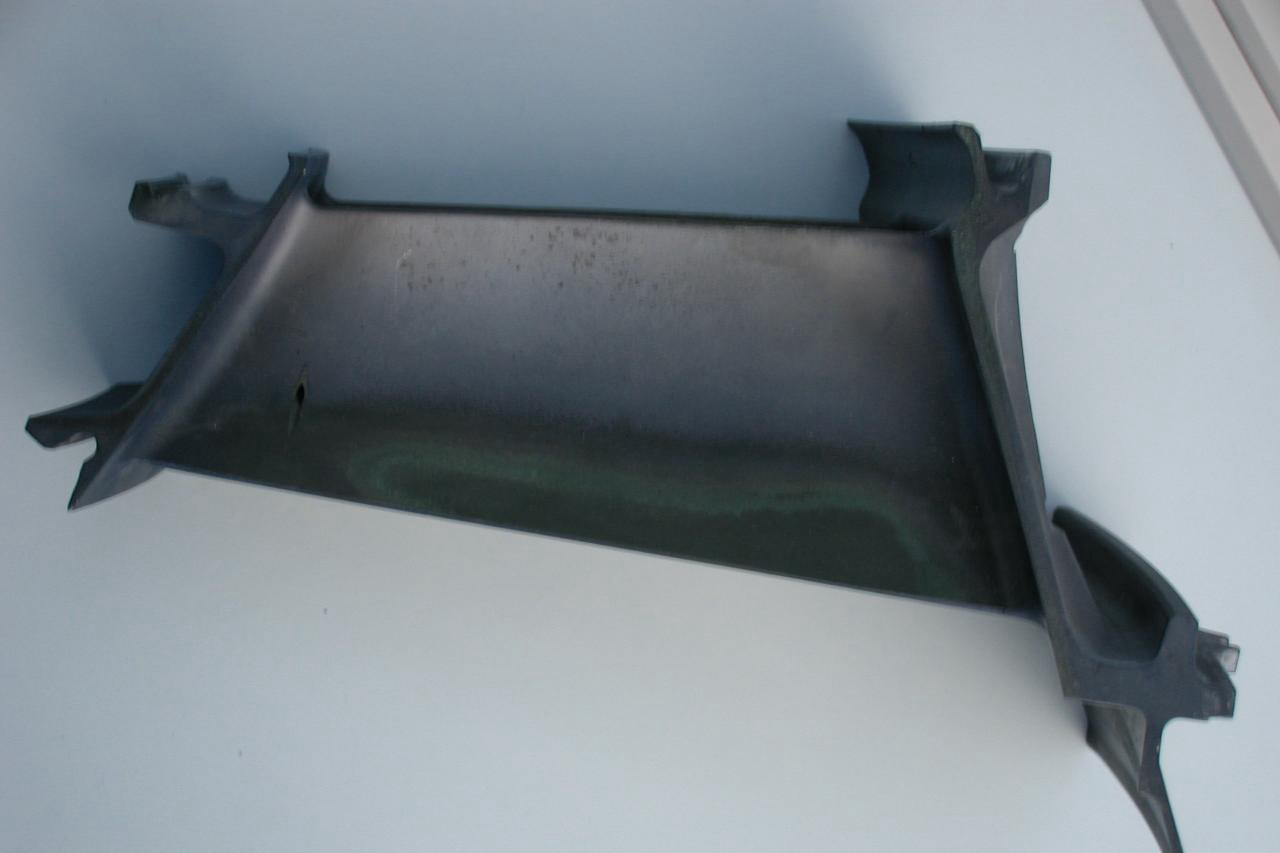

Vacuum investment casting is one of the most common techniques for producing complex, high-precision superalloy parts. This process involves creating a mold from a wax pattern, which is then coated with a ceramic shell. The mold is heated in a vacuum to remove the wax and harden the ceramic shell, creating a cavity in which molten superalloy is poured. This process is ideal for turbine blades and engine parts requiring intricate shapes and fine detail.

Single crystal casting produces components with superior mechanical properties, particularly for applications exposed to high temperatures and stresses, such as turbine blades in jet engines. In this process, a superalloy is melted and slowly cooled in a controlled manner to form a single, uninterrupted crystal. This crystal structure provides enhanced resistance to creep and fatigue, making it particularly valuable for critical aerospace and power generation components.

Equiaxed crystal casting produces parts with a more uniform grain structure. This process involves cooling the molten superalloy faster than single-crystal casting, resulting in equiaxed crystals. While these parts do not have the high-performance characteristics of single-crystal components, they offer a good balance of strength, flexibility, and cost-effectiveness for parts like combustion chambers and casings.

