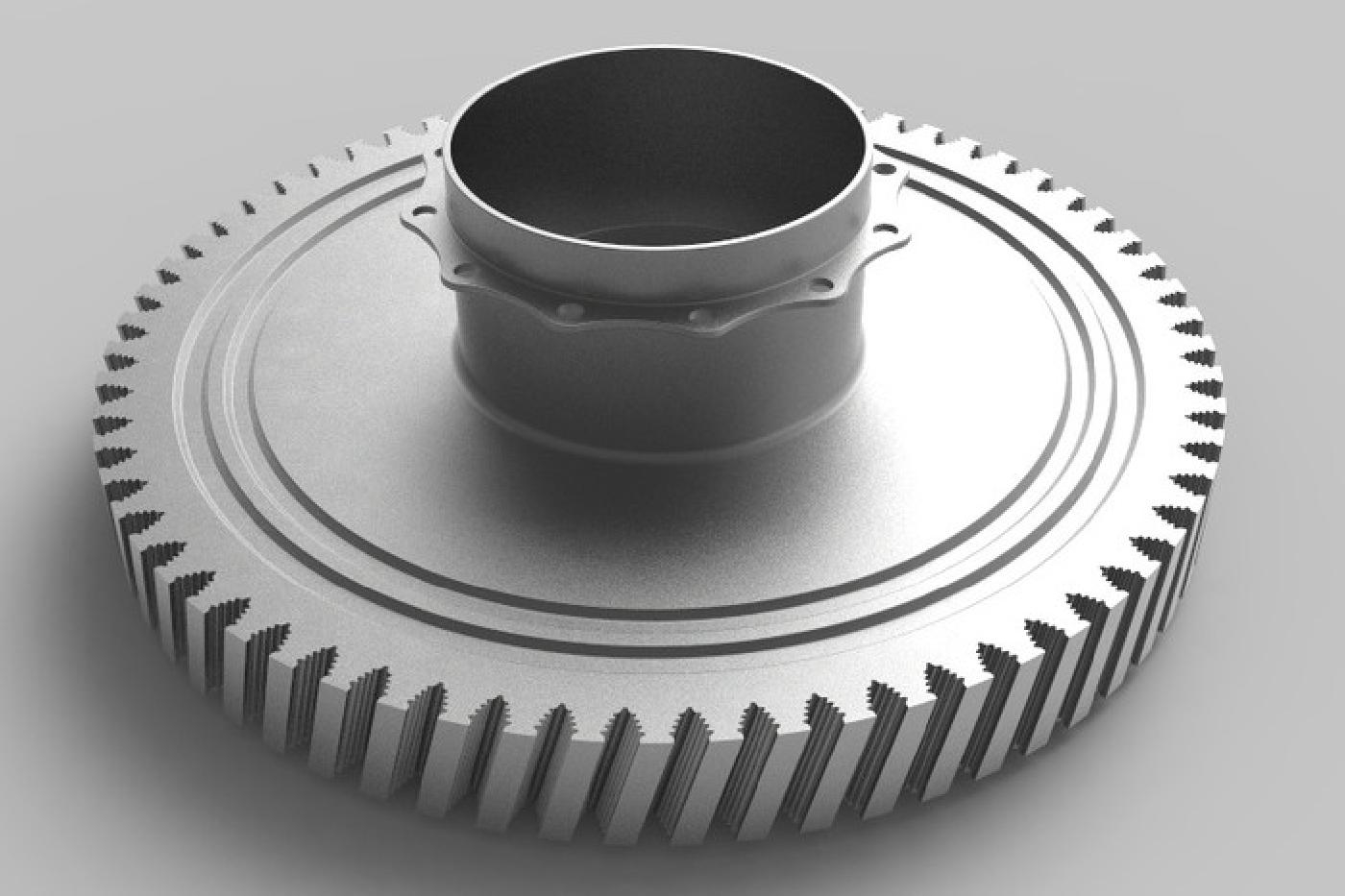

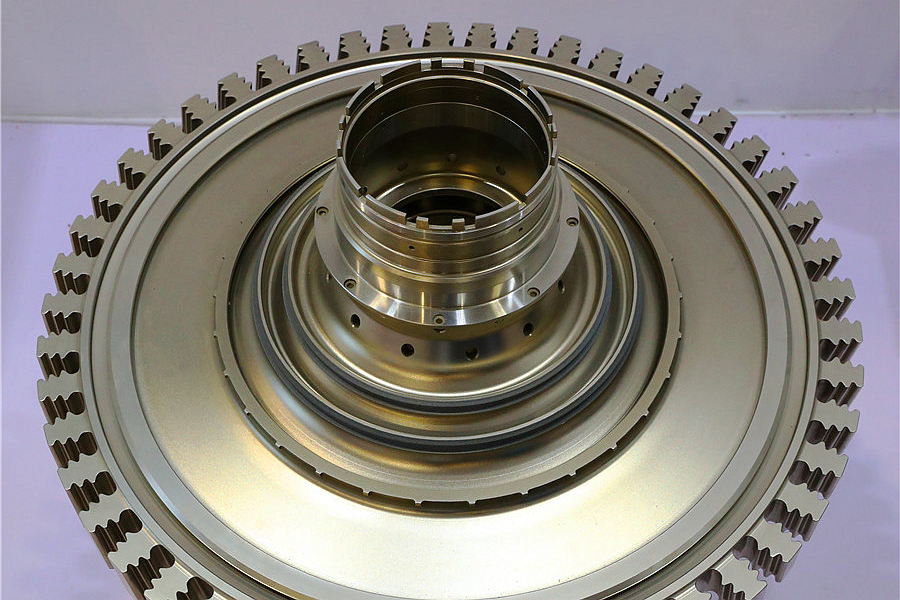

Double Alloy Monolithic Disc Hot Isostatic Pressure Diffusion Connection Technology

Double alloy monolithic discs, particularly for turbine applications, require cutting-edge manufacturing technologies to ensure their performance under extreme conditions. One of the most advanced methods used in their production is the Hot Isostatic Pressing (HIP) diffusion connection technology. This process is crucial for creating highly durable, high-performance components such as turbine discs, blades, and other critical engine parts. These components, which experience extreme temperatures and stresses, demand the utmost in material integrity and reliability.

The HIP process is essential for producing monolithic discs that meet the demanding specifications of aerospace, power generation, and defense industries. In this blog, we will explore the manufacturing process, suitable superalloys, post-processes, testing methods, and applications of the double alloy monolithic disc using HIP technology.

Manufacturing Process

Creating a double alloy monolithic disc begins with selecting the right materials and alloys for the turbine's operational demands. These materials are then subjected to the HIP diffusion connection process, which allows two different alloys to bond under high pressure and temperature. The HIP process enhances the mechanical properties of the disc, ensuring it can withstand extreme operational environments.

The first step in the manufacturing process is material selection. High-temperature superalloys, such as Inconel, CMSX, Rene, Nimonic, and Stellite, are used in turbine applications. These alloys are chosen for their exceptional strength, resistance to creep and fatigue, and thermal stability. For the HIP process, two types of alloys are used to create the double alloy monolithic disc, which combines different materials with complementary properties. This ensures that each alloy can contribute its specific strengths to the final product, such as thermal resistance, fatigue strength, or creep resistance.

