High-Temperature Alloy Pump Components Production Unit

Induction of Superalloy Pump Components

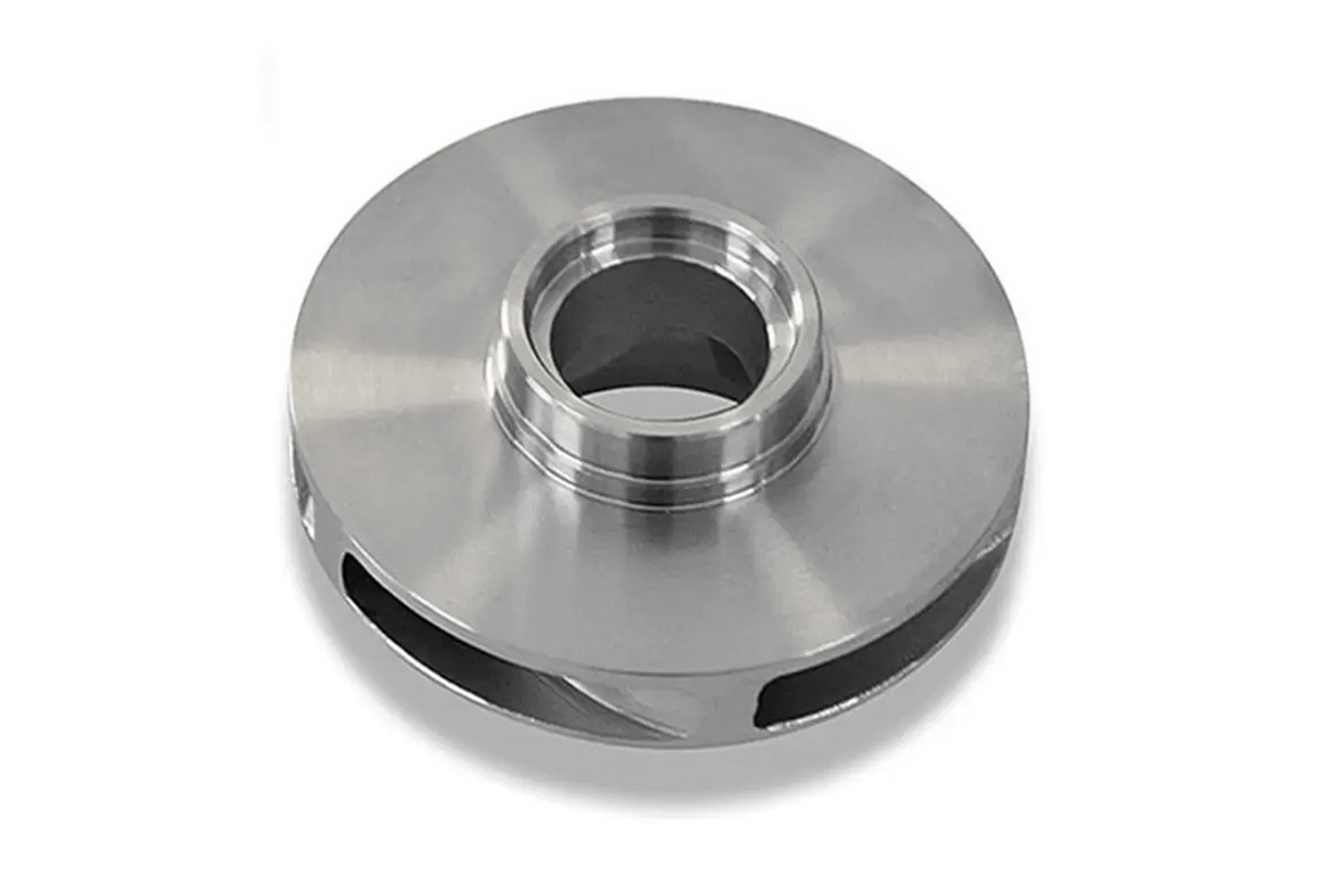

Superalloy pump components are critical elements used in high-pressure and high-temperature pumping applications. These components are designed to handle extreme conditions involving corrosive fluids, high temperatures, and significant mechanical stress. The unique properties of superalloys, such as their high strength and resistance to oxidation and corrosion, make them ideal for manufacturing pump components used in challenging environments. Typical materials include superalloys like Inconel, Hastelloy, and Nimonic, which are known for their mechanical stability under extreme operating conditions.

