High-Temperature Alloy Armor System Parts Supplier

Induction of Superalloy Armor System Parts

Superalloy armor system parts are crucial components designed for industries that require high-performance materials capable of withstanding extreme temperatures, mechanical stresses, and environmental degradation. These parts are primarily used in defense and aerospace applications, where durability, heat resistance, and protection against mechanical wear are paramount. Superalloy armor system parts are engineered to offer exceptional protection against high-temperature environments, ballistics, and abrasion, which makes them ideal for high-stress systems such as military vehicles, aircraft, and advanced defense technologies. Materials for these parts are specifically chosen for their superior mechanical properties, such as exceptional hardness, thermal stability, and resistance to corrosion and wear. These characteristics are critical in maintaining the structural integrity of armor systems, ensuring longevity and performance in harsh conditions.

Commonly used superalloys in these applications include cobalt-based alloys such as Stellite, nickel-based alloys such as Nimonic, and high-performance alloys like Rene alloys, each offering unique advantages in producing armor components. These alloys enhance strength and resistance to the thermal stresses typically experienced in military and aerospace environments. Their application in high-performance armor parts allows for producing materials capable of resisting high-energy impacts, heat, and mechanical fatigue, ensuring that components function reliably under extreme conditions.

Superalloys Used in Superalloy Armor System Parts

Selecting the suitable superalloy material is pivotal for the performance and longevity of armor system components. The following are three of the most commonly used superalloys in manufacturing armor system parts, each chosen for their specific properties: heat resistance, mechanical strength, and wear resistance.

Stellite Alloy

Stellite alloys are cobalt-based superalloys known for their excellent hardness, wear resistance, and high-temperature stability. The most common grades used for armor system parts include Stellite 6, Stellite 12, and Stellite 21. These alloys are often employed in environments where extreme hardness and resistance to abrasion are required. Stellite 6, in particular, is widely used for wear-resistant components such as valve seats, pump parts, and ballistic armor due to its outstanding ability to resist friction and thermal degradation.

Stellite 6 is a widely recognized alloy for its toughness and corrosion resistance, making it ideal for parts exposed to abrasive wear and high temperatures. Stellite 12 has enhanced resistance to oxidation at elevated temperatures, making it suitable for high-temperature applications such as exhaust valves and other engine components. Stellite 21, on the other hand, offers exceptional resistance to oxidation and wear at elevated temperatures, making it an excellent choice for components subject to continuous exposure to high heat and mechanical stress.

The high cobalt content in Stellite alloys ensures their exceptional wear resistance, which is crucial in armor-piercing projectiles and other military applications that require materials capable of withstanding extreme abrasive conditions.

Nimonic Alloy

Nimonic alloys are a family of high-performance nickel-based superalloys used in high-temperature and high-stress applications, including aerospace, power generation, and defense industries. They are particularly favored for their high oxidation resistance, excellent creep strength, and superior fatigue resistance at elevated temperatures. Some of the most commonly used Nimonic grades include Nimonic 80A, Nimonic 90, and Nimonic 263.

Nimonic 80A is an excellent choice for high-temperature applications due to its superior strength and oxidation resistance at temperatures up to 700°C. It is often used in turbine blades, gas turbines, and military aerospace components, making it ideal for thermal fatigue resistance applications. Nimonic 90 offers improved creep and oxidation resistance, making it suitable for gas turbines, jet engines, and other components subjected to high-stress conditions. Nimonic 263 is a high-strength alloy that maintains its mechanical properties under high temperatures and high-pressure conditions, making it essential for components in advanced defense and aerospace systems.

The combination of high-temperature stability, excellent fatigue resistance, and superior creep strength in Nimonic alloys makes them essential for parts that require heat resistance and structural integrity, such as armor-piercing projectiles and military vehicle components.

Rene Alloys

Rene alloys, including Rene 41, Rene 80, and Rene 95, are high-performance nickel-based alloys known for their exceptional strength and durability under extreme thermal and mechanical stresses. These superalloys are used extensively in gas turbines, aerospace engines, and armor-piercing projectiles due to their ability to withstand high temperatures and mechanical fatigue.

