Benefits of Using the Seed Crystal Method in Casting

The seed crystal method has revolutionized the casting of single-crystal components, offering unparalleled precision and reliability. This method ensures a uniform, defect-free crystal structure by initiating crystal growth from a predefined seed. This is critical for high-performance applications where materials face extreme mechanical stresses and high temperatures.

The seed crystal method plays a pivotal role in aerospace, power generation, and defense industries, where the integrity of turbine blades, guide vanes, and other critical components directly impacts operational efficiency and safety. Its benefits include improved mechanical properties, increased resistance to thermal fatigue, and extended component lifespans. Through advanced casting techniques, this method enables manufacturers to meet the stringent demands of modern engineering applications.

The Casting Process with the Seed Crystal Method

The seed crystal method is a cornerstone of single crystal casting, combining advanced techniques to achieve defect-free components.

Directional solidification is integral to this process. It employs a controlled temperature gradient to guide the molten alloy’s solidification in a single direction. The seed crystal is positioned at the base of the mold, serving as the template for crystal growth. As the material solidifies, the crystal structure extends from the seed, ensuring uniformity and eliminating grain boundaries. This method is closely aligned with directional solidification techniques that enhance the structural integrity of critical components.

Seeding techniques ensure the alignment of the crystal structure. The placement of the seed crystal within the mold is carefully calculated to promote optimal growth. Misalignment during this stage can result in secondary grains, compromising the component’s structural integrity and performance. To avoid this, advanced superalloy casting methods are utilized to maintain consistency.

