Enhance Surface Finish in High-Temperature Alloys via EDM

In high-performance industries like aerospace, power generation, and defense, surface finish is a crucial attribute of component quality. A superior surface finish improves functionality, longevity, and resistance to environmental factors, all essential for parts operating under extreme conditions. For superalloy components, achieving an optimal surface finish presents unique challenges. Superalloys—such as Inconel, Hastelloy, and CMSX—are designed to withstand extreme temperatures and corrosive environments, making them inherently difficult to machine with conventional methods.

Electrical Discharge Machining (EDM) offers a solution by providing a non-contact, precise machining process that achieves the desired surface finish without compromising the material’s structural integrity. This blog explores how EDM enhances surface finishes in superalloy castings, the materials and post-processing methods contributing to optimal results, and the quality control practices ensuring consistent surface quality.

Material Selection and Challenges in Superalloy Castings

Superalloys, including Inconel, Monel, Hastelloy, CMSX, and Rene alloys, are engineered to perform under extreme conditions. These alloys are known for their resistance to high temperatures, corrosion, and mechanical wear, making them invaluable in applications where durability and reliability are paramount. However, these same properties present challenges when achieving a high-quality surface finish.

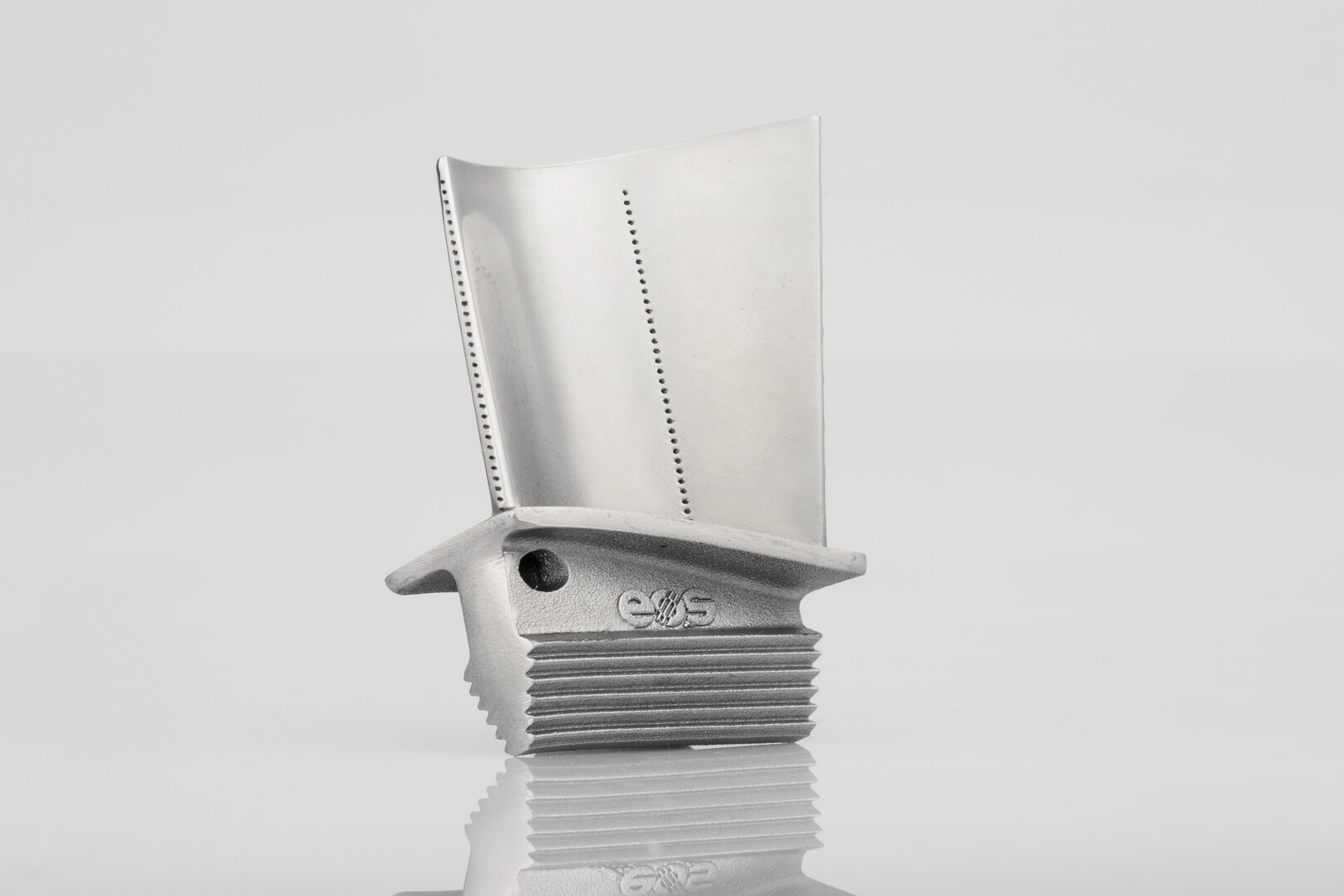

The hardness and heat resistance of superalloys makes them challenging to machine with traditional methods that rely on physical contact. During conventional machining, superalloy surfaces may be prone to micro-cracks, tool marks, or thermal damage, compromising the material’s integrity. Additionally, superalloy components often feature complex geometries, such as the intricate cooling channels in turbine blades, which are challenging to machine without affecting the surface finish.

EDM is uniquely suited to address these challenges. EDM can achieve a smooth, consistent surface finish even on hard and brittle superalloys by employing controlled electrical discharges rather than mechanical force. This process minimizes the risk of surface irregularities, enabling the production of superalloy components with superior surface quality.

How EDM Improves Surface Finish in Superalloy Castings

Electrical Discharge Machining (EDM) generates electrical sparks between a conductive electrode and the superalloy workpiece, which are submerged in a dielectric fluid. The sparks create tiny, controlled explosions that erode material from the surface without direct contact. This non-contact approach means that EDM can machine hard materials without causing physical deformation or introducing mechanical stress.

The controlled erosion of EDM allows it to achieve nuanced, uniform surface finishes on superalloy parts. Because EDM does not rely on cutting tools, there are no tool marks or burrs on the surface. It is especially advantageous for intricate geometries or complex shapes, where traditional tools might struggle to maintain a smooth surface.