Rene 41 is known for its high tensile strength and resistance to thermal degradation, making it ideal for high-temperature applications. It is often used in turbine blades, military vehicles, and other components exposed to extreme conditions. Rene 80 is an advanced nickel-based superalloy with high strength, fatigue resistance, and oxidation resistance at temperatures up to 1200°C. It is ideal for jet engines, gas turbines, and military systems. Rene 95 is among the most advanced superalloys, offering exceptional strength and creep resistance at extremely high temperatures. It suits the most demanding applications, including armor-piercing projectiles and aerospace applications.

Rene alloys are often preferred for their ability to maintain strength and integrity under high mechanical stresses and thermal cycles, ensuring the durability and longevity of armor system components.

Typical Superalloy Part Manufacturing Process

Manufacturing superalloy armor system parts involves advanced processes that ensure the material properties and component geometry meet the high standards required for military and aerospace applications. The primary methods for producing superalloy armor system parts are vacuum investment casting, powder metallurgy, and precision forging. Each of these methods plays a crucial role in optimizing the performance and mechanical properties of the final parts.

Vacuum Investment Casting

Vacuum investment casting is a precision manufacturing technique often used to produce high-performance superalloy components. The process involves pouring molten superalloy material into a mold under vacuum conditions to create a precise, defect-free part. The mold is typically made from a ceramic material that can withstand the high temperatures of the molten metal.

Several variations of investment casting are used for different purposes, including Superalloy Single Crystal Casting, Superalloy Equiaxed Crystal Casting, Superalloy Directional Casting, and Special Steel Investment Casting. Single crystal casting is used to create components with uniform grain structures, which are essential for high-strength and high-temperature applications. Directional casting allows for controlled grain growth in specific directions, enhancing the component's mechanical properties. The investment casting process is beneficial for producing complex geometries and intricate designs often required for armor system components.

Powder Metallurgy

Powder metallurgy (PM) is another advanced manufacturing technique commonly used to produce superalloy armor system parts. PM involves the compaction and sintering of metal powders to form solid components. The primary advantage of powder metallurgy is its ability to create parts with a homogeneous microstructure and uniform properties.

In armor system applications, powder metallurgy produces parts that require precise control over their mechanical properties, including wear resistance, thermal conductivity, and strength. This method is particularly suitable for producing complex parts with intricate geometries that cannot be easily achieved using traditional casting or forging methods. Powder metallurgy also offers the ability to produce high-density parts with low porosity, ensuring that the components can withstand high-stress levels and thermal cycling.

Precision Forging

Precision forging is when superalloy materials are shaped under high pressure to produce parts with exceptional mechanical properties. Three main types of forging are used for superalloy armor system parts: rough forging, free forging, and isothermal forging.

Rough forging is used to create the initial shape of a part before it is further processed.

Free forging involves shaping the material by applying pressure, allowing the part to take on more complex geometries.

Isothermal forging is performed at elevated temperatures, which allows for better control over the material's grain structure and mechanical properties. You can read more about this technique in Isothermal Forging of High-Temperature Alloys.

Precision forging is particularly useful for creating parts that require high strength and resistance to mechanical fatigue, such as armor-piercing projectiles, military vehicle components, and gas turbine blades. For more precision forging techniques, see Superalloy Rough and Superalloy Free Forging.

Superalloy Armor System Parts Manufacturing

In superalloy armor system parts manufacturing, the goal is to select the appropriate combination of materials and processes to ensure that the final components meet the specific requirements of military, aerospace, and other high-performance applications. Vacuum investment casting, powder metallurgy, and precision forging are the most common manufacturing methods used to create parts with optimal properties, including heat resistance, strength, and durability.

The choice of manufacturing process depends on the geometry and material requirements of the specific armor system part being produced. For example, complex parts with intricate designs may be best suited to investment casting. In contrast, parts that require high-density and uniform mechanical properties may be better suited to powder metallurgy. Precision forging is ideal for parts requiring high strength and mechanical stress resistance.

