High-Temperature Alloy Engine Components Production Unit

High-Temperature Alloy Engine Components

High-temperature alloy engine components are crucial in some of the most demanding industries worldwide, including aerospace, energy, marine, and defense. These components are designed to withstand extreme temperatures, mechanical stress, and corrosive environments, ensuring performance and safety in critical applications. In this blog, we’ll explore the materials, manufacturing processes, and post-processing techniques used in producing high-temperature alloy engine components and their industry applications.

Induction of High-Temperature Alloy Engine Components

High-temperature alloys are specifically engineered to maintain strength and integrity at elevated temperatures. In the context of engine components, these alloys must endure the intense heat generated during combustion and operation while maintaining excellent mechanical properties such as fatigue, creep, and corrosion resistance.

High-temperature alloy engine components are typically found in aerospace engines, gas turbines, combustion chambers, heat exchangers, and various power generation and defense applications. These components must withstand temperatures well above the melting point of most metals while maintaining their structural integrity, making the material selection and manufacturing processes critical to their success.

Materials used in high-temperature alloy engine components include superalloys, which are designed for extreme thermal and mechanical stress. Superalloys are typically nickel-based, cobalt-based, or iron-based and often contain multiple elements to enhance their high-temperature performance, such as chromium, aluminum, molybdenum, tungsten, and titanium.

Superalloys Used in High-Temperature Alloy Engine Components

The heart of high-temperature alloy engine components lies in the choice of material. Superalloys exhibit excellent resistance to high-temperature oxidation and corrosion. They are the materials of choice for demanding environments like those in gas turbines, aerospace engines, and other high-performance applications.

Nickel-Based Alloys

Nickel-based superalloys are among the most common choices for high-temperature engine components. They are prized for their exceptional high-temperature strength, oxidation resistance, and resistance to thermal creep. One of the most popular nickel-based alloys used in engine components is Inconel 718, widely used in turbine blades, jet engine components, and heat exchangers. The alloy’s strength at elevated temperatures, good weldability, and oxidation resistance make it ideal for demanding aerospace and power generation applications.

Inconel 625 and Inconel 718 are often used in components exposed to high temperatures and corrosive environments, as their high nickel content gives them superior resistance to heat, oxidation, and corrosion. Other nickel alloys like Rene 41 and Rene N5 offer even higher strength and resistance to thermal fatigue, making them suitable for turbine blades and other critical engine parts.

Cobalt-Based Alloys

Cobalt-based superalloys like Stellite and Haynes 188 are typically used for high wear and corrosion resistance applications. They are ideal for gas turbine seals, compressor blades, and valve seats in combustion engines. These alloys tend to be more resistant to wear and galling than nickel-based alloys but are generally less resistant to high-temperature creep.

Iron-Based Alloys

Iron-based superalloys like Nimonic 80A are also used in specific high-temperature applications, such as turbine blades in jet engines and power turbines. Nimonic alloys combine high-strength iron with other elements like nickel and titanium, which enhance their resistance to creep, oxidation, and corrosion.

High-Temperature Alloy Engine Components Manufacturing Process

The production of high-temperature alloy engine components involves several sophisticated manufacturing techniques to meet the rigorous standards required by industries such as aerospace, power generation, and defense. These processes must ensure that the parts are defect-free, dimensionally precise, and capable of withstanding extreme conditions. Some of the critical manufacturing techniques include:

Vacuum investment casting is one of the most common processes for manufacturing high-temperature alloy engine components. This technique involves creating a mold from a ceramic shell around a wax or plastic component pattern and then melting it away. The mold is placed in a vacuum environment to ensure high precision and reduce defects caused by air contamination.

The vacuum environment is essential for producing the high-quality, high-density castings required in turbine blades, combustion chambers, and other engine components. This process is ideal for producing complex geometries and intricate internal features without extensive machining.

In aerospace applications, single crystal casting produces turbine blades that can withstand higher temperatures without experiencing fatigue or creep. A single alloy crystal is grown in the mold without grain boundaries, ensuring the metal structure is uniform and defects-free.

Single crystal turbine blades, made from alloys such as CMSX-4 or SC-C (single crystal alloys), are highly resistant to fatigue and thermal stresses. This process is crucial for components in gas turbines where uniformity and precision are critical to long-term durability and performance.

Superalloy forging is another critical process, especially for more significant, thicker components like turbine disks and high-pressure casings. Forging involves heating the alloy to a specific temperature and then shaping it using mechanical force. This process aligns the grain structure of the metal, enhancing the mechanical properties of the component, such as tensile strength, fatigue resistance, and toughness.

Forging is particularly important for producing significant, high-performance components that must be strong and resistant to wear and tear. The process is used extensively in the aerospace and power generation industries.