In comparison to conventional machining methods, EDM offers several benefits for improving surface finish:

Reduced Surface Roughness

EDM provides a fine finish with minimal roughness, which is ideal for parts requiring precise tolerances. This aspect is particularly beneficial for superalloy components used in high-performance applications requiring accurate surface finishes.

Minimized Thermal Impact

Although EDM involves localized heating, the dielectric fluid dissipates heat quickly, preventing thermal distortion and preserving the alloy’s microstructure. It minimizes thermal stress, preserving superalloy parts' physical integrity and material properties.

Uniform Finish

EDM can achieve a consistent surface finish across complex geometries, ensuring that all areas of the part meet the required quality standards. This uniformity is especially valuable in superalloy parts requiring precision engineering for demanding environments.

By avoiding mechanical force and controlling thermal impact, EDM produces a polished, smooth surface that is essential for high-performance superalloy parts used in demanding applications.

Post-Processing Techniques to Achieve Optimal Surface Finish

After EDM machining, post-processing steps are often used to enhance the surface finish further and ensure the component meets performance standards. At NewayAero, several advanced post-processing techniques are employed to achieve the desired finish on superalloy castings.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is commonly used to eliminate porosity and increase material density. During HIP, the part is subjected to high pressure and temperature in an inert atmosphere, encouraging a more uniform microstructure. By reducing porosity, HIP contributes to a smoother surface and enhances the component’s resistance to stress and fatigue, ensuring a high-quality finish for critical applications.

Heat Treatment

Heat treatment is another post-processing method that benefits the surface quality of superalloy parts. Controlled heating and cooling cycles refine the material’s microstructure, increasing hardness and durability. A refined microstructure ensures that the superalloy responds well to EDM finishing, providing a smoother, more resilient surface essential for high-performance parts.

Thermal Barrier Coatings (TBC)

Thermal Barrier Coatings (TBC) are applied to superalloy parts operating in high-temperature environments. TBCs provide a layer of insulation, protecting the surface from thermal degradation and improving its resistance to wear. TBC ensures a uniform layer for parts with intricate surfaces that maintains the surface finish even under extreme temperatures, which is particularly valuable in aerospace and energy applications.

EDM as a Finishing Process

Finally, EDM itself can serve as a final finishing process. After other post-processing steps, EDM can be used to make fine adjustments to the surface, achieving precise dimensions and an optimal finish. By carefully controlling material removal, EDM produces a smooth, polished surface that meets exact specifications, ensuring the component is ready for demanding operational conditions.

