How Heat Treatment Enhances Alloy Durability and Life

Introduction to Heat Treatment

Heat treatment is an essential post-processing technique that significantly enhances superalloy components' durability, strength, and performance. By applying controlled heating and cooling processes, heat treatment can improve superalloys' structural integrity, often used in high-stress, high-temperature environments. Industries like aerospace, power generation, and chemical processing rely heavily on these enhancements, operating under extreme mechanical and thermal stresses.

The durability and lifespan of superalloy components can be significantly extended through heat treatment. This process helps relieve internal stresses, refines grain structure, and optimizes alloy homogeneity, enabling these components to withstand operational stress and repeated thermal cycles. Heat treatment is crucial for achieving long-term reliability and efficiency in applications where maintenance and downtime are costly.

What is Heat Treatment in Alloy Castings?

Definition and Purpose of Heat Treatment for Superalloy Castings

Heat treatment refers to a series of processes in which alloy castings are subjected to specific temperature cycles to alter and improve their properties. Standard methods include annealing, solution treatment, aging, quenching, and stress-relieving treatments. Each technique serves a unique purpose, addressing distinct characteristics within the alloy to optimize it for real-world applications. The process sequence typically involves

heating the component to a target temperature,

holding it for a specified time and

cooling it at a controlled rate to refine its internal structure.

Heat treatment's primary goal is to enhance superalloy components' performance, longevity, and resilience. By restructuring the alloy's internal grain structure and homogenizing its composition, heat treatment reduces the risk of warping, cracking, and fatigue. It enables superalloy parts to maintain strength, toughness, and stability even when exposed to extreme heat, mechanical loads, or environmental stressors. Heat treatment enhances the component's mediate mechanical properties and ensures that these properties are retained over time, increasing the component's thermal life.

How Heat Treatment Enhances the Durability and Life of Superalloy Components

Heat treatment enhances durability by reducing internal stresses, refining the microstructure, and creating a more uniform distribution of elements within the alloy. It strengthens the material and ensures it can withstand mechanical and thermal fatigue. Components like turbine blades, combustion chambers, and gas turbine nozzles undergo continuous high-stress cycles that would lead to degradation without the stability and resilience provided by heat treatment.

Specifically, heat treatment processes like annealing and aging increase fatigue resistance by relieving residual stresses accumulated during the initial casting, forging, or machining processes. When stresses are left unaddressed, they can weaken the alloy over time, resulting in microcracks or fractures. By relieving these stresses, heat treatment ensures that the alloy remains structurally intact, minimizing the risk of premature failure. Additionally, heat treatment improves the alloy's ability to resist creep—deformation due to prolonged exposure to high temperatures—which is essential for parts that operate under constant thermal loads.

Heat Treatment Vs. Other Post-Processing Techniques

Comparison to Similar Post-Treatment Processes

While heat treatment is a crucial post-processing technique, other methods also enhance the quality and durability of superalloy parts. Hot Isostatic Pressing (HIP), for instance, densifies parts by applying high-pressure gas in a heated environment, reducing porosity and eliminating internal voids. However, HIP does not explicitly target stress relief, so it does offer the same enhancements in fatigue resistance or thermal stability as heat treatment.

Thermal Barrier Coating (TBC) is another post-processing technique that applies a thin, heat-resistant layer to protect superalloy surfaces from extreme temperatures and oxidation. While TBC effectively shields the component's surface, it does not impact the alloy's internal structure.

CNC machining and deep hole drilling are essential for achieving precise shapes and finishes. However, they can introduce residual stresses that require subsequent heat treatment to stabilize the parts. Therefore, while TBC, HIP, and machining processes each serve valuable purposes, heat treatment remains unmatched in its ability to improve the surface and internal structure of superalloy components, extending their operational lifespan.

Benefits and Disadvantages

The primary benefit of heat treatment is its ability to relieve residual stresses, thereby enhancing fatigue resistance and mechanical properties. However, heat treatment may occasionally cause slight dimensional changes due to thermal expansion and contraction, which could require additional finishing steps.

HIP, while highly effective in improving density and structural integrity, does not relieve residual stress, making it a complementary process to heat treatment rather than a replacement. Thermal coatings protect against oxidation and corrosion but do not address internal stresses or enhance the core properties of the alloy.

What Superalloy Parts Need Heat Treatment?

Various superalloy components require heat treatment to achieve the durability and performance needed in critical applications. Below is an expanded list of commonly treated superalloy parts and how they benefit from heat treatment:

Vacuum Investment Castings

Produced in a vacuum environment to avoid contamination, these castings are used in applications like gas turbine nozzles. Heat treatment improves fatigue resistance and dimensional stability, making them suitable for high-stress environments where precision and strength are paramount.

Single Crystal Castings

Single crystal castings are used for turbine blades in jet engines with no grain boundaries, which can be weak points under stress. Heat treatment preserves the single-crystal structure and prevents recrystallization, significantly increasing the part's creep resistance and lifespan in high-temperature conditions.

Equiaxed Crystal Castings

Heat treatment improves the isotropic properties of these castings, making them resistant to multi-directional stresses. This treatment benefits compressor blades and impellers operating under fluctuating loads and directions.

Directional Castings

Directional castings achieve higher strength along the grain axis by aligning grain structures in a single direction. Heat treatment supports this structure, enhancing the alloy's ability to handle high-temperature operations, especially in rotating machinery and turbine blades.

Special Alloy Castings

These are made from unique alloys tailored for specific, often corrosive or high-temperature environments. Heat treatment ensures these components retain their specialized properties while remaining free from internal stresses.

Powder Metallurgy Superalloy Parts

Parts made from powder metallurgy often contain tiny pores. Heat treatment densifies these structures and provides homogeneity, increasing the apart strength and reliability under heavy loads.

