Finite Element Simulation for Predicting Component Failures

Predicting Component Failures with Finite Element Simulation (FES)

Predicting component failures is critical in industries that rely on high-performance materials, such as aerospace, power generation, and military applications. The failure of even a single part, such as a turbine blade or a heat exchanger, can lead to catastrophic consequences, including reduced operational efficiency, unplanned downtime, or, in the worst case, catastrophic system failure. To mitigate these risks, engineers have increasingly turned to Finite Element Simulation (FES) to predict how components will behave under real-world conditions, helping to extend the lifespan of critical parts and improve their reliability.

How FES Works in Predicting Component Failures

Finite Element Simulation is a computational tool that allows engineers to simulate the behavior of components under various stresses, temperatures, and environmental conditions. FES can predict how materials like superalloys will respond to thermal and mechanical loading in the context of turbine blades and other high-performance components. This helps identify potential failure points, such as cracks, fatigue, or thermal-mechanical fatigue (TMF) before they occur in real-world applications.

Using FES, engineers can optimize designs for maximum strength and durability, ensuring that components can withstand the stresses they will face during their operational life. This predictive capability is critical in industries like aerospace, where turbine blades are exposed to extreme conditions, and even minor design flaws or material weaknesses can lead to failure.

Additionally, FES can help engineers optimize post-processing techniques, such as heat treatment, to enhance the material properties of components and ensure their performance in harsh environments. By simulating these processes, engineers can decide which treatments will offer the best results for extending component lifespan and minimizing risk.

Benefits of FES for High-Performance Materials

Finite Element Simulation has revolutionized how engineers approach material testing and design. By predicting failures before they happen, FES allows for proactive maintenance, design improvements, and cost reductions. It enables the optimization of materials, manufacturing processes, and operational conditions to increase reliability, reduce the risk of failure, and improve the overall efficiency of critical systems.

Applying FES to High-Temperature Alloys and Turbine Components

FES provides invaluable insights into applications such as turbine engines, where components are subjected to extreme temperatures, high mechanical stresses, and corrosive environments. High-temperature alloys such as Inconel, CMSX series, Rene alloys, and single crystal alloys are often used for turbine blades, heat exchangers, and other critical components due to their ability to withstand harsh conditions. However, these materials face unique challenges in real-world applications, including creep, thermal cycling, and oxidation, which must be modeled accurately to predict component failure.

Turbine blades, for example, experience high cyclic loading due to the thermal expansion and contraction during engine operation and mechanical stresses from gas flow and centrifugal forces. These components often operate at temperatures exceeding 1,000°C, accelerating material degradation. FES can simulate how these stresses accumulate over time, allowing engineers to predict where and when cracks or failures will likely occur.

By modeling the single crystal structure of certain alloys, such as CMSX-4 or Inconel 718, FES can simulate how the material will perform under these extreme conditions. Unlike polycrystalline materials with grain boundaries that can become failure sites under stress, single crystal alloys lack these boundaries, offering enhanced performance. However, even single-crystal materials can fail over time due to thermal fatigue, creep deformation, or the accumulation of microstructural defects. FES helps predict the progression of these failure mechanisms, improving the reliability of the design.

Simulation for Material Behavior under Extreme Conditions

High-temperature alloys used in turbine blades, heat exchangers, and other critical components must withstand extreme temperatures, corrosive environments, and high pressure. Oxidation and corrosion are significant concerns in these applications, as they can lead to material degradation and eventual failure. Finite Element Simulation (FES) can simulate how materials perform under these harsh conditions, providing valuable insights into their durability and expected lifespan.

For example, Inconel alloys are known for their resistance to oxidation and corrosion. However, these materials can degrade even under certain conditions, such as exposure to high-pressure steam or aggressive gas environments. By simulating these extreme conditions, engineers can predict how the material will degrade over time and make design adjustments to improve corrosion resistance.

FES can also simulate the effects of other environmental factors, such as erosion or abrasion when components are exposed to high-speed gas flows or particulate matter. By incorporating these factors into the simulation, engineers can better understand how the component will degrade and predict when maintenance or replacement will be required.

Simulation for Stress and Fatigue Analysis

One of the primary applications of FEA is in the stress and fatigue analysis of components. In turbine blades, for instance, the material is subjected to high tensile, compressive, and shear stresses as it operates at extreme temperatures and speeds. FEA helps simulate how these stresses are distributed throughout the blade, allowing engineers to identify the areas of highest stress and the potential for failure. FEA in Superalloy Castings provides critical insights into stress management and component durability.

Fatigue refers to the gradual weakening of a material due to repeated loading and unloading cycles. Over time, this cyclic loading can cause microscopic cracks in the material, eventually leading to failure. FEA can model these cyclic loads and simulate how cracks propagate, helping engineers predict the number of cycles a component can endure before failure occurs. By identifying the potential failure sites early in the design process, engineers can redesign the component to reduce stress concentrations or select materials with improved fatigue resistance. Fatigue Testing in Superalloy Castings helps validate fatigue resistance in turbine components.

In high-temperature alloys, fatigue is often compounded by other failure mechanisms, such as creep or thermal cycling. Creep is the slow deformation of a material under constant stress at high temperatures. Over time, creep can cause significant dimensional changes in a component, leading to failure. FEA can model this time-dependent behavior and predict the onset of creep deformation, providing engineers with data to select materials that can better resist long-term thermal stresses. For Creep Testing in Superalloy Materials, FEA models are crucial for understanding material behavior under extreme conditions.