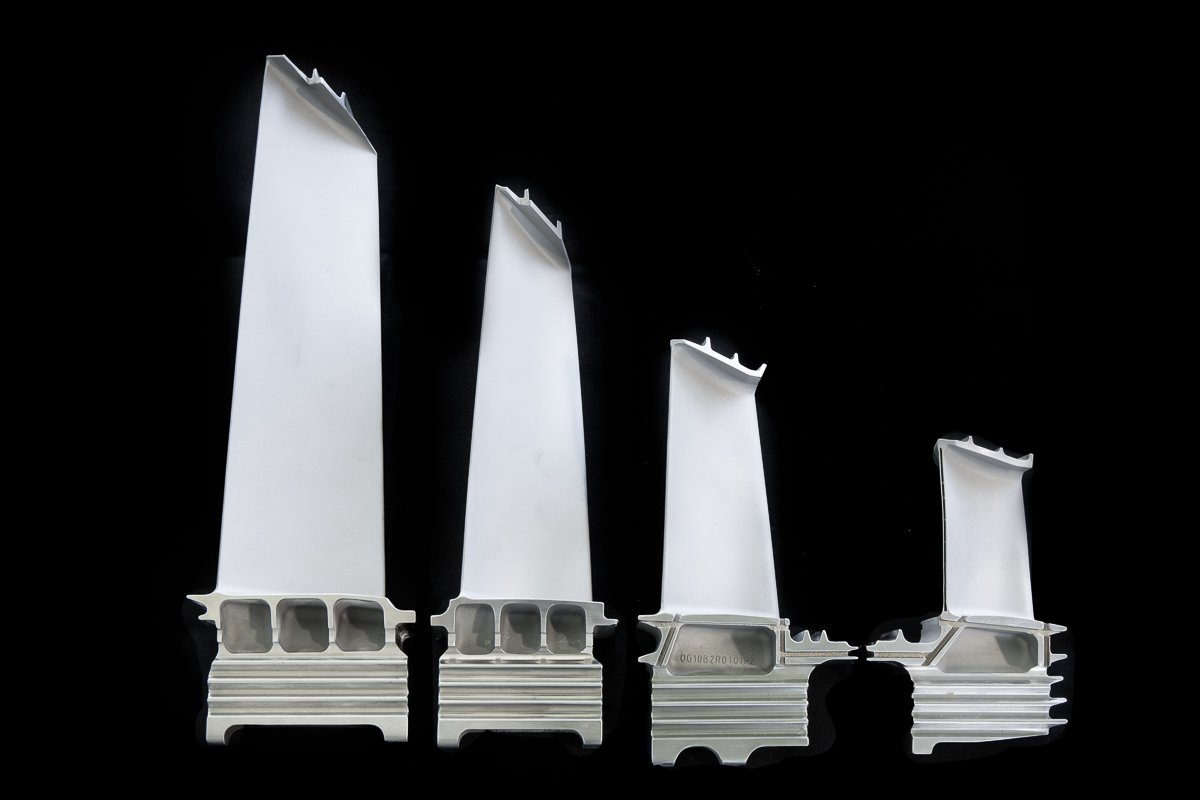

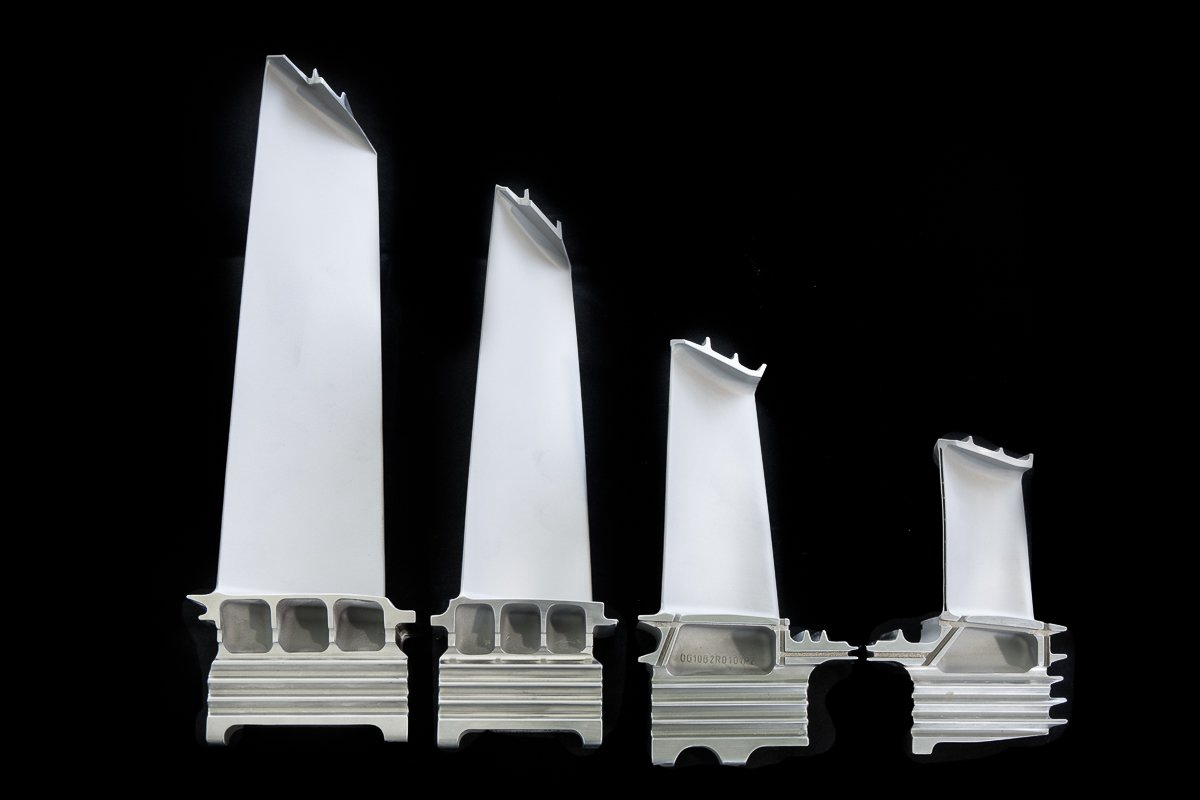

Advanced mold designs play a critical role in supporting the seed crystal method. These molds are engineered to maintain the proper environment for crystal growth, incorporating features like helical channels to filter out unwanted grains. Additionally, the materials used for molds are selected for their thermal stability and ability to withstand high temperatures. Innovations in mold technology are often complemented by post-casting processes such as superalloy CNC machining to achieve precise dimensions and surface finishes.

