Benefits of Material Testing and Analysis on Superalloy Castings

Superalloys are materials engineered to withstand extreme temperatures, stress, and corrosion, making them essential for applications in aerospace, power generation, chemical processing, and defense. These high-performance alloys are commonly used in critical components like turbine blades, engine parts, and industrial machinery. In this blog, we will explore the various types of superalloys, the advanced manufacturing techniques employed to process them, the post-processing treatments, and the testing and inspection methods that ensure their reliability in demanding applications.

Introduction to Superalloys

Superalloys, or high-performance alloys, are designed to operate in environments where ordinary materials would fail. Engineered for exceptional mechanical strength, resistance to thermal and environmental degradation, and long-term durability in high-temperature conditions, superalloys are essential for critical applications in aerospace, power generation, automotive, and chemical industries. These alloys are typically based on nickel, cobalt, or iron and are alloyed with chromium, molybdenum, titanium, and aluminum to achieve their high-performance properties.

Superalloys excel in harsh environments such as elevated temperatures, oxidative and corrosive conditions, and cyclic loading. Their resistance to creep, fatigue, oxidation, and corrosion makes them ideal for turbine blades, combustion chambers, and other high-stress components in industries that demand reliability and longevity.

Material Overview: Types of Superalloys

Superalloys are categorized based on their primary metal, with each category offering distinct benefits for specific applications. Here's a closer look at the different superalloy types commonly used in manufacturing:

Inconel Alloys

Inconel alloys are high-performance nickel-chromium-based superalloys designed for extreme environments such as those found in jet engines, gas turbines, and chemical reactors. They are renowned for their excellent oxidation resistance and ability to maintain strength at high temperatures. Common grades like Inconel 718, Inconel 625, and Inconel 939 are widely used in turbine blades, combustion chambers, and exhaust systems.

Monel Alloys

Monel alloys are primarily nickel and copper, with other elements like iron and manganese. Known for their high strength and corrosion resistance, Monel alloys are especially suited for marine environments. Common grades like Monel 400 and Monel K500 are used in seawater desalination systems, chemical processing equipment, and other highly corrosive environments.

Hastelloy Alloys

Hastelloy alloys are primarily nickel, with significant amounts of molybdenum, chromium, and iron. These alloys are recognized for their resistance to oxidation, corrosion, and high-temperature stability, making them suitable for chemical processing, aerospace, and nuclear power applications. Common grades like Hastelloy C-276 and Hastelloy C-22 are widely used in high-temperature and corrosive environments.

Stellite Alloys

Stellite alloys are cobalt-chromium-based alloys known for their hardness, wear resistance, and ability to withstand high-temperature degradation. These alloys are frequently used in components that endure extreme wear and tear, such as valves, pumps, and cutting tools. Common grades like Stellite 6B and Stellite 21 are widely applied in the oil, gas, automotive, and power generation industries.

Titanium Alloys

Ti-alloys are lightweight, high-strength materials known for their corrosion resistance and excellent performance at elevated temperatures. Titanium alloys like Ti-6Al-4V and Ti-5Al-2.5Sn are commonly used in aerospace, marine, and medical applications where a high strength-to-weight ratio is crucial.

Rene Alloys and Single Crystal Alloys

Rene alloys are designed to perform under extreme temperatures and stresses, particularly in gas turbines and aerospace applications. Rene 104 and Rene 88 are known for their high creep strength and resistance to oxidation. Single-crystal alloys, such as CMSX-4 and PWA 1480, are used in turbine blades and other high-stress components where uniformity and grain structure are critical for performance.

Advanced Superalloy Manufacturing Processes

Manufacturing superalloy parts require specialized techniques to ensure their high-performance characteristics are maintained throughout the production process. Let's explore some of the critical methods used to manufacture superalloy components.