Once the alloys are selected, they are prepared for the HIP process. The alloys are typically powder-based, allowing easier manipulation and bonding during the HIP process. The powders are carefully mixed in precise proportions to achieve the desired properties in the final disc. These materials are then placed into a sealed container known as a "can," which is subjected to heat and pressure during the HIP process.

In the HIP process, the alloy can be heated to high temperatures, typically between 1,200°C and 1,300°C, while subjected to high-pressure argon gas at around 100 to 200 MPa. This combination of heat and pressure facilitates the diffusion bonding of the two alloys, ensuring a uniform and strong bond between the materials. The HIP process significantly reduces porosity and increases the mechanical properties of the alloy, such as tensile strength and fatigue resistance, which are critical for turbine applications.

The disc can cool once the bonding process is complete and the solidified material is carefully removed from the can. The resulting disc is a monolithic structure that incorporates the best properties of both alloys, offering enhanced strength, resistance to thermal fatigue, and exceptional creep resistance. This manufacturing process results in turbine components with superior durability and performance characteristics, ensuring their ability to withstand the high demands of modern aerospace and industrial applications.

Suitable Superalloys

The selection of superalloys is crucial to the success of the HIP diffusion connection process, as these materials must possess specific characteristics that allow them to perform well under high-temperature, high-stress environments. Several superalloys are commonly used for the production of double-alloy monolithic discs, each offering unique benefits in terms of strength, temperature resistance, and fatigue life.

Inconel Alloys

Inconel alloys like Inconel 718 and Inconel 738 are among the most commonly used superalloys in turbine applications. These alloys are known for their excellent high-temperature strength, oxidation resistance, and creep resistance, making them ideal for use in turbine discs exposed to extreme thermal and mechanical loads. The versatility of Inconel alloys makes them well-suited for the HIP process, where their ability to bond with other alloys can enhance the overall performance of the final disc.