Testing and Quality Control for Surface Finish Assurance

Ensuring a high-quality surface finish requires rigorous testing and quality control. NewayAero employs various advanced testing methods to verify that the surface finish of each superalloy part meets the required standards. This quality control process is essential to ensure each component functions reliably in its intended application.

Coordinate Measuring Machines (CMM) and 3D Scanning Instruments.

Coordinate Measuring Machines (CMM) and 3D Scanning Instruments are used to verify the dimensional accuracy of superalloy parts. These tools provide detailed measurements of complex geometries, ensuring that the surface finish is consistent across all part areas. With 3D scanning, NewayAero can inspect the entire surface and detect any performance-related irregularities.

Metallographic Microscopy and Scanning Electron Microscopy (SEM)

Metallographic Microscopy and Scanning Electron Microscopy (SEM) are used to analyze the surface quality at a micro level. These techniques provide high-resolution images of the surface, revealing details that may not be visible to the naked eye. By examining the surface structure, metallurgists can assess the quality of the finish and identify any areas that need further refinement.

Surface Roughness Testing

Surface Roughness Testing is employed to quantify the surface finish, measuring parameters such as average roughness (Ra) to ensure it meets industry standards. Surface roughness testing provides a numerical value for the quality of the finish, allowing NewayAero to verify that each part has achieved the desired smoothness.

Industry Applications and Benefits of Enhanced Surface Finish in Superalloy Parts

A high-quality surface finish is essential in numerous industries where superalloy parts are required to function under extreme conditions. Enhanced surface finishes provide benefits such as improved fatigue resistance, reduced wear, and corrosion resistance. These benefits in aerospace, power generation, oil and gas, and defense translate into more durable components, improved performance, and lower maintenance costs.

Aerospace and Aviation

In aerospace, superalloy components with a smooth surface finish are used in turbine blades, combustion chambers, and exhaust systems. A polished surface helps reduce drag and friction, which improves airflow and fuel efficiency. Additionally, smoother surfaces are less prone to wear and fatigue, extending the lifespan of critical components in aircraft engines. Enhanced surface finishes are precious for jet engine components that operate in high-stress, high-temperature environments.

Power Generation

For power generation applications, turbine parts with enhanced surface finishes contribute to improved efficiency and longevity. Components must endure high rotational speeds and temperatures in gas and steam turbines. A smooth surface finish reduces friction and minimizes the risk of thermal degradation, allowing turbine parts, like superalloy heat exchanger parts, to operate more efficiently and reliably.

Oil and Gas

Superalloy parts with fine finishes are essential in oil and gas pumps, valve seats, and other flow control components. A smooth surface improves flow characteristics, reducing turbulence and friction within the system. Additionally, an enhanced finish offers better resistance to corrosion, which is crucial for components exposed to harsh chemicals or high-pressure environments. For example, high-temperature alloy pump components benefit from reduced wear, which prolongs their service life in offshore applications.

Military and Defense

The defense industry relies on superalloy parts for mission-critical applications where reliability and durability are paramount. Components like missile segments and firearm accessories benefit from enhanced surface finishes, which reduce wear and improve performance under stress. A fine surface finish ensures that these parts maintain their integrity even under extreme mechanical loads, contributing to the durability of superalloy armor system parts.

Conclusion

In manufacturing high-performance superalloy parts, achieving a high-quality surface finish is essential for reliable, efficient performance. EDM offers a unique solution for producing smooth, precise finishes on superalloy castings, addressing the challenges posed by traditional machining methods. EDM enhances surface finish without introducing mechanical stress by employing controlled electrical discharges, making it ideal for complex, high-hardness materials.

NewayAero combines EDM with advanced post-processing techniques like Hot Isostatic Pressing (HIP), heat treatment, and thermal barrier coatings to deliver components with optimal surface finishes. Rigorous testing and quality control ensure that each part meets strict standards for dimensional accuracy and surface smoothness, guaranteeing that it performs as expected in demanding applications.

A superior surface finish provides substantial benefits for aerospace, power generation, oil and gas, and defense, from improved efficiency to enhanced durability. By leveraging EDM’s precision and NewayAero’s expertise, clients receive high-quality superalloy components engineered for long-lasting performance in extreme environments.

FAQs

What advantages does EDM offer over traditional machining methods for achieving surface finish in superalloy parts?

How does EDM achieve a smooth surface finish on superalloy components without causing thermal damage?

What types of post-processing techniques complement EDM for optimal surface finish on superalloys?

How does NewayAero ensure consistent surface finish quality across different superalloy parts?

In which industries is an enhanced surface finish most beneficial for superalloy components, and why?