How TBC Enhances Durability and Efficiency in Alloy Components

Thermal Barrier Coatings (TBCs) are crucial in enhancing the performance and lifespan of high-temperature alloy parts used in aerospace, power generation, and marine industries. These coatings serve as a protective layer that insulates critical components from extreme temperatures, increasing their durability and efficiency.

In this blog, we will explore the materials used in TBCs, the manufacturing processes, post-processing techniques, testing and inspection methods, and the diverse industry applications where TBCs are essential.

Materials Used in Thermal Barrier Coatings

Superalloy Substrates

High-temperature alloys, or superalloys, form the foundation for components requiring Thermal Barrier Coatings (TBCs). These materials are engineered to withstand extreme heat and pressure, which is critical in aerospace and power generation applications. Common superalloy substrates include:

Inconel alloys (e.g., Inconel 718, Inconel 625): Known for their excellent mechanical properties, resistance to oxidation, and strength at high temperatures, Inconel alloys are widely used in turbines, combustion chambers, and exhaust systems.

CMSX series (e.g., CMSX-2, CMSX-486): These single-crystal superalloys are ideal for aerospace applications, particularly turbine blades, due to their exceptional creep resistance, high-temperature stability, and fatigue strength.

Monel alloys (e.g., Monel 400): A nickel-copper alloy known for its excellent resistance to corrosion in marine and high-temperature environments.

These superalloys are selected for their ability to maintain strength and integrity in extreme operating conditions, making them suitable substrates for TBC applications.

TBC Materials

The most commonly used material for Thermal Barrier Coatings (TBCs) is yttria-stabilized zirconia (YSZ). YSZ is a ceramic with remarkable thermal insulating properties, making it highly effective in shielding components from extreme temperatures. Its low thermal conductivity helps reduce heat transfer, while its high melting point (around 2700°C) ensures it maintains structural integrity under intense thermal stress.

Other ceramic materials used in TBCs include:

Barium zirconate: Known for its high thermal stability and ability to withstand extreme heat.

Mullite Offers excellent thermal insulation and is used in applications requiring moderate thermal protection.

The choice of TBC material is tailored to the specific application and the environmental conditions the component will face, such as the temperature range, exposure to thermal cycling, and mechanical loads.

Coating Thickness and Application Materials

The thickness of the TBC plays a crucial role in its performance. It must be thick enough to provide adequate insulation while not so thick that it negatively impacts the component's structural integrity. Typically, TBCs are applied with thicknesses ranging from 100 to 300 microns, depending on the substrate material and operating conditions.

The application materials for TBCs include:

Bond coats: Often made from MCrAlY (a mix of nickel, cobalt, chromium, aluminum, and yttrium), bond coats ensure strong adhesion between the TBC and the superalloy substrate while providing oxidation resistance.

Topcoats: The ceramic TBC layer, typically made from yttria-stabilized zirconia or other ceramics, provides the thermal insulation.

The selection of these materials depends on the specific requirements of the component and the operating environment to ensure optimal protection against heat, oxidation, and thermal cycling.

Manufacturing Process for Applying TBCs

Thermal barrier coatings (TBCs) protect high-temperature alloys in extreme environments. Applying TBCs involves several steps and techniques to ensure maximum performance and durability. Here are the key processes used to apply TBCs to high-temperature alloys.

Coating Techniques

There are several methods for applying TBCs to high-temperature alloys, with plasma spray coating and electron beam physical vapor deposition (EB-PVD) being the most common.

Plasma Spray Coating: This technique involves using a high-energy plasma jet to melt ceramic powders, which are then sprayed onto the surface of the superalloy substrate. The molten particles cool rapidly and solidify, forming a dense, well-bonded coating. Plasma spraying is a fast, cost-effective method, making it suitable for high-volume production, particularly in aerospace and power generation industries. This process is ideal for creating coatings with good adhesion and thermal insulation properties.

Electron Beam Physical Vapor Deposition (EB-PVD): EB-PVD involves evaporating the ceramic material in a vacuum chamber and condensing it onto the component surface as a thin, uniform coating. This process produces coatings with a fine columnar microstructure, providing superior spallation resistance. It is particularly effective in high-temperature environments, such as for turbine blades, where resistance to cracking and thermal cycling is essential. EB-PVD is highly favored in aerospace applications because it provides consistent, durable coatings.

Preparation of the Substrate

Before the TBC can be applied, the substrate (typically a superalloy component) must be prepared to ensure strong adhesion of the coating. It involves several steps:

Cleaning: The part is thoroughly cleaned to remove any oils, dirt, or other contaminants that could impair the bond between the coating and the substrate.