Directional casting is similar to single crystal casting but aims to align the grain structure in a specific direction to enhance properties like creep resistance. This process is especially beneficial for producing turbine blades subjected to high mechanical stress. The direction of the grain flow helps reduce the material's susceptibility to failure under load, thus improving the durability of critical engine components.

Powder metallurgy is a process that involves forming components by compacting metal powders and then sintering them at high temperatures. This method is particularly effective for creating parts with intricate geometries, such as turbine discs, and can achieve high material density and fine-grain structures. It also provides excellent control over the alloy's composition and microstructure, making it ideal for parts that require tight tolerances and high performance.

Forging (including precision, isothermal, rough, and free forging) is widely used in superalloy part manufacturing because it produces solid and high-performance components. Forging involves shaping a material by applying localized compressive forces using hammers or presses. The process improves the material's mechanical properties, such as tensile strength and fatigue resistance, by aligning the grain structure in the direction of the applied stress. It produces components like turbine discs, gears, and structural parts for aerospace and power generation.

CNC machining is a subtractive manufacturing process involving computer-controlled machines cutting and shaping superalloy parts to precise dimensions. This technique is precious for finishing components that have already been cast or forged, providing tight tolerances and smooth surfaces. CNC machining is commonly used for high-precision aerospace components, such as brackets, housings, and turbine blades.

3D printing (or additive manufacturing) has emerged as a revolutionary technology for producing superalloy parts. In this process, the material is deposited layer by layer to build up a part from a digital model. 3D printing allows for complex geometries and rapid prototyping, making it ideal for small production runs and custom components. Superalloy 3D printing is increasingly used in aerospace, medical, and defense applications for parts such as heat exchangers, combustion components, and custom-engineered solutions.

Benefits of Different Superalloys

Selecting a specific superalloy for a given application is crucial to achieving optimal performance. Superalloys like Inconel, CMSX, Hastelloy, Stellite, and Titanium Alloys each offer unique benefits suited to specific environmental conditions.

Inconel Alloys

Inconel alloys, such as Inconel 718 and Inconel 625, are highly resistant to high temperatures and oxidation, making them ideal for use in gas turbines, exhaust systems, and aerospace engines. These alloys retain their mechanical properties even under extreme conditions, offering durability and reliability.

CMSX Series

CMSX Series, including CMSX-10 and CMSX-486, are single-crystal superalloys known for their exceptional creep resistance and high-temperature fatigue strength. These materials are critical for high-stress applications like turbine blades in jet engines, where their resistance to deformation under load is vital.

Hastelloy

Hastelloy is a family of corrosion-resistant alloys used extensively in the chemical and petrochemical industries. With their superior resistance to oxidation and corrosion, Hastelloy alloys are used in components that operate in aggressive environments, such as reactors, valves, and heat exchangers.

Stellite Alloys

Stellite alloys, with their hardness and wear resistance, are often used in applications requiring parts subjected to high friction and erosion. Stellite alloys are frequently found in valves, nozzles, and other critical components in aerospace and industrial applications.

Titanium Alloys

Titanium Alloys are prized for their lightweight, strength, and corrosion resistance combination. Alloys like Ti-6Al-4V are widely used in aerospace, medical implants, and high-performance automotive applications, where low weight and high strength are crucial.

Post-Processing Techniques Comparison

Once superalloy parts have been manufactured, various post-processing techniques are employed to enhance their performance and meet stringent industry standards.

Hot Isostatic Pressing (HIP) eliminates porosity in metal parts, improving their overall strength and fatigue resistance. This process subjects the parts to high pressure and temperature in a vacuum, ensuring uniform density and material integrity. HIP is often used for high-performance parts, such as turbine discs and structural components, to enhance mechanical properties and ensure their reliability in aerospace and energy applications.

Heat Treatment involves heating a superalloy to a specific temperature and then cooling it in a controlled manner to achieve desired mechanical properties. Depending on the alloy and intended application, this process can improve hardness, tensile strength, and flexibility. For superalloy turbine blades, heat treatment ensures the material can withstand the extreme temperatures and mechanical stresses encountered in operation, improving fatigue resistance and overall performance.

Superalloy Welding is necessary for joining superalloy components together, often for complex assemblies. Special welding techniques, such as electron beam and laser welding, ensure that the welded joints maintain the material's high strength and resistance to high temperatures. Welding ensures that parts maintain structural integrity and reliability under high-stress conditions, which is crucial for gas turbines and aerospace structures.