Prototyping for Superalloy Armor System Parts

Prototyping and small-batch production are critical steps in developing superalloy armor system parts. Prototyping allows engineers to test and refine designs before full-scale production begins, ensuring that the components meet all the required performance criteria. Small-batch production is especially beneficial for custom parts, enabling manufacturers to create armor system components tailored to specific applications. By leveraging 3D printing services, manufacturers can quickly iterate on designs, reducing development time and costs.

Superalloy 3D Printing

Modern techniques such as superalloy 3D printing are commonly used for prototyping and small-batch production. This method allows for rapid iteration of designs and the creation of complex geometries that would be difficult or impossible to achieve with traditional manufacturing methods. With superalloy 3D printing, engineers can test different configurations, materials, and design features before moving to total production, ensuring the final armor system parts meet the necessary performance standards.

Superalloy CNC Machining

Superalloy CNC machining is another essential technology for prototyping and small-batch production. While 3D printing allows for design flexibility, CNC machining ensures that the final parts meet exacting tolerances and surface finish requirements. It is essential for components used in defense and aerospace applications, where high precision is required for optimal performance and reliability. CNC machining complements 3D printing by providing finishing touches and detailed features crucial for high-performance superalloy armor systems.

Superalloy Armor System Parts Post-Process

After the superalloy armor system parts are manufactured, post-processing steps are required to enhance their mechanical properties and ensure they meet the required standards. Common post-processing techniques include heat treatment, surface finishing, and coating.

Heat Treatment

Heat treatment processes such as aging or annealing improve the strength and hardness of the parts. Heat treatment is essential for optimizing mechanical properties in superalloy armor components, ensuring they can withstand high-stress and high-temperature conditions in defense applications.

Surface Finishing

Surface finishing techniques such as polishing or coating provide additional protection against wear, oxidation, and corrosion. Surface quality improvement through advanced polishing and coating techniques ensures that armor components maintain their integrity and durability in harsh environments.

Coatings

For armor system parts exposed to high-temperature and high-stress environments, coatings such as ceramic or carbide are often applied to improve wear resistance and extend the component's lifespan. Thermal barrier coatings (TBC) and other specialized coatings help protect components from oxidation and wear, ensuring their long-term reliability.

These post-processing techniques enhance the performance and durability of superalloy armor system parts, ensuring they meet the stringent demands of aerospace and defense applications.