CMSX Series

The CMSX series, including CMSX-10 and CMSX-4, are nickel-based single-crystal superalloys designed explicitly for use in turbine blades and discs. These alloys offer excellent resistance to thermal fatigue and creep deformation and superior resistance to oxidation and corrosion at high temperatures. The CMSX alloys are ideal for the HIP diffusion connection process due to their superior material properties, which the bonding of different alloys in the monolithic disc structure can optimize.

Rene Alloys

Rene alloys, such as Rene 104 and Rene 108, are high-performance superalloys designed for use in advanced turbine systems. These alloys provide excellent resistance to high-temperature corrosion and oxidation and superior creep and fatigue resistance. Their ability to withstand extreme thermal cycling and high stresses makes them a preferred choice for turbine components, including those created with the HIP process.

Nimonic Alloys

Nimonic alloys, such as Nimonic 75 and Nimonic 90, are widely used in turbine applications due to their excellent high-temperature strength and resistance to thermal creep. These alloys are often selected for their ability to withstand high-stress levels and thermal cycling, making them ideal candidates for the HIP diffusion connection technology. The high tensile strength and oxidation resistance of Nimonic alloys further contribute to the performance of double alloy monolithic discs.

Post-Processes

After the double alloy monolithic discs are formed using the HIP diffusion connection process, several post-processing techniques are applied further to enhance the component's mechanical properties and surface characteristics. These post-processes are critical to ensuring that the final product meets the stringent performance requirements of turbine applications.

Heat Treatment:

Heat treatment is a critical post-processing step that further enhances the material properties of the turbine disc. This process involves subjecting the disc to controlled heating and cooling cycles to optimize its microstructure. Heat treatment improves the alloy's strength, hardness, and fatigue resistance, making it more suitable for high-performance turbine applications. Different heat treatment methods, such as solution treatment and aging, may be employed depending on the alloy used to achieve the desired properties.

Surface Finishing:

Surface finishing techniques, such as polishing, shot peening, and coating, are employed to improve the turbine disc's fatigue resistance and overall surface quality. Shot peening, for example, introduces compressive stresses to the surface, which enhances fatigue resistance and prolongs the component's lifespan. Polishing and coating help to reduce surface roughness and improve the component's resistance to oxidation and corrosion.

Welding and CNC Machining:

In some cases, superalloy welding is used to further reinforce the turbine disc, especially in areas requiring additional strength. CNC machining shapes the disc precisely, ensuring it meets the required specifications and tolerances. These post-processing techniques ensure the turbine disc is ready for use in demanding applications.

Testing of Double Alloy Monolithic Turbine Discs

Testing is a critical part of the manufacturing process to ensure the quality and performance of the double alloy monolithic disc. Several testing methods are used to evaluate the mechanical properties, structural integrity, and overall suitability of the turbine disc for high-performance applications.

Tensile Testing

Tensile testing measures the strength and flexibility of the superalloy used in the turbine disc. This test involves applying a uniaxial tensile force to the component until it breaks, allowing engineers to assess its tensile strength, yield strength, and elongation. These properties are essential for ensuring the turbine disc can withstand the high operational stresses. Tensile testing provides insights into how the material behaves under stress, a key factor in ensuring durability under extreme operating conditions.

Metallographic Analysis

Metallographic analysis is used to examine the microstructure of the superalloy, revealing details about grain structure, phase distribution, and any defects. This analysis is essential for ensuring that the material is free from imperfections that could compromise the performance and durability of the turbine disc. Metallographic analysis helps assess grain structure and phase distribution, which is critical for the part’s resistance to high-temperature stresses.

Creep and Fatigue Testing

Creep and fatigue testing are used to assess the long-term performance of the turbine disc under high-stress and high-temperature conditions. Creep testing measures the material's deformation under a constant load at elevated temperatures, while fatigue testing evaluates the material's ability to withstand cyclic loading. These tests ensure that the turbine disc will maintain its integrity throughout its service life. Creep and fatigue testing help simulate real-world operational conditions and ensure that turbine discs remain reliable under repeated stresses.

X-Ray and 3D Scanning

X-ray imaging and 3D scanning techniques detect internal defects, such as porosity or voids, that may have occurred during the HIP process. These non-destructive testing methods allow for a thorough disc inspection without damaging it, ensuring the component is free from internal flaws. X-ray and 3D scanning are essential for identifying hidden defects and ensuring the component's integrity and performance under operational stress.

Industry and Application of Double Alloy Monolithic Discs Manufactured Using HIP Technology

Double alloy monolithic discs manufactured using Hot Isostatic Pressing (HIP) technology have broad applications across several industries. These components are critical in environments where high temperatures, high pressures, and extreme stresses are the norm.