Controlled cooling systems are essential for maintaining a uniform solidification process. Precise thermal management ensures that the cooling rate supports directional solidification without introducing defects. Innovations in cooling technology, such as advanced thermal sensors and adaptive cooling systems, further enhance the reliability of the seed crystal method. These systems are often integrated with vacuum investment casting to protect the material during solidification and improve final component quality.

Suitable Single Crystal Casting Superalloys

The success of the seed crystal method relies heavily on the choice of superalloys. These materials must exhibit exceptional strength, resistance to thermal fatigue, and stability under extreme conditions.

Inconel Alloys

Inconel alloys, including Inconel 738 and Inconel 713, are widely used in single crystal casting. Their excellent high-temperature properties and oxidation resistance make them suitable for demanding environments. However, the complex composition of these alloys requires precise control during the casting process to ensure a uniform crystal structure.

CMSX Series

The CMSX series of superalloys, such as CMSX-4, CMSX-10, and CMSX-486, are engineered specifically for single crystal applications. These alloys are known for their superior creep resistance and mechanical strength at high temperatures. Advances in CMSX formulations have minimized segregation during solidification, making them ideal for use with the seed crystal method.

Rene Alloys

Rene alloys, including Rene 104 and Rene 88, offer exceptional thermal stability and resistance to fatigue. These properties make them a preferred choice for high-performance applications. However, achieving defect-free casting with Rene alloys demands rigorous process control and the application of advanced seeding techniques.

Specialized Single Crystal Alloys

Specialized single-crystal alloys, like PWA 1484 and CMSX-2, are tailored for applications requiring extreme durability and thermal resistance. These alloys are commonly used in gas turbines and jet engines, where operational demands are at their highest. The seed crystal method ensures that these materials achieve their full potential by eliminating grain boundaries and enhancing structural integrity.

Post-Processing Benefits for Seed Crystal Casting

Post-processing is critical to optimizing the properties of single-crystal components cast using the seed crystal method. Each step is designed to enhance the material’s performance and ensure the integrity of its crystal structure.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is a post-processing technique that eliminates porosity and improves the material’s density. This process involves applying high pressure and temperature to the component, consolidating the material and enhancing its mechanical properties. In the seed crystal method context, HIP ensures that the single crystal structure remains intact while improving resistance to fatigue and creep.

Heat Treatment

Heat treatment is another essential post-processing step. Heat treatment enhances tensile strength, ductility, and thermal fatigue resistance by altering the material's microstructure. The process must be carefully controlled for single crystal components to prevent unwanted recrystallization, which can compromise the crystal structure.

Surface Coatings

Surface coatings, including Thermal Barrier Coatings (TBC), extend the lifespan of single crystal components by protecting them from oxidation and thermal damage. TBCs create a protective layer that reduces heat transfer, improving the component’s durability in high-temperature environments. Advanced coating methods ensure uniform application without affecting the underlying crystal structure.

