Fuel System Attachments: High-Performance Alloy Delivery for Aerospace Industry Leaders

Introduction

Fuel system attachments are critical components within the aerospace industry, ensuring seamless fuel delivery and consistent system performance. These attachments must endure some of the most challenging conditions, including high temperatures, pressures, and corrosive environments. To meet these extreme demands, manufacturers utilize high-performance alloys specifically engineered for superior durability and reliability. This blog explores the characteristics, manufacturing processes, industry applications, and quality assurance techniques involved in producing fuel system attachments for the aerospace sector.

What Are Fuel System Attachments?

Fuel system attachments include various parts such as fittings, connectors, couplings, and valves that are crucial in connecting different sections of an aircraft’s fuel delivery system. These components ensure fuel flows smoothly and at the required pressure, maintaining optimal engine performance. The reliability of fuel system attachments is essential for the safe operation of an aircraft, as any failure in these components could compromise flight safety and efficiency. Their robust design must handle various operating conditions, from rapid temperature shifts to intense vibration and high-altitude pressure changes.

High-Temperature Alloys Used in Manufacturing Fuel System Attachments

Aerospace applications demand materials that perform excellently under high temperatures while maintaining mechanical integrity. High-temperature superalloys meet these requirements due to their exceptional strength, oxidation resistance, and ability to retain properties under thermal stress. Some of the commonly used alloys include:

Inconel Alloys

Inconel is a family of nickel-chromium-based superalloys known for their high-temperature strength and oxidation resistance.

Inconel 718: One of the most widely used superalloys in aerospace, offering high tensile strength, creep resistance, and stability at temperatures up to 1300°F (704°C). This alloy is ideal for components like fuel system attachments that must maintain performance under high stress.

Inconel 625: Known for its outstanding weldability and resistance to both oxidation and corrosion. This alloy is often used in components exposed to severe environments where durability and longevity are crucial.

Hastelloy Alloys

Hastelloy alloys provide excellent resistance to corrosion and maintain their strength in extreme temperatures, making them suitable for high-performance aerospace applications.

Hastelloy C-276: Renowned for its resistance to pitting, crevice corrosion, and stress corrosion cracking. Its resilience makes it preferred for fuel system attachments exposed to harsh chemicals and high temperatures.

Titanium Alloys

Titanium offers a unique balance of high strength, low density, and corrosion resistance, making it suitable for aerospace fuel system components.

Ti-6Al-4V: A popular titanium alloy with a high strength-to-weight ratio and can withstand temperatures up to 752°F (400°C). It is widely used for fuel system attachments that require lightweight yet strong materials.

The properties of these high-temperature alloys ensure that fuel system attachments maintain their structural integrity and performance, even under the most severe operational conditions.

Industry Applications of Fuel System Attachments

Fuel system attachments are used in a wide range of aerospace applications, each with specific performance requirements:

Commercial Aircraft: In commercial aviation, the reliability of fuel system attachments is vital for safe and efficient fuel management. Components such as fuel valves, couplings, and fittings ensure the proper transfer and regulation of fuel across the aircraft.

Military and Defense Aircraft: Military jets operate under conditions that push their systems to the limit. Fuel system attachments in these aircraft must withstand high G-forces, rapid temperature shifts, and exposure to fuels with aggressive properties. High-performance alloys like Inconel 718 and Hastelloy C-276 are commonly used to ensure these components function without failure.

Spacecraft: Fuel system attachments used in space applications face unique challenges, including the vacuum of space and extreme temperature variations. These conditions require components made from superalloys capable of performing reliably under such circumstances.

Helicopters: Helicopter fuel systems operate in environments with constant vibrations and varying temperatures. Titanium alloys are often used for their lightweight properties and resistance to fatigue, ensuring the integrity of the fuel system.

Manufacturing Process and Equipment of Fuel System Attachments

The manufacturing process for fuel system attachments involves precise techniques and equipment to meet the stringent standards of the aerospace industry. The steps include:

Design and Engineering: This phase is critical for defining the specifications of the fuel system attachments. Advanced software tools, such as CAD and finite element analysis (FEA), are used to design and simulate the performance of components under different stress and thermal conditions.

Material Selection: Engineers select high-temperature alloys based on properties like heat resistance, mechanical strength, and corrosion resistance. The chosen alloy impacts the overall performance and longevity of the fuel system attachment.