Vacuum Investment Casting

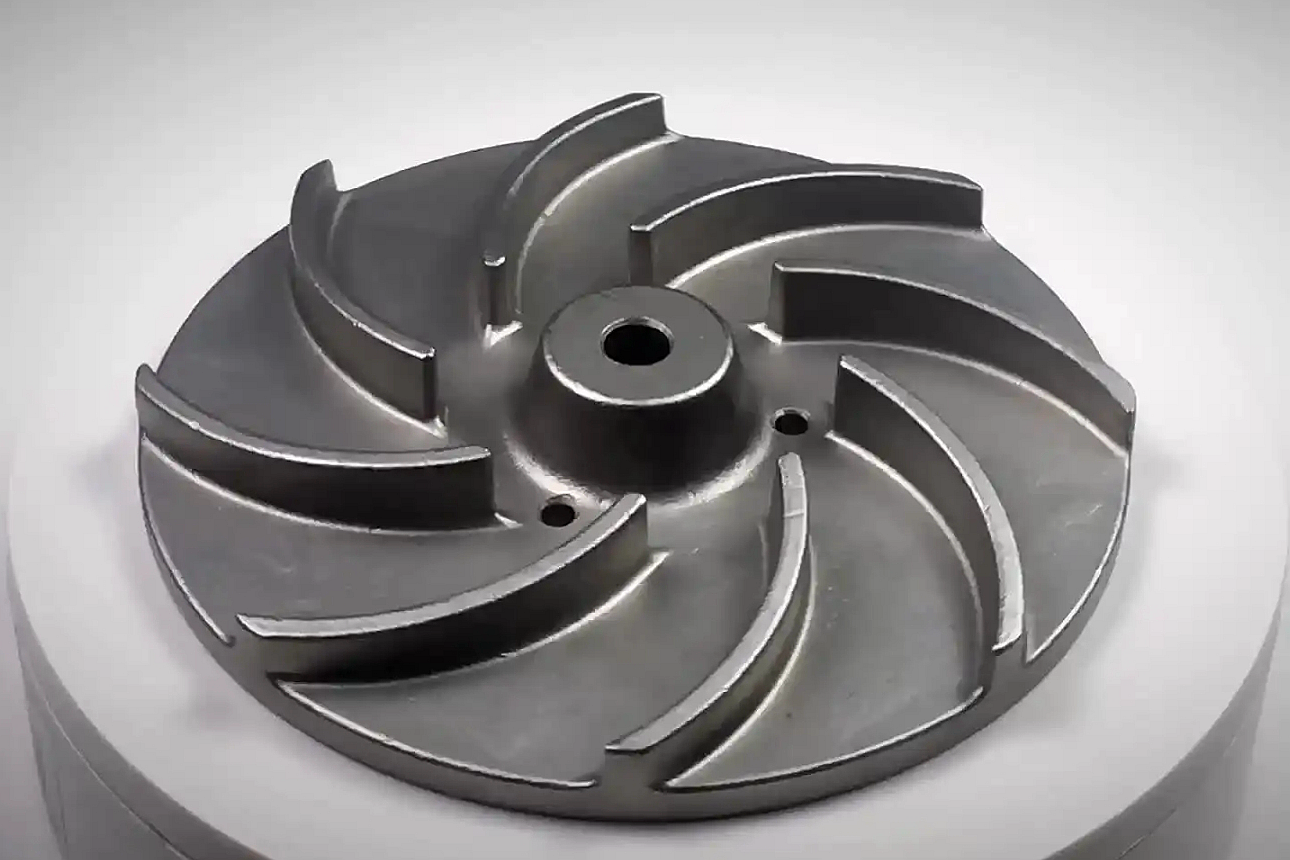

Vacuum Investment Casting is one of the most commonly used methods for producing high-precision superalloy components. The process involves the creation of a wax pattern of the part, which is then coated with a ceramic shell. Once the shell has hardened, the wax is melted, and molten superalloy is poured into the mold. The process occurs in a vacuum to eliminate air bubbles and minimize contamination.

Subtypes of Vacuum Investment Casting:

Single Crystal Castings: This method produces parts with a single crystal structure, eliminating grain boundaries that could reduce the material's mechanical properties. Single crystal casting is commonly used for turbine blades in jet engines, where durability and resistance to high-temperature fatigue are critical.