Surface Roughening: Techniques such as grit blasting or sandblasting are used to roughen the surface of the substrate. It creates a micro-rough texture, which increases the surface area and enhances the bond strength between the TBC and the substrate.

Layering and Bond Coatings

Thermal barrier coatings are typically applied in two distinct layers: a bond coat and a topcoat.

Bond Coat: The bond coat is the first layer applied to the substrate and is typically made from MCrAlY alloys (where M is a metal such as nickel or cobalt). This layer intermediates the superalloy substrate and the thermal barrier coating. It improves the adhesion of the TBC to the substrate, protects against oxidation, and enhances the overall durability of the coating.

Topcoat: The topcoat is the thermal barrier usually made from yttria-stabilized zirconia (YSZ). This material provides thermal insulation, protecting the underlying substrate from extreme temperatures in high-performance applications like gas turbines and aerospace components.

Combining these layers ensures that the TBC system effectively protects against oxidation, thermal cycling, and mechanical wear, enhancing the longevity and performance of high-temperature alloy components.

Manufacturers can produce TBCs that offer exceptional protection and durability for components operating in extreme environments using advanced coating techniques, precise substrate preparation, and a multi-layer approach.

Post-Processing of TBCs

Heat Treatment for Coating Integrity

After the TBC is applied, it is often subjected to heat treatment to ensure the coating has the desired microstructure and bonding strength. Heat treatment helps to relieve residual stresses, ensuring that the coating will not crack or delaminate during thermal cycling. It also promotes the diffusion of the bond coat into the substrate, further improving the bonding strength. Precision heat treatment is critical for achieving optimal properties in high-temperature alloy parts, enhancing durability and efficiency.

Curing and Stress Relief

The curing process involves subjecting the component to controlled heat cycles to allow the TBC to solidify and develop its optimal thermal properties. During curing, any stress accumulated during the application process is relieved, reducing the risk of cracking. The curing process also ensures that the bond between the TBC and the superalloy is robust enough to withstand the harsh conditions it will face during operation. Thermal barrier coatings play a crucial role in extending life and improving the performance of superalloy components, especially in high-temperature applications.

Additional Surface Treatment

In some cases, additional post-processing treatments are applied to enhance the performance of the TBC. Hot Isostatic Pressing (HIP) eliminates any defects or porosity in the coating and ensures that the TBC has a dense, uniform structure. HIP involves applying high pressure and temperature to the coated part in a controlled environment, which helps to close any voids or cracks within the coating. This process enhances the component's density and integrity, making it more resistant to thermal stresses and improving its durability.

Testing and Inspection of TBCs on High-Temperature Alloys

Quality Control in TBC Coatings

Comprehensive testing and inspection methods are employed to ensure the durability and performance of Thermal Barrier Coatings (TBCs). The quality control process starts with a visual inspection to identify any apparent flaws, such as cracks, delamination, or incomplete coverage. Advanced techniques such as Water Immersion Ultrasonic Testing can be utilized for internal defect detection, ensuring the uniformity of the coating and substrate bonding.

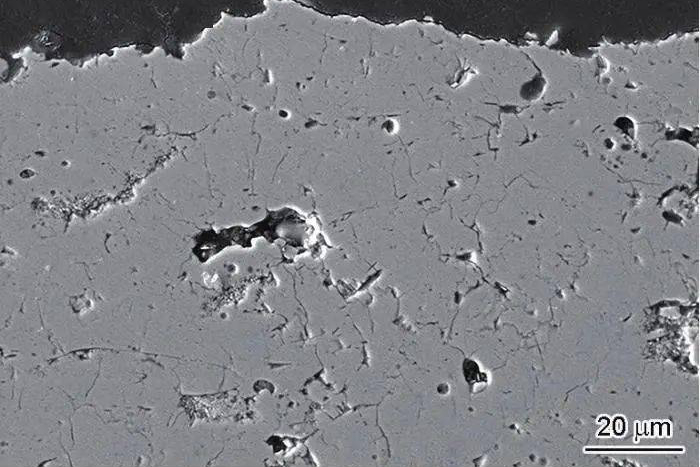

Microstructural Analysis

One of the most critical tests for TBCs is microstructural analysis, typically done using scanning electron microscopy (SEM). SEM allows for a detailed examination of the coating's structure at the microscopic level, helping to identify any defects that could impact its performance. This test is aligned with failure analysis in superalloy single crystals, where similar microstructural investigations help detect issues affecting overall reliability and durability.

X-ray and CT Scanning

X-ray and computed tomography (CT) scanning detect internal defects such as voids, cracks, or porosity in the coating. These non-destructive testing methods are essential for identifying potential failure points that could compromise the TBC's insulating properties. Techniques like Line Array Industrial CT are beneficial for evaluating internal defect patterns in superalloy castings, ensuring the structural integrity of both the coating and the underlying material.