Fabrication Methods:

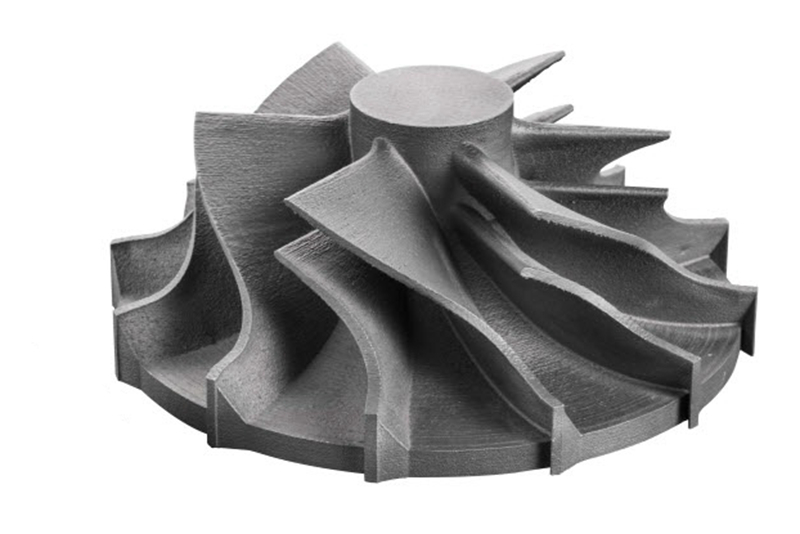

Vacuum Investment Casting: This process creates intricate parts with high precision and superior surface finishes. Casting in a vacuum minimizes inclusions and defects, producing high-purity components ideal for aerospace applications.

Single Crystal and Directional Casting: These techniques improve the mechanical properties of components by aligning the grain structure to reduce potential weak points. This alignment enhances fatigue resistance, which is crucial for components subjected to cyclic stress.

Superalloy CNC Machining: CNC machining is essential for achieving tight tolerances and intricate geometries required in fuel system attachments. The precision of CNC machining ensures that each part meets aerospace specifications.

Rapid Prototyping and Verification Process

Rapid prototyping has transformed the way fuel system attachments are developed. Manufacturers can produce prototypes quickly and efficiently using 3D printing technologies like Selective Laser Melting (SLM) and Laser Engineered Net Shaping (LENS).

Benefits of Rapid Prototyping:

Accelerated Development:

3D printing allows for quick turnaround times in prototype creation, enabling faster iterations and shorter development cycles. Learn more about SLM 3D Printing Superalloys for enhanced rapid prototyping.

Cost-Effective:

Additive manufacturing reduces the need for expensive tooling and minimizes material waste, making the prototyping phase more cost-effective. Localized Repair LENS Technology can further optimize resource use during prototype adjustments.

Enhanced Design Flexibility:

Complex geometries that would be difficult or impossible to achieve through traditional manufacturing methods can be quickly produced using 3D Printing Inconel 625 SLM technology.

Verification Process:

The prototypes are subjected to rigorous testing, including mechanical stress testing, dimensional accuracy checks with 3D Scanning Reverse Engineering Vanes, and thermal simulations to confirm performance under expected conditions. This iterative approach allows for design adjustments before full-scale production, ensuring optimal results.

Typical Post-Process and Surface Treatment of Fuel System Attachments

Post-processing is essential in ensuring fuel system attachments meet performance and durability standards. Typical post-process techniques include:

Hot Isostatic Pressing (HIP):

HIP Porosity Elimination Superalloys improve the mechanical properties of superalloy components by applying high pressure and heat, effectively eliminating internal porosity. This process enhances density and fatigue resistance, crucial for parts operating under high stress.

Heat Treatment:

Different heat treatment processes, such as solution treatment and aging, are applied to optimize the alloy's microstructure. This process enhances mechanical strength, toughness, and resistance to thermal fatigue.

Surface Treatments:

Thermal Barrier Coatings (TBC):

TBC Durability Efficiency Alloys provide additional protection against heat, extending the lifespan of fuel system attachments.

Anti-Corrosion Coatings:

They are applied to prevent degradation from exposure to corrosive fuels and environmental factors, ensuring the component's reliability over time. Techniques such as Surface Treatment Corrosion Resistance are essential for maintaining long-term integrity.

Typical Inspections for Fuel System Attachments

To ensure the highest quality, fuel system attachments undergo a variety of inspection and testing protocols:

Industrial CT Scanning:

Internal Defect CT Imaging is used to detect internal defects, such as voids or cracks, that could compromise the integrity of the component. This non-destructive testing method provides a comprehensive view of the internal structure.

Ultrasonic Inspection:

They are utilized to assess material consistency and detect subsurface flaws. This method effectively ensures the homogeneity and reliability of superalloy components, as highlighted in Ultrasonic Inspection CNC Superalloy.

SEM (Scanning Electron Microscopy):

SEM Imaging Superalloy Components provides detailed imaging and analysis of the surface and microstructure, enabling manufacturers to identify and correct potential issues.

Tensile and Fatigue Testing:

Evaluate the component's mechanical properties, including tensile strength, yield strength, and fatigue life. This testing ensures that the part can withstand its operational stresses in service.

Conclusion

Fuel system attachments are indispensable in the aerospace industry, where performance, reliability, and safety are paramount. High-performance alloys such as Inconel 718, Hastelloy, and titanium ensure these components can withstand extreme conditions, providing consistent performance and structural integrity. Manufacturers can produce fuel system attachments that meet the highest standards through advanced manufacturing methods, rapid prototyping, and stringent post-processing and inspection procedures.

As technology progresses, integrating innovative manufacturing techniques and high-quality materials will continue to enhance the performance and reliability of fuel system attachments. This advancement supports safer, more efficient aerospace operations and improves aerospace technology.