Equiaxed Crystal Castings: In this process, the material solidifies, resulting in roughly equal size and orientation grains. It is suitable for parts that need uniform strength and resistance to fatigue.

Superalloy Directional Castings: This process controls the cooling rate to produce a part with a directional grain structure. It's used for turbine blades and other components that experience high-stress and high-temperature environments.

Special Alloy Castings: Used for casting materials with unique or custom properties, such as high corrosion resistance or specific mechanical characteristics required for specialized industries.

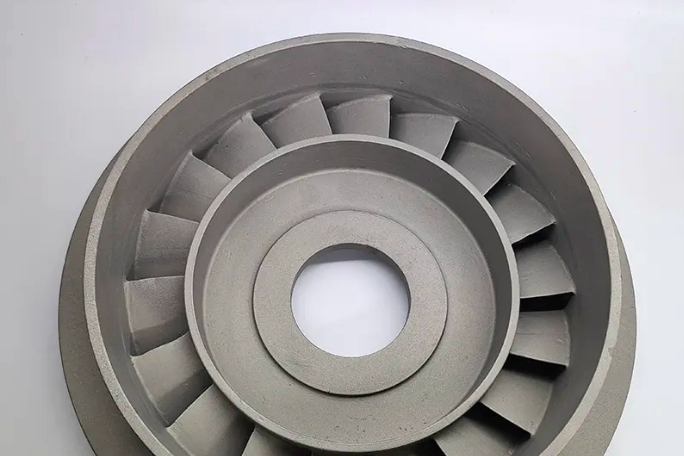

Powder Metallurgy Parts

Powder Metallurgy (PM) involves the creation of parts from metal powders that are compacted and then sintered at high temperatures. The process allows for producing high-density parts with excellent material properties, including uniform composition and improved strength. Powder Metallurgy Turbine Discs are a prime example of where this technique is used, enabling high-strength, lightweight components for aerospace and power generation.

Superalloy Precision Forgings

It forges superalloy shapes under high pressure, resulting in parts with superior mechanical properties. Precision Forging can be performed at high temperatures to maintain material integrity while shaping the part. This technique is often used for complex geometries that are challenging to achieve with casting. Isothermal Forging is particularly useful for creating turbine discs and other complex components, as it maintains uniformity throughout the part.

CNC Machined Superalloy Parts

CNC Machining is essential for creating high-precision superalloy parts. This technique enables manufacturers to produce complex geometries with tight tolerances and excellent surface finishes. CNC machining is often used after casting or forging to refine parts and meet specific design requirements.

3D Printed Superalloy Parts

3D Printing, or additive manufacturing, is an emerging technology that is revolutionizing the production of superalloy parts. This method allows for the rapid prototyping of complex components and creating custom parts with intricate geometries that would be difficult to achieve with traditional manufacturing methods. 3D printing is increasingly used in aerospace and automotive industries for low-volume production and testing of superalloy components.

Post-Processing for Superalloy Parts

Heat Treatment

Heat Treatment is a crucial post-processing step used to refine the microstructure of superalloys. It involves heating the material to a specific temperature and then cooling it at a controlled rate. Heat treatment can improve strength, flexibility, and fatigue resistance. Precision heat treatment plays a crucial role in enhancing the performance of superalloy components, especially for applications requiring high temperature and mechanical durability.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is a process in which superalloy parts are subjected to high pressure and temperature to eliminate any porosity that may have formed during the casting or powder metallurgy processes. It improves the material's density, reduces defects, and enhances its mechanical properties. HIP is essential for enhancing the integrity of superalloy components, ensuring they perform reliably under high-stress conditions.

Thermal Barrier Coatings (TBC)

For superalloy parts that will be exposed to extreme temperatures, Thermal Barrier Coatings are applied to protect the surface from oxidation and thermal degradation. TBCs are used in components such as turbine blades to extend life and maintain performance in high-temperature environments. These coatings are critical for boosting the durability of superalloy components, especially in aerospace and energy applications.