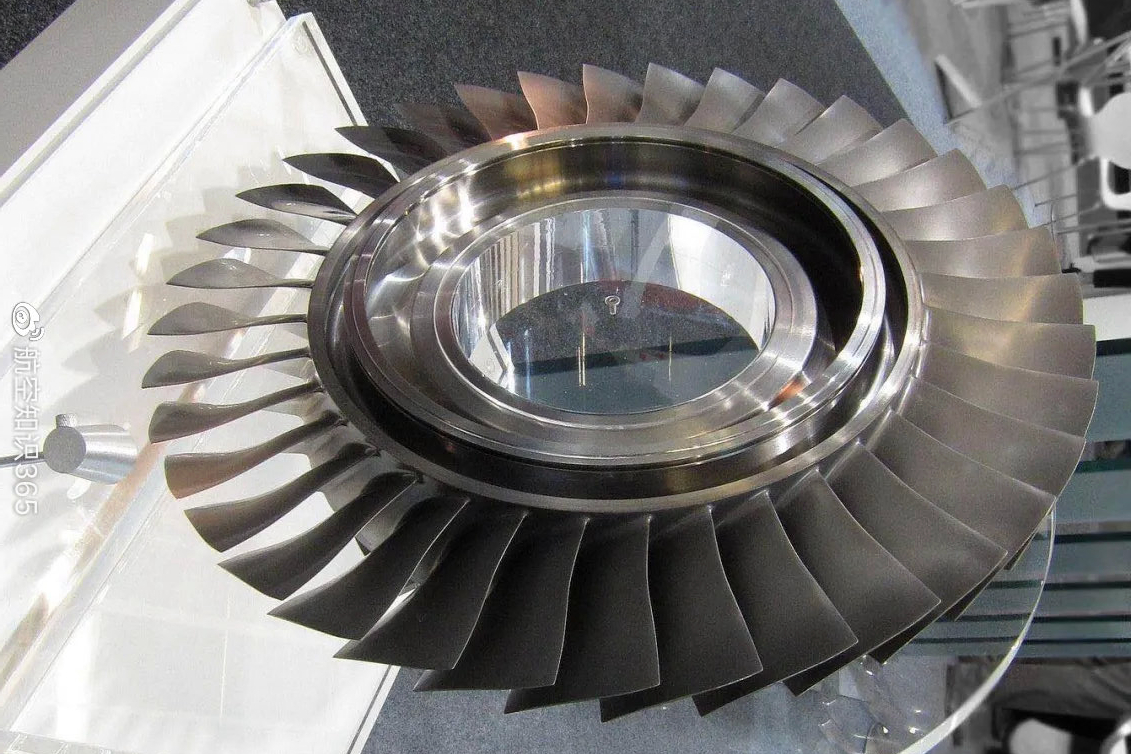

Aerospace and Aviation

In the aerospace and aviation industries, double alloy monolithic discs are used in turbine engines, such as jet and gas turbines. These discs are subject to extreme temperatures and stresses during flight, making their durability and performance crucial for safety and efficiency. HIP technology helps ensure the monolithic discs' strength, resistance to thermal fatigue, and overall structural integrity. Learn more about our applications in the aerospace and aviation sector.

Power Generation

Power plants that rely on gas and steam turbines use double alloy monolithic discs to ensure optimal performance and reliability. HIP technology provides the necessary material strength and resistance to high temperatures, which is essential for power generation turbines operating under continuous, demanding conditions. Explore our Power Generation solutions for turbine components.

Oil and Gas

The oil and gas industry uses turbines in exploration, drilling, and production applications, where high-performance materials are critical. Double alloy monolithic discs created using HIP technology are designed to withstand the extreme environments and long operational lifespans required in oil and gas turbines. Learn how our components support the oil and gas sector.

Marine and Military

Naval vessels and offshore platforms rely on turbine engines for propulsion and power generation. In military applications, turbine engines are used in aircraft, missiles, and other high-performance machinery. Double alloy monolithic discs provide the necessary reliability and performance in these mission-critical systems. Visit our Marine and Military and Defense sections for more information on our solutions.

Automotive

The automotive industry benefits from double alloy monolithic discs, particularly in developing high-performance vehicles with turbine engines. These components provide the strength and durability for automotive turbines to operate efficiently under high-temperature and high-stress conditions. Explore our high-performance automotive turbine components.

FAQs

What is the Hot Isostatic Pressure (HIP) process and how does it benefit turbine disc manufacturing?

How do different superalloys contribute to the performance of double alloy monolithic discs in turbine applications?

What are the most critical post-processing techniques for ensuring the durability of turbine discs?

How is tensile strength tested for turbine components created with HIP technology?

What industries benefit from the use of double alloy monolithic discs in their turbine systems?