Thermal Barrier Coating (TBC) protects superalloy parts from thermal degradation. A thin ceramic layer is applied to high-temperature components, such as turbine blades, to protect them from the intense heat encountered during operation. TBC significantly extends the service life of superalloy components in gas turbines and other high-performance applications, enhancing heat resistance and preventing material failure.

CNC Machining and EDM (Electrical Discharge Machining) fine-tune part dimensions and geometries after casting or forging. These processes help achieve tight tolerances and smooth surface finishes, which are critical for the performance and reliability of superalloy parts in demanding applications. CNC machining is particularly useful for creating complex geometries and ensuring precision in gas turbine components, while EDM allows for intricate feature creation in hard-to-machine superalloys.

Testing Methods for Superalloy Components

The performance of superalloy parts must be rigorously tested to ensure they meet the required specifications for strength, durability, and resistance to extreme conditions. Several testing methods are employed during the manufacturing process:

Tensile Testing measures the material's strength and flexibility under tension, helping manufacturers determine the maximum load a component can withstand before failure. For turbine blades and other high-performance parts, tensile testing is essential to ensure structural integrity.

Cyclic Fatigue Testing evaluates how a material responds to repeated loading and unloading, critical for parts that experience fluctuating stresses during operation. This testing is essential for components exposed to dynamic forces, such as turbine blades and engine components.

Metallographic Analysis examines the microstructure of a material to identify defects, grain structure, and overall quality. This analysis helps manufacturers understand the material's behavior and performance characteristics under different conditions.

X-ray and CT Scanning are non-destructive testing methods used to inspect the internal structure of superalloy parts. These techniques help identify internal voids, cracks, or inclusions that could compromise the integrity of the component.

Simultaneous Thermal Analysis (STA) assesses how superalloys perform under varying thermal conditions, helping manufacturers understand how materials behave at high temperatures and during thermal cycling. This testing is vital for components like turbine blades and exhaust systems that experience extreme thermal loads.

Electron Backscatter Diffraction (EBSD) is used to analyze the crystallographic structure of materials, providing insights into grain orientation and texture. This method helps understand how superalloy parts will behave under mechanical stress and thermal conditions.

Applications and Industry Use of Superalloy Parts

Superalloy parts are integral to various industries that require components capable of withstanding high temperatures, mechanical stress, and corrosion. Some of the critical industries and applications include:

Aerospace and Aviation

Superalloy parts, such as turbine blades, combustion chambers, and exhaust nozzles, are essential in jet engines, which must operate under extreme conditions. These high-performance components ensure engines' safe and efficient operation, even in the most demanding aerospace environments.

Power Generation

Gas turbines, steam turbines, and other critical components in power plants rely on superalloys to withstand high temperatures and stress. Superalloy materials are used in superalloy heat exchanger parts, turbine blades, rotors, and nozzles, ensuring high efficiency and long-term reliability under demanding conditions.

Oil and Gas

Components like valves, pumps, and pipes, which are exposed to high pressures and corrosive environments, often use superalloy materials for their durability and resistance to wear. Superalloys are well-suited for high-performance applications such as high-temperature alloy pump components, where resistance to wear and corrosion is critical for ensuring continuous operation in the oil and gas industry.

Marine

Superalloys are used in naval ship components, including heat exchangers, propellers, and structural parts that must resist high temperatures and saltwater corrosion. The corrosion resistance and strength of superalloys ensure that marine applications, such as superalloy naval ship modules, perform reliably in harsh maritime environments.

Chemical Processing

Superalloys are critical in reactors, heat exchangers, and valves that resist high temperatures and aggressive chemical environments. These components are essential for the chemical processing industry, where superalloys like superalloy heat exchanger parts ensure the safe handling of corrosive chemicals at elevated temperatures.

Defense

Superalloy components are found in military-grade parts, including those used in aircraft, missiles, and naval systems, where reliability and performance are paramount. For example, superalloy armor system parts are crucial for military applications, offering strength, durability, and resistance to extreme conditions, which are vital for mission success.

Superalloys are indispensable across these industries, ensuring critical components' performance, longevity, and reliability under extreme conditions.

FAQs:

How does simulation impact the manufacturing of superalloy parts?

What advantages does Single Crystal Casting offer over other casting methods?

Why are Powder Metallurgy techniques preferred for certain superalloy components?

What is the role of CNC machining in achieving tight tolerances for superalloy parts?

How does Electron Backscatter Diffraction (EBSD) aid in improving superalloy part quality?