Testing and Inspection of Superalloy Parts

To ensure that superalloy parts meet the necessary standards for performance, several testing and inspection methods are employed:

Coordinate Measuring Machine (CMM) Checking

This tool is used to measure the dimensions of superalloy parts with high precision, ensuring that they meet the required specifications. Precision measurement methods like CMM checking ensure that superalloy components meet stringent tolerances, which is crucial for parts such as turbine blades or discs that require exact dimensional accuracy.

X-ray Checking

X-rays inspect the internal structure of superalloy parts for defects such as voids, cracks, or porosity. Like X-ray and CT scanning in superalloy directional castings, this technique helps detect potential failure points within the material, ensuring that the internal structure is free from defects that could compromise performance.

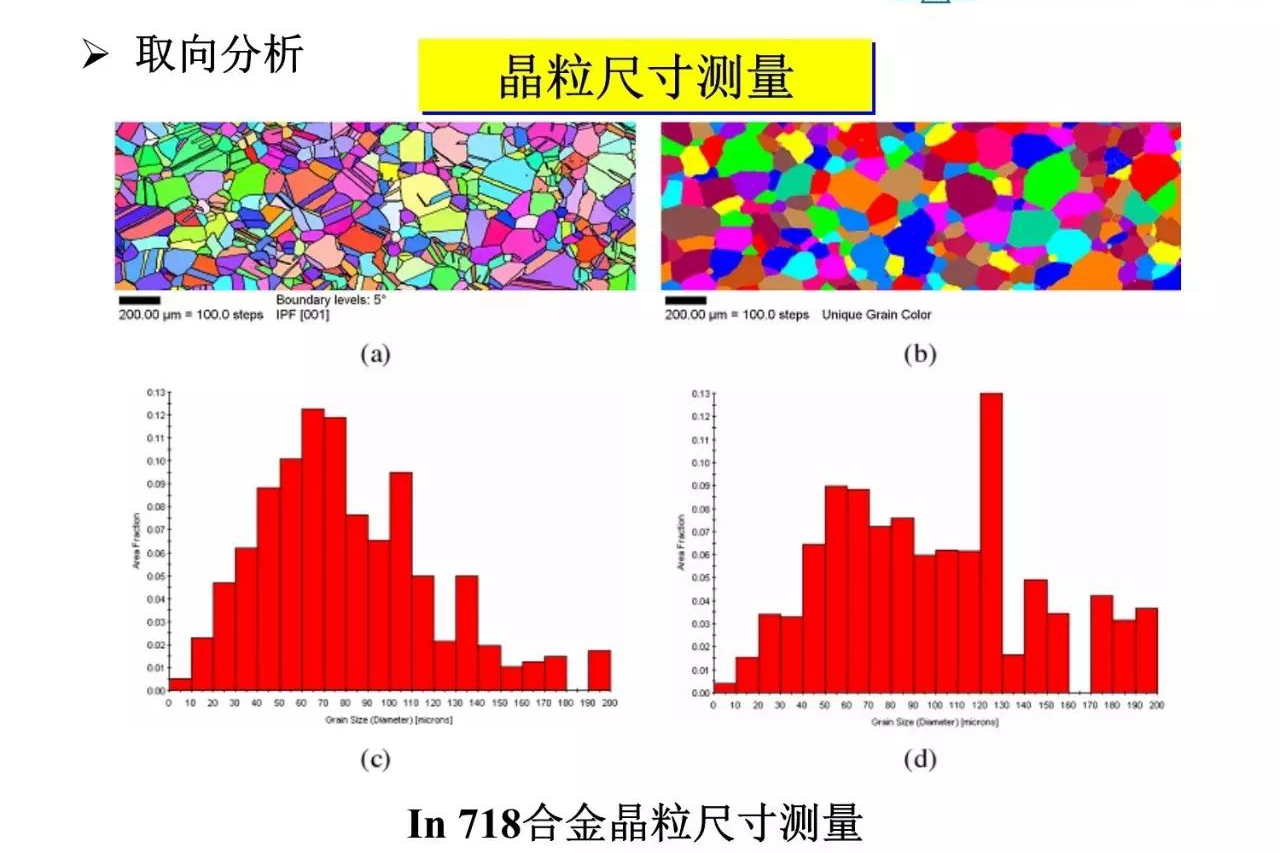

Metallographic Microscopy

This method examines the microstructure of superalloy parts and ensures they have the correct grain structure and phase distribution. It is similar to metallographic analysis employed during quality assurance processes. The microstructure analysis provides valuable insights into material properties like grain boundaries, phase composition, and alloy homogeneity.

Scanning Electron Microscope (SEM)

SEM provides

high-resolution images of the material's surface,

enabling detailed analysis of defects,

surface conditions, and

material composition.

SEM analysis is essential for detecting small-scale defects, understanding the root causes of failures, and providing the data necessary to improve part designs and manufacturing processes.

Tensile Testing

This test measures the strength and flexibility of superalloy parts under stress, ensuring they meet performance requirements. Tensile testing is vital for understanding the mechanical properties of superalloys in high-stress environments, helping predict component lifespan and durability, especially for critical parts such as turbine blades.

ICP-OES

Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) is used to analyze the chemical composition of superalloy parts, ensuring they meet the necessary alloy specifications. This method is crucial for elemental composition analysis, ensuring all materials used in casting and forging are within the correct alloy grade. This analysis ensures that the superalloy will perform as expected in extreme conditions by identifying impurities or deviations in the material's composition.

Industry Applications of Superalloy Parts

Superalloy parts are critical to various industries where high strength, resistance to heat and corrosion, and long-term durability are essential. Here are some critical industry applications:

Aerospace