Superalloy pump components are commonly employed in industries that demand consistent performance and reliability, such as oil and gas, chemical processing, aerospace, and power generation. The materials used provide

excellent performance in maintaining strength at elevated temperatures,

resistance to chemical attack, and

Tolerance to the wear and fatigue experienced during continuous operation.

Superalloys Used in Superalloy Pump Components

In manufacturing superalloy pump components, the choice of material is vital to ensuring their performance and durability under harsh conditions. Here are three commonly used superalloy brands and their corresponding grades used in pump component manufacturing:

Inconel Alloys

Inconel 625: Known for its excellent corrosion resistance and strength, Inconel 625 is used for pump components exposed to seawater and aggressive chemical environments.

Inconel 718: Inconel 718 is widely used for components that require high tensile strength, oxidation resistance, and good weldability, making it ideal for high-pressure pump applications.

Inconel 600: This alloy is well-suited for pump parts exposed to high temperatures and corrosive atmospheres, particularly in chemical and petrochemical processing.

Hastelloy Alloys

Hastelloy C-276: Hastelloy C-276 offers exceptional resistance to a broad range of chemicals, making it suitable for pump components in chemical and wastewater processing systems.

Hastelloy B-2: With excellent resistance to hydrochloric acid, Hastelloy B-2 is perfect for manufacturing pumps that handle highly reducing acids.

Hastelloy G-35: Hastelloy G-35 is designed for highly oxidizing chemical applications, making it ideal for pump components used in chemical processing industries.

Nimonic Alloys

Nimonic 75: This alloy provides good oxidation resistance and high-temperature strength, making it suitable for pump components in high-temperature environments.

Nimonic 80A: Known for its strength and creep resistance, Nimonic 80A is used in pump parts that must maintain mechanical integrity under high-temperature conditions.

Nimonic 105: Nimonic 105 offers superior creep resistance and is often used in applications that face continuous high-temperature exposure, such as aerospace and energy sector pumps.

Superalloy Pump Components Manufacturing Process

Vacuum Investment Casting is a preferred method for manufacturing superalloy pump components, primarily due to its ability to create high-precision complex shapes. The process involves creating a wax pattern coated in ceramic material to create a mold. The mold is then evacuated of air, and molten metal is poured under vacuum conditions. It prevents oxidation and ensures a high-quality finish. Using an automatic wax press in this process further enhances accuracy and repeatability for complex geometries.

Single Crystal Casting is ideal for creating pump components that require exceptional resistance to thermal fatigue and creep. Single crystal structures have no grain boundaries, which makes them exceptionally resistant to thermal stress. This makes them highly suitable for components used in high-stress environments.

Equiaxed Crystal Casting produces components with a consistent grain structure, offering balanced mechanical properties crucial for parts subjected to cyclic stress. Using an equiaxed crystal furnace ensures temperature management precision, helping minimize porosity and cracking defects.

Directional Casting allows grains to align along a specific direction, enhancing strength and durability in applications where pump components are subjected to directional forces. Directional solidification improves mechanical properties, making it ideal for high-performance pumping systems.

Vacuum investment casting is highly suitable for pump components that require intricate geometries, excellent surface finish, and dimensional precision. Precision pouring plays an essential role in achieving complex geometries for these components.

Powder metallurgy is a highly efficient process for manufacturing superalloy pump components. This method involves compacting metal powders into a desired shape and then sintering them to form solid, dense components. Powder metallurgy allows precise control over the alloy's microstructure, resulting in components with enhanced strength, fatigue resistance, and excellent wear characteristics. Using argon atomizing pulverizing technology ensures consistent alloy composition and optimal particle size control, which is critical to producing high-quality components.

The ability to achieve near-net shapes and control the material composition ensures that pump components meet the stringent requirements of high-pressure and high-temperature applications while minimizing material wastage and post-processing. Powder metallurgy is especially beneficial for producing components that need uniform distribution of material properties and complex geometries.

Precision forging is another manufacturing process that is well-suited for superalloy pump components. Forging involves shaping metal using localized compressive forces, resulting in components with excellent mechanical properties. The three types of precision forging techniques include:

Rough Forging: Rough forging is used to form the initial shape of the pump component, providing a foundation for further refinement.

Free Forging: Free forging creates components with complex shapes and requires high customization. Free forging helps achieve greater flexibility in design.

