Benefits of Superalloy Friction Welding Service

Friction welding (FW) has become a vital process in manufacturing high-performance components for industries that demand superior strength, heat resistance, and reliability. Friction welding stands out among the various material joining methods, particularly for superalloys used in challenging applications like aerospace, power generation, and oil and gas. Superalloy friction welding combines the benefits of exceptional material properties with advanced welding techniques, creating defect-free bonds with high structural integrity. This blog delves into the manufacturing process, the superalloys best suited for friction welding, the post-processes that ensure optimal performance, and the testing methods used to verify the quality of welded parts.

Manufacturing Process

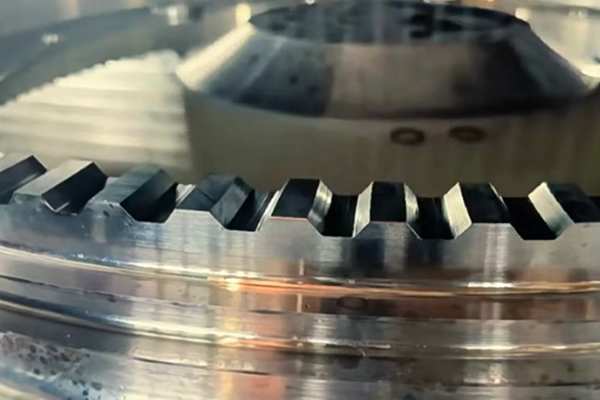

Friction welding is a solid-state welding process where heat generated by mechanical friction between two workpieces creates a bond when pressure is applied. The key to this process is the frictional heat generated at the interface between the two pieces, which allows the materials to soften and bond without reaching the melting point, minimizing distortion and defects. The primary types of friction welding include continuous and inertia friction welding.

In continuous friction welding, one piece is rotated while the other remains stationary. The frictional heat generated is maintained through constant rotational movement, and pressure is applied to force the materials together. The process is ideal for long or cylindrical parts, allowing for continuous movement and stable heat generation.

On the other hand, inertia friction welding involves rotating a workpiece at high speed and then applying pressure to create the weld once the rotational speed is reduced to a specified level. The stored rotational energy in the rotating part generates the necessary frictional heat. This method is often used for shorter parts or when higher bonding strength is required.

Friction welding integrates seamlessly with manufacturing processes such as vacuum investment casting, single crystal casting, equiaxed crystal casting, and powder metallurgy. These methods are frequently used to create superalloy parts with complex geometries, which are then welded using friction welding techniques to form critical joints. CNC machining and 3D printing can also be combined with friction welding to fine-tune dimensions and ensure precise part characteristics.

The primary benefit of friction welding for superalloys is that it creates solid and defect-free joints with minimal material loss, reducing the need for filler metals and post-weld treatments.

Suitable Superalloys for Friction Welding

Friction welding is ideal for high-performance superalloys that exhibit exceptional resistance to high temperatures, oxidation, corrosion, and fatigue. These materials are often used in demanding environments like jet engines, gas turbines, and power plants, where components must withstand extreme thermal and mechanical stresses.

Inconel Alloys

Inconel alloys, such as Inconel 718 and Inconel 625, are some of the most commonly used materials in friction welding due to their superior resistance to oxidation and high-temperature corrosion. These alloys are well-suited for aerospace and power generation applications, where their high tensile strength, excellent weldability, and resistance to thermal and mechanical stresses are essential. Inconel alloys' ability to perform in extreme environments makes them ideal for turbine blades, discs, and other hot-section components in jet engines and gas turbines.

Hastelloy Alloys

Hastelloy alloys, including Hastelloy C-276 and Hastelloy X, are designed for environments that demand exceptional resistance to high temperatures and corrosive conditions. These alloys are widely used in chemical processing industries, high-performance engines, and heat exchangers. Friction welding of these alloys ensures the creation of high-integrity joints without compromising their excellent corrosion resistance and mechanical properties. The process is particularly advantageous for applications with critical sealing and structural integrity.

Nimonic Alloys

Nimonic alloys, such as Nimonic 75 and Nimonic 90, offer excellent high-temperature strength and are commonly used for turbine components. Friction welding of these alloys ensures the retention of their mechanical strength under extreme conditions, including thermal cycling and high mechanical loads. Their resistance to thermal creep and the ability to maintain structural integrity during high-temperature operation make them ideal for gas turbines, combustion chambers, and other aerospace components.

