Boosting Performance of Cast Alloys Through Heat Treatment

Cast alloys are widely used in various industries, including aerospace, automotive, power generation, and oil and gas. These materials are highly valued for their ability to be cast into complex shapes and withstand challenging operational conditions. Cast alloys include a variety of metals, from aluminum alloys used in lightweight automotive parts to superalloys employed in high-temperature aerospace applications.

Heat treatment is crucial in enhancing cast alloys' performance and mechanical properties. Through controlled heating and cooling processes, heat treatment refines the microstructure of these alloys, increasing their strength, toughness, and resistance to various stresses. This process is essential for optimizing cast alloys, ensuring that each component can meet the rigorous demands of its specific application, from high-stress turbine blades to corrosion-resistant downhole tools.

Understanding Cast Alloys and Their Challenges

What Are Cast Alloys?

Cast alloys are metals that have been melted, poured into a mold, and allowed to solidify into a desired shape. Common types of cast alloys include:

Aluminum Alloys: Lightweight and corrosion-resistant, commonly used in automotive and aerospace applications.

Superalloys: High-temperature alloys like Inconel and Hastelloy are widely used in turbine blades and jet engines.

Cast Irons: Known for excellent wear resistance and used in various industrial applications, such as pipes, machinery parts, and automotive components.

Each cast alloy type has unique properties suited to different applications, but they all face similar challenges in their untreated form.

Challenges in Cast Alloys

Despite their benefits, cast alloys often have challenges that can compromise performance. Common issues include:

Porosity: Small voids or bubbles within the alloy can reduce strength and fatigue resistance.

Inconsistent Microstructures: Cast alloys often solidify with grain boundaries and non-uniform microstructures, leading to variable mechanical properties.

Residual Stresses: The casting process can create internal stresses that may cause warping, cracking, or premature failure.

Importance of Heat Treatment

Heat treatment is essential for addressing these challenges and enhancing cast alloy performance. By refining the microstructure, relieving internal stresses, and improving homogeneity, heat treatment processes enable cast alloys to reach their full potential. This optimization is critical in high-stress applications where the alloy's properties directly impact safety, performance, and durability.