Isothermal Forging: Isothermal forging maintains a constant temperature throughout the forging process, which helps ensure a uniform grain structure and superior material properties. Pump components must withstand extreme pressures and high temperatures.

Precision forging is highly beneficial for manufacturing pump components that must endure cyclic loading, high mechanical stress, and extreme operating conditions, making it an excellent choice for critical pumping applications.

Prototyping and Low Volume Production for Superalloy Pump Components

Prototyping and low-volume production are essential for developing and validating superalloy pump components. These processes allow engineers to test and refine designs before moving to full-scale production. Advanced technologies like 3D printing and CNC machining are used for prototyping and small-batch production.

3D Printing Services

3D printing, also known as additive manufacturing, allows for rapidly prototyping complex geometries. This technique is valuable for creating functional prototypes that can be tested for fit and performance.

Superalloy 3D Printing

The use of superalloy materials in 3D printing provides the ability to produce lightweight, intricate designs that can withstand harsh conditions. It is an ideal approach for validating new pump component designs.

Superalloy CNC Machining

CNC machining produces prototypes and low-volume parts with high precision and tight tolerances. It ensures that each component meets the exact specifications required for demanding applications.

These methods help reduce lead times and provide flexibility in design, enabling efficient prototyping and iteration during the development of superalloy pump components.

Superalloy Pump Components Post-Process

After the initial manufacturing of superalloy pump components, post-processing is necessary to enhance their properties and ensure they meet performance standards. Common post-processing methods include:

Heat Treatment: Heat treatment is used to improve the mechanical properties of the alloy, such as tensile strength and toughness, by controlling the heating and cooling cycles. This process refines the microstructure to optimize performance under operational stresses.

Hot Isostatic Pressing (HIP): HIP eliminates internal porosity and increases superalloy components' density, ensuring enhanced fatigue and creep resistance. This process is essential for creating components that withstand the demanding conditions of industrial applications.

Surface Coating: Applying protective coatings, such as anti-corrosion and anti-wear layers, helps extend the service life of pump components by reducing their exposure to harsh environments. Thermal barrier coatings (TBC) are also used to protect against high temperatures.

These post-processing methods ensure that the superalloy pump components are ready for the high demands of the industrial applications they are designed for.

Superalloy Pump Components Quality Inspection

Quality inspection is a crucial part of the manufacturing process to ensure that superalloy pump components meet stringent requirements for safety and performance. Standard inspection methods include:

Coordinate Measuring Machine (CMM): Used to verify the dimensions of components against design specifications to ensure they meet the required tolerances, similar to dimensional accuracy verification in equiaxed crystal casting parts.

X-ray and Ultrasonic Testing: Non-destructive testing methods like X-ray and ultrasonic testing detect internal flaws, such as porosity or cracks, that could affect performance. This method aligns with internal defect detection in superalloy components for quality assurance.

Tensile Testing: Evaluates the mechanical properties of the material, such as tensile strength and flexibility, ensuring that the pump components can withstand operational stresses, akin to measuring tensile strength in superalloy components.

Metallographic Analysis: Used to examine the alloy's microstructure and identify any potential defects or irregularities that could compromise the component's performance, much like metallographic and SEM analysis in superalloy parts production.

Industry Applications of Superalloy Pump Components

Superalloy pump components are used across various industries that require efficient and reliable performance under extreme conditions. The following are some typical applications:

Oil and Gas: Pump components in oil and gas extraction must handle corrosive fluids and high pressures, making superalloys the ideal material.

Chemical Processing: Superalloy pump components transfer highly corrosive chemicals safely, maintaining performance under challenging conditions.

Power Generation: In power plants, pump components are needed to handle high-temperature fluids and steam, requiring materials that can withstand thermal cycling.

Aerospace: Pumps in aircraft and aerospace applications must endure significant temperature variations and pressures, making superalloy components a perfect fit.

These applications benefit from superalloy pump components' durability, reliability, and high performance, ensuring consistent operation and minimal downtime.

FAQs about Superalloy Pump Components Manufacturing

What are the key advantages of using superalloys for pump components?

How does vacuum investment casting improve the quality of superalloy pump components?

What role does powder metallurgy play in the production of superalloy pump parts?

How does post-processing, like HIP and heat treatment, enhance pump component performance?

What quality control measures are essential for ensuring the reliability of superalloy pump components?