Precision Machining

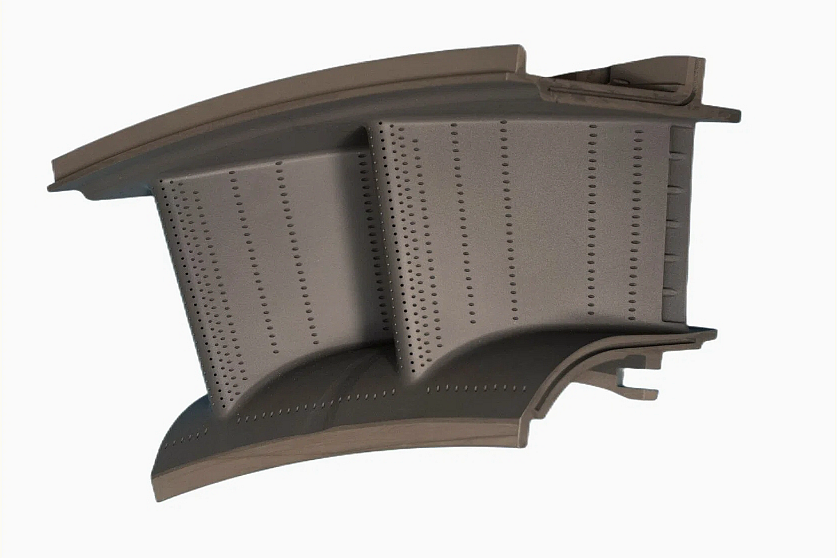

Precision machining is required to achieve single crystal components' final dimensions and geometries. CNC machining and drilling techniques create intricate cooling channels and other design features. These processes must be executed with extreme precision to maintain the integrity of the crystal structure and meet the tight tolerances required for high-performance applications.

Testing and Quality Assurance

Rigorous testing is essential to verify the quality and reliability of single-crystal components produced using the seed crystal method. These tests ensure that the components meet the stringent standards of high-performance applications.

Metallographic Microscopy and SEM

Metallographic microscopy and Scanning Electron Microscopy (SEM) examine the crystal structure and identify defects such as grain misalignments or secondary grains. These techniques provide detailed insights into the microstructure, confirming the uniformity and alignment of the crystal.

X-ray and CT Scanning

X-ray testing and industrial CT scanning are critical for non-destructive testing. These methods allow manufacturers to inspect the internal integrity of components, detecting voids, cracks, and other defects that may not be visible on the surface. Industrial CT scanning is valuable for verifying complex internal features like cooling channels.

Mechanical Testing

Mechanical testing evaluates the component’s performance under simulated operational conditions. Tensile testing assesses the material’s strength, while fatigue testing evaluates its ability to withstand repeated thermal and mechanical loads. These tests are crucial for ensuring the component’s long-term reliability.

Electron Backscatter Diffraction (EBSD)

Electron Backscatter Diffraction (EBSD) provides a detailed crystal orientation and alignment analysis. This advanced technique is essential for verifying that the component meets design specifications and identifying deviations that could impact performance.

Industry Applications of the Seed Crystal Method

The seed crystal method is used across various industries where the reliability and performance of single crystal components are critical. Each application benefits from the method’s ability to enhance material properties and ensure structural integrity.

Aerospace and Aviation

In aerospace and aviation, single-crystal components are used in jet engines to optimize performance and efficiency. The seed crystal method ensures that these components withstand high temperatures and mechanical stresses, meeting the stringent standards required for aerospace and aviation applications, where safety and reliability are paramount.

Power Generation

The power generation industry relies on single-crystal components for gas and steam turbines. These components play a crucial role in improving energy efficiency and reducing emissions. The seed crystal method addresses the challenges of high operational temperatures and mechanical loads, extending the lifespan of critical turbine parts. Power generation plants benefit significantly from this precision casting technique, ensuring the durability and performance of turbine components.

Oil and Gas

In the oil and gas sector, single-crystal components are used in compressors and turbines that operate under extreme conditions. The durability and reliability of these components are critical for minimizing downtime and maintenance costs. The oil and gas industry leverages the seed crystal method to enhance the resistance of these components to thermal fatigue and mechanical stress, enabling continuous operation in harsh environments.

Defense and Military

Defense and military applications demand high-performance components for propulsion systems, advanced weaponry, and other critical technologies. The military and defense sector depends on the seed crystal method to ensure that components deliver consistent performance in the most demanding environments, supporting mission-critical operations with unmatched reliability.

FAQs

How does the seed crystal method improve the structural integrity of single crystal components?

What are the key advantages of using CMSX and Rene alloys with the seed crystal method?

How do advanced mold designs support the seed crystal casting process?

What testing methods are most effective for verifying the quality of seed crystal cast components?

What industries benefit most from the seed crystal method in casting?