Overview of Heat Treatment Processes for Cast Alloys

Types of Heat Treatment for Cast Alloys

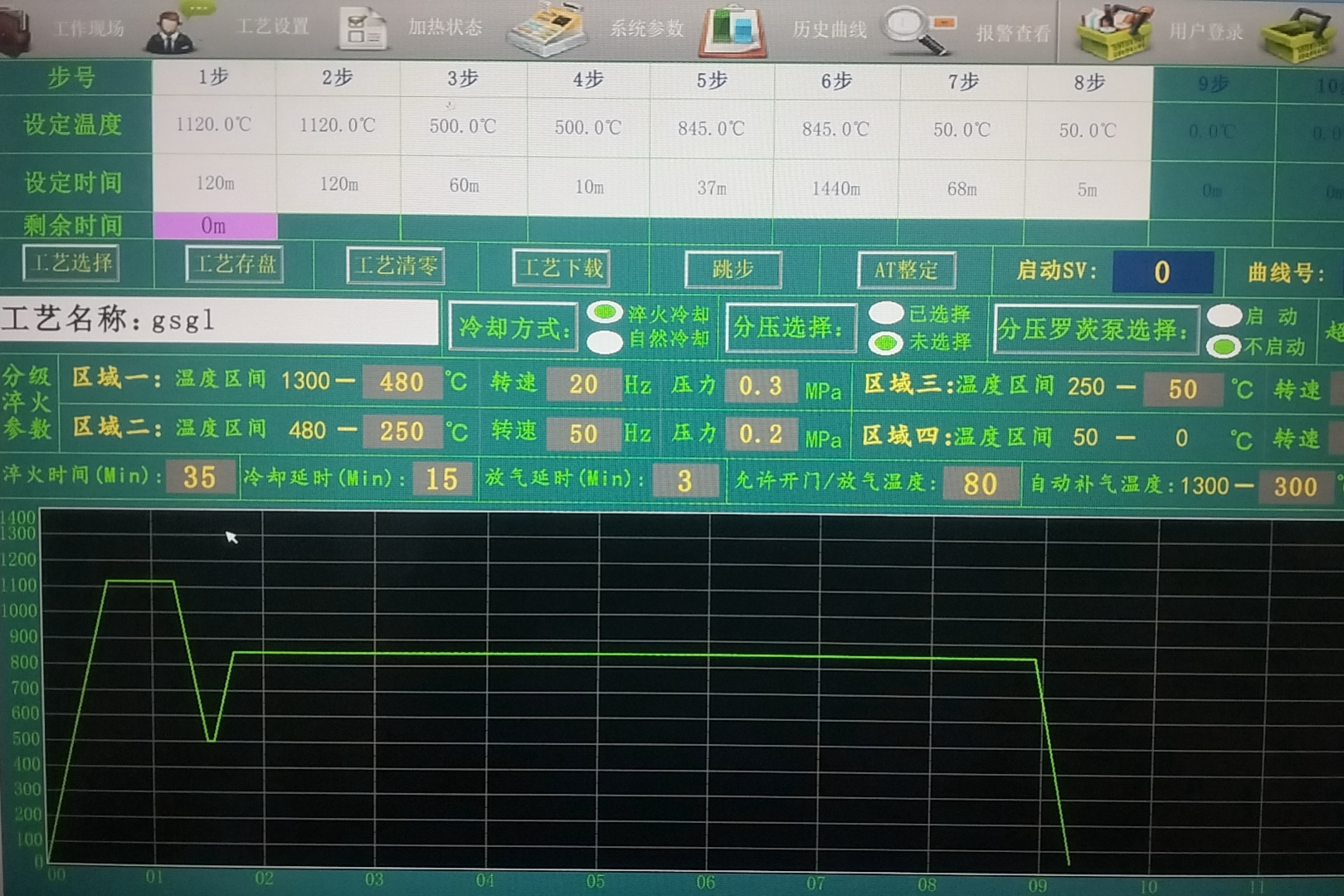

Annealing: This process involves heating the alloy to a specified temperature and then cooling it in a controlled manner. Annealing softens the alloy, reduces hardness, and relieves internal stresses, which helps prevent brittleness and improves ductility. This process is valuable for applications where enhanced toughness and flexibility are required.

Solution Treatment and Aging: Solution treatment heats the alloy to dissolve solute atoms into a solid solution, homogenizing the microstructure. Rapid cooling, or quenching, follows to "freeze" the alloy in a supersaturated state. Aging is then applied by reheating the alloy at a lower temperature to precipitate fine particles, strengthening the material. This combination enhances strength and hardness, making it ideal for high-performance parts.

Quenching: Quenching is a rapid cooling process, typically performed in water or oil, that locks in specific microstructures, increasing hardness and tensile strength. Quenching is often followed by tempering to reduce brittleness, balancing hardness and toughness.

Stress Relieving: Stress-relieving treatments are applied to reduce residual stresses in the alloy without significantly altering its hardness or strength. This process is essential for complex castings with uneven internal stresses, preventing deformation during machining or use.

Selection of Heat Treatment

The appropriate heat treatment process selection depends on the alloy type and its intended application. The required mechanical properties, environmental conditions, and operational stresses determine the most effective heat treatment approach. Proper selection ensures the alloy performs reliably in its application, whether it requires high strength, toughness, thermal stability, or a combination of these properties.

How Heat Treatment Improves Performance of Cast Alloys

Enhanced Mechanical Strength

Heat treatment strengthens cast alloys by refining their microstructure and redistributing phases within the alloy. Techniques like solution treatment and aging create a more homogeneous structure, increasing tensile strength and improving load-bearing capacity. This improvement is crucial in applications like aerospace, where both strength and weight are critical, enabling components to perform reliably under high stresses.

Increased Toughness and Ductility

Heat treatment enhances an alloy's toughness and flexibility, making it more resistant to fractures and deformations. Annealing, for instance, reduces brittleness and increases flexibility, benefiting applications where components are exposed to impact or sudden loads. More challenging, more ductile alloys can better absorb energy without breaking, making them ideal for automotive and industrial uses where durability is essential.

Improved Creep and Fatigue Resistance

Creep resistance is crucial for materials used in high-temperature environments, where long-term stress can cause gradual deformation. Aging and solution treatment refines the alloy's microstructure, boosting its resistance to creep. Fatigue resistance, essential for parts subjected to cyclical stresses, is also enhanced by heat treatment, which improves grain structure and reduces the likelihood of crack initiation and propagation, ensuring longevity in high-stress applications.

More excellent Corrosion and Oxidation Resistance

Heat treatment improves an alloy's resistance to oxidation and corrosion, both on the surface and within its internal structure. By refining the microstructure and removing impurities, heat treatment reduces pathways for corrosive elements, making treated alloys suitable for harsh environments like oil, gas, and chemical processing. This enhanced resistance contributes to the durability and reliability of parts exposed to corrosive chemicals or extreme conditions.