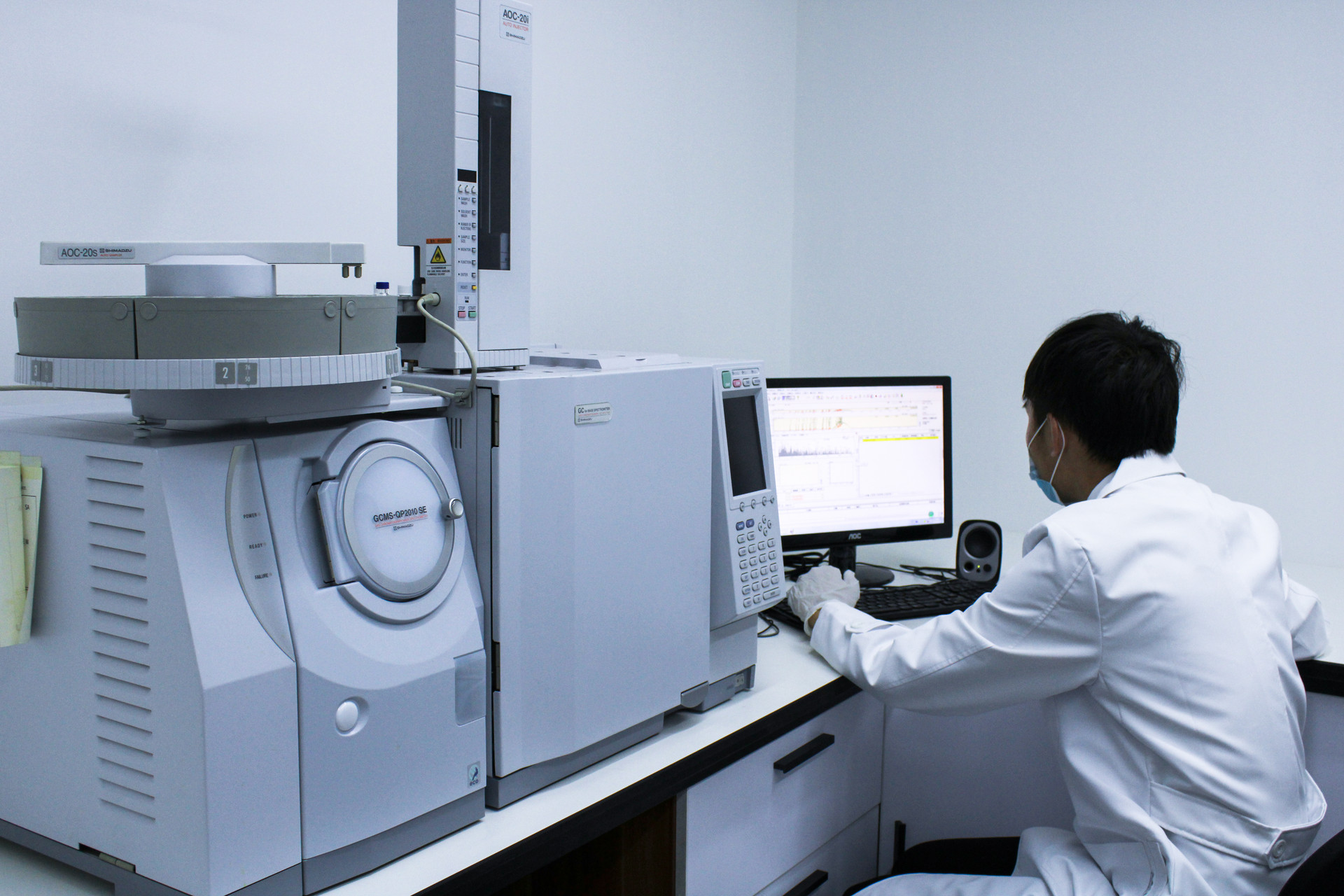

Superalloy Armor System Parts Quality Inspection

Quality inspection ensures that superalloy armor system parts meet the stringent standards required for military and aerospace applications. Non-destructive testing methods such as X-ray inspection, ultrasonic testing, and eddy current testing detect internal or external defects in the parts. These methods help ensure the structural integrity and performance of the components under extreme conditions.

Mechanical testing, including tensile and fatigue testing, is also performed to verify the strength and durability of the components under real-world conditions. These tests simulate operational stresses to ensure that the superalloy armor system parts can withstand the rigorous demands of military and aerospace environments.

By combining non-destructive testing with mechanical testing, manufacturers ensure that the armor system parts meet the highest quality, durability, and safety standards, making them reliable for critical applications.

Industry Applications of Superalloy Armor System Parts

Superalloy armor system parts are widely used across military, aerospace, and defense industries. These components are essential for applications such as:

Military: Military vehicles, armored personnel carriers, and ballistic armor require superalloy components to ensure protection and durability under extreme conditions. Superalloy armor system parts are designed to provide enhanced strength and resilience against high-impact forces.

Aerospace: In aerospace, superalloy materials are used in critical components like turbine blades and combustion chambers, which must withstand extreme temperatures and mechanical stresses.

Defense: Superalloy parts are also integral in armor-piercing projectiles and advanced defense systems, where high strength, heat resistance, and durability are paramount to ensure effectiveness and reliability.

These industries rely on superalloy armor system parts to provide superior protection, reliability, and performance under the most demanding conditions.

FAQs about Superalloy Armor System Parts Manufacturing

What are the key properties of superalloy armor system parts?

How do Stellite alloys enhance the performance of armor system components?

What is the advantage of using powder metallurgy in armor system manufacturing?

How does precision forging improve the strength of superalloy parts?

What industries benefit most from superalloy armor system parts?