Performance Testing

Thermal Cycling Testing

This test simulates the extreme temperature variations that TBC-coated parts experience during operation. It subjects the component to repeated heating and cooling cycles to ensure the coating can withstand thermal shock without cracking or delaminating. Thermal Physical Properties Testing plays a critical role in measuring the material's response to temperature changes, thus ensuring the stability of superalloy components during operational extremes.

Creep and Stress Testing

High-temperature alloys are subjected to creep testing to evaluate how they deform under sustained stress at elevated temperatures. TBCs help to enhance the creep resistance of alloy components, and these tests ensure that the coating does not degrade under high-pressure conditions. This test is analogous to stress resistance evaluation in directional castings, where internal stresses and material behavior under extreme conditions are assessed to predict alloy parts' lifespan and failure points.

Adhesion and Bonding Strength Testing

The bond strength between the TBC and the substrate is critical for the coating's performance. Adhesion testing, such as peel-off or scratch tests, assesses how well the coating adheres to the surface under mechanical stress. Adhesion analysis in superalloy parts using ultrasonic technology can help evaluate the quality of bonds, ensuring that the coatings remain intact under operational forces.

Advanced Analysis Techniques

In addition to the above tests, advanced techniques such as Glow Discharge Mass Spectrometry (GDMS) and Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) are used to analyze the composition of the coating and ensure that it meets the required standards. These methods help to detect any impurities in the coating material that could affect its thermal and mechanical properties. ICP-OES, in particular, plays a critical role in verifying the alloy composition, ensuring that no contaminants affect the TBC's performance in high-stress environments.

Industry Applications and Benefits

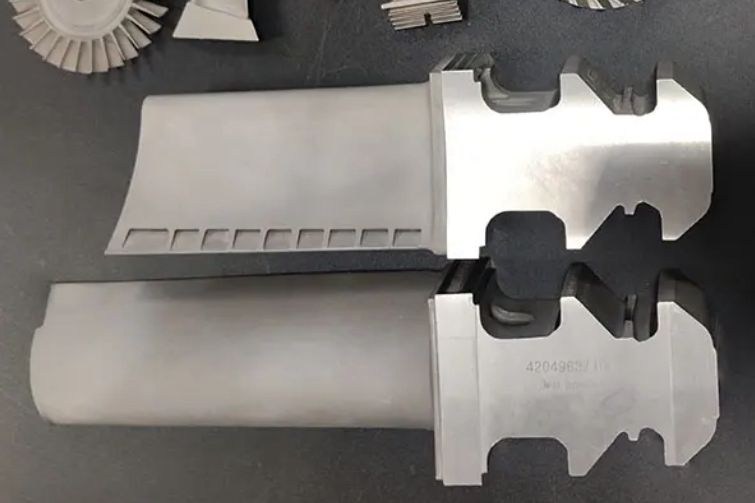

Aerospace and Aviation

Thermal Barrier Coatings (TBCs) are crucial in the aerospace industry, where components like turbine blades and combustor liners are subjected to extreme temperatures. TBCs significantly enhance the durability and efficiency of these components, allowing them to withstand the high heat generated during jet engine operation. By reducing the temperature experienced by the superalloy substrate, TBCs improve the engine's overall performance, increasing fuel efficiency and reducing maintenance costs. Additionally, TBCs help extend the lifespan of aerospace components, reducing the frequency of replacements and downtime.

Power Generation

In the power generation industry, TBCs are used in gas turbines to improve performance and extend the life of critical components. The high temperatures in power plants can cause significant wear on turbine blades and other parts. By applying TBCs, these components can better resist thermal damage, oxidation, and erosion. As a result, gas turbines operate more efficiently, leading to increased energy production and reduced operational costs.

Marine and Automotive Industries

TBCs are also used in marine and automotive applications, particularly in components exposed to high temperatures, such as marine turbines and automotive turbochargers. By providing thermal protection, TBCs help to enhance the performance and longevity of these parts, reducing downtime and the need for frequent maintenance. The result is improved reliability and reduced operational costs for industries that rely on high-performance engines.

FAQs

What is the primary function of a Thermal Barrier Coating (TBC) in high-temperature alloys?

How does plasma spray coating differ from EB-PVD when TBCs are applied?

What are the key factors determining a TBC's effectiveness on a superalloy component?

How does TBC impact the overall performance and lifespan of turbine blades in aerospace applications?

What tests are performed to ensure the quality and durability of TBCs on high-temperature alloy parts?