Precision Forging Parts

Forged superalloy parts benefit from heat treatment, which increases their strength and stability. These parts, commonly used in aerospace structures, enhance durability and improve wear resistance.

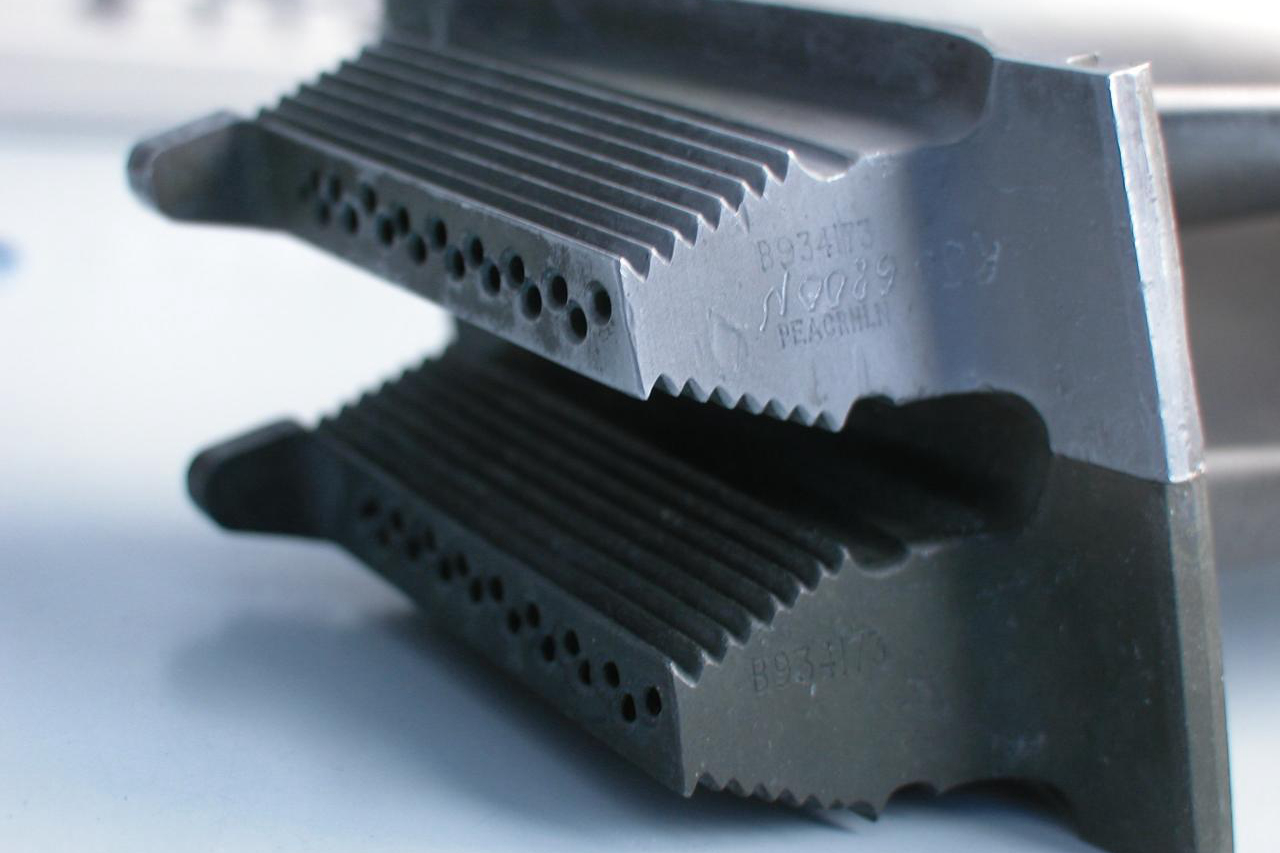

CNC Machined Superalloy Parts

Machining can introduce residual stresses that weaken the part. Heat treatment relieves these stresses, improving the stability of high-tolerance parts and reducing the risk of deformation during use.

3D Printed Superalloy Components

Rapid cooling in additive manufacturing leaves residual stresses in printed parts. Heat treatment stabilizes these parts, ensuring they retain their shape and structural integrity over time.

Inspections of Superalloy Parts After Heat Treatment

Common Inspection Methods for Superalloy Parts After Heat Treatment

To ensure that heat-treated superalloy parts meet stringent quality standards, manufacturers employ a variety of inspection methods, including:

Coordinate Measuring Machine (CMM): This tool verifies that dimensional tolerances are met by measuring the part's geometry with high precision.

X-Ray Inspection: X-rays detect internal flaws, such as voids or inclusions, that may compromise the structural integrity.

Ultrasonic Testing: Ultrasonic waves identify subsurface defects, such as microcracks or density inconsistencies, ensuring the part is internally sound.

Metallographic Microscopy: This method examines the alloy's rain structure, helping confirm that the microstructure meets the required standards for durability and strength.

Tensile Testing: This testing assesses mechanical properties, including tensile strength and yield, ensuring the part can withstand operational stress.

Importance of Inspection

Inspection is essential after heat treatment to verify that stress relief and structural improvements have been achieved without introducing new defects. These tests confirm that the heat treatment has successfully enhanced the component's performance, durability, and lifespan. Early detection of flaws allows for corrective action before the part is deployed, reducing the risk of failure in critical applications and giving manufacturers confidence that each part meets the rigorous standards required for high-stakes industries.

Heat Treatment FAQs

What are the main types of heat treatment processes used in superalloy casting?

How does heat treatment prevent cracking in high-temperature applications?

What inspection methods are commonly used after heat treatment?

How long does a typical stress relief heat treatment cycle take?

What is the difference between heat treatment and hot isostatic pressing?