In the aerospace industry, superalloy parts are used for turbine blades, engine components, and combustion chambers. These components must perform under extreme conditions, withstanding high temperatures, mechanical stresses, and corrosive environments. Superalloys like Inconel and Rene alloys are commonly used in jet engines, where performance and reliability are paramount. These superalloys are essential for maintaining the high efficiency of superalloy jet engine components.

Power Generation

Superalloys are widely used in gas, steam, and power plant components. These parts operate under extreme temperatures and stresses, requiring materials with superior resistance to fatigue, oxidation, and corrosion. Power generation companies rely on superalloys for parts that can endure the harsh environments inside turbines and other critical equipment. Key applications include superalloy heat exchanger parts and turbine blades, which must operate efficiently at high temperatures.

Chemical Processing & Marine

In chemical processing, superalloy parts are used in reactors, pumps, and valves, where resistance to corrosion and wear is essential. Similarly, in the marine industry, superalloys are used in seawater desalination systems, offshore platforms, and ship engines to withstand the corrosive effects of saltwater. These applications ensure long-term durability and performance in superalloy reactor vessel components and other critical systems.

Automotive & Industrial

Superalloys are used in automotive applications such as high-performance engines, exhaust systems, and turbochargers. They are also used in industrial machinery and turbine components that operate in high-stress and high-temperature environments. Superalloys are crucial for these applications' superalloy exhaust system parts and transmission component assemblies.

Defense & Military

Superalloy parts are crucial in the defense sector, particularly in missile systems, military aircraft, and high-performance engines. These materials must perform reliably under extreme conditions, ensuring that military equipment can operate efficiently and safely. Superalloys are used in applications such as superalloy missile segments and military turbine engines, where high-temperature resistance and strength are paramount.

FAQs

What are the main differences between single crystal and equiaxed crystal castings for superalloy parts?

How does powder metallurgy enhance the performance of turbine discs compared to traditional casting methods?

What are the advantages of using CNC machining for superalloy parts over traditional machining methods?

Why is post-processing, such as heat treatment and HIP, essential in superalloy manufacturing?

What are the most common testing methods to ensure superalloy components' integrity and reliability?