Thermal Stability

Heat-treated cast alloys achieve excellent thermal stability, allowing them to maintain their properties under high-temperature fluctuations. This stability is accomplished through precise heat treatment processes that ensure a stable, refined microstructure. Thermally stable components in power generation, such as turbine blades and generator parts, can withstand continuous exposure to high temperatures without degradation, making them suitable for demanding power generation applications.

Heat treatment significantly improves cast alloys' performance, durability, and reliability through these benefits, preparing them for high-stress, high-temperature environments where failure is not an option.

Essential Heat Treatment Techniques to Boost Cast Alloy Performance

Solution Treatment and Aging for Precipitation Hardening

Solution treatment dissolves undesirable phases within the alloy, creating a uniform structure while aging precipitates strengthening phases that increase hardness and durability. This combination is highly effective for superalloys, where precise microstructure control is essential for high-temperature applications, providing enhanced performance in stress-intensive environments.

Hot Isostatic Pressing (HIP)

HIP applies high pressure and temperature to the alloy, eliminating internal voids and reducing porosity. This process optimizes density and improves mechanical properties, making it valuable for critical aerospace and industrial components where strength and reliability are paramount. By enhancing material uniformity, HIP ensures that parts can perform under extreme conditions without compromising structural integrity.

Quenching and Tempering

Quenching rapidly cools the alloy to lock in specific microstructures, boosting hardness and tensile strength. Tempering follows quenching, reheating the alloy at a controlled temperature to reduce brittleness. This combination balances strength and elasticity, making it ideal for parts required to withstand high-stress environments, such as structural components in heavy machinery and power generation.

Annealing for Stress Relief

Annealing relieves residual stresses and achieves a more uniform grain structure, critical for castings with irregular internal stresses from solidification. By reducing brittleness, annealing enables cast alloys to endure demanding applications without cracking or deforming, making it especially valuable for components exposed to mechanical shocks or heavy loads.

Specialized Treatments for Superalloys

Superalloys, designed for high-temperature and high-stress applications, often undergo specialized treatments like directional solidification and single-crystal growth. These techniques refine the grain structure, imparting enhanced mechanical properties and thermal stability, essential for components like turbine blades, which must withstand continuous exposure to high temperatures without structural degradation.

Quality Control and Inspection of Heat-Treated Cast Alloys

Common Inspection Methods

Non-Destructive Testing (NDT): Techniques like X-ray, ultrasonic testing, and dye penetrant testing detect internal flaws, ensuring that the heat-treated alloy meets quality standards without compromising structural integrity.

Hardness and Tensile Testing: These tests verify that the alloy has achieved the desired mechanical properties, such as strength and hardness.

Metallographic Analysis: Examining the alloy's microstructure confirms that the heat treatment process has successfully optimized grain structure and phase distribution.

Importance of Quality Control

Quality control is essential in heat-treated cast alloys to confirm that they meet the performance standards and specifications required for their application. Proper inspection helps prevent failures, ensuring each component operates reliably in critical and high-stress environments.

Applications of Heat-Treated Cast Alloys

Aerospace Components

Heat-treated cast alloys are essential in aerospace applications, where they are used in turbine blades, engine parts, and structural components. The strength, creep, and oxidation resistance achieved through heat treatment allow these components to withstand extreme temperatures and mechanical stresses over long operational periods.

Automotive Industry

In the automotive sector, heat-treated alloys are used in high-performance engines, exhaust systems, and lightweight structural parts. Heat treatment improves these alloys' strength-to-weight ratio, corrosion resistance, and durability, improving fuel efficiency and longer-lasting parts.

Power Generation

Heat-treated cast alloys play a critical role in power generation, where they are used in turbines, generators, and other components exposed to high temperatures and pressures. Heat treatment's thermal stability and creep resistance ensure reliable performance and prolonged service life in these high-stress applications.

Oil and Gas

The oil and gas industry requires materials that endure high pressures, temperatures, and corrosive environments. Heat-treated alloys, with their enhanced corrosion and oxidation resistance, are used in downhole tools, drilling equipment, and valves to ensure durability and reduce maintenance needs in harsh operational conditions.

General Industrial Applications

Heat-treated cast alloys are also used in general industrial applications, such as pumps, valves, and structural components, where durability, corrosion resistance, and strength are essential. These alloys provide reliable performance in environments that demand robustness and resilience.