Titanium Alloys

Titanium alloys, such as Ti-6Al-4V and Ti-10V-2Fe-3Al, are well-suited for friction welding due to their excellent strength-to-weight ratio and corrosion resistance. These alloys are commonly used in aerospace and marine applications, mainly where lightweight yet high-strength components are essential. Titanium alloys perform well under high-stress and high-temperature conditions, making them ideal for critical structural components like compressor blades, landing gear, and aerospace fasteners.

Post-Processes for Friction Welded Superalloy Parts

After a superalloy part is welded using friction welding, post-processing steps are often necessary to optimize the properties of the final component. Post-processing can enhance mechanical performance, reduce residual stresses, and achieve the desired material properties.

One of the most common post-processing methods is heat treatment, which is used to relieve stresses, enhance hardness, and increase the overall mechanical properties of the welded parts. For example, superalloys like Inconel 718 often undergo solution heat treatment followed by aging to increase strength and improve creep resistance. This treatment also ensures that the weld has properties similar to or superior to the base material.

Another post-process used in friction welding is Hot Isostatic Pressing (HIP), employed to densify the material further, eliminating any microvoids or porosity created during the welding process. HIP can also improve the material’s resistance to fatigue and increase its overall strength.

Surface treatments, such as grinding and polishing, are often applied to friction-welded superalloy parts to meet dimensional specifications and surface finish requirements. These processes help achieve the necessary tolerances and maintain the surface integrity, preventing stress concentrations or cracks that could lead to premature failure.

Thermal Barrier Coatings (TBC) are frequently applied to superalloy parts exposed to extreme temperatures. TBCs help reduce the thermal load on the material, enhancing its resistance to oxidation and corrosion, particularly in aerospace and power generation applications.

Testing and Quality Control

Friction welding of superalloy parts requires stringent testing and quality control to ensure the integrity and performance of the welded joints. Various testing methods are employed to evaluate the friction-welded components' mechanical properties, bond quality, and durability.

Tensile testing is one of the most essential forms of testing to determine the strength and elongation of the welded joint. Tensile testing reveals how the weld will perform under different loading conditions and provides valuable data on the bonding strength of the superalloy parts.

Microstructural examination through metallographic analysis is performed to assess the quality of the weld and ensure that no defects like cracks, porosity, or inclusions are present. A well-executed friction weld should show a smooth, homogeneous microstructure, indicating a successful bond between the two materials.

Ultrasonic and X-ray testing are non-destructive testing methods used to detect internal flaws that might not be visible through conventional means. These techniques help identify any hidden defects or areas of weakness in the welded components, ensuring the reliability of the final product. Ultrasonic inspection is beneficial for locating subsurface defects such as voids or microcracks.

Other important tests include hardness testing, fatigue testing, and impact testing. These tests help evaluate the material’s resistance to wear, crack propagation, and ability to perform under cyclical loading conditions. Additionally, these tests ensure that the friction-welded parts will perform reliably in demanding applications such as turbine engines, where material durability is critical.

Industry and Application of Superalloy Friction Welding

Superalloy friction welding is used extensively in industries where the reliability of high-performance components is paramount. These industries require materials that can withstand extreme environments, such as high temperatures, corrosive conditions, and mechanical stresses.

Aerospace Industry

In the Aerospace and Aviation industry, friction welding joins turbine blades, exhaust components, and structural parts. Superalloys like Inconel and Hastelloy are ideal for these applications, as they offer exceptional strength and resistance to oxidation at elevated temperatures.

Power Generation Industry

The Power Generation industry also relies on superalloy friction welding for turbine discs, heat exchangers, and other critical components. Power plants' high mechanical stresses and thermal cycles make high-integrity joints crucial for ensuring operational efficiency and longevity.

Oil and Gas Industry

In the Oil and Gas industry, friction welding is used to manufacture components like valves, drill pipes, and pressure vessels. The ability of superalloys to resist corrosion and maintain their mechanical properties in harsh environments is critical in these applications.

Automotive, Marine, and Defense Sectors

The Automotive, Marine, and Military and Defense sectors also benefit from superalloy friction welding, where components such as engine parts, structural elements, and armor systems must meet stringent performance requirements under extreme conditions.

Frequently Asked Questions (FAQs)

What are the primary advantages of using friction welding for superalloy parts?

Which superalloys are most commonly used in friction welding, and why?

What is the role of post-processing in improving the performance of friction-welded superalloy parts?

How does friction welding compare to traditional welding methods for superalloy components?

What testing methods are most effective for ensuring the integrity of friction-welded superalloy parts?