Powder metallurgy creates high-density, high-performance components by compacting metal powders and then sintering them at high temperatures. This technique is often used for creating turbine discs, blades, and other parts that require high strength, low weight, and precise control over microstructure.

Powder metallurgy allows manufacturers to control the alloy composition more precisely than traditional casting or forging methods. It results in parts with superior mechanical properties and fine-grain structures.

Prototyping and Low-Volume Production

Rapid prototyping and low-volume production are essential for industries like aerospace and defense, where design iterations and tight tolerances are critical. Several advanced manufacturing technologies, including CNC machining and 3D printing, make creating high-quality, high-temperature alloy components easier in smaller quantities.

CNC Machining of High-Temperature Alloys

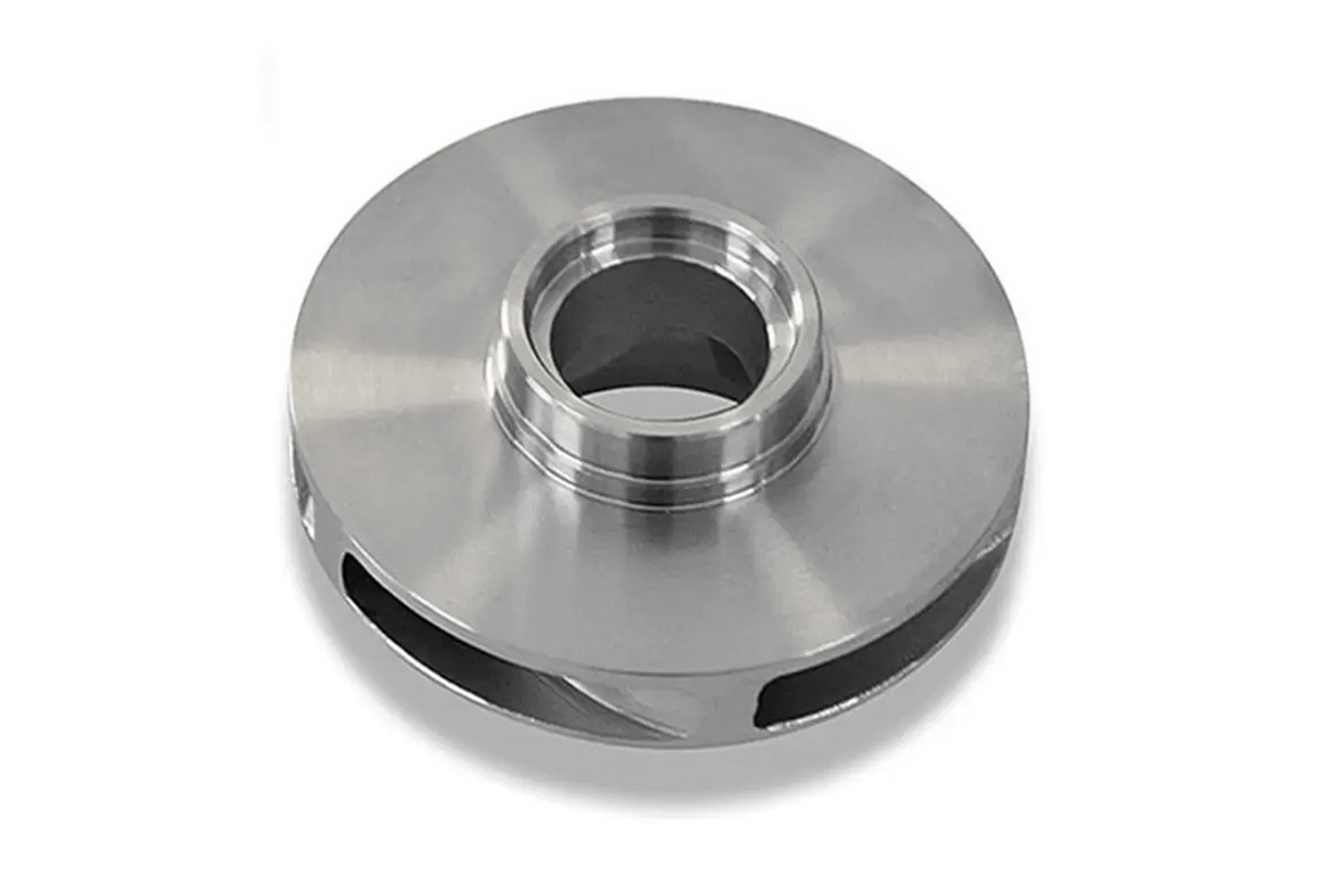

CNC machining is a common technique used in the prototyping and low-volume production of high-temperature alloy engine components. CNC machines use computer-controlled precision cutting tools to remove material from a solid workpiece, creating the desired shape. CNC machining provides tight tolerances and a high-quality surface finish for high-temperature alloys.