Optimization of Component Design Using FES

One of the critical benefits of FES is its ability to optimize the design of high-temperature alloy components. By running multiple simulations with different design parameters, engineers can explore various design options and select the one that best meets performance, durability, and cost requirements. FEA in Superalloy Castings offers a powerful tool for assessing component performance before production.

FES enables engineers to test various material compositions, geometries, and manufacturing methods in a virtual environment before physical production. For example, FES can simulate how different turbine blade coatings, such as Thermal Barrier Coatings (TBCs), will perform, allowing engineers to select the optimal coating for a given application. These simulations help identify the best material combinations for both efficiency and longevity.

Additionally, FES can help engineers design components with better load distribution and stress resistance, reducing the likelihood of failure under extreme conditions. This reduces the need for costly physical prototypes and testing, speeding up the design process and lowering overall costs. FEA for Stress Analysis in Superalloy Castings provides data-driven insights that ensure the final product meets performance and safety standards while minimizing production expenses.

Integration of FES with Other Engineering Tools

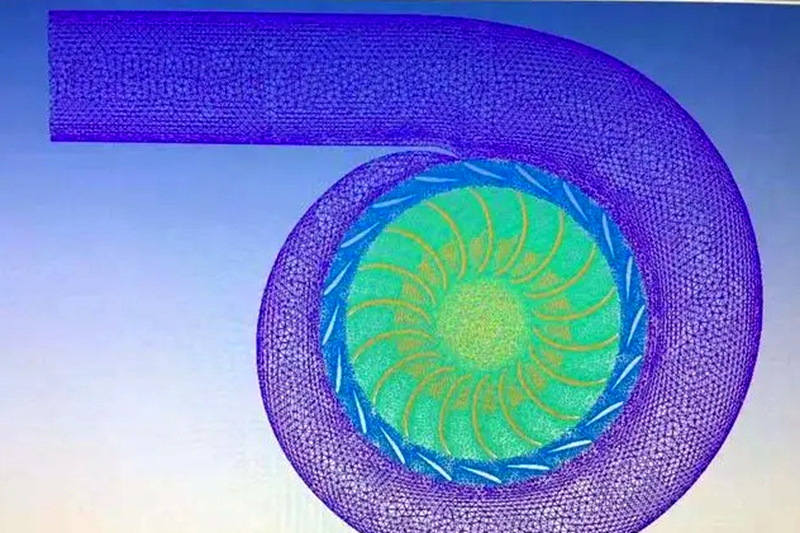

FES is often used with other simulation tools to provide a more comprehensive understanding of how components will behave under real-world conditions. For instance, Computational Fluid Dynamics (CFD) is often integrated with FES to model the fluid flow around a component, such as the gas flow around a turbine blade. By combining FES and CFD, engineers can simultaneously analyze a component's thermal and mechanical behavior, optimizing the design for both efficiency and durability. CFD in Superalloy Components helps simulate high-performance turbine blades' aerodynamic and thermal properties.

In addition to CFD, Computational Materials Science (CMS) can be used alongside FES to model how the material's microstructure affects its performance. This can be particularly useful for high-temperature alloys, where the microstructure is crucial in determining the material's resistance to creep, fatigue, and thermal degradation. CMS in Superalloy Castings helps optimize material selection by modeling grain structure and phase distribution.

FES is also critical in supporting additive manufacturing (3D printing) of high-temperature alloys. By simulating the behavior of components produced through additive manufacturing, engineers can predict potential issues such as residual stresses or material defects, allowing for more efficient production and improved part quality. 3D Printing in Superalloy Components is pivotal in achieving precision in complex geometries and minimizing manufacturing errors.

Industry Applications and Benefits of FES in Component Failure Prediction

FES (Finite Element Simulation) is used across a wide range of industries that rely on high-performance materials, including:

Aerospace and Aviation

FES is used to predict turbine blade failure, optimize engine components, and improve the reliability of flight-critical systems. For example, superalloy jet engine components benefit from FES by improving performance and extending service life under harsh operating conditions in the aerospace industry.

Power Generation

Power plant gas turbines benefit from FES simulations to predict failures in high-stress components like turbine blades and heat exchangers. Power generation relies on FES to enhance the reliability and efficiency of turbine blades and other critical components, ensuring smoother operation in demanding environments.

Oil and Gas

FES helps improve the durability of pumps, valves, and heat exchangers in extreme conditions. FES simulations predict potential component failures in the oil and gas industry and optimize designs for longer service life in high-stress, corrosive environments.

Military and Defense

Components such as missile parts, exhaust, and armor systems benefit from FES to predict failures and improve operational readiness. Military and defense applications, including superalloy armor system parts, rely on FES to ensure that materials perform optimally under extreme stress conditions.

Automotive

FES is used in engine components to predict fatigue and improve performance and reliability. The automotive industry uses FES for simulation-driven design processes to optimize components like superalloy transmission assemblies, ensuring improved durability and efficiency.

FAQs

What are the primary advantages of using Finite Element Simulation for predicting component failures in high-temperature alloys?

How does FES simulate material behavior under thermal cycling and creep in turbine components?

What role does FES play in optimizing the design of turbine blades and other critical high-temperature components?

How can FES be integrated with other simulation tools like CFD and CMS for more accurate predictions?

What are the challenges in modeling oxidation and corrosion in high-temperature alloys using FES?