The ability to machine complex geometries and achieve acceptable tolerances is essential in applications such as turbine blades and combustion chambers, where precise material properties and dimensions are critical for performance.

3D Printing of High-Temperature Alloys

3D printing (additive manufacturing) is increasingly used for prototyping and small-batch production of high-temperature alloy components. Technologies like Selective Laser Melting (SLM) and Wire Arc Additive Manufacturing (WAAM) allow for creating highly complex parts directly from a digital model, with less material waste and quicker turnaround times than traditional methods.

SLM technology, for example, uses a laser to melt powdered metal and fuse it layer by layer to build up the desired component. It’s particularly well-suited for alloys like Inconel 718, Titanium alloys, and Hastelloy. This process enables the production of complex geometries, including internal channels and cooling passages, that would be difficult or impossible to achieve with traditional casting or machining methods.

High-Temperature Alloy Engine Components Post-Process

After the initial manufacturing process, high-temperature alloy engine components typically undergo several post-processing steps to enhance their mechanical properties and meet industry standards.

Heat treatment is a critical post-processing step to improve the mechanical properties of high-temperature alloys. It involves heating the component to a specific temperature and then cooling it in a controlled manner to alter the microstructure and enhance properties like strength, hardness, and fatigue resistance. Heat treatments such as solution annealing and aging are commonly used for superalloys like Inconel and Rene alloys. Maximizing strength through heat treatment is essential for improving the reliability and performance of engine components.

Hot isostatic pressing (HIP) eliminates internal porosity and improves cast or forged components' density and mechanical properties. In this process, the component is subjected to high pressure and temperature in an inert gas environment. HIP is significant for improving the reliability and lifespan of high-temperature engine components, ensuring they can withstand the intense conditions they will be exposed to in service. The benefits of Hot Isostatic Pressing are crucial for enhancing component integrity.

Superalloy Welding and Thermal Barrier Coating (TBC)

Superalloy welding and thermal barrier coating (TBC) are post-processing techniques to repair and enhance high-temperature alloy engine components. Welding is often necessary for joining parts together, while TBC is applied to protect components from oxidation and thermal degradation. TBCs, typically made from zirconia-based materials, provide a protective layer that significantly increases the lifespan of components exposed to extreme temperatures, such as turbine blades and combustion chambers. The role of TBC in extending the service life of high-temperature engine components is essential for performance.

High-Temperature Alloy Engine Components Quality Inspection

To ensure the performance and safety of high-temperature alloy engine components, strict quality control measures must be implemented at every stage of manufacturing. Inspection techniques like ultrasonic testing, X-ray inspection, metallographic analysis, and dimensional measurement are employed to detect defects and ensure compliance with industry standards.

Non-Destructive Testing (NDT)

Non-destructive testing (NDT) methods like ultrasonic testing and X-ray inspection detect internal and surface defects without damaging the components. These techniques help identify cracks, voids, or inclusions that could compromise the component’s performance.

Industry Applications of High-Temperature Alloy Engine Components

High-temperature alloy engine components are critical to many industries that rely on high-performance, durable parts. Some of the most important applications include:

Aerospace: Turbine blades, engine nozzles, and combustion chambers used in jet engines and rocket propulsion systems.

Power Generation: Gas turbines, including industrial and utility power plants, are used in electricity generation.

Marine: High-temperature alloys are used in propulsion systems and engine components for naval ships and offshore platforms.

Defense: Components like missile parts, armored vehicles, and weapon systems require high-strength and heat-resistance superalloys.

Industry Applications of High-Temperature Alloy Engine Components

High-temperature alloy engine components are critical to many industries that rely on high-performance, durable parts. Some of the most important applications include:

Aerospace and aviation: Turbine blades, engine nozzles, and combustion chambers used in jet engines and rocket propulsion systems.

Power generation: Gas turbines, including industrial and utility power plants, are used in electricity generation.

Marine: High-temperature alloys are used in propulsion systems and engine components for naval ships and offshore platforms.

Military and defense: Components like missile parts, armored vehicles, and weapon systems require high-strength and heat-resistance superalloys.

FAQs about High-Temperature Alloy Engine Components Manufacturing

What are the main types of high-temperature alloys used in engine components?

How does the casting process affect the performance of high-temperature alloy engine components?

What are the advantages of using 3D printing for manufacturing high-temperature alloy engine parts?

How do post-processing treatments like HIP and heat treatment improve component durability?

What industries benefit the most from